Editorial

It's July, so happy Fourth, or Bastille Day, depending on your geo-political alignment. To me right now, it just means ordering more wood for the fireplace, and Epsom salts for the spa. Apart from putting together what I modestly think is a pretty good issue of MEN, I've not achieved much during June. Some books got read and I must admit to having had fun following all the new product releases and announcements in my old field of computers and the like—just because I've retired, doesn't mean the brain stops, I hope!

Two announcements, perhaps three, maybe even four, have the pundits and self-proclaimed industry prophets turning out conflicting prognostications like there's either no tomorrow, or if there is, it will be sufficiently distant that you won't remember what they said was going to happen when something entirely different occurs. The big one is Microsoft's Surface tablet announcement. It's not a release because they won't say when you can buy one, nor how much it will cost. Naturally, I read about it on my iPad which I don't think is really threatened by it. Next would be Microsoft's announcement regarding their much vaunted Windows 8 RT—the OS for phones which they hope will get their foot in the smartphone door. Guess what? It won't run on current hardware. There's a giant billboard I see driving to the YMCA for my weekly "Masters in Motion" class (Ruthie and I call it "Geriatrics in Traction", which may be closer to reality). In giant letters, Nokia is urging people to buy their new smartphone with Windows 7.5 installed. Windows 8 is expected to be released around autumn in the northern hemisphere, at which time, all Nokias running Windows 7.5 become un-upgradable orphans! Nokia knows this, as do the carriers pushing contracts using the soon to be obsolete devices. Makes me kinda think that someone buying into that now will have every right to be rather peeved in a few months time.

On more germain topics, Adrian Duncan's piece from last month on the Rivers has been very well received, though the problem of loosing the background part way through under "WebKit" based browsers has prompted us to split it into two. There have been several updates, so if you are reading this in July 2012, have a gander at the current New and Updated Index. This page is replaced every month, hence the limited applicability window. Adrian even thinks there may be more to add to the Rivers story...who'd a thunk it? I've had fun too, as you'll read in our lead item, so with no more idle prattle from me, here we go...

Don't Believe Everything...

Don't believe everything you read, not even if it appears in Model Engine News! The latest misinformation appears in the David Janson PAL 55 review which was added last month. I feel real bad about this one as I had a nagging suspicion that his assertions were a bit off, and I had the references at my fingertips to check, but didn't. Luckily, Tim Dannels, editor of the Engine Collectors' Journal, and author of the American Model Engine Encyclopedia emailed to set the record straight. In fact, it was the AMEE which I should have consulted when I got that tiny, sneaking suspicion in the back of my brain. If I had, you would not be reading this. To right the wrong, a new PAL 55 review page has been created, and a link and footnote added to the Janson PAL 55 review page which contains a lot of good material, he's just a bit off in regard to the numbers built and sold.

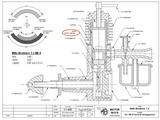

Nemett's Engine Plans

As notices have now appeared in both the Model Engineer and companion magazine, Model Engineers' Workshop, I'm happy to inform everyone that the plans created by the late Malcolm "Nemett" Stride will be available again, Real Soon Now. David Clark, the current Editor of the Model Engineer, has obtained copies of the most recent CAD drawings for Malcolm's NE15S "Lynx" single cylinder, four-stroke engine, and his later twin cylinder, in-line, four-stroke Bobcat, along with the rights to publish them. He intends to include them as a series of inserts in the magazine when the current skeleton clock series comes to an end. This is good news as we've received lots of emails here asking for copies, which we've been honor bound to decline. Malcolm, I should remind you, was the author of Miniature Internal Combustion Engines.

The ME announcement which appeared on page 801 of Issue #4431 made me feel better about the PAL 55 fiasco as it got poor old Malcolm's nom de plume a bit wrong. In writing his first IC Topics columns for the ME, he signed himself "Nemett", not "Nemmet" as appears in the ME headline. But that's all right as we all know that on occasions, Dyslexia Rules, KO?

TCalc Fixed

Good News! I finally extracted the lazy digit which was inhibiting investigation of the problem reported in May this year where MEN's Two-stroke Timing Calculator had ceased to generate diagrams to back up the numbers. I'd like to say that I found the problem, but actually I cheated. All I did was adequately document the problem, turn it loose at Stack Exchange, then go to bed. The answer had been found by the time I woke up the next morning and TCalc was all singing and dancing soon thereafter. How did we ever get by before the Internet?

Atom Minor Mk III (continued)

Jan Huning's build of the ETW Atom Minor Mk III continues this month with the Main Bearing Housing, and Rear Endplate. Note that for this series, I'm using the component names Westbury chose in his Atom Minor book rather than those more commonly used today. Shouldn't cause anyone any confusion though as the names are quite logical. The photo shows the "endplate" mounted on a light press-fit mandrel to machine the taper for the venturi inlet.

Northfield-Ross Power

Does one bad apple spoil the barrel? In this case, probably not, but it does make for some caution when you pull out the next one. Hence, it is with a certain sense of trepidation that I've added the David Janson review of the Ross Flat-four boxer (see our lead item for why I'm a tad nervous). Janson's review centers on the flat-four model, but as he mentions the other Ross models and since I had photos available, I've enhanced his review with some extra images not present in the actual review. It's worth mentioning that the Ross boxer engines are very compact because the opposing cylinders are exactly in-line. This requires that the conrods sit off-center on the wrist pins. Purists will ghasp with dismay and explain why this is evil, dangerous, and should be avoided. Strangely, Louis Ross' two, four, and six boxers run just fine.

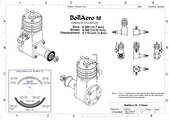

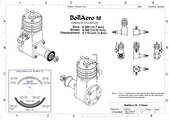

TBR Boll Aero

As Mel Brooks once famously said, "It's good to be King!" It's also good to kill two birds with one stone (not that anyone would contemplate such a heinous deed in this enlightened age), so in this single News Item, we get to see the Twin Ball Race versions of Chris Boll's Boll Aero, beautifully crafted by Mike Nelson (UK), and learn that Chris and our old mate, Rob Jenkins, have collaborated on a new design for a 1.4cc side port diesel which they have dubbed, the BJ Cicada (the "BJ" bit should be self evident and the rest is due to the noise it makes). To sustain some sense of suspense, I'll hold off on showing a picture of the new engine until next month.

Back on Mike's engines, be sure to visit Mike's Website to see his 3D CAD cut-away drawings of the engine, and read the list of modifications and refinements an experienced engine builder can incorporate into a simple engine design. The "as-is" Boll Aero is easy to build and runs just fine. Mike reports that his versions both started within a couple of flips on ten year old fuel. They have a feel just like his Oliver Tigers, so he concludes that the extra effort was well worth it.

[aside: What are those engines sitting on, Mike—reject pistons?  ]

]

Slick, or Slack?

In the April 2012 issue, we mentioned an Aurora K-Mills restoration job which included a photo showing the inlet ports had been drilled at very different heights. This sparked some emails suggesting this was intentional, so The Motor Boys dug into their collections to see if the "real" Mills exhibited this feature. To set the scene, the two cylinders in this photo, provided by Motor Boy, Les Stone, are your average K-Mills job. No doubt about the staggered height, although differences in the port heights between the two rather suggests that the variation is due to slackness in manufacture, rather than intent by design.

The cylinders in this photo, provided by Motor Boy, David Owen, are all of genuine, original, Mills manufacture. On the far left we see a Mk I cylinder with a nice, horizontal slot for the inlet. The rest are all Mk II cylinders and would suggest rather strongly that Kumar's boys are not the only ones unable to consistently keep their ducks in a row. Not only do the heights vary, so does the spacing! Now you might be thinking that the Indian Mills, being a legitimate copy of the English engine, copied the design, or even used the same tooling. We really don't think so.

The cylinders in this photo, provided by Motor Boy, David Owen, are all of genuine, original, Mills manufacture. On the far left we see a Mk I cylinder with a nice, horizontal slot for the inlet. The rest are all Mk II cylinders and would suggest rather strongly that Kumar's boys are not the only ones unable to consistently keep their ducks in a row. Not only do the heights vary, so does the spacing! Now you might be thinking that the Indian Mills, being a legitimate copy of the English engine, copied the design, or even used the same tooling. We really don't think so.

Think about it. Would the staggered arrangement convey any benefit? Absolutely not. In a side-port, crankcase-charged, two-stroke model engine, induction will commence as soon as the lower edge of an inlet port is uncovered by upward movement of the piston. The inlet will remain open until that same point is covered again on the piston downstroke. All that another port at a slightly higher level is going to do is to very, very slightly reduce the rate at which the full inlet porting area is uncovered. The actual timing is set by the lowest inlet port edge.

So-called "long-stroke" side-port engines are renown for their gentle handling characteristics. Having made more than a few and studied the timing set-ups of many more, I know they are quite forgiving in respect of timing. You'd really have to try hard to stuff up the port locations to the point where one would behave badly, or even refuse to run. That is one of the reasons why I frequently recommended designs like the ML Midge, the BollAero, or the Deezil as great first projects for new engine builders—they can get things a bit wrong, and still produce a running engine. Rather looks like both Aurora and the sainted Mills Brothers also knew and accepted a generous manufacturing tolerance, especially in the inlet port drilling operation.

New Books and Magazines This Month

Even though The Library foundations sunk a bit more during June due to new acquisitions, I'm going to look at some regular magazines received which will be of interest to those who are not subscribers.

The first is that venerable old English magazine, the Model Engineer, currently a fortnightly publication. Issue #4431 of Volume 208 saw a return of IC Topics, a column begun by Edgar T Westbury way back in the mists of time (the 20th Century), and revived in the 21st Century by the late Malcolm "Nemett" Stride. This time around, the banner is hoisted by Alex Whittaker, who kicks off with a series detailing the construction of his Firefly .46 Glow engine. This is a bar-stock design intended for first-time builders and capable of powering your average .40 powered R/C model. Some may recognize Alex and his engine since it has already appeared in the ME's companion magazine, Radio Control Models & Electronics (RCM&E). ME Editor, Dave Clark, assures us that this is not a simple reprint as the new series will go into greater depth and include 3D drawings to supplement the CAD plans, plus many additional construction photos.

In the first part, Alex introduces the design by explaining what his goals were and how he met them. Basically, he wanted a simple to build engine which would turn a 10x6 prop at 10,000 rpm on FAI fuel; ie, straight 1:4 lubricant and methanol,

no nitromethane.

Even better, Alex persuaded four would-be engine builders to take one pace forward and each make an example of the Firefly from the CAD plans alone, without the safety-net of being able to ask the designer questions. He reports that each engine was completed and ran first time, and that this was each builder's first model engine construction project.

Beauty is in the eye, etc, and one photo in the first part shows a technique that just plain horrifies me! But then, we'd be foolish to argue with success, and I've always said that much of making model engines is finding a process which works repeatedly for you. Starting with a "large" engine such as a .46 cuin glow has advantages and disadvantages. On the plus side, being competitively large, the parts are easier to machine. On the down side and for the same reason, mistakes are more costly. You will also require somewhat larger equipment than tabletop machines like the excellent little Sherline. To build this engine, you'll need a lathe with a swing in the region of 3-1/2" (UK), or 7" (US), something like the Mini Lathe, Myford ML7 (sob), or South Bend. Alex himself used a 3-in-1 Combination machine to build his prototype—a machine which long-time readers will know I myopically tend to turn my aristocratic nose up at, totally ignoring Alex's success (though he does say it is "...maddeningly uncooperative at times..."

The actual construction series, written by Frank Payne, commences in ME #4432 and will continue in each issue, not alternate "even numbered ones" as has been the case in past years—a policy which I thought rather dubious so I'm glad to see it changed. For non-UK residents, the cost of an annual 26 issue subscriptions is a bit steep at £79.95 (US$125.53 at today's exchange rate). Thankfully, the publisher offers a Digital Subscription for a very reasonable £29.99 (US$47.09, or $1.81 per issue). The publishers even have apps available so you can read it on your iPad, iPod, iPhone, or Android device. I've become absolutely addicted to reading things on my iPad, so I'll be going digital only when my current printed sub runs out (digital access, including the ME on-line archive is included with a print subscription). Check it out at The Model Engineer Website.

So there you go. ME is running what promises to be a good construction series on a practical, modern, two-stroke, front rotary induction, cross-flow, glowplug ignition, R/C engine, made from bar-stock and capable of using either commercial, or shop-made components for the throttle and muffler. If you can't wait, check out Alex Whittaker's web site. I predict we'll see quite a few of these made in years to come.

-oOo-

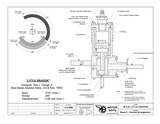

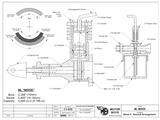

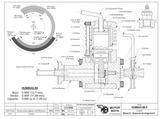

Next, we have Issue #27 of Model Engine Builder. This issue contains the complete plans and instructions for a cute little twin cylinder, alternate firing diesel called by its designer, Gail Graham, the "Lobo Pup". As noted in our March 2010 issue, Gail generously placed his CAD plans for the engine in the public domain, and as he hales from New Mexico (USA), his original plans use the Imperial measurement system. The MEB article is by Don Brymer, who explains that as he prefers to work in Metric, he redrew the plans, converting as required (not as straight-forward as it seems since 7.9375mm reamers (5/16") are hard to come by, while 8mm ones are more common). Incidentally, the nice CAD work on this one is credited to Tom Hare.

Issue #27 also contains Yet Another Way of making piston rings. This one, by Tom Schwartz, falls under the no heat-treat required approach. Instead, a fixture is used to hold the oversize ring "closed" while it is machined to the finished diameter. Tom goes to some length presenting the math behind his dimension selections. This we call a Brave Decision (Minister), as it is known that readership diminishes by half for every equation printed. But there are masochists, like me, who actually revel in this stuff, and will use it to compare ring parameters chosen by others.

Regarding the method itself, I first saw this described by fellow Australian, Paul Chernikeeff, in describing the construction of his R350 seven cylinder radial, printed in the May 1999 issue of Airborne. A revised form of the article appeared later in SIC, Vol 13, Issue 74. As both point out, the method has been around a long time and has been proven on "full size" rings, way before being applied to model engines. There can be no argument regarding the practicality of this ring making approach. Another case, it seems, of "what works for me". I'll probably stick with the heat treat approach, described in the Feeney Construction Log, page 8, which works for me  . The amount of fixture making is about the same, and I don't buy the assertion that a ring made using cold forming will exert equal cylinder wall pressure around its diameter any more than one made to the annealed "Trimble" method will.

. The amount of fixture making is about the same, and I don't buy the assertion that a ring made using cold forming will exert equal cylinder wall pressure around its diameter any more than one made to the annealed "Trimble" method will.

As an aside, or footnote to the "cold formed rings" approach, they obviously worked well for Paul Chernikeeff, who, with his brother Matthew, went on to found Rotec Aerosport and make full scale radial engines based on Paul's model design! Don't know for sure, but I doubt they make their own rings for their 110HP seven and 150HP nine cylinder radials.

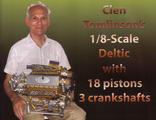

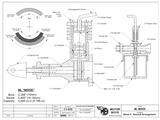

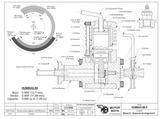

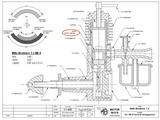

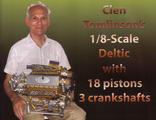

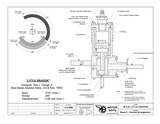

Meanwhile, back on topic, there's a lot more in Issue 27, like the centerfold which features Clen Tomlinson's breath-taking Clentec, and Editor, Mike Rehmus' continuing series on building the Humbug, a 1.5cc diesel or glow engine intended expressly to be built on a tabletop machine such as the

Sherline, which also makes for inexpensive mistakes—maybe. As I always seem to end up saying, if you read this web site each month and are not a MEB subscriber, you should be.

Engine Of The Month: Fuji Chapter 4

If you recall, in our last episode of The Fuji Story, Adrian Duncan described all of the .099 cuin glows manufactured by Fuji during the 1950's. This month, we continue this epic journey with the .099's made during the 1960's. I think we'd be on solid ice in saying that there has never been such an in-depth look at this marque ever published before in any English language media. In fact, I rather doubt even the Japanese have ever catalogued this series of engines so thoroughly. Head to Fuji Chapter 4 for the details and follow the navigation links at the top and bottom of the page to the previous chapters. Beware though, there's more to come...

Tech Tip of the Month

If you've read this month's piece on Mike Nelson's TBR BollAero and noticed the brief mention of the Humbug which I designed for Model Engine Builder magazine way back in 2004, you may be wondering why the Humbug, specially designed for a beginner to make on a table-top machine, has Rear Rotary Valve (RRV) induction, while the engines I frequently recommend for beginners to build are all long-stroke, side-port diesels! The answer, like engine design, is grounded in compromises and trade-offs.

As well as being within the capacity of table-top lathes, I wanted the Humbug to not require any thread cutting, port milling, nor any more fits of the close and critical type than was absolutely necessary. The Deezil, BollAero, and ML Midge all require the builder to make a long, parallel bore into the crankcase for the cylinder. The fit of the cylinder in this bore needs to be such that it can be easily removed during assembly and service, not to mention the inevitable "fettling" which new engines built by first-time builders seem to require. But at the same time, this bore needs to provide a gas-tight fit to isolate the inlet, exhaust, and transfer ports from each other. That's not especially hard, but I know from emails that it is an area where a significant number of first time builders come to grief, and the cure is a new crankcase, a new cylinder, or trying to fix the problem with gasket goo and blind optimism.

Even though it may look like an "advanced" sort of design, building a RRV engine is quite simple in comparison. As detailed in the Humbug plans, you can get the recess for the crankpin drive in the right place with a simple adaptation of the jig used to machine the crankpin itself. The port can be cut with a hacksaw and a file and the required surface finish can be quickly obtained with some 800 glass paper, oil, and any handy flat surface. If you make a mistake, making another costs almost nothing in terms of time and materials. This has been demonstrated countless times since the plans for Roy Clough Jr's Little Dragon appeared in 1950.

If there's an advantage enjoyed by the Deezil, BollAero, ML Midge, and Mills 1.3 replica designs over the Humbug and Little Dragon, it's the docility of operation inherent in the old "long-stroke" side-ports. I should mention the reason I keep putting talky-marks around the term long-stroke is because the stroke is not long in any shape nor form—but the conrod is. This leads to the tall engine profile which presumably gave it the odd name. It also gives it lower friction due to reduced piston side-force during the power stroke. The higher revving RRV designs are a bit more tricky to handle in comparison, an aspect which can discourage a first-time builder. See? It's compromises, all the way down.

To end this discussion, here's a story for would be builders to remember. There once was a manufacturer who decided to make a nice looking "long-stroke", side-port replica in a modern CNC workshop. The machines were programmed to produce a generous chamfer around into the top of the cylinder bore in the crankcase, presumably so the radius on the cylinder flange would not prevent the cylinder and crankcase from mating correctly. Well, the chamfer turned out to be a bit too generous, and even though the fit of the cylinder into the crankcase was perfect, the chamfer formed a channel between the transfer passage at the front and the exhaust cut-outs at the side. The result was a lack of primary compression (crankcase compression) meaning that except for a short Baarrp following a port prime, the engines would not run. Keep this salutatory tale in mind if you ever build such an engine; a sharp edge with a soft gasket is the way to go.

It Went Lean On Me...

I've found another in the series, duke's mixture, which is well worth preserving and digesting. It dates from January, 1991, and starts off this way, The words "It went lean on me" has to be one if the most used, least understood phrases in modeling today. Somehow, I don't think times have changed all that much as that's a curse I still regularly hear muttered on the flying field. Duke offers an explanation, and a fix. Click on the image to go direct to the page (bet you didn't know there was a 1989 movie of that name, as well as a one-hit-wonder for Bill Withers back in '72. You are now fully trivia ready...  )

)

Briefly Noted

This section is intended to alert you to little things that are hard to expand to a full news item, or cunningly wind into the Editorial, but are worthy of note never the less.

- A kind reader alerted me to an article in the August 1986 issue of Aeromodeller wherein Vic Smeed relates how, at age 16, he drew up plans for a small rubber model to fly in an area near where he lived called "Victoria Park". Vic named the model the Victoria Parker, and it has been added to his list of flying designs.

- Another reader pointed out a long standing error in the displacement given for the Arden reviews taken from Model Aircraft of October, 1946. I'd listed the values as cc's when they should have been cuin's. All fixed now.

- I was going to talk about desaxé for this month's Tech Tip, but found I'd already done so way back in August 2004. As a consolation prize to self, a reference to this has been added to our FAQ.

- If you've ever tried to use the "Buy Now" button (lower left of the menu bar, or on the MBI Plan Book page) and not had a good experience due to time-outs, blank pages, error messages, etc, it may be fixed now! An email from a reader/victim gave me a clue to the problem—not experienced by everybody—so I've taken the risk of modifying the PayPal supplied code snippet to always open in a new Tab (or Window under that IE thing). I'm hoping this will be the universal fix.

- A new link has been added to our Links page of a company who manufacture a V12 and a 14 cylinder, dual-bank radial for R/C use. The company name is Artus Motor and their multi-lingual web site is well worth a visit.

- As suspected, we've had to split The Rivers Saga into Part I, and Part II due to problems regarding its length when viewed in just about every browser except IE8! The full Table of Contents appears at the top of each part, and ToC headings cross-link between the two pages, plus there's nav links at the bottom of each page, so hopefully, you'll have no troubles. Adrian tells me that there's more to come, so the split was very necessary!

- Adrian has updated a couple of past reviews. The Hornet has some changes and a new image, while the CS Twin has been updated with the results of further testing. Click this link to go direct to the new performance and experiments section.

Don't Believe Everything...

Don't Believe Everything...

Nemett's Engine Plans

Nemett's Engine Plans

TCalc Fixed

TCalc Fixed

Atom Minor Mk III (continued)

Atom Minor Mk III (continued)

Northfield-Ross Power

Northfield-Ross Power

TBR Boll Aero

TBR Boll Aero

Slick, or Slack?

Slick, or Slack?

It Went Lean On Me...

It Went Lean On Me...

Editorial

Editorial

New Books and Magazines This Month

New Books and Magazines This Month

Engine Of The Month: Fuji Chapter 4

Engine Of The Month: Fuji Chapter 4

Tech Tip of the Month

Tech Tip of the Month

Briefly Noted

Briefly Noted

Standard Stuff

Standard Stuff

]

]