Editorial

February was a wet month—back, the archivists say, to the "normal" monsoonal weather pattern we used to have twenty years ago that everybody has forgotten about. Vast amounts of rain fell all over the state causing lots of flooding and hardship to country folk already experiencing hardship from the drought. Here in Brisbane, some of the rain even reached our dam catchments with the result that the water level has risen from less than 20% full at the start of January to almost 40% at the start of March. Unsurprisingly, water restrictions remain in place and the water usage by good residents of Brisbane continues to average less than 140 litre per person, per day. We've had a reprieve and a warning, but the problem of increasing population without a corresponding increase in the support infrastructure has essentially not changed. Everyone recognizes the need for a new dam, but no body wants it in their back yard. There is a pithy statement that covers this: Ha-ha-ha. Your end of the boat is sinking.

As you will read below, I've had a zero shop-progress month. But the Free Plan is complete (ish) and represents the most complex plan I've done so far: fourteen sheets in all. It's not perfect, but I don't think it contains any show-stopper mistakes (and just watch me eat those words next month). Content wise, we have a large and comprehensive piece by Adrian Duncan on the first FROG model engines, More Whippet Project pages, and a model engineering Tech Tip that will be of interest to Quorn owners (and those with a set of castings Under The Bench, or those thinking about it). We also have an unexpected set of drawings of the Clerget Rotary engine which can be downloaded by everybody, not just MEN Members.

Although February was not as short as it usually is, web site traffic was up. As I do last minute polishing of this month's pages just prior to pushing them out to the web site, Model Engine News has had over 19,000 unique visitors who have delivered over 1.5 million hits. Now if only I could figure out a way to make a buck 'outa this...

My Bad

First, refresh you memories regarding the Brian Turner F2B engine mentioned here last month. The photos and text on the Stuka Stunt forum are being put together by Mr Mike Nelson (UK) who incidentally has a rather nice control line oriented site which Al Rabe fans will appreciate (and I count myself in this group). A link to Mike's site is now in the non-commercial section of the Links Page. Anyway, Mike tactfully mentioned that I'd got it all wrong regarding the purpose behind the offset venturi. My assumption was that it was offset to take advantage of the longer opening for a smaller crankshaft port this layout provides. What I had not considered was that such an configuration also shifts the required location of the shaft port and by placing the inlet on the port side of the engine, the opening can be brought in-line with the crankpin and so make a small contribution to shaft balance. More shots of construction are appearing under separate threads, but Mike says that after the engines are complete and tested, he will gather all the photos and place them on his web site. He also hopes to include scans of the plans. Right now, the links you need to see (I think) are:

Clerget Plans

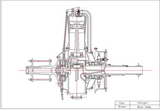

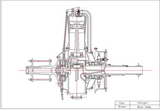

Some months back, Model Engine News was approached by Mr Brian Dolby (UK), asking if any readers might be interested in drawings he was preparing of the WWI Clerget rotary. Way back in July 2003 I reviewed a nice little reprint volume from Camden (UK) which contained drawings of all the parts in the engine, suitable I thought for scanning, scaling, and CAD tracing. This is almost what Brian has done. He began by photo enlarging the General Arrangement, then measuring and scaling each part so it could be re-drawn under AutoCAD. The GA was rebuilt placing each part on a separate layer, allowing them to be later extracted for orthographic projection and dimensioning. Brian has most generously made his hard work available under a Creative Commons Attribution Noncommercial Share Alike 3.0 License, meaning you can download them from here and pass them around provided you do not charge anything for them and credit Brian with the work. Note these are not model engine plans! They depict the full size engine and omit things like thread callouts, material specifications, etc. But a talented and determined model engineer armed with these and the Camden book could build a running model Clerget. Brian is also willing to answer questions about his work. He can be contacted direct as Brian (at) bdolby.fsnet.co.uk.

More AH Pictures and Details

Just over a year ago, MEN posted a tribute page to the late Arne Hende and his range of miniature and full size reproductions of famous and obscure engines—not to mention a smattering of his own designs. As the page came together, I for one was astounded by the breadth of his work. Well, last month I received an email from Dan Vincent who made the presentation boxes for Arne's engines. Dan kindly supplied images for several of the engines appearing in the list that were missing from the photo montage. He also supplied another to add to the list: a full size EPC Moth reproduction. During this exchange, Dan included some trivia about some of the engines that will fascinate the many AH devotees. Click the link above to visit the updated page.

Members' March Free Model Engine Plan

It being that time of year again, MEN Members may go to the Members' Page and grab a copy of the first free model engine plan for 2008. As hinted at earlier, this is a reverse engineering of the neat little Vega 30. I present this plan set with some trepidation as the release marks the first plan set done using Alibre Design as the CAD package, so I'm venturing into new waters on a complex subject: a side valve four-stroke. To my knowledge, there is at least one detail which if not precisely wrong, is not entirely precise. It's in an isometric view, so at least it should not hurt. Besides, I can always fix it later if the burden on my conscience becomes too great. I also have some misgivings regarding the cam profile and timing. The numbers presented were derived using a shaft mounted degree wheel and plunger DTI on the valves, so I know they accurately echo an engine that has done a significant amount of running, to judge by the carbon on the exhaust valve. The cam profile was then estimated by curve fitting measured lift to CamCalc II. The result is close, though I can't really say if the base circle was undercut for tappet clearance, which would impact the accuracy a bit.

While on the Vega subject, some really good news: I received an unexpected email from Mr John Harbone (whose name I am now carefully spelling correctly—sorry John  ), the designer and builder of the Vega range. John found the review on the Web and has been kind enough to call it fair to the engine in assumptions and findings. He has also let me into a detail of the story that has resulted in Yet Another Revision to the Vega page regarding a small but significant number of Vegas that were CNC, but not actually made by him.

), the designer and builder of the Vega range. John found the review on the Web and has been kind enough to call it fair to the engine in assumptions and findings. He has also let me into a detail of the story that has resulted in Yet Another Revision to the Vega page regarding a small but significant number of Vegas that were CNC, but not actually made by him.

ALERT! |

Just days after release, an alert reader caught the VEGA Fever along with a giant error in the plans: the cam bush centers in the backplate don't match those in the crankcase, and the valves try to lift the head off the cylinder. The backplate drawing and head have been corrected, along with some other minor issues. This was deemed so dire as to warrant immediate action, so if you downloaded the plans before March 7, you should grab them again. Updated sheets will have a suffix that tracks the revision state. The revised sheets (so far  ) are: ) are:

|

So Where's My Whippet Already?

Good question. The thing sitting on the Myford's bed is the Myford's motor. On the last day of January, turning on the motor also turned off the house via the switch box earth leakage detector. So a week of denial was needed before the offending motor got removed—a big job, given that I can't get around the back of the machine. Then another week while I cogitated on what to do about the problem, followed by an hour spent brushing, blowing and shaking swarf out of the connections box and the motor casing, after which the motor was back to normal. Next was the two weeks with the motor sitting as seen here while I think about the dirty, knuckle-busting job of re-mounting it and the taper turning fitting that had to be removed to get it un-mounted. One thing holding me back is the thought of fitting a phase converter with speed control instead; a most appealing prospect since half the job is done while the single phase motor sits where it is. Meantime, no lathe and no progress. But there are two new Whippet pages to read, and one way or another, turning capability will be restored next week, or the one after...

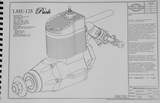

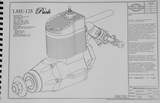

Product Review: LME125 Puck

Not only is it raining water down here, it seems to be raining side-valves too. First was the ETW Whippet marine engine, then the Vega Range which ultimately led to this month's Members' Free Plan set. Now there's the Little Locos' Puck. This engine got a pre-announcement here in the November 2005 page—which it would be a good idea to review before reading much more as I see no reason to repeat the general description of the engine given there. Back already? Ok, this month we have a close look at what you get when you plonk down your $35.00 (plus shipping and handling) with Little Locos Model Engineering.

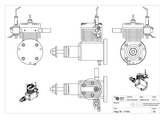

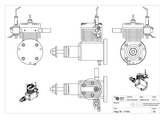

Like the earlier LME-370 Pip radial, the Puck plans are presented as a comb-bound book of 11 x 17 single sided sheets. The book comprises two sections. The first consists of 21 pages of CAD drawings that detail the engine components and the jigs and fixtures you'll need to build it. The second part is a very well written set of machining instructions comprising 38 double column pages, profusely illustrated by photographs.

Like the earlier LME-370 Pip radial, the Puck plans are presented as a comb-bound book of 11 x 17 single sided sheets. The book comprises two sections. The first consists of 21 pages of CAD drawings that detail the engine components and the jigs and fixtures you'll need to build it. The second part is a very well written set of machining instructions comprising 38 double column pages, profusely illustrated by photographs.

The very clear and easy to read CAD work uses 3D modeling similar to that described here in the December 2007 page, meaning you get the required orthographic views, plus isometrics. Parts are presented in 1:1, 1.5:1, and 2:1 scale, dimensioned in Imperial measurements. The different scales used improves clarity by allowing the dimensions to be placed clearly, without crowding. The drawings include a page of exploded views, with all parts numbered. A second bill of materials page lists the parts in number order with the page number where each can be found, the quantity required, the material, and required stock size. For manufactured parts like the bearings and gears, the supplier and their part reference are provided. You don't really get to know a set of plans until you build from them, but to my fairly close inspection, they appeared very well thought out and complete. I have one quibble, which I'll mention in the wrap-up.

The very clear and easy to read CAD work uses 3D modeling similar to that described here in the December 2007 page, meaning you get the required orthographic views, plus isometrics. Parts are presented in 1:1, 1.5:1, and 2:1 scale, dimensioned in Imperial measurements. The different scales used improves clarity by allowing the dimensions to be placed clearly, without crowding. The drawings include a page of exploded views, with all parts numbered. A second bill of materials page lists the parts in number order with the page number where each can be found, the quantity required, the material, and required stock size. For manufactured parts like the bearings and gears, the supplier and their part reference are provided. You don't really get to know a set of plans until you build from them, but to my fairly close inspection, they appeared very well thought out and complete. I have one quibble, which I'll mention in the wrap-up.

The best value in this quite modestly priced plan set is the effort designer Todd Snouffer has spent preparing the machining instructions. His equipment is quite modest: a center lathe, a round column mill/drill (like the piece of junk in my shop that I like to winge and moan about), and a rotary table—again like mine— that can be bolted to the mill horizontally as well as vertically. With this, some ordinary milling cutters and a slitting saw, Todd has managed to produce a bar-stock, side-valve four-stroke that combines form and function (meaning it's not an unattractive engine, IMHO

The best value in this quite modestly priced plan set is the effort designer Todd Snouffer has spent preparing the machining instructions. His equipment is quite modest: a center lathe, a round column mill/drill (like the piece of junk in my shop that I like to winge and moan about), and a rotary table—again like mine— that can be bolted to the mill horizontally as well as vertically. With this, some ordinary milling cutters and a slitting saw, Todd has managed to produce a bar-stock, side-valve four-stroke that combines form and function (meaning it's not an unattractive engine, IMHO  ). The instructions cover all aspects, from a bit of history of the "Haibe Hi-Power Head", Sir Harry Ricardo, and Bill Shakespeare, through ring and cam making, concluding with the recommended fuel mix and running instructions.

). The instructions cover all aspects, from a bit of history of the "Haibe Hi-Power Head", Sir Harry Ricardo, and Bill Shakespeare, through ring and cam making, concluding with the recommended fuel mix and running instructions.

Todd has carefully designed his head to provide a 9.5:1 compression ratio, making it suitable for methanol and glow-plug ignition. Sensibly, he uses a commercial OS carburetor. You could make your own, but you'd spend an age at it and could well end up with an inferior item. The plan set represents very good value, although I did spot some things I'd be tempted to change—as alluded to earlier. Some are minor and represent personal preferences and experience, but the piston had me a bit worried. It is 2024-T3 aluminum (good) specified as having a minimum diameter of 0.6775" and maximum diameter of 0.6880". Now the cylinder bore is called out as 0.6800" to 0.6805", so we'll have to call the 0.6880" diameter for the piston a typo, otherwise it's not going to fit the bore! Ok, that would be obvious to Blind Freddy and the Drover's Dog, but there was a problem with the slot for the rod in the piston too, so Todd got an email. His response was swift and included corrected replacements in PDF format. He will be adding an updates and corrections page to the Little Locos web site where plan owners and the terminally curious can get, well, updates and corrections!

At $35 per set, you are paying about 0.50c per page, or maybe 0.25c per page if we consider the large format involved. The engine is well thought out, as are the jigs and machining sequence. If my calendar for the next 100 years was not so full, I'd be seriously considering a Puck, just for the fun of it; four and a half stars  .

.

New Books and Magazines This Month

Issue #135 of the Model Engineers' Workshop arrived during February. MEW is a stablemate to the Model Engineer and this issue is worth mentioning for a couple of reasons. First because it contains Yet Another article on Toolmakers Clamps by long-time contributor Harold Hall. The variation on the traditional design for these clamps described in MEW #7 (also by Harold) got a mention here just last month in Page 7 of the Whippet Construction series. In his new piece, Mr Hall describes both the "traditional" design and his variation. He even shows a way to use these clamps on a mill or drill press table that had not occurred to me. This is one of the few magazines I still subscribe to and always find something useful in each issue.

The second item worth mentioning is an advertisement for what the vendor terms a "Morse Taper Chuck Adaptor" for the popular Vertex range of rotary tables. This adaptor is almost exactly like the one I made years and years ago that allows me to unscrew chuck and work from the lathe, transfer both to the rotary table on the mill, then back again with very good concentricity. An example of this can be seen on page 7 of the Feeney Construction Log. It is one of the most genuinely useful gadgets I've ever made, but that is not the only reason I mention it. The vendor is Chronos Engineering Supplies, a regular ME and MEW advertiser of tooling for model engineers. They offer these adaptors in 2MT and 3MT to fit the 6" and larger rotary tables, with nose threads to mimic the Myford and Boxford lathes. This indicates that Chronos has had these specially made to suit the most popular lathes likely to be found in an English country garden shed—suggesting to me that the popularity of model engineering as a leisure activity is steadily increasing. I've felt this was the case for some time. Certainly this web site continues to attract readers and Members. Good to see, and full marks to Chronos for seeing the need to supply a highly useful, precision made accessory.

The second item worth mentioning is an advertisement for what the vendor terms a "Morse Taper Chuck Adaptor" for the popular Vertex range of rotary tables. This adaptor is almost exactly like the one I made years and years ago that allows me to unscrew chuck and work from the lathe, transfer both to the rotary table on the mill, then back again with very good concentricity. An example of this can be seen on page 7 of the Feeney Construction Log. It is one of the most genuinely useful gadgets I've ever made, but that is not the only reason I mention it. The vendor is Chronos Engineering Supplies, a regular ME and MEW advertiser of tooling for model engineers. They offer these adaptors in 2MT and 3MT to fit the 6" and larger rotary tables, with nose threads to mimic the Myford and Boxford lathes. This indicates that Chronos has had these specially made to suit the most popular lathes likely to be found in an English country garden shed—suggesting to me that the popularity of model engineering as a leisure activity is steadily increasing. I've felt this was the case for some time. Certainly this web site continues to attract readers and Members. Good to see, and full marks to Chronos for seeing the need to supply a highly useful, precision made accessory.

-oOo-

More coincidences. While creating the link to the LME-370 Pip radial for the Puck review, I noticed that Nevil Shute's novel, Trustee from the Toolroom, was mentioned in the same MEN issue. This is a rather charming story, if a bit dated, whose hero was modeled on Edgar T Westbury. And for even more coincidence, a local radio station in Brisbane is currently presenting this as a bookreading during afternoon drive-time; almost makes me look forward to traffic jams. Amongst many other things, Nevil Shute Norway, to give him his full name, was himself a model engineer. In fact, he was building a very nice ETW Seal at the time he died here in Australia. I'm sure older readers would enjoy this book; maybe some younger ones will too, and get a smile at the very accurate descriptions of making model IC engines, not to mention the view expressed by "Keith Stewart" on bathing

More coincidences. While creating the link to the LME-370 Pip radial for the Puck review, I noticed that Nevil Shute's novel, Trustee from the Toolroom, was mentioned in the same MEN issue. This is a rather charming story, if a bit dated, whose hero was modeled on Edgar T Westbury. And for even more coincidence, a local radio station in Brisbane is currently presenting this as a bookreading during afternoon drive-time; almost makes me look forward to traffic jams. Amongst many other things, Nevil Shute Norway, to give him his full name, was himself a model engineer. In fact, he was building a very nice ETW Seal at the time he died here in Australia. I'm sure older readers would enjoy this book; maybe some younger ones will too, and get a smile at the very accurate descriptions of making model IC engines, not to mention the view expressed by "Keith Stewart" on bathing  although this may be the author poking fun at the average Australian's preconceptions on English standards of personal hygiene. Well worth chasing down at your local library, or through the link in the Book Review page.

although this may be the author poking fun at the average Australian's preconceptions on English standards of personal hygiene. Well worth chasing down at your local library, or through the link in the Book Review page.

Engine Of The Month: First Frogs

For obvious reasons, the early FROG (UK) engines are sometimes called the "Bicycle Spoke Frogs". This month, Adrian Duncan leads us through the series from the first spark ignition FROG 175 of 1946, to the glow plug version of 1949 (with a smattering of diesels in between), and finally their quiet, unlamented extinction in 1951. Any reader who was a bit mystified by our description of a certain Watzit as a Froggy Topsy may now see the tenuous connection by joining the BS FROGS with the Topsy.

Tech Tip of the Month

Almost a year ago—the April 2007 issue to be precise, our Tech Tip gave a brief coverage of some of the various collet types model engineers might encounter and their relative advantages. In case you don't feel like following the link, the page describes how the "ER" series of collets close at both ends and so provide excellent axial alignment of work over a comparatively large range per collet. This month's tip shows a way of using the small ER16 collets to hold drills from 3/8" downwards for sharpening in the Quorn Tool and Cutter Grinder. Even if you don't have a Quorn, you might get an idea from the new Drill Sharpening (2) page, like problem solving through the direct application of PayPal.

Another Whippet

Malcolm Beak should be familiar to MEN readers for his many marine oriented models that are sprinkled through the Gallery, including a compression ignition version of the ETW Kiwi, and a very nice water cooled version of Russell Watson-Will's Fig Tree Pocket Twin from the Motor Boy's Plans Book. Malcolm has been following my own Whippet Adventures with wry amusement, having encountered similar material and castings problems years ago on the Woking Precision sourced castings. Click on the picture to find how he addressed them on the brand new Gallery Page. This is an all new page with work from other builders too—be sure you see the lot.

Double D and other Beauties

Did that get your attention? The "D" in this case is for Dooling, and the Double part should be obvious from the picture. Information on the engine can be found in the new Gallery page, along with a number of other readers' engines. Always be sure to check the New and Updated pages list each month to see what's new. As well as the Double-D, there are a couple of Helium repros which I'll expand on next month, right after I get a motor refitted to the Myford...

My Bad

My Bad

Clerget Plans

Clerget Plans

More AH Pictures and Details

More AH Pictures and Details

Members' March Free Model Engine Plan

Members' March Free Model Engine Plan

So Where's My Whippet Already?

So Where's My Whippet Already?

Another Whippet

Another Whippet

Double D and other Beauties

Double D and other Beauties

Editorial

Editorial

Product Review: LME125 Puck

Product Review: LME125 Puck

New Books and Magazines This Month

New Books and Magazines This Month

Engine Of The Month: First Frogs

Engine Of The Month: First Frogs

Tech Tip of the Month

Tech Tip of the Month

Standard Stuff

Standard Stuff

.

.

More coincidences. While creating the link to the

More coincidences. While creating the link to the