Editorial

First, let me say how much I enjoyed my visit to Vietnam. This may be because we were staying with expat family who know the local scene, but the food was terrific and remarkably inexpensive, and the sights, sounds as viewed from the back of a motor scooter were a lot of fun (some of the smells are especially memorable  ). As a baby-boomer, I'd spent my late teens and early twenties, rather ambivalent about visiting Vietnam. And as a dual US-Australian citizen, I had plenty of "opportunity" being offered all-expenses paid trips by both governments! Being then a bit of a gung-ho kid (or idiot, if you prefer), neither did I try to avoid the generous offers and was quite willing to experience the joys, preferably from the right hand seat of a 'chopper. But circumstances various saw me deferred by both travel agencies until both I and the conflict were sufficiently old that the generous offers were rescinded. History, and the miserable treatment afforded to veterans in both countries, suggests I was one lucky little lad. But times change and if you are thinking of doing it now, go right ahead—I sincerely doubt you'd regret it. And be sure to visit the war museum in Saigon (many locals still call it that). With the right attitude, the captions under the photos are good for a knowing grin. I know that history is written by the winners, but not even victory can change an F4 Phantom into an A6 Intruder!

). As a baby-boomer, I'd spent my late teens and early twenties, rather ambivalent about visiting Vietnam. And as a dual US-Australian citizen, I had plenty of "opportunity" being offered all-expenses paid trips by both governments! Being then a bit of a gung-ho kid (or idiot, if you prefer), neither did I try to avoid the generous offers and was quite willing to experience the joys, preferably from the right hand seat of a 'chopper. But circumstances various saw me deferred by both travel agencies until both I and the conflict were sufficiently old that the generous offers were rescinded. History, and the miserable treatment afforded to veterans in both countries, suggests I was one lucky little lad. But times change and if you are thinking of doing it now, go right ahead—I sincerely doubt you'd regret it. And be sure to visit the war museum in Saigon (many locals still call it that). With the right attitude, the captions under the photos are good for a knowing grin. I know that history is written by the winners, but not even victory can change an F4 Phantom into an A6 Intruder!

Sometimes I wonder how, where, and when I acquired this rather large Albatros that seems to have draped itself around my scrawny neck. Times were, I could bash out a MEN issue in a couple of evenings. Now it takes close to all my available spare time for the month to do the job and my own model engineering output has shrunk accordingly. But pretty much every month, I get the chance to help some reader in some way (usually drawing on the assistance and vast knowledge of the Motor Boys) and that makes it all right again. I also feel the face of the site is subtly changing, with Adrian Duncan's intensive research into obscure engines making the site of increasing value to collectors. The "News" part of the site is still catered for as I'm getting more and more requests to add links to commercial suppliers—most of which get deleted, but some are genuine and appropriate. Even more welcome are the unsolicited books related to our passion that are sent for review (have I mentioned before how much I appreciate graft  )? I answer all emails received promptly, but with the increasing volume, photos sent in might take a while to actually get incorporated. Worse, some worthy subjects get entirely forgotten. If yours is one such case, I apologies and say don't be afraid I'll be offended by a "Hey dude! Where's my photo!?" email. And if the construction series are getting fewer, I really regret it, but there are only so many hours in a day and as I intend never to retire, that is how it will probably stay for the foreseeable future. Ok, enough; let's get on with it...

)? I answer all emails received promptly, but with the increasing volume, photos sent in might take a while to actually get incorporated. Worse, some worthy subjects get entirely forgotten. If yours is one such case, I apologies and say don't be afraid I'll be offended by a "Hey dude! Where's my photo!?" email. And if the construction series are getting fewer, I really regret it, but there are only so many hours in a day and as I intend never to retire, that is how it will probably stay for the foreseeable future. Ok, enough; let's get on with it...

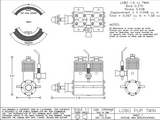

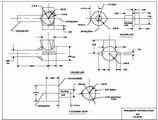

Lobo Pup Twin Cylinder Diesel

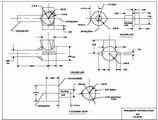

The work of Gail Graham (New Mexico, USA) on MEN Plans has appeared in these pages several times (see The Gallery, Page 12, Gallery, Page 15, and MEN, May 2006. He has now gone on to design and very publically built his own twin cylinder side-port diesel, fully documenting and explaining his setups on the Home Model Engine Machinist forum. Follow this link to Page One of the sixteen (16) pages in which he builds two examples of the engine. The first is a ball-race version using CNC on some components; the second a plain bearing version made by winding the handles like the rest of us. I really take my hat off to Gail as the "wiki" format he chose to present the series demands he reply to all sorts of comments, questions, and suggestions along the way—ranging from the typical but important beginner variety, to the plain silly. Be warned, clicking the link may lead to the well-spent loss of several hours of your life!

The first page has links to all of the CAD drawings as PDF downloads (8 sheets). Gail has placed these in the Public Domain for non-commercial use. On request, he can provide then in DXF or DWG format for those with CAD capability who want to try incorporating changes of their own. Aspects of the design I rather like include the "splined" fit prop-driver, the innovative use of cap head screws for the T-bar compression levers, and the simple but effective jig he devised to align the Taplin-style two piece crankshaft spool while the Loktite cures.

Raise the Moat

While looking for something else entirely in my bound volume of Model Engineer for 1949, I noticed one of my now very old business cards and wondered what it was I book-marked all those years back. It turned out to be an Edgar T Westbury piece, one of his Petrol Engine Topics column, titled A Curious Old Gas Engine. Now I was as curious as ETW, but in this case the curiosity was as to why I'd marked what looked like an old stationery engine of stove-pipe proportions and no obvious distinguishing features. So I started reading and after an interminable preamble, got to the "meat" of a most unusual design that should be of special interest to Australians and Kiwis as the piston is, in effect upside down! Bound volumes are near impossible to scan with any decent result, so I've run the output through the OCR process, fixed the unresolved words resulting from the bend and distorted margin, and present a nice curiosity from the past for your enjoyment, amusement, and perhaps, experimentation.

Super Morton M-7

Bruce Satra of Vernal Engineering sent in this nice progress shot of a Super Morton M-7 being built by Otis Baker (Iowa, USA). At first glance it might look like a bog standard old M-5 with a bar-stock crankcase and a pointy snout, but the design has evolved considerably over past years both cosmetically and mechanically to the point where it is a serious, flight-rated power-plant (as opposed to a nice nose-weight capable of generating a lot of noise and a bit of wind). The new cylinder castings from Vernal allow the inlet and exhaust openings to be placed at the original side location, or at the rear for much easier and more efficient pipe-work. The case is turned and milled, making a more robust item that is easier to machine, even if you do produce a lot of swarf in the process. Internally, extra gear train support, 4140 steel rockers, a new cam, higher compression glow ignition, poston rings, and roller tappets account for the significant increase in top end speed and power. Oh yes, it has a couple of extra pots, too  . The exhaust collector ring is pure Otis and not available from Vernal, but all the other parts are, including fully machined and finished stainless steel valves and phosphor bronze valve cages. Vernal have just released their 2010 pricing for the Super M-5, and the astounding Pratt and Whitney R1830 double bank radial. Time to give the old check-book a bit of a hiding. Remember the lesson of the Wright J5, if it's not under your bench right now, you may never get to build one.

. The exhaust collector ring is pure Otis and not available from Vernal, but all the other parts are, including fully machined and finished stainless steel valves and phosphor bronze valve cages. Vernal have just released their 2010 pricing for the Super M-5, and the astounding Pratt and Whitney R1830 double bank radial. Time to give the old check-book a bit of a hiding. Remember the lesson of the Wright J5, if it's not under your bench right now, you may never get to build one.

New Suppliers

Email contact from a couple of UK companies arrived during the month that I'm sure will be the answer to the prayers of some readers. Casting is an art that is beyond the capacity of many model makers, if not their capability. You need large, expensive equipment to melt and pour metal—and yet more to do it safely! But making patterns for sand casting is not difficult. The problem is finding the foundry who will do one-off castings at an affordable price. Hogan & Sons are a Foundry based in Sheffield South Yorkshire. Peter Hogan emailed to say that they have the skills and ability to cast all metals with over thirty-five years in the casting trade and are looking to get started in castings for the model engineering enthusiast. To this end, they offer a one stop shop for all your casting and pattern making needs. Their foundry has four types of casting medium; green sand, air set, lost wax, and die casting. Better still, they are willing to cast one-off, or one thousand-off! In the UK, call Peter on 07789-444979, or click the link above to email him.

The other is a metal-by-mail supplier called Noggen End Metals (who now appear in the Suppliers page, a service to readers that the server logs show gets a good working over each month). In addition to the usual suspects, Noggen End offer the exotics such as Titanium, Meehanite 250, machinable ceramics, and various plastics. They target the model maker and car/bike restorer, so they understand your special needs as opposed to those of commercial manufacturers. I sampled the web site and found all the materials I'd need to build a bar-stock engine with no trouble, at what look like reasonable prices, given I'm a colonial and not really in touch with costs in auld Blighty. The oft-mentioned MEN server logs tell me a lot of things. One of them is that England represents the second highest source of web site hits each month, so this should be of interest to many readers (USA is the run-away winner, as you'd expect).

Bar Humbug, At Last!

Mention of bar-stock engines brings to mind a design I did four years back at the request of Mike Rehmus of Model Engine Builder magazine. The design drew on the observations arrising from the review of Beginner engine designs series that ran here some years ago. Basically, I wanted no milling, no thread cutting, no engineering at watch-making scale, and piston aside, one that required no close fits over a deep bore length. Then I also wanted an engine that was not unattractive, yet did not look like a Midge, or Little Dragon clone. Mike added to the restrictions, requesting (more like demanding, actually) that all machining should be capable of being performed on table top machines like the excellent little Sherline lathe. This (pun alert) turned out to be remarkably difficult. Three prototypes were made and anything that I had to devote more than casual precision to was redesigned (which is why the published version appears slightly different to the prototypes). The MEN style CAD drawings were handed over to Mike who re-drafted them in 3D CAD. The plans and first part of a serialization showing detailed construction have now appeared in issue 21 of Model Engine Builder.

At the time, I made arrangements with my pal, Roger Schroeder, to have castings made for the crankcase and backplate for those who wanted a more "traditional" engine. Roger looked at the three head bolts and proposed a triangular Reuleaux head, just to be different. We dubbed the result the Custom Humbug. There is some not entirely tongue-in-cheek justification for the head shape. The front of a model engine cylinder receives more cooling than the rear due to the prop blast and turbulent flow behind the head. High performance engine designers worry about distortion cause by differential thermal expansion, and hence increased friction this causes. This led some old "gassie" manufacturers to produce "teardrop" head profiles even thouhg their engines were not exactly what you'd call high performers. It was more like tail-fins on 60's gas-guzzlers, and examples abound, for example, the Dennymite "Airstream", Merlin "Super-B", Canadian "Super Hurricane", AHC "Thor", and Stanley Machine & Tool Company "Gremlin 29". The idea was to place more cooling fin area behind the cylinder than in front. This is all a bit empirical and more marketing-hype than serious engineering.

However, there have been some top speed, racing and even aerobatic fliers who, in the pursuit of an edge over their competition, have resorted to adding baffles inspired by full-size engine installations. The aim is similar: ensure even cooling and minimize distortion by directing airflow directly and smoothly to the rear of the cylinder(s). Reports suggest this has resulted in small, but measurable success for some, so it's not entirely a daft concept and becomes increasingly important as the engine size increases. But in our case, let's not kid ourselves; it's purely cosmetic. Anyway, the Custom Humbug patterns now reside with my good friend, Kirk Burwell (see last month's bit about Hemingway Kits), so the castings may become available again—watch this space, as the say...

New Books and Magazines This Month

A lot of fun stuff arrived during February that is worth mention. First was Model Engineers' Workshop #161. This one is of special interest because of part one of a series on building a neat little die filer (see the picture on the cover). Imagine something like a shaper rotated through 90° so the oscillating action is vertical. Now attach a file to the ram poking it up through a table that can be tilted. The file is arranged to cut on the down-stroke, so the work will be pulled down onto the table by the cutting action. Now imagine the neat little ways you could use that to effortlessly file away in hard to get at places with no danger of rocking the file so the filed faces are deliciously flat. The "die filer" name comes about because of how such devices where used in the past to file a precise draft in complex punch and die blocks before hardening.

I have a set of Andy Lostquest Model Lathe Accessories castings for a larger die filer under the bench that followed me home from my time living in Portland OR over a decade ago. Trouble is they are larger than the Myford will swing, so progress has been postponed. The MLA die filer is a serious piece of hardware, but I like the MEW one better because it is smaller, all plate construction, and designed to be driven by the lathe headstock, securing to the bed like a fixed steady. It also has an arm that supports the top end of the file making it harder to deflect the file by pressure applied to the work, and to have your eye accidentally poked out by the end of the file (the MEW one would just punch your lights out with the file frame). As seen here in this example beautifully built by Neil Butterfield, the Model Lathe Accessories one is stand-alone and needs it's own motor. I sure could have used this one in the last few days. Oh well. Maybe someday.

-oOo-

The next item is issue #21 of Model Engine Builder. This issue contains the first part of a multi part series on a cam grinding machine—or should the be Yet Another Cam Gringing Machine. Overall, I like the article, even though it does not list cam fabrication through tangential cuts using a lift table like the one created by CamCalc in the analysis of alternate cam forming methods (*sniff*). The machine to be described in subsequent issues is somewhat limited in only being able to grind a single cam, not an entire multi-lobe shaft. Still, the article is well written, informative, and should be a mine of ideas.

Issue #21 also contains the first part of a series on building a simple bar-stock engine called the Humbug. The article was written by ye editor himself who is also doing the build. I think this is better than having the construction described by the designer/author because a third party is more likely to really describe the process from an average builder's perspective. The plans appear in the issue and I spotted a couple of issues that escaped the QA phase. None are serious and Mike will fix them as he goes along, I'm sure. For one, the 3D CAD cut-away sections show the conrod "assembled" upside down. Again in the cut-away, the head has not been "screwed down" all the way, so the glow-plug button is floating some distance above where it should seat on the top of the cylinder liner. Next, the orientation of the head screws has also been rotated 30° clockwise as viewed from the top. None of these is earth shattering. Oh yes, did I mention that the design comes from some bloke named Chernich? Looks a bit pedestrian, if you ask me.

-oOo-

The last book is the latest edition of Frank and Viki Anderson's Blue Book guide to prices for American model engines, covering makes and models produced between 1911 and 2009. This is the 5th edition and now contains 114 pages. We reviewed the 4th edition of the Anderson Blue Book back in the July 2006 issue, so I won't repeat myself; what I said then still applies to the current edition. Instead I'll address what has changed so you can decide if it's worth the $45 get yourself a copy for reference, or update your shelf copy. Also, back in '06, I was not giving out "star" ratings. I'll rectify that too.

First, there is the extra four years of coverage. The 4th edition cut off at 2005 (reasonable, seeing it appeared in 2006). Then there's valuation changes which reflect the prices the Andersons have observed in the MECA swap sheets and the prices fetched in eBay actions. There are new makers and models included, such as Edwards, OTC, Nelson Aero Products, Simplex, RJL Industries (hmmmm...), and probably others I missed in my walk-through. Corrections have been made, principally Frank and Viki say, to the the Fox descriptions to satisfy the critics  . The "bonus" pages at the back of the book have changed too. The page of "Additional Engines", ones the Andersons have heard about, but not included, has changed somewhat and now features a picture of the six cylinder M&M. I thought Bert Streigler's was the only one, but this is a different engine, so there are at least two! The info pages at the end of the book have changed too. I rather enjoy these, and the 5th edition has different ones from the 4th, so I'm not about to bin, nor give away the 4th edition (cunning trick, Frank).

. The "bonus" pages at the back of the book have changed too. The page of "Additional Engines", ones the Andersons have heard about, but not included, has changed somewhat and now features a picture of the six cylinder M&M. I thought Bert Streigler's was the only one, but this is a different engine, so there are at least two! The info pages at the end of the book have changed too. I rather enjoy these, and the 5th edition has different ones from the 4th, so I'm not about to bin, nor give away the 4th edition (cunning trick, Frank).

So onwards to the rating. As I said in the review of the 4th edition, the Blue Book serves a different, complimentary purpose to Tim Dannels' American Model Engine Encyclopedia and a serious collector of American model engines needs both. If I have a quibble with the 5th edition, it would be the page devoted to the RJL magpie engines. The pictures leapt out at me because some are not American! We see an Aussie Taipan 40, the English Allen-Mercury, and ME Snipe, and a Japanese Fuji. This is because RJL's owner has acquired the designs and says they may be produced again, some day. I kinda doubt it, but I'm old and cynical. The Blue Book lists no prices for most of the RJL engines listed even though they are being traded in their original guise. Sensible decision. More sensible, drop 'em! So apart from that, I enthusiastically endorse the 5th edition of the Anderson Blue Book, give it four and a half stars  , and posthumously award the same rating to the 4th edition. Visit the Blue Book web site, or email Frank and Viki to get your own copy.

, and posthumously award the same rating to the 4th edition. Visit the Blue Book web site, or email Frank and Viki to get your own copy.

-oOo-

Engine Of The Month: The K-Hawk

The "K" Engineering engines represent a brief interlude in the history of English production model engines which have had some small representation on these pages owing to two facts: first is their rarity today; the other is the rather unusual cylinder retention method used on some of the designs. "K" hit the ground running as it were by taking over the designs of Harold Kemp. One of the gratifying aspects of running this web site is the occasional email arriving out of the blue, frequently triggered by a search on a name by a relative of some model engine pioneer. The page on Harold is a good example. His daughter was looking for information about her father, found the MEN pages and was amazed that anyone remembered his model engines! Do we ever. Adrian Duncan is a big Kemp and "K" admirer and has gone to a remarkable amount of effort to document the smallest of Harold's creations, the 0.2cc Hawk. This pioneering late 40's engine was one of those acquired by "K" and offered by them in two other refinements during their brief period in the sun. We believe the Kemp/K Hawk page presents more information about this engine that has ever appeared before in any medium.

As usual, the page is as accurate as we could make it, but we will revise any aspect if you can provide contrary, documented evidence. In fact, Adrian gets a big kick out of such information as we know that sadly, the window is closing. If you have something we don't know about old engines, it's in immanent danger of being lost for ever, so don't be shy, or think we don't care. We most certainly do! Contact us through the email address at the bottom of this, and most other pages.

Tech Tip of the Month

Some years back, probably more than any of us care to count, the catch-phrase was Do you know where your kids are? This spawned all kinds of take-offs and was what popped into my mind this past month as I received a very big and unpleasant surprise. The surprise was not very big dimensionally, but the impact on my complacency was sufficiently severe that I immediately thought to myself, Do you know how accurate your measuring tools are? Most very definitely, I didn't. Neither did I truly understand the reason until I sat down to write this item. After the first version was put into words, I knew it just did not add up. A few hours later, while doing something else, my subconscious came up with the answer which was quickly proven and this month's tech tip got elevated from a in-line quickie to a full blown page of its own! I hope it gives you something to try for yourself and possibly saves you from producing needless scrap! We also get to look at a seldom used, but very useful shop-made lathe accessory: the chuck back-stop. So click the thumbnail or follow the link to the Measuring Tool Maintenance page

Editorial

Editorial

New Books and Magazines This Month

New Books and Magazines This Month

Engine Of The Month: The K-Hawk

Engine Of The Month: The K-Hawk

Tech Tip of the Month

Tech Tip of the Month

Standard Stuff

Standard Stuff

). As a baby-boomer, I'd spent my late teens and early twenties, rather ambivalent about visiting Vietnam. And as a dual US-Australian citizen, I had plenty of "opportunity" being offered all-expenses paid trips by both governments! Being then a bit of a gung-ho kid (or idiot, if you prefer), neither did I try to avoid the generous offers and was quite willing to experience the joys, preferably from the right hand seat of a 'chopper. But circumstances various saw me deferred by both travel agencies until both I and the conflict were sufficiently old that the generous offers were rescinded. History, and the miserable treatment afforded to veterans in both countries, suggests I was one lucky little lad. But times change and if you are thinking of doing it now, go right ahead—I sincerely doubt you'd regret it. And be sure to visit the war museum in Saigon (many locals still call it that). With the right attitude, the captions under the photos are good for a knowing grin. I know that history is written by the winners, but not even victory can change an F4 Phantom into an A6 Intruder!

). As a baby-boomer, I'd spent my late teens and early twenties, rather ambivalent about visiting Vietnam. And as a dual US-Australian citizen, I had plenty of "opportunity" being offered all-expenses paid trips by both governments! Being then a bit of a gung-ho kid (or idiot, if you prefer), neither did I try to avoid the generous offers and was quite willing to experience the joys, preferably from the right hand seat of a 'chopper. But circumstances various saw me deferred by both travel agencies until both I and the conflict were sufficiently old that the generous offers were rescinded. History, and the miserable treatment afforded to veterans in both countries, suggests I was one lucky little lad. But times change and if you are thinking of doing it now, go right ahead—I sincerely doubt you'd regret it. And be sure to visit the war museum in Saigon (many locals still call it that). With the right attitude, the captions under the photos are good for a knowing grin. I know that history is written by the winners, but not even victory can change an F4 Phantom into an A6 Intruder!

, and posthumously award the same rating to the 4th edition. Visit the

, and posthumously award the same rating to the 4th edition. Visit the