Editorial

Our heading picture is my excuse for why this month's issue was delayed a few hours. It is now the afternoon of May 1, 2010, and the Queensland State F2B control line aerobatics championships are over for another year. In the shot, we see the top three. From left to right are Noel Corney (second), PA .75 with C/F pipe and three blade Majik airscrew; Joe Parasi (first), PA .75 with C/F pipe and three blade Majik airscrew; and Ron Chernich (third), ST .60 and G/F three blade Bolly prop. Noel and Joe are flying the same design, developed over several years by Joe, although Joe's is fully take-apart for his frequent assaults on the world F2B champs. I was flying my old Genesis, slightly enlarged to .60 size with 660 sqin of wing. The weather was fine and warm, and even though the wind had come up a bit by round three, it was not awful. I'm not disappointed with third place as I've not really been practicing and the other two perversely refused to make the mistakes I was hoping for. So all things considered, a good day out.

My flying buddy has just returned from two weeks in the United States, spending time in San Francisco, New York, Las Vegas (for a broadcasting conference), and Denver. As usual, he tried to visit as many hobby stores as possible, but found some he knew from previous visits had closed down and the remainder had pretty much gone all-electric. I wonder what this signifies? Has the financial crisis hit hobby spending? Or maybe modellers prefer to get their stuff on-line, so the local shops have just given it up as a bad joke? Back when we were starting out in aeromodelling (late 50's), there seemed to be a model store within cycling distance of every kid I knew, regardless of where they were. The ones around us stocked no American stuff at all; it was all English, plus the obligatory Taipan. Beyond doubt, this explains our addiction to diesels. I did not see a Baby Bee, nor an issue of Model Airplane News until 1960, and what a revelation they were. Model engineering is not all that different in that materials and raw stock, once available locally, now have to be sourced from interstate, or overseas (mostly). Oh well, let's be grateful for tiny mercies: at least the stiff we need can be sourced!

The weather is cooling slightly, though I used to don a jacket in years past when heading out in the early morning for the State F2B contest which has been held on the long, May Labour Day weekend for as long as I now care to remember. Today, it was a pleasant 18° Centigrade at 0700, so I did not even bother. Makes me think winter Downunder is going to be another non-event, but it's no longer oppressively hot and humid, so some shop-time is possible at last. We've had the odd spot of rain as well and the water restriction spectre, though still being imposed, is set at the least restrictive level. Yes, life is good, and I hope I don't have cause to regret writing that any day soon!

And the Humbug Prize Goes To...

Michael Atkinson, of Cornwall, UK, is the first to send a photo of his completed, running Humbug 09. For this, he receives a copy of the Motor Boys Plan Book on CD which will probably come as a bit of a surprise since he did not even know there was a competition and prize in the offering! Mike asked a lot of good questions while building the engine regarding why certain things were the way they were. To help other, many of these will be reflected in the detailed building instructions being prepared by Model Engine Builder magazine editor in chief, Mike Rehmus.

I have to confess to getting both a buzz and a certain feeling of relief to see this successful culmination of effort. There were certain design aspects I took with the Humbug in the interests of simplicity which vaguely worried me in respect of repeatability—so even though I made three prototypes, there was a niggling worry that tolerances might add up wrong on plans built engines and builders would come gunning for me. By the way, did you notice the little tank in Mike's photo? The printing on it says Chanel No 5. Like we said in last month's tech tip, tanks are where you find 'em! And check out Page 16 of the Gallery to see the nice job Mike made of the TOP 20, plans for which appeared in Model Engine World an age ago.

Valves In Abundance

Start by checking out what we had to say about this rather unusual looking two-stroke (yes, two-stroke) on page five of the Watzits. When it appeared in the Engine Collectors' Journal issue #186, it was labeled a Three Valve Watzit. I called it a novel idea (click the thumbnail above), and Les Stone calls it an exercise in an abundance of valves. Of all of us, Les has the strongest claim to applying a name to it because he's gone and actually built one like it. In doing this, he's made yet another Watzit connection, this time to the British Magnum by utilizing a Magnum crankcase he had lying around. In fact, the crankcase seen in the answer to the "Marinated Watzit" is the actual case involved in Les' latest creation. You can read all about it by visiting the Les Stone Tribute Page.

Stamp Collecting

You are looking a sight-glass oiler, assembled and in component form. These are an oil reservoir that typically supplies oil to spinning bearings and visual feedback to the operator regarding the level of oil remaining. It was not all that many years ago that a pair of these adorned the headstock bearings of the Myford ML7 lathe. Now, did you notice the elephant at the bottom of the photo in the form of a matchstick? That is one tiny set of components and is the remarkable work of Find Hansen, who lives on an island called Bornholm, which is a part of Denmark. Find specializes in four-stroke stationary engines which use Hot Bulb ignition. His engines are not models, rather they are miniature hot bulb engines, made to his own designs and requirements. If you are not familiar with this type of engine, I suggest you visit his web site at http://www.findsminimodelhotbulbengines.dk/index.html. Be prepared to loose an hour or so marveling at the exceptional workmanship and quiet understatement in the pictures, words, and videos. Find's URL has been added to the Links page. Oh yes, the title for this news item? After looking at this example of model engineering and so realized our own limitations, the Motor Boys have all decided to take up some other hobby.

More Information on Old Friends

We must thank the growing legion of readers out there who provide us with supplemental information on our engine reviews. If you look in the New and Updated pull-down list of this month's Engine Finder, you notice changes to the K Vulture and Ball Race Elfins pages. Thanks go to Brian Cox, Eric Offen, and Paul Rossiter for their generous help. Luckily there's nothing to un-learn in the changes, and as usual, there's the difficulty of trying to let you know what has changed. This is hard, but in the case of the Vulture, we suggest re-reading all of the Mk III "Bald Vulture" section as thanks to Paul, this is now based on examination and restoration of an actual example of the engine.

The Alags are Coming

Of the many engines we want to cover here, the Awful Alag has been high on the list for some time. Perhaps I'm being unkind as I know owners who think the Alags are brilliant little engines, but I know from first hand experience that the ones which appeared on the market here in Australia during the late 1950's were different from the local Taipans in two significant ways. The Alags were cheaper than Taipans, and the Taipans ran while the Alags didn't. We do have an Alag in the Finder, and a red herring mention of the name under the cryptic clue of A Good Little Socialist Diesel in the Watzit pages. This latter item eventually attracted the attention of Walter Strum (Germany) who pointed out the spelling error, now corrected, in the name of the company who marketed the engine in Germany. Alag produced four engines, the X-2 5cc glow, the X-3 2.5cc diesel, the X-4 1.5cc diesel, and the X-5 1cc diesel. The picture here shows an X-3 with the German Engel (Angel) packaging and instructions.

Walter generously went on to provide a wealth of photos of the engines, including scans of the Engel catalog page seen here showing an in-line twin Alag. A Twin! That sure gets my attention every time. As far as we know, this was a special from Engel, the actual Hungarian manufacturer having nothing to do with it. It has been cunningly made by cutting the journal off a pair of cases and screwing them together onto a stub—with a spot of labour intensive facing and thread-start jiggling—which also forms the bearing for a connecting crankshaft "spool" and venturi. The spool provides the rotary inlet valve—most probably with opposed timing, just like the Hinds Twin, an Australian design which was run as a construction series in SIC during 1990. I have one junk-box X-3 which I now view not as useless parts, but half a twin. There must be another half out there somewhere (hint, hint  ).

).

New Books and Magazines This Month

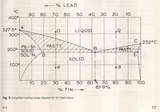

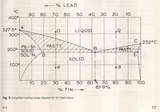

Hands up! Who out there ever had to reproduce this diagram for an exam? If you are like me, you probably didn't even remember having to cram for this taxing feat of mental regurgitation until seeing the diagram again, which we recognize as depicting the eutectic characteristics of lead and tin, as used in what we term "soft solder". I also recall feeling that being required to memorize the damn thing was a rather cruel and worthless obligation. Having listened to the lecture and read the notes, I understood what it was telling me, and knew in what text book it was located in the unlikely event that I ever needed to consult it while soldering wires to the pins on a valve socket. I'm not saying the knowledge was, or is useless, it's most certainly not! An understanding of the this diagram aptly explains why we use 60/40 solder for electrical work, while 50/50 is better suited to soldering up fuel tanks—how useful is that! And it is the very useful nature of such knowledge that brings us, in my favored 'round-about way, to the first of this month's books.

Last month, we looked at two little volumes in the Workshop Practice Series. Here's another, Number 9 in the series, by the same author, Mr Tom Tubal Cain Walshaw, titled Soldering and Brazing, Argus Books, England, 1985, ISBN 0-85242-845-0. I confess that I did not buy this volume as I doubted it had anything to tell me that I did not already know—hubris, I think that is called, or perhaps conceit. It came to me in a box or two of books that had graced the library of my late friend, Russell Watson-Will. The reason I suddenly decided to actually have a read was twofold. First was the curiosity engendered by having reviewed two Tubal Cain works recently: how could anyone, even Tubal Cain, spin a book out of the subject of soldering and brazing? Second, I figured there might be a useful tip in the brazing section that I may not know, or have forgotten. You can see where this is going, I'll bet...

In 136 pages containing the customary eleven chapters plus appendices, TC explains the whys, wherefores, and therefors of soft and hard soldering. The distinction lies in the temperature at which the operation takes place. So-called "soft" solders melt at around 200°C, while brazing alloys require the work be raised to between 600 and 700°C. The book explains all this, together with the different filler alloys that can be used in the process, including brass swarf (my "careful" nature now wails at the thought all the brazing filler from my chip tray that has gone out in the trash!) Chapters describe both processes, the various fluxes that can be used along with the why, when, and precautions to be taken in using them, plus suitable equipment for applying the heat and holding the work, how to design a joint that assures the necessary capillary action will occur, and how to "step-braze". This last operation uses knowledge of the eutectic characteristics of commercial filler rods so that on complex jobs, later re-heats do not melt earlier joints. All useful stuff!

I should know by now that you never know it all, especially these days when so much seems to be escaping through a growing number of holes in the head, making the occasional refresh a valuable exercise. Tables in the book list various silver-brazing alloys by their commercial names, many of which are still "on the books" today, much to my surprise. Many contain cadmium which is quite poisonous, and these are becoming increasingly hard to obtain which may be no bad thing, although given the small and infrequent brazing sessions an average model engineer is likely to undertake, the danger is rather small. However, to anyone to whom soldering and brazing is a bit of a mystery, or a task viewed with trepidation owing to past traumatic experiences, I give this volume a ringing four and a half stars  , missing out on the gold ring only because some of the product related information is a little UK-centric and dated. Like the rest of the Workshop Practice series, it is still in print and available from Amazon for a mere $23.26 at the time of writing.

, missing out on the gold ring only because some of the product related information is a little UK-centric and dated. Like the rest of the Workshop Practice series, it is still in print and available from Amazon for a mere $23.26 at the time of writing.

-oOo-

The next book, which actually was a new entry into the Library shelves during April, is Volume 34 of Engine Collectors' Journal. For me, the arrival of the new ECJ volume is always one of the major, highly anticipated events for the year. I read once that what marks the difference between a human child and adult is the ability of the latter to delay gratification (and let's not get into where that leaves all of the beloved Gen-Y  ). I could get my ECJ fix in a very adult way with a subscription that would deliver an issue each couple of months. But that is not enough delay! I prefer to be positively venerable and so wait until Uncle Tim binds up the past six issues into a volume which takes as long as it takes, generally about a year. I then become uncommunicative while the past half dozen issues are digested with glee and delight—are you getting the impression that I like ECJ yet?

). I could get my ECJ fix in a very adult way with a subscription that would deliver an issue each couple of months. But that is not enough delay! I prefer to be positively venerable and so wait until Uncle Tim binds up the past six issues into a volume which takes as long as it takes, generally about a year. I then become uncommunicative while the past half dozen issues are digested with glee and delight—are you getting the impression that I like ECJ yet?

ECJ Volume 34 encompasses issues 193 through 198. It also marks a subtle shift in presentation, with a shift to glossy paper for the color cover on issue 196, extending to color on the inside of the front cover from the following issue. The usual index page now moves to page 3, allowing this valuable glossy, full color real-estate to be dedicated to one of the subjects. Speaking of which, volume 34 covers a lot of interesting ground, all the way from some very unusual Cox prototype engines which I had no idea existed, through an informative series on Fox needle valves (under the apt name of Foxology), all the way to a feature on Sten Dahl, the name behind the DAMO engines, as seen on the cover shot seen above.

Sadly, volume 34 also contains the last Enginuity columns from our friend and founder Motor Boy, Roger Schroeder. By coincidence, Roger's final column was on an engine I'd made and sent to Tim in thanks for his efforts in brokering the AHC diesel deal. I tested each engine in a rig intended to prevent hold-down marking of the lugs. In this I was not entirely successful, so Roger and Randy Ryan come up with a way to apply some cosmetic repair to the lugs which is a technique that should appeal to all amateur engine restorers. And I'm not going to repeat it here; you'll have to write to The Publisher, or by visit the ECJ Website and part with a very modest $17.50 (add $13.00 for overseas delivery) for 62 pages of enjoyment. A well deserved Five Stars  and as before, tell Tim you read about it here—it helps keep the graft flowing

and as before, tell Tim you read about it here—it helps keep the graft flowing  !

!

Engine Of The Month: Drone Diesel

This is one that has been on our to-do list for quite some time as it is a nice engine, and one of considerable historic importance with a connection from the USA to Australia. I don't actually have one in my little collection, but Adrian Duncan has a garden full and has done quite a bit of testing in regards to their care and feeding, so he got the job of assembling the history as best he could. The results forced us to re-examine the page on fixed compression diesel operation which has been updated with Adrian's latest findings. As usual, click the thumbnail picture, or look up Drone Diesel in the Engine Finder to read about Leon Shulman's valiant attempt to popularize compression ignition engines in the USA of the late 1940's.

Tech Tip of the Month

How sad it is that age gets to us all. How much sader is it when age afflicts our tools as well! If there's one simple hand tool that every model engineer will most probably posses, it must be the humble hacksaw. This is not a tool I reach for often as my Far Eastern cut-off saw does a better job in most cases, with far less effort. But during the past month, I needed to saw through a piece of 5/16" diameter drill rod while the powered saw was busy cutting through a piece of 3" steel bar in the background, so I either had to wait for this lengthy cut to complete, or reach in the bottom drawer for the trusty, venerable, hacksaw. This I did and the little piece of drill rod (silver steel, if you prefer) was parted off in no time. Now why am I telling you this?

As I picked up the hacksaw to put it away for another decade, something caught my eye—like my alleged sense of humor, the stupid thing was warped! I've had this hacksaw frame since February 1965 when as a young Technician In Training (and yes, the Department of Civil Aviation did use the acronym to officially describe us), it was issued to me as part of my toolkit. I'd guess it has had a saw blade in it ever since, so the cast alloy part that has warped has been under tension for forty-five and a bit years. This month's tech Tip could be some ponderous statement like "be sure to slack off tension on your hacksaw blade before putting the tool away", but I seriously doubt anyone would follow the advice, not even, or especially me! Eclipse is not an awful brand of tool, so if it's happened to me, it may have happened to others. Who else was a warped hacksaw? Luckily, the deflection does not hurt for the occasional use it gets subjected to.

I've mentioned before the value of reading outside your specialty. It's remarkable how frequently this will uncover techniques which do have application to tasks you may be faced with while making model engines. Since reading the story of Lillian Lawerence, aka "Curley", and "LBSC", I've become rather fascinated by his prodigious output. After all, he spent virtually his entire life making his living through model engineering and wrote from first hand experience. His topic was live steam and his preference was locomotives, but his techniques are worth investigating. For instance, the first job tackled when making a locomotive is generally to cut out the frames from plate steel. Today, we might simply throw money at the problem and draw it up in CAD, export it in DXF, then send the file off to the local firm with water-jet cutting equipment and save ourselves the effort of marking out, then reaching for the hacksaw. In Curly's day, this was not an option and how he went about making long, straight cuts in steel plate of 1.5 to 4mm in thickness is a useful tip to have tucked away in your bag of tricks. That's between about 1/16 and 5/32 inch. I've amazed myself lately in actually starting to think in metric for preference!

Along with the hacksaw, any model engineer worthy of the name is going to have a bench vice. The jaws of your vice are hard. You might eventually damage them with a hacksaw and determination—certainly countless apprentices have managed to do so when the vice in question is not their own—but it takes genuine effort. Curley suggested taking advantage of this and using the tops of the jaws to guide the hacksaw blade for straight cuts. After all, you are going to have to grip the frames in the vice anyway. He recommended marking out one frame, then temporarily riveting a second frame blank underneath it so that both can be done at once, to the same dimensions.

The line scribed in the metal is then aligned with the top of the jaws, allowing a smidge of extra for later filing down to remove the saw cut marks. To make the cut, the blade is rotated to be horizontal in the hacksaw so that the frame will clear the job. Initially, the end of the work is set inside the jaw length so the blade can be lain on the jaws to start the cut. You then continue the cut to just less than the jaw length while keeping the blade in sliding contact with the jaws. Slide the work along and repeat as required (Curly liked to write ditto-repeato) to produce a straight cut needing only a bit of a touch-up with a file to clean up the saw marks. This should be done by a technique called draw-filing, where a fine file is held in both hands at right angles to the job, then drawn along the metal to produce a fine, flat finish (that's a tip from me, not LBSC  ).

).

Saws cut better when more teeth are in contact with the job at any one time, so make life easier for yourself by angling the blade while cutting; don't try to cut with it at right angles to the job if you can avoid it. You should also choose a blade with a tooth pitch such that you always have at least two teeth in contact with the work at any one time. If not, expect it to jam and possibly break off teeth. For model work, 32 teeth per inch (TPI) was usually the go back "in the day". In researching this piece, I did a quick web search and found that things have not changed that much as blades are still specified by TPI. It rather surprises me to find an area where metrication is creeping in rather slowly. With effort, I did manage to locate suppliers quoting power hacksaw blades in teeth per centimeter. The finest I could find was 13 TPC which is just finer by my calculation, giving 33 TPI.

-oOo-

A reader question came in during the month that prompted a long reply to what some would view as blindingly obvious. I tend to believe that there are no bad questions (well, almost none anyway) and that this was one which has probably puzzled many who are new to the concepts of compression ignition model engines—or diesels, as we commonly call them. So after sending of the response, I decided to make a new Frequently Asked Question (FAQ) entry and expanded even further on my email response. I mention it here because it is technical in nature and includes a tip which I think is very important to model engine builders, so click here to discover why the contra piston of a diesel does not go up and down with the piston when the engine is not firing.

And the Humbug Prize Goes To...

And the Humbug Prize Goes To...

Valves In Abundance

Valves In Abundance

Stamp Collecting

Stamp Collecting

More Information on Old Friends

More Information on Old Friends

The Alags are Coming

The Alags are Coming

Editorial

Editorial

New Books and Magazines This Month

New Books and Magazines This Month

Engine Of The Month: Drone Diesel

Engine Of The Month: Drone Diesel

Tech Tip of the Month

Tech Tip of the Month

Standard Stuff

Standard Stuff

).

).

, missing out on the gold ring only because some of the product related information is a little UK-centric and dated. Like the rest of the Workshop Practice series, it is still in print and

, missing out on the gold ring only because some of the product related information is a little UK-centric and dated. Like the rest of the Workshop Practice series, it is still in print and

and

and