The Fuji Story

by Adrian Duncan

Chapter 1—Historical Background

Chapter 1—Historical Background Chapter 2—Fuji Corporate History

Chapter 2—Fuji Corporate History Chapter 3—Fuji in the '50's: The Classic 099 Series

Chapter 3—Fuji in the '50's: The Classic 099 Series-

1st Model, Fuji .099 (Model 099-1)

1st Model, Fuji .099 (Model 099-1) -

2nd Model, Fuji .099 (Model 099-2)

2nd Model, Fuji .099 (Model 099-2) -

3rd Model, Fuji .099 (Model 099-3)

3rd Model, Fuji .099 (Model 099-3) -

4th Model, Fuji .099 (Model 099-4)

4th Model, Fuji .099 (Model 099-4) -

5th Model, Fuji .099 (Model 099-5)

5th Model, Fuji .099 (Model 099-5) -

Interlude: The Silver Arrow 29 and the Adoption of Die-casting at Fuji

Interlude: The Silver Arrow 29 and the Adoption of Die-casting at Fuji -

6th Model, Fuji .099 (Model 099-6): First of the "Menasco" Series

6th Model, Fuji .099 (Model 099-6): First of the "Menasco" Series -

7th Model, Fuji .099 (Model 099-7): Second of the "Menasco" Series

7th Model, Fuji .099 (Model 099-7): Second of the "Menasco" Series -

Meanwhile, Back At Head Office

Meanwhile, Back At Head Office -

8th Model, Fuji .099 (Model 099-8): Third of the "Menasco" Series

8th Model, Fuji .099 (Model 099-8): Third of the "Menasco" Series -

9th Model, Fuji .099 (Model 099-9): Fourth of the "Menasco" Series

9th Model, Fuji .099 (Model 099-9): Fourth of the "Menasco" Series -

10th Model, Fuji .099 (Model 099-10): Fifth of the "Menasco" Series

10th Model, Fuji .099 (Model 099-10): Fifth of the "Menasco" Series -

11th Model, Fuji .099 (Model 099-11): Sixth of the "Menasco" Series

11th Model, Fuji .099 (Model 099-11): Sixth of the "Menasco" Series -

12th Model, Fuji .099 (Model 099-12): Last of the "Menasco" Series

12th Model, Fuji .099 (Model 099-12): Last of the "Menasco" Series -

Meanwhile, Back at the Factory

Meanwhile, Back at the Factory  Chapter 4—The Classic Fuji 099 Series in the Sixties

Chapter 4—The Classic Fuji 099 Series in the Sixties

In the first chapter of this in-depth study of the Fuji engines, we brought the story up to the point in 1949 when the Fuji Tokushu Kiki company had commenced production of the earliest Fuji models at a workshop located in Tokyo. We saw that the new venture got its start with a pair of basically similar designs in the .099 and .29 cuin displacement classes.

After stepping aside to review the corporate history of the Fuji venture in the last chapter, it's time now to follow the further history of the Fuji marque by tracing the evolution of the .099 cuin series.

1st Model, Fuji .099 (Model 099-1)

What appears to be the earliest model of the Fuji .099 is illustrated in the attached photos. It was evidently among the first products of the new company in 1949 and is accordingly designated under our previously-discussed model identification system as Model 099-1. Although an extremely simple engine which was clearly intended to be produced with the minimum possible amount of complex machining work, it is nonetheless a design of considerable distinctiveness. Since all of the subsequent models in the series evolved from this original design, it's worth spending some time describing it fully.

The illustrated engine bears the serial number 1770. At present the highest serial number of which we are aware for one of these models is 3501, indicating that total production was likely quite small—probably no more than four thousand or so.

The simplicity of the design is underscored by the fact that the engine consists of only 16 individual components, including the tank, tank mounting screw, glow-plug, prop driver, prop nut, prop washer, spraybar, spraybar nut and needle! Can't get much more basic than that and still end up with a motor that runs! The tank mounting screw was the only screw used in the assembly, both the cylinder and backplate being of the screw-in pattern. All cast components were produced by sand-casting.

The backplate is machined all over on this model, apparently from a sand-casting, and there is no provision for applying any form of unscrewing tool—the component must have been tightened using a lathe chuck, collet wrench or similar. The backplate has a "step" machined into its rear outer circumference for tank location, along with a tapped central boss for the tank mounting screw.

These engines were originally supplied as illustrated with a plain aluminium tank similar to that used on the companion 29 model. However, many examples encountered today have mistakenly been retro-fitted with the later red-anodized tanks that were to become something of a Fuji trademark with their .099 engines (and others) for many years. The Fuji .099 series were to retain their back tanks up to the early 1970's, long after practically all other manufacturers outside of Britain had discarded this once-common feature.

In the above context, it should be noted that the tank mounting "step" machined onto the backplate perimeter on this early model has a slightly larger diameter than that encountered on the later variants. Accordingly, the tanks from the later models will not fit an unmodified Model 099-1 backplate without forcing. Unfortunately, some examples are encountered in which the backplate has been re-machined to take a later red tank. Others may well have been retro-fitted with a backplate from a later model. We do not endorse such modifications of an engine of this rarity, but they do appear! Others have a later tank forced or swaged into position.

Apart from the tank, this engine introduced two other trademark features which were to appear on various Fuji engines during the 1950's. The first of these was the use of a screw-in cast-iron cylinder having radial porting, integrally-turned cooling fins and a blind bore. The second was the use of a rather odd beam mounting lug design with a very thin and shallow partial lug running full length fore and aft on each side in the usual location and two expansions per side at the mounting hole locations.

This mounting lug set-up looks (and is!) extremely vulnerable to cracking or shearing during a hard crash. The situation is compounded by the fact that the case material is relatively porous as cast. I have encountered several Fuji models having fractured lugs of this type. Indeed, sister 099-1 engine number 2220 in my own collection has a cracked lug which has been neatly repaired, while 099-3 number A786 (see below) has an un-repaired broken lug. The fracture on the latter example exposes the porosity of the crankcase material.

Having criticized the form of the mounting lugs, it's only fair to point out that the same design approach was used by O.S. for their contemporary 29 and (later) 36 twin-stack glow models as well as their Max-I 29 and 35 models of 1954. Boxer followed suit with their own twin-stack 29 model which bore a very close resemblance to the O.S. product. Moreover, the configuration was not confined to Japan—AMCO were to use the same lug design on their famous 3.5 BB diesel of 1951. So Fuji were far from being alone at this time in employing such an arrangement.

The best approach to minimizing the risk of damage to the lugs during use appears to be to make a pair of 1/8" thick rectangular alloy plates of the appropriate size and drilled with two holes apiece at the correct spacing to allow passage of the mounting bolts. These are positioned on top of the lugs and act in effect as clamps to distribute mounting stresses throughout the mounting lug system rather than concentrating it at the mounting holes. More importantly, they do much to spread crash-related shock loadings throughout the entire mounting lug system rather than relying solely upon the rather skimpy "expansions" around the mounting holes.

On most of these engines, the name "FUJI" is stamped vertically into the right-hand side of the upper crankcase (facing forward). This stamping was clearly done prior to the case being brushed and tumbled to a bright finish, since the letters have smooth edges and a similar surface finish to the rest of the case. On engine number 1770, the "FUJI" identification has been omitted—presumably this was a "Friday afternoon special" and someone either forgot or just couldn't be bothered to do the stamping! If that engine were a postage stamp, It would be worth a lot of money!

The serial number of the engine usually appears in a small rectangular "panel" cast onto the side of the crankcase beneath the right-hand mounting lug, with the designation 09 in the corresponding location beneath the left-hand lug. Both sets of numbers were stamped onto the case after tumbling. On engine number 2220 the locations of these numbers are reversed, but this is almost certainly an incidental switch caused by inattention on the part of the person doing the stamping. Perhaps they simply didn't care.

The front of the main bearing on the crankcase of this variant is machined into the form of a steep taper which matches the bearing end diameter to that of the rear of the prop driver. This is the only Fuji .099 model to feature such a provision.

The case incorporates a spectacular-looking forward-facing intake for the crankshaft rotary valve. This appears to be intended to take advantage of the "ram air" effect to effectively "supercharge" the engine—a theory which has not stood the test of time. The externally visible angle of this intake is misleading—it rather gives the impression that induction is routed through the crankweb. In reality, the actual venturi throat is drilled internally off-axis at a somewhat less dramatic angle and meets the upper bearing surface in the usual location just forward of the front crankcase wall, leaving an unbroken length of journal forward of the crankweb to provide a base seal and an unbroken bearing surface.

A conventional needle valve assembly consisting of a spraybar and a rigid needle is fitted into this venturi. The needle features a brass thimble which is split for tension, and also sports a knurled brass control knob at the outer end. Variations of this component were to be used on all subsequent Fuji .099 models up to 1958 or thereabouts.

The crankshaft itself features a counterbalanced full-disc crankweb and a round induction port to match the base of the venturi. Gas passage diameter is 5mm. The prop driver is located on the shaft by a square section milled onto the front of the journal which keys into a square-shaped broached opening in the centre of the machined alloy prop driver. Interestingly, the prop driver face is completely plain with no knurling, presumably to allow some prop slippage in the event of a crash and thus help to prevent breakage of the working parts. The driving faces of both the prop driver and the plain machined prop washer are generously relieved in the centre, perhaps to ensure that the engine's operating torque is transmitted though the outer circumference of the drive set-up with less chance of incidental slippage during normal operation. I have experienced no slippage problems with these low-compression and rather docile motors.

The engine is fitted with a machined steel rod, matching the similar set-up used in the companion 29 model. The turned "balls" in which the big and little end bearings of the rod are formed are ground flat at the rear to effectively displace the actual rod column to the rear of the bearing centres. This ensures that the rod column clears the crankweb counterbalance. A plain steel fully floating gudgeon pin is used in the conical-topped cast iron piston.

This variant of the screw-in cylinder Fuji .099 is one of only three of which we are aware which do not feature a separate alloy head mounted on top of the cylinder. On this first version, seven of the eight cooling fins are turned very thin indeed and appear highly vulnerable to damage—please take care when handling one of these! The top fin is significantly smaller in diameter and thicker than the others and has four holes drilled equilaterally around its circumference to allow for the use of a suitable pin wrench to unscrew and retighten the cylinder. Please use the proper tools and techniques if you really must dismantle one of these models!

The absence of a separate cylinder head as used on later models gives the engine a rather squat "truncated" look, and the plug body is completely exposed down to the base. A contemporary brass-bodied Sun plug is fitted to the illustrated example—these were the standard fittings in Fuji engines at this time.

The porting arrangements on this model are in some respects analogous to those used in the contemporary American OK Cub models, the first of which had also been introduced in 1949. An unthreaded annular space around the full circumference of the outer cylinder just below the exhaust port belt feeds the cylinder through three transfer ports drilled upwards at an angle between the three exhaust ports. The tops of the transfer ports very slightly overlap the bottom of the exhaust ports. A similar unthreaded annular space is provided at the top of the crankcase casting. The result of this arrangement is the creation of an unthreaded annular passage encircling the cylinder at transfer port level, exactly as per the OK Cub design. The advantage is that the functioning of the transfer ports should in theory be independent of the position in which the screw-in cylinder happens to end up when tightened.

The difference between the Fuji and OK systems is the manner in which the annular passage is supplied with gas from the lower crankcase. Instead of the twin bypass passages of the OK set-up which interrupt the female thread in the case at the sides, the male cylinder screw-in thread in the Fuji is interrupted by three flat channels milled into the outer wall of the lower cylinder directly below the transfer ports. These act as bypass passages to feed both the transfer ports and the annular space around the cylinder, which then assumes a flow-balancing function by promoting the even distribution of gas between the three transfer ports regardless of the cylinder orientation when screwed home. The corresponding female thread in the case itself is uninterrupted. This same set-up was later to be adopted in the original Elfin 1.49 and 1.8 BR models of 1954.

Bore and stroke measurements are square at 12.70 mm and 12.70 mm each for an actual displacement of 1.61 cc (0.098 cuin). These dimensions were to be retained in all Fuji .099 models throughout the period under discussion. The engine weighs exactly 3 ounces complete with tank, plug and fuel tubing.

This variant appears to be quite rare outside of Japan, suggesting that this model was never exported in any quantity. Indeed, my two examples are among the very few that I've ever encountered in the metal, although I am aware of at least two other examples elsewhere. Both of my engines have clearly had quite a bit of use, and I'm fortunate indeed that they remain in such fine condition apart from the cracked lug in number 2220. The rod bearings are a little loose, but compression seal and main bearing fit are still more than adequate. Both engines still start and run very well, albeit no world-beaters in performance terms.

It's worth recalling for context at this point that the .099 model just described was accompanied by a sandcast Fuji .29 cuin model of generally similar design but featuring a very different transfer porting system. This model will be fully described in our companion study of the Fuji 29/35 models.

A neat little sandcast .049 model of generally similar design was also introduced during the Fuji company's first few years. Other models soon followed—indeed, the range was destined to expand quite rapidly over the next 5 years or so, as we shall see in due course. All of these models will be fully described in companion chapters dealing with the other displacement categories.

2nd Model, Fuji .099 (Model 099-2)

At some point either side of serial number 4000 or thereabouts, a few relatively minor modifications made their appearance. The serial numbering sequence seems to have continued without a break despite these changes, implying that the manufacturers themselves did not see them as being sufficient to justify a re-start of the numbering sequence. We have access to engine number 5239 of this type.

This variant of the engine retains the same cylinder fin configuration and appears identical to its predecessor at first glance. However, there are in fact several differences which are not immediately obvious. The tank is still made of plain aluminium but now has a slightly smaller internal diameter, similar to that used on the later red-tank models to be described in subsequent sections of this article. The tank is also two millimetres shorter than that used on the 099-1 model. The backplate has been modified with a thicker rim having a slightly smaller diameter shoulder to locate the re-designed tank. Consequently, a red tank from a later model will fit this variant without modification or forcing.

The revised backplate continues to lack any provisions for backplate removal. Most obviously, the taper which was formerly machined at the forward end of the main bearing where the crankshaft emerges has been omitted, with the bearing being left as cast. This was presumably a cost-reduction measure since it eliminated one machining step.

The squared end to the crankshaft for keying to the prop driver has been replaced in this example by the more common single flat arrangement seen on later models of the engine, although the shaft is otherwise unchanged from that of the previous model. This is one of the anomalies presented by the early Fuji engines, since we are aware of at least one later variant of the Fuji .099 which retains the earlier square keying system for the prop driver. It would appear likely that Fuji was experimenting with different shaft designs at this time and released engines in the same series having different shaft configurations. We shall encounter this again when we examine the next model in the series.

On the cited example, the serial number has been placed on the other side of the engine and "09" replaced by "099". Of course this may just be an operator-related anomaly as opposed to a wholesale change for this variant—a similar anomaly was noted in connection with model 099-1 discussed earlier. A more inexplicable departure is the fact that the four equally spaced removal holes in the top fin have been replaced in this example by 5 holes in an irregular pentagonal arrangement. As none of these holes are diametrically opposite or anywhere close to evenly spaced, it would appear that this most likely represents an operator error during the drilling of these holes which was corrected to the best of the operator's ability. Since it is unique in our extensive experience of these engines and moreover has no logical basis, we cannot claim it as a standard feature of the 099-2 variant.

On the basis of the single example of this variant to which we have access, we are unable to draw any legitimate conclusions regarding the number which may have been produced.

3rd Model, Fuji .099 (Model 099-3)

We mentioned above that the seven very thin cooling fins machined onto the cast iron cylinder of the two Fuji .099 models described so far were highly susceptible to damage from a variety of causes. It seems that Fuji themselves realized this at some point and decided to do something about it. While they were at it, they also seem to have decided to make a few performance-enhancing modifications as well.

The result was a variant that appeared at first glance to be essentially identical to the previous model but which had a revised cylinder featuring slightly thicker and hence somewhat less fragile cooling fins. The cylinder height remained unaltered, and to allow for the increased fin thickness the number of fins was reduced by one. Hence there were now only six thin cooling fins between the port belt and the thick upper flange. The revised cylinder continued to feature the blind bore and plain unadorned head of its predecessor.

A less obvious change in the cylinder was a slight revision of the transfer timing. We noted that in the two original models the top of the three drilled transfer passages came up to a point only just above the bottom of the exhaust slots, providing a minimal degree of overlap with a generous blowdown period. The revised cylinder featured modified transfer timing, the top of the transfer holes now extending to a level roughly half-way up the exhaust slots. This of course increased the transfer period and reduced the blowdown period. The objective was presumably to improve top end performance. The exhaust period was unaltered in this variant. Another performance modification was a slight increase in the diameter of the induction hole in the centre of the crankshaft from 5mm to 5.5mm.

A further change was in the method of producing several of the components. For the first time, we begin to see the use of pressure die-casting, albeit as yet on a small scale. The backplate, prop driver and prop washer of this variant were produced by the die-casting method, replacing the fully-machined components used previously. However, the main crankcase casting continued to be produced by sand-casting and was in fact identical to that used in its predecessor.

On one of our examples (number A786), the new die-cast prop driver continues to be keyed to the shaft on a square section milled onto the front of the shaft, but advantage was taken of the new production method to incorporate a circle of cast-on raised "teeth" to grip the rear face of the prop when mounted. The cast prop washer incorporated the dummy "bolt heads" which were seen on many Japanese (and some American) engines at this time.

Our later example of the same model (number A1112) uses the same single-flat prop driver keying system as that seen on 099-2 engine number 5239. This is a further indication that Fuji had been experimenting with different shaft configurations. A special batch of prop drivers must have been broached to create a square-section recess to fit a corresponding batch of square-keyed shafts.

The tank mounting "step" cast into the rear circumference of the revised backplate had the slightly smaller diameter first seen on its machined 099-2 predecessor, and for the first time the tanks fitted to these engines were of the familiar red-anodized pattern. This fitting was to remain unaltered from this point onwards—indeed, a red-anodized tank from a 1965 Model 099-15 (see following chapter) will fit the 099-3 backplate perfectly. The revised backplate also had slots for removal cast into its outer circumference—a welcome improvement.

Finally, the serial number continued to appear in the cast-on rectangular "panel" beneath the right-hand mounting lugs, but the former .09 designation which had appeared in the left-hand panel was no longer present. In contrast to the previous model, the serial number was apparently stamped on before the tumbling process, since its edges are rounded like those of the "FUJI" name which continued to appear on the right-hand side of the case above the mounting lugs.

In all other respects, this model was identical to its predecessor. The changes were however sufficient that Fuji themselves considered this to be a distinct variant, since they actually re-started the serial number sequence with an A prefix added to distinguish this series from the original model. The very significant changes to the cylinder finning and porting plus the shaft hole modification probably account for this.

Our lowest confirmed serial-numbered example of this variant bears the serial number A786. The numerical intersection between this and the numbers found on the previous models appears to confirm that the numerical sequence was restarted at A1 when the revised cylinder was introduced. We are also in possession of illustrated engine number A1112 of this type. This is the highest confirmed serial number so far known for this extremely rare variant. Engine number A786 was missing its tank as received, but engine number A1112 had a red tank which we believe to be original.

Based on the limited serial number data presently on hand, it seems that this variant appeared after perhaps some 7,000 to 10,000 examples of the two previous models had been produced in total. The time required for the fledgling company to make this number of engines (along with the concurrent production of their .29 model) argues that the variant just described probably appeared at some indeterminate point during the latter half of the year 1950 or perhaps early 1951.

One little-remembered fact is that the Fuji .099 engines quickly became well-known in Japan for powering a series of small tether cars. These early Fuji-powered cars are quite rare outside of Japan, selling for relatively high prices when they do appear. They featured sand-cast aluminium chassis with the powerplant mounted transversely at the rear. Indications are that the serial numbers which appeared on the chassis and on the powerplant were matched—a recent eBay offering featured such a car which bore the matching serial number 2501 on both the chassis and the engine. The engine in this car was a Fuji 099-3 model like that just described.

This unquestionably implies that the engines used in the cars were numbered independently from Fuji's mainstream aero engine production. In fact, it appears very likely that the role of Fuji was confined to the manufacture of the engines used in many of these cars. The most familiar Fuji-powered cars are those which were sold under the name "Midgetee". These were actually produced by an individual named Jiro Shimatani, who began marketing small cast aluminium tether cars in around 1948 under the New Star label, using Hope 29 engines.

In 1949 Shimatani-san designed and marketed a wooden-bodied car called the Dat Prince, which was powered by the then-new Fuji .099 engine. He then switched back to cast aluminium chassis and introduced his "Midgetee" line using mainly (but not exclusively) Fuji .099 and .29 engines. These are often mistakenly referred to as "Fuji cars", although they are in fact products of a separate company and were sometimes sold with powerplants other than those from Fuji. The engines were presumably supplied under contract. It would seem that they must have been supplied un-numbered so that they could be marked with the same number as their chassis during their assembly by Mr. Shimatani and his colleagues.

4th Model, Fuji .099 (Model 099-4)

It's clear that by the time 1951 rolled around Fuji had ramped up their production significantly. The application of die-casting to some of the minor components of the previous model is indicative of a growing concern with production capacity.

At some indeterminate point in 1951, according to the very scanty information presently available on the Model Engine Company of America (MECOA) web site, the company decided to make a few further changes to the.099 model described above. Oddly enough, it appears that Fuji did not bother to start a new serial number sequence at this time, instead simply carrying on with the A prefix numerical sequence begun with the previous variant. They were to reprise this anomaly again in the future, as we shall see in due course. Whatever Fuji's opinion at the time, the changes evident in the revised model are more than sufficient for present-day collectors who care about such things to regard this as a distinct variant.

The illustrated example of the revised model bears the serial number A4355, while the highest recorded number for one of these models is A5744. The lowest serial number of our acquaintance for this variant is A2593 which appeared on eBay some time ago. This latter figure makes it clear that no more than perhaps 2500 or so examples of the previous 099-3 variant were manufactured before the changes to create the 099-4 variant were introduced.

The changes embodied in the revised design were once again focused for the most part upon the cylinder. The sand-cast crankcase with its stamped "FUJI" identification was unchanged from that of the previous model, and the serial number was stamped as before on the side of the crankcase under the right-hand mounting lug. As before, no indication of the displacement appeared anywhere on the engine. Rather oddly, Fuji failed once more to take advantage of the opportunity to eliminate the rather weak "twin expansion" mounting lugs. They were retained unaltered.

The basic design concept remained unchanged, the one-piece screw-in cast-iron cylinder with radial porting, six integral fins and blind bore being retained. The most obvious change was to be seen in the upper cylinder configuration. The former thick upper fin with its four holes for the application of a pin wrench was eliminated in favour of a central boss of relatively small diameter, through which the plug installation hole was drilled and tapped. A separate finned "cylinder head" machined from light alloy bar-stock was pressed onto this boss (presumably after the cylinder was screwed down really hard) and swaged in place using a punch at four points around the circumference of the joint between the head and the boss.

It must be understood that the bore of this model remained blind—the new head was in fact a "dummy" which really only served a cosmetic function and reduced the engine's visual tendency towards "squat-ness". The engines will run perfectly well with the "head" entirely removed. This feature mirrored the similar arrangement which had been pioneered in America by O&R and had first appeared in Japan a year or so previously on Hope's original "New 29" model.

This rather unique arrangement appears at first sight to be a recipe for trouble in terms of the engine staying together, but in fact the heads of these engines generally stay put in normal use with no problems unless the engine is subjected to a hard crash impact involving the cylinder or the head is loosened during ham-fisted attempts to unscrew the cylinder. I'd recommend strongly against unnecessarily disturbing the screw-in cylinder of any Fuji with this type of head—it would be all too easy to disturb the staked-on head while trying to loosen and re-tighten the cylinder, and the correct fore-and-aft alignment of the head fins cannot be guaranteed upon re-assembly.

Another change, and not one for the better in my personal view, was the final elimination of the square-section keying of the prop driver to the shaft in favour of a single flat milled into one side of the shaft, with the die-cast prop driver having a corresponding internal "key" to lock it to the shaft. This arrangement is far more prone to wear and eventual failure than the square section used originally, making it hard to understand why this change was made. A taper fitting is more durable than either, of course. Be that as it may, the single-flat locking system was to survive for the rest of the long production life of the classic Fuji .099 series. Presumably, cost considerations once again played a role in this decision.

This model also featured a further expansion of the use of die-casting in the production of these engines. The former steel con-rod was replaced in this variant by a pressure die-casting in light alloy featuring a bronze-bushed big end. Otherwise, the revised model was essentially identical to its predecessor, including the slightly enlarged central gas passage in the shaft. The full-disc counterbalanced crankweb was retained unaltered as was the use of a simple round hole for the induction port in the shaft. The only change to the shaft was the provision of a shoulder on the crankpin at its junction with the crankweb to keep the revised rod clear of the crankweb during operation. Bore and stroke were identical, and the weight too remained the same at 3 ounces exactly all complete.

Based on the fact that the lowest serial number yet encountered for the next variant to be described is A7167, it would appear that perhaps as many as 4,000 examples of the 099-4 variant may have been manufactured in total.

5th Model, Fuji .099 (Model 099-5)

At some indeterminate point in time, most likely in 1952, the variant just described was subject to a number of further modifications. Once again, Fuji evidently didn't see these as warranting the start of a new serial number sequence, apparently continuing the sequence already started some time previously with the 099-3 model.

The porting arrangements remained unaltered in this variant, but the revised model featured an upper cylinder having fewer and thicker cooling fins yet again—presumably even the six somewhat thicker fins on the third and fourth variants had been found to be too vulnerable to damage. There were now only five relatively thick and hence far sturdier fins above the exhaust port belt instead of the former six.

The crankcase casting was essentially unaltered from that of its predecessor. However, the deck height was slightly raised by facing off the cylinder seat at the top of the crankcase some 1.5 millimetres higher above the crankshaft centre line. The geometric relationship of the exhaust and transfer ports were unchanged from the previous model, so the effect of the raising of the cylinder was to increase both exhaust and transfer periods. The objective of this change appears to have been to further improve high-speed performance.

By rough volumetric measurement, the compression ratio of around 8:1 was unaltered by the raising of the cylinder, so it seems that the machining specifications of the blind bore must have been amended to lower the cylinder head in order to maintain the compression ratio. The engine was otherwise unchanged from its predecessor.

As noted earlier, the lowest serial number yet confirmed for one of these models is A7167, while the highest number of our present acquaintance is illustrated engine number A8583. If these numbers were near the lower and upper limits, this would imply that this should by rights be one of the rarest Fuji .099 models. However, nice examples of this variant turn up with surprising frequency. Either they were really treasured or they didn't get used much! More probably, the change came about very soon after engine number A5376 and continued well past A8583, possible deep into the 9,000 range. If this is the case, over 4,000 examples may well have been produced in total. This figure is more in keeping with the number of survivors.

This model of the Fuji .099 appears to have remained in production until mid 1953. By that point in time, the engines were packed in a plain and quite sturdy dark yellow cardboard box with an attractive blue or red label on top featuring English-language lettering. This shows that penetration of the English-speaking market was beginning to assume some importance for the company. At this time too the label included a neat little circular trade-mark in addition to the familiar "winged" Fuji trade-name. The trade mark was later to be dropped, although the "winged" Fuji trade name was retained for some years thereafter. The manufacturers continued to be identified as Fuji Tokushu Kiki Works.

Interlude:

The Silver Arrow 29 and the Adoption of Die-casting at Fuji

It's now necessary to briefly leave our main subject in order to document a major production change which was phased in by Fuji over a period of time beginning in 1950. This was the progressive elimination of sand-casting in connection with the production of the cast components of the Fuji range in general.

According to Japanese sources, one of the characteristics which always set Fuji apart from their domestic rivals was the fact that, alone among Japanese manufacturers, they pursued a policy of doing all of their own manufacturing in-house—they did not sub-contract any aspect of the production of their model engines. This included the production of the required castings. There are indications that they may have departed from this practise at a later stage, as documented in Chapter 2, but even then they appear to have retained ultimate control over their own manufacturing activities.

A general switch to die-casting would clearly require a major investment in the acquisition of the necessary equipment and know-how at Fuji's own production facilities—no small undertaking! The company appears to have adopted a very rational approach to this issue. We have seen that they first tried their hand at die-casting on a very small scale with a few of the minor components of their 1950 .099 model (099-3), later adding the con-rod of their 1951 .099 variant (099-4) to their die-casting repertoire. It would seem that their purpose in doing this was to gain first-hand experience with the new technology as well as test its economic benefits (if any). They were clearly hedging their bets at this time, since the balance of the cast components for the range as it then stood continued to be produced by sand-casting.

However, by the middle of 1952 things had changed quite drastically! The Fuji range was now sufficiently well-established in the marketplace that the long-term future of the company in the model engine business must have seemed assured. Apart from the model engines themselves, the company had become a major producer of glow-plugs which were supplied with all Fuji engines and were also to be found in use in Japanese engines other than those made by Fuji. These were made by the Sanko Plug Company, as mentioned earlier, but they bore the Fuji name regardless.

By this time too, the scale of engine production and the scope of the range had reached levels at which the use of sand-casting was no longer viable if the company was to continue to expand. Clearly their sales prospects were now sufficiently promising for a major investment in die-casting technology to be deemed worthwhile.

However, at the time of which we are now speaking the company was still a relatively small concern by industrial standards. Consequently, a wholesale switch to die-casting for the entire range would represent a level of investment which the company might find difficult to justify. For this reason, the decision was apparently taken to make the wholesale switch to die-casting one model at a time, both to gain further experience and in the hope that the initial trial would confirm that the economics of the revised casting process justified the same production change being applied to other models in the range.

The first Fuji model to be produced entirely by die-casting was the .29 cuin; Silver Arrow model. This was Fuji's first loop-scavenged design, and it replaced the original radial-ported 29 model mentioned earlier. It appears to have been introduced in the latter half of 1952. We will describe this model in detail in our companion article on the Fuji 29/35 models. Suffice it for now to say that Fuji clearly learned well from their experiences with the Silver Arrow. They were to give ample proof as time went by that their die-casting skills were second to none in the model engine manufacturing field, regardless of one's standards of comparison.

The other models in the range continued to be offered in their sand-cast configurations, a fact which is confirmed by a range illustration belatedly published in the July 1955 issue of Aeromodeller magazine. Despite the publication date, this illustration is clearly a Fuji promotional montage showing the range as it existed in early 1953, since the disc-valve sand-cast .29 "racing" model (which was phased out during that year) is still illustrated and the .15 model (introduced in 1954) is not included. However, the die-cast Silver Arrow is very much in evidence alongside its sand-cast siblings, including the 099-5 model described earlier.

Apart from being the first Fuji model to be die-cast throughout, the Silver Arrow is significant in that it represents the first step in what was to be a gradual but inexorable move away from the old (and it must be said, individualistic) Fuji radial-ported designs towards the completely conventional loop-scavenged designs that were to come. But that was still in the future as of 1952. For now, let's return to our discussion of the Fuji .099 models.

6th Model, Fuji .099 (Model 099-6):

First of the "Menasco" Series

The initial experiment with die-casting appears to have been a success as far as Fuji was concerned. Having tested the economics and honed their production skills on the 29 Silver Arrow just mentioned, they were ready to make the additional investment necessary to tackle other models in their range. The next Fuji design to receive the full-house die-casting treatment appears to have been the doubtless-popular .099 model. The resulting sixth version of the Fuji .099 seems to have been introduced in mid 1953, some time after the introduction of the Silver Arrow. The illustrated example bears the serial number H2263, which is the highest number yet encountered for one of these models, the lowest being H0276 (eBay offering).

It would appear from this that the serial numbering was re-started at H0001 for this new series. However, I have an example of this engine which bears the clearly-struck serial number AT4, thus not conforming to any known Fuji serial number sequence. Indications are that this was a very early example of this variant since it retains the fully machined head of the previous model which it replaced. This may explain the retention of the A prefix—it may even represent a short-run prototype series.

We have also taken note of similar engine number HR1 59 (as written) which appeared on eBay recently. As far as we could tell, that example was identical in all respects to the others in this series, hence we are presently unable to explain this seeming anomaly in the numbering.

With this model and several of its companions in the range, Fuji introduced yet another trade-mark feature which was to be applied to other Fuji models and was destined to last for some time on the .09, .15 and .19 designs—the well-known "twin stack" crankcase. They appear to have been influenced by O.S. in adopting this feature, since O.S. had used the twin-stack configuration on their .29 cuin models since 1948 and had used the same arrangement on their competing 1951 "New .099" model. K.O. also used the twin stack configuration in their .099 model of 1953, and Mamiya were soon to follow suit with their revised 1954 9X .099 model as well as their .15 offering of the same year.

Oddly enough, Fuji failed yet again to take advantage of the new die to eliminate the very evident weakness represented by the "twin expansion" mounting lugs—these continued to be featured on the new model, as did the rather problematic "single-flat" keying of the prop driver onto the crankshaft.

The cylinder of the revised Fuji .099 model was identical to that of its predecessor, retaining the swaged-on alloy cylinder "head" as a cosmetic complement to the blind bore which continued in use. The heads on a very few examples—perhaps the earliest ones—were identical to those used on the previous model (perhaps using up left-over stocks), but at some early point during the production run a switch was made to a die-cast head as opposed to one machined from solid bar. The cast fins on this revised head were generally similar in profile and depth to the milled fins of the previous component.

The internal porting arrangements were unchanged from the previous model. However, the use of die-casting with its closer dimensional control of the finished castings encouraged the designer to reduce the outside diameter of the upper case "spigot" into which the cylinder screwed from 19.5 mm to 19 mm even. This was achieved by marginally reducing the wall thickness of the case. Absent too was the spectacular "ram air" intake, which was replaced by a far less striking stubby angled venturi of conventional bell-mouthed form. The crankshaft was made considerably longer than that of its predecessor, and the induction port in the crankshaft was now cut square in typical American fashion to give more rapid opening and closing.

The small "flat" cast into the crankcase for the serial number was now located on the lower right side of the main bearing rather than beneath the right-hand mounting lug. The final change was the addition of the twin stacks, which served no functional purpose other than perhaps to reduce the tendency for dirt to enter the cylinder during a crash. On this model, these stacks were relatively small in sectional area and had rounded corners.

It can't be denied that the engines looked really good with their new styling! The attractive red tanks set off the rest of the engine very nicely from a visual standpoint, and the continued application of a light tumbled finish to the castings also helped.

Apart from the technical changes documented above, the new .099 model also marked the beginning of an interesting brand-name association which was to continue throughout the balance of the 1950's in various forms. The new die incorporated the name "Fuji 099" cast onto the right hand side of the case (looking forward) under the stack on that side. The area beneath the left-hand stack bore the letter "M" cast in relief. It was soon to become apparent that this mysterious letter "M" stood for Menasco, a famous name in full-sized American air racing.

Although at present I can offer absolutely no direct supporting evidence, the application of the Menasco name to these engines appears at first sight to suggest some kind of a tie-in between Fuji and the American Menasco company of Los Angeles, California. The implication is that the Fuji manufacturers had serious intentions of penetrating the American market at this time and had entered into an agreement with Menasco to allow the use of the Menasco name to add a touch of "brand recognition" to their US marketing efforts. Oddly enough though, the Menasco name was only ever directly associated with the Fuji .099 models. Even more oddly, the name appears never to have been used in any of Fuji's promotional leaflets. Strange ... wish we knew more!

The name Menasco means little to most model aircraft enthusiasts today, but the case was doubtless very different back in the first half of the 1950's. Menasco Manufacturing had been associated with the full sized aero industry since the mid nineteen-twenties, having been established by Albert Menasco in 1926 in Los Angeles.� Albert Menasco was deeply involved with the then high-profile sport of full-scale air racing, and his products were popular with racers looking for small displacement high-performance aero engines.

The company's first product was an air-cooled rebuild of a Salmson radial aero engine. In 1929, Menasco introduced the 4-A, the first example of what was to become its main product line, the inverted in-line high-performance aero engine. By the outbreak of WW2 in late 1941 (as far as the USA and Japan were concerned), the name of Menasco was well and truly identified in the American public mind with high performance full-sized aircraft.

The Menasco company ended full-sized engine development and manufacturing after World War II.� However, the well-established association of the Menasco name with air racing and the high-performance aero industry was unchanged by this and the application of the name to Fuji engines destined for the US market may well have had value in this context at the time in question. The exact nature and extent of Menasco's involvement with Fuji remains unclear—if anyone out there has any authoritative knowledge, let's hear from you!

The Menasco company remained in business over the years, changing its name to Menasco Aerospace and being noted more recently for its high-tech landing gear. After becoming a part of Coltec Industries, Menasco Aerospace was acquired by Goodrich Aerospace in 1999.�

It seems worth recalling at this point that the connection of the Menasco name with the Fuji .099 series came about at around the same time as the company was marketing their "Silver Arrow" .29 model. The name "Silver Arrow" was popularly applied to the famous stable of Auto Union and (later) Mercedes-Benz Grand Prix racing cars which were so widely known in the early fifties. The use of the Menasco name may have been no more than a parallel marketing ploy intended to impart a "racing" cachet to the .099 engines bearing this designation. If so, it was clearly aimed directly at the US market.

In various forms, the "Menasco" Fuji .099 models were to remain in production throughout the remainder of the 1950's, finding their way all over the world in the process as Fuji expanded their international marketing efforts. Let's now look at the further variants in the order in which the observable design progression and other evidence suggest that they appeared.

7th Model, Fuji .099 (Model 099-7):

Second of the "Menasco" Series

As we pointed out earlier, the Menasco connection with full-sized air racing had ended after WW2, and it appears that by 1954 not enough people understood the significance of the letter "M" which appeared on the previously-described model. It was presumably for this reason that the Fuji company now made a change to the crankcase die so that the full word "Menasco" appeared cast in relief onto the left side of the case in the same stylized script which had first been used in 1953 on the second Silver Arrow variant, with the other side remaining unchanged. This pretty much confirmed that the letter "M" initially used stood for Menasco but the letter alone lacked the brand recognition power of the full Menasco name, hence the switch. Illustrated engine number H4553 typifies this variant.

It appears from the serial numbers reported for this and the previous model that this change was made after perhaps 3000 or so examples of the first "Menasco" Fuji .099 (model 099-6) had been made. Engine number H2263 is presently the highest serial number of which we are aware for that model, and by the time we reach serial number H4553 we see the changes which gave rise to Model 099-7 now under discussion. This implies that the company did not see the changes involved to be sufficient to justify the commencement of a new serial number sequence and that they simply carried on with the Hxxxx numbering sequence begun with Model 099-6. However, from a collector's standpoint the changes are certainly sufficient to warrant the treatment of the revised engine as a different variant.

The highest serial number of which we are aware for the revised model is H5444. The implication is that perhaps 3000 examples of this model were produced in total. The frequency with which Fuji were amending their .099 design at this time meant that the numbers of each variant actually produced were quite small.

The cylinder of the revised .099 model retained the same five cooling fins and curved side profile above the exhaust belt of its predecessor and at first glance looked identical. However, a closer look reveals that the diameter of the portion of cylinder above the top fin and beneath the swaged-on head was increased, and two flats were milled into it on opposing sides to create a purchase for a wrench to be used for tightening the cylinder prior to swaging the head in place.

Another observable change was the addition of an expansion at the front of the main bearing which was machined to form a fairly lengthy "collar" at that point. The bearing length of this model was slightly longer than that of the previous variant, but this was offset by the prop driver having a shorter length that that of its predecessor. The prop overhang was thus unchanged. The crankshaft journal length was made slightly longer to match the longer bearing, but the threaded portion of the shaft at the front was shortened, giving an overall reduction in crankshaft length. Presumably the length of thread formerly provided had been (correctly) judged excessive in the context of the props normally used with this engine.

Apart from the changes noted, the engine remained indistinguishable from its predecessor. The fact that an illustration of this variant appeared in the July 1954 issue of Aeromodeller magazine proves that it was certainly on the market as of the first half of 1954, allowing for editorial lead-time.

Meanwhile, Back At Head Office

It was at about this time that the Fuji engines ceased to be identified with Fuji Tokushu Kiki and were instead credited on the leaflets to a new company named Fuji Bussan, a name which was to be retained for the balance of our study period. The term "bussan" means more or less "products", so the new business entity translated roughly into Fuji Products.

The Company's box style was also changed at around this time, seemingly reflecting a far greater emphasis upon the marketing side coinciding with the appearance of Fuji Bussan. The new box was substantially larger than its predecessor and was decorated in a striking brown-and-yellow colour scheme with yellow and white lettering and bordering. The former circular trade-mark was dropped in connection with these new boxes. However, the familiar "winged" Fuji emblem was retained, appearing on the boxes in a far more prominent rendition. The contents were identified by a stamp applied to a white circle included for the purpose, so the same box could be used for a number of models.

The Fuji range had expanded considerably by this time. The 1954/55 summary of the world's model glow-plug engines prepared by Peter Chinn (Model Aircraft, May 1955) confirmed that as of that period the .099 was accompanied by companion Fuji models in the .049, .15, .19. .29 and .35 cuin displacement categories. However, the previously-mentioned "racing" version of the Fuji 29 had reportedly been discontinued at some point in 1953.

A careful consideration of this impressive list underscores the fact that at this time Fuji continued to lead its rival Japanese manufacturers into some new market areas—it had been early in the field with .049, .099 and .35 cuin models, and the original twin-stack .15 cuin model introduced in 1954 was the first-ever commercially-made Japanese engine in the 2.5 cc International competition displacement category. Peter Chinn specifically commented on this in a footnote to his 1954/55 listing. Now, back to the Fuji .099 models ...

8th Model, Fuji .099 (Model 099-8):

Third of the "Menasco" Series

The next changes to the Fuji .099 focused upon the crankcase and cylinder head. It's presently unclear when these changes occurred, but we would probably be not too far out by suggesting mid 1955 as the most likely date, based on the evidence of leaflets and serial numbers in our possession.

These changes resulted in the appearance of the eighth model of the Fuji .099 and the third member of the series to carry the Menasco association. Fuji themselves undoubtedly saw this as a distinct variant since they re-started the serial numbering system at 00001. The sole example of our present acquaintance is illustrated engine number 00973.

It appears that by this time Fuji had become somewhat sensitive to the issue of the relative fragility of the "twin-expansion" mounting lugs. One may wonder why they didn't simply do away with these altogether and go to a pair of solid lugs. However, they did not do so—instead, they took steps to increase the strength of the existing design.

The four expansions through which the mounting bolts passed were made significantly thicker and somewhat wider than they had been on the previous model. Although this would doubtless have yielded greater strength, it's still hard to see why they didn't go all the way and simply eliminate the problem altogether. In all other respects, the crankcase remained unchanged from that of the previous model, including the relatively small round-edged twin stacks.

The cylinder head was also changed in this model. The staked-on cast alloy component of its predecessor was retained, but the casting was substantially higher than the former component and had far sharper edges. This change alone gave the revised model a very distinctive appearance by comparison, as the attached images will show.

In all other respects, the new model was identical to its predecessor. This appears to be one of the rarer Fuji .099 variants—the illustrated engine bearing the serial number 00973 is the sole example which I've ever encountered. At present we have no way of knowing how many were made, but the number can't have been high.

9th Model, Fuji .099 (Model 099-9):

Fourth of the "Menasco" Series

The relative rarity of the above model implies that it wasn't long before further changes were made to the engine's design. Once again these changes were essentially confined to the crankcase, cylinder and cylinder head. They were probably implemented in early 1956. The result was the ninth variant of the Fuji .099 and the fourth model of that displacement to display the Menasco connection.

The basic design approach of a radially-ported screw-in cast iron cylinder with integral fins, blind bore and swaged-on head was retained along with the twin-stack case configuration. However, the outside diameter of the upper crankcase spigot into which the cylinder was threaded was increased from 19 mm to 20 mm. This allowed the lower cylinder to be made a little thicker, which in turn allowed for an increase in the size and depth of the three flats machined into the lower cylinder O/D to feed the transfer ports. The intent was clearly to improve transfer efficiency by providing bypass passages having a larger area.

Apart from the increase in its lower outside diameter, the cylinder on this model was essentially unchanged from that of its predecessor. The blind bore and staked-on alloy cylinder head were retained, the head once again being a die-cast unit with the cooling fins incorporated into the casting. It differed from the head used on the previous model in having somewhat thinner fins as well as a less sharply-angled side profile, although the height of the component remained unchanged.

The revised case featured twin stacks which were considerably larger than those formerly used. These larger stacks had squared-off corners as opposed to the rounded corners of their predecessors. Another very minor change to the crankcase was a reduction in the length of the "collar" at the front of the main bearing. This coincided with a slight reduction in the length of the main bearing, the crankshaft journal length being amended to match. Moreover, the "collar" was not machined like its predecessor, being left in its as-cast state.

For reasons which must forever remain unclear, the vulnerable "twin expansion" mounting lugs were not only retained but returned to the thinner section which had been replaced on the previous model by more substantial expansions. Given the frequently-demonstrated weakness of these lugs, it's a little hard to explain this apparently retrograde step. The single-flat prop driver mounting was also retained, and the markings on the case were unchanged.

Bore and stroke remained unaltered, but the more substantial cylinder resulted in a slight increase in the all-up weight from 3 ounces even to 3.2 ounces. The only other change was the application of a matte finish to the cast components This was apparently created by vapour-blasting. Our illustrated engine no. 5993 typifies this model, and the highest serial number that we have recorded to date for this variant is engine number 6064.

It would appear that the switch to the revised model may not have been accompanied by a return of the serial number sequence to engine number 1. At present, the lowest serial number that we have for one of these engines is 01879, which is greater than our sole serial number of 00973 for the previous variant. It's possible that Fuji did not see the changes as being sufficient to warrant a re-starting of the number sequence, although this is undeniably inconsistent with their response to other changes. It's also possible that we are simply missing some key serial numbers. Either way, this issue remains unresolved.

Although they were never marketed with any intensity in England, I recall seeing several of these models in use there during my own early years as a power modeller in the late 1950's and early 1960's. They weren't outstandingly powerful on the straight fuel then in general use in Britain (due to the high cost of nitromethane) but they did appear to be very dependable if one overlooked the fact that the mounting lugs with their twin expansions were quite vulnerable to crash damage. I particularly recall one that had been damaged in this manner—its resourceful owner had simply made up a radial-mount backplate and carried on using it!

10th Model, Fuji .099 (Model 099-10):

Fifth of the "Menasco" Series

At some point during 1957 there occurred the first of three relatively closely-spaced amendments to the established radial port "Menasco" Fuji .099 model. The impression given is that Fuji were experimenting with a number of different design concepts in fairly quick succession, since all of the next three variants are far less common than most of the others.

The first model in this series, and the fifth Fuji .099 model to bear the Menasco name, focused once again upon changes to the crankcase. After trying the effect of thicker and broader expansions on the mounting lugs with the 099-8 model described earlier, the company had inexplicably reverted to the thinner expansions with the 099-9 model just described. They now elected to go back once again to more substantial expansions, but by trying a different approach—seemingly they were having difficulty making up their minds on this thorny issue!

The new variant featured thicker expansions than the previous model, although they were not as thick as those seen on the earlier 099-8 variant. To make up for this, the expansions were made substantially wider in an axial sense and were no longer tapered laterally in plan view, thus increasing the amount of metal available to resist mounting and impact forces.

Another change, and a welcome one at that, was the inclusion of a pair of lugs in the interior of the backplate recess. These allowed for easy removal and re-tightening of the backplate without risk of damage.

The cylinder head on this variant reverted to the slightly more angular profile of the 099-8 model, although it was otherwise unchanged. The matte finish on the case was also rather more heavily applied than it had been on the previous model, being apparently produced by sandblasting. In all other respects, this variant was essentially unchanged from its predecessor.

It appears that this variant was made in reasonable numbers—our sole example bears the serial number E4669, confirming that production must have reached around 5000 as a minimum. Readers of our earlier chapter on the corporate history of the Fuji enterprise may recall that it was around this time that Tannan Industries may well have become involved in the manufacture of the Fuji range. Some of the changes which are apparent in this variant may possible arise from some level of involvement by Tannan, although we can't state this as an established fact on the basis of present evidence. Hopefully some reader having greater knowledge than we do will enlighten us on this point.

11th Model, Fuji .099 (Model 099-11):

Sixth of the "Menasco" Series

In late 1957 or perhaps early 1958 the Fuji designers elected to experiment with a far more significant design change than any previously applied to this series. The resulting model is one of the more interesting and at the same time least common variants of the Fuji .099, because it is unique among the Fuji twin-stack models in employing a screw-in alloy cylinder head in place of the former staked-on item. This feature appears to have represented a short-lived experiment on the part of the Fuji design team.

The reason for this change was most likely the fact that the continued use of a screw-in cylinder with a staked-on head made retention of the correct alignment of the head cooling fins rather problematic. If the cylinder became loose, as can easily occur with this type of assembly, or had to be removed for repair purposes, it was rare for the same head fin alignment to be re-established when the component was re-tightened. There was also the issue of insecurity of the swaged-on head—they were certainly known to come loose in service if carelessly treated.

The solution adopted by Fuji at this stage was to design a new cast iron cylinder which dispensed with the blind bore used previously. Instead, the bore was open at the top and a threaded recess was machined into the upper cylinder. The plain unfinned alloy head simply screwed into this, a thin copper gasket being used to seal—all very Cox-influenced! The glow-plug was now mounted in a tapped hole in the centre of the alloy head rather than being threaded directly into the top of a blind-bored cylinder. This gave far greater security to the head and also made the radial alignment of the cylinder and head when tightened completely immaterial—no head fins to line up.

Naturally, the cylinder had to be made substantially taller to accommodate the threaded recess for the head, and this characteristic makes this version of the Fuji .099 readily distinguishable at a glance from the other variants in the Menasco series. There were 6 integrally-machined cooling fins between the upper surface of the exhaust stacks and the lower surface of the head, instead of the former 5 fins. The outside diameters of these fins and the revised cylinder head were also 2 mm greater than those of the previous model. The unfinned head was provided with four holes into which a pin spanner could be inserted for tightening.

The port belt on the revised cylinder was made somewhat thicker below the ports, but the seat in the main crankcase casting was set lower as well. The net result of this was a slightly later opening of the exhaust ports. However, transfer period was more or less unchanged because the transfer ports were slightly enlarged and opened a little earlier, overlapping the exhaust to a larger extent than formerly.

Otherwise, the engine was essentially unchanged apart from the use of a somewhat lighter sand-blasted matte finish on the crankcase than that applied to the previous model. The extended "twin expansion" mounting lugs with no lateral taper were retained, although their vertical thickness reverted yet again to the thinner dimension seen on the 099-9 model. The upper corners of these expansions were now rounded instead of being squared-off. The retention of this highly vulnerable mounting lug design continues to baffle us!

It's extremely difficult to state with any certainty exactly when this variant first appeared. All that we can say is that we have a Fuji advertisement (in Japanese) which shows this variant along with a version of the Fuji 29 which is known to have been introduced in early 1957 and to have remained in production for several years thereafter. So our suggested date of late 1957 appears to be a reasonable estimate for the introduction of this model. It is also consistent with the tentatively-established production figures for the previous variant.

The model just described was still in evidence in September 1959, when it appeared in an Aeromodeller advertisement for the Fuji range. However, there is reason to believe (based on the 29 model which appears in that advertisement) that the photograph may have been a "file" illustration supplied by the factory and may well date from 1958.

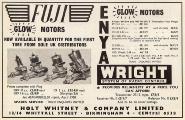

The advertisement in question was placed by Holt Whitney and Company Ltd. of Birmingham, who had recently become the UK distributors for both Fuji and Enya. The advertisement claimed that the Fuji engines were then becoming available in Britain "in quantity for the first time". This advertisement is important in that it dates the commencement of Fuji's major sales efforts in Britain to mid 1959. In addition to the 099-11 model described above, the twin-stack 15 is still in evidence along with the tankless .049 glow model with alternative beam and radial mounting and a Cox-style twin-port cylinder. Rather oddly, the .19 model is not mentioned in this advertisement, although it had certainly been in existence for some years and appeared in Fuji's leaflets and Japanese-language advertisements. It appears that it may not have been imported into Britain, where there was no recognized competition class exclusively for this size of powerplant.

The advertisement is informative in another sense in that it provides us with a direct comparison of costs between the contemporary Fuji and Enya models as of mid 1959 in Britain. The Fuji .099 was advertised at �2 4s 9d including plug, while the competing Enya .09 sold for �3 0s 6d without a plug. Since plugs cost at least 2s 6d (based on the same advertisement), this meant that the true cost of the Enya was �3 3s 0d ready to run—around 40% more expensive than the Fuji. There's no doubt at all that the Enya was the superior engine, but the Fuji was a perfectly adequate powerplant for general-purpose use and the cost difference might well sway a modeller on a budget who just wanted a serviceable engine for sport flying.

This highlights the fact that Fuji had by this time abandoned any ambitions (if they ever had any) of trying to compete with the likes of Enya and O.S. in performance terms. Instead, they had positioned themselves in the marketplace as an attractive and well-made "economy" range which offered more than acceptable performance and longevity for sport-flying purposes at a very reasonable price. In effect, they had carved themselves a market niche which was then relatively free from direct domestic competition.

One interesting observation that may be made at this point is the fact that as of 1957 the Fuji Bussan company was still advertising from a location in the Kyobashi district of Tokyo, where they had reportedly started way back in 1949. Another Japanese-language advertisement for the Fuji 099-11 model just described confirms this location. The Kyobashi district was already beginning to move upmarket in a business context, and it's possible that the company retained their head offices there but had relocated their actual manufacturing activities elsewhere. We leave this as a matter for further research by others.

Returning to our description of the 099-11 model, we are presently aware of only two examples of this seemingly rare variant, bearing the serial numbers T1801 and T2159 respectively. Since we know that the previous model (099-10) reached at least serial number E4669, it's clear that the serial number sequence was re-started for this new variant and that at least 2159 examples were made.

However many were actually manufactured, this is unquestionably one of the least common variants of the Fuji .099. This suggests that it was probably in production for a relatively short time. It may have been more in the nature of a "transitional" variant than anything else—perhaps a short-lived experiment which was quickly abandoned for reasons which must remain obscure pending further enlightenment ...

12th Model, Fuji .099 (Model 099-12):

Seventh and Last of the "Menasco" Series

The next version of the Fuji .099 to appear seems to represent a re-appraisal of the revised cylinder and head design which had appeared on the previous version. This variant reverted to the blind-bored cylinder with swaged-on head that had characterized the other "Menasco" Fuji's prior to the advent of the 099-11 version just described.

It seems likely that this change was driven both by cost considerations and by the realization that if a plain head was retained there was no longer any concern with regard to the alignment of the cylinder and head regardless of how the head was attached. The company did however improve the security of the head by changing the method of attachment—instead of being swaged in place at only four points around the head-cylinder interface, the swaging now extended around the full circumference of that interface. Little chance of one of these heads coming loose!

The head continued to be unfinned as in the previous model and still retained the four holes for the pin spanner, although these were no longer of much practical use given the method of attachment. The larger outside diameter of the fins and head was carried over from the previous model, as was the matte case finish.

The change in the method of head attachment eliminated the need for the threaded recess in the top of the cylinder as used in the previous model, so the cylinder was once again shortened, there being only 4 fins instead of the former 6. The cylinder configuration below the fins appears to have been unchanged from the previous model, however. The result was an engine that was actually very similar to the earlier 099-9 variant but with a modified cylinder, a plain unfinned head and improved swaging provisions for the head. It retained the same case design with the twin expansion lugs and similar cast-on identification.

Again, we do not know for certain when this variant first appeared. Our present best estimate would be sometime in late 1958, but we can't be sure pending the uncovering of new and persuasive information. Our own example of this variant bears the serial number V1395, while the highest serial number yet encountered for this variant is V8338, suggesting that at least 9,000 or so were made.

Since we know that the previous 099-11 model reached at least engine number T2159, it's a logical deduction from the intersection between the two numbering sequences that the manufacturers rightly saw this as a distinct production and accordingly followed their usual practise of restarting the serial number sequence with a new letter prefix attached.

The circumstance which gives the model just described a special place in the history of the Fuji .099 series is the fact that, as events were to prove, it was to be the seventh and last of the Fuji .099 models to carry the "Menasco" identification.

Mike Clanford's useful but often inaccurate A-Z book includes an illustration of one of these models which has been converted to spark ignition. This illustration may be found on page 84 of Clanford's book, and it is incorrectly identified as a 1955 Fuji 29! There is however no question that this is an owner conversion of one of the 099-12 glow-plug models just described.

Meanwhile, Back at the Factory

We have now carried the tale of the Fuji .099 models almost to the end of the 1950's as well as the end of the "Menasco" series, of which the model just described (Model 099-12) was to be the final example. It's important to remain mindful of the context in which the Fuji .099 series was continuing to evolve, and hence it's time once again to briefly step away from that series and catch up on what had been happening with the rest of the Fuji range during the period just covered.

Beginning in 1955, the 29 and 35 models had gone through several further design evolutions and were increasingly taking on the appearance of Enya "clones". These will be described in detail in our companion study of the 29 and 35 models. The Fuji .15 continued to be offered in its radial port twin-stack configuration throughout this period. It sported a finned staked-on head along with a very distinctive pair of stacks which tapered in side view towards the rear in a manner somewhat suggestive of the earlier "aerofoil exhaust" Enya .19 and .29 models. The original Fuji .15 had used a screw-in backplate and tank very much like those of the companion .099 models, but this version was soon replaced by the illustrated revised model in which the backplate was attached by three screws, with no provision for the fitting of a back tank.

The Fuji .049 remained in production in its tankless configuration, albeit with a re-designed cylinder which reverted to radial porting, thus ending Fuji's experiment with Cox-style porting. The radial port version of the Fuji 19 was also continued at this time. At some point, likely in 1959, it acquired twin stacks of its own and thus took on the appearance of an oversized .099 model.

By 1957 and for some time afterwards, the generic style of box in which the engines were supplied had changed again from the earlier brown-and-yellow version mentioned above to a similar box on which the same decoration appeared in two-tone green, with white English lettering and a white circle in which the engine model was stamped. The manufacturers were still identified on the boxes as the "Fuji Bussan Co. Ltd". of Tokyo, Japan, while the "Fuji Bussan K.K." designation appeared on the instruction leaflet. The "Fuji Tokushu K. K." designation which had last appeared on the .29 Silver Arrow model had not been seen since 1954.

At this point, it's also necessary to remind our readers that the development and manufacturing activities connected with the Fuji range appear to have undergone some very substantial changes as of 1958 or thereabouts. Firstly, the scope of the range had begun to expand significantly. 1957 had seen the introduction of several outboard motor models (.049 and .061 cuin) which displayed an almost virtuosic mastery of the die-making and die-casting processes. Secondly, serial numbers from subsequent models in the .099 cuin series and others show that Fuji production took what amounted to a quantum upward leap at this time. Finally, it is from this point onwards that we begin to see an ever-increasing pace of development of the Fuji engines from their somewhat under-developed state as of 1958 into the thoroughly up-to-date range that they were to become by the 1970's.

The clear implication of this is that Fuji had somehow engineered a significant expansion of both their technical capabilities and their manufacturing capacity, at the same time engaging a more dynamic design team. At present we don't know how this was managed—whether by developing additional in-house capacity or by out-sourcing their design and production in whole or in part. The possibility exists that Tannan Industrial, who are definitely known to have taken up the manufacture of the Fuji range as of the late 1960's, may in fact have entered the production and perhaps the development picture at this earlier point.