Editorial

September in Brisbane is a great time for working in the shop, and as a genuine, original, partially machined Sugden Special crankcase had arrived in my mailbox, it seems a grand opportunity to finish it off, as we see here. I've classified the Sugden as an "Intermediate" skill level project, though it's really only just over the hurdle from being within a Beginner's capabilities. The engine is now finished and running noisily.

I'm pleased as the Sugden has been on my "must build" list for over 10 years, and having a running example allows me to update the Sugden Special review page with photos of a complete engine, and an aspect which had not hitherto fore been obvious! As parts of the construction were a little unusual, they have been documented and a link placed in the Model IC Engine Construction Projects page which has been revised and had a face-lift (or click the pic for direct access).

Next, the mythical MEN Only CD has shipped at last! I believe that I've caught up with everyone who kindly expressed their interest before I was quite ready. So if you have not heard from me, but think you should have, please accept my abject apology, and mail me again:

[email protected].

Reports from customers have been very gratifying, many writing to say that the "cookie" alone is worth the price of the disk.

You might also notice that a "Members" link has crept into the nav-bar. This link is password protected and will provide update downloads and "exclusive" pages to CD owners only. I'll be emailing all CD'ers with their username and password as soon as it is fully operational; which will hopefully be later this month (where have you heard that before?  Please be patient; we'll get there eventually).

Please be patient; we'll get there eventually).

Finally, my sympathy goes out to all those in the USA who have suffered directly or indirectly as a result of the hurricanes in the past month. They rotate the other way and we call them cyclones down here, but that makes no difference to their victims. Meanwhile, the Wide Brown Land continues in the grip of the worst drought in over 100 years with some major cities facing imminent danger of running out of water all together. Don't tell me the weather patterns are not changing...

ETW and the Deltic

Back in 2001, Ken Croft sent a picture of an ambitious project under construction that he'd spotted at the Midlands Exhibition, specifically the "Clentec", an engine based on Napier's "Deltic" design. While browsing through an old Model Engineer, I came across a feature on the Deltic by none other than ETW himself who had just been out for a "jolly" on a captured and converted WWII German Schnellboot powered by a pair of Deltics. As my new scanner came complete with OCR (Optical Character Recognition) software, it seemed like a grand opportunity to expand on this unique engine and increase the Edgar T Westbury content.

It was even more topical as a recent issue of the ME contained yet another picture of progress by Clen Tomilinson on his Clentec seen at another exhibition. Compare the picture above with how the engine looked in 2001. I can only imagine the number of hours that have disappearing into all that pipework and the centrifugal scavenging blower.

It was even more topical as a recent issue of the ME contained yet another picture of progress by Clen Tomilinson on his Clentec seen at another exhibition. Compare the picture above with how the engine looked in 2001. I can only imagine the number of hours that have disappearing into all that pipework and the centrifugal scavenging blower.

New Watzit and Gallery Entries

Tim Dannels, editor of ECJ passed on some photos sent to him of a sparker that we can't identify. These are now on the Watzit Page, but I think the beast is unidentifiable. And Siegfried Fleischmann from Bavaria has sent in some pictures of a batch of twin-shaft Oliver Tigers he made to install in some very attractive tether cars. More pictures of these, plus some words on the challenges he faced making them appear on Page 6 of the Gallery. Also new in the Gallery is Ed Solenberger. Ed has made a Battiwallah (from Motor Boy Vincent Chai's die castings) and a nice, green, Book 60.

Estate Auctions

A snippet sent by several friends in England is worth passing on. The annual Midlands Model Engineering Exhibition will be held from the 14th to the 19th of October at the Warwickshire Exhibition Centre (current UK-English spelling of the word used in deference to the location  ). On display for the last time will be the Gerald Smith Engine Collection which will then go under the hammer at Gildings on November 19th (that hyperlink may not stay active for long). Gerald Smith was a designer and builder, not a collector. His multi-cylinder engines have appeared in numerous publications over the years—his three cylinder "Osprey" features prominently in Chinn's 4-Stroke book. The 18 cylinder radial pictured here won the Model Engineer Championship Silver Cup at the International Model Engineering Exhibition of 1930. For a long time, this was the only model engine of this type in existence. So sell the house and attend the auction...

). On display for the last time will be the Gerald Smith Engine Collection which will then go under the hammer at Gildings on November 19th (that hyperlink may not stay active for long). Gerald Smith was a designer and builder, not a collector. His multi-cylinder engines have appeared in numerous publications over the years—his three cylinder "Osprey" features prominently in Chinn's 4-Stroke book. The 18 cylinder radial pictured here won the Model Engineer Championship Silver Cup at the International Model Engineering Exhibition of 1930. For a long time, this was the only model engine of this type in existence. So sell the house and attend the auction...

Incidentally, the judge for Aero Engines at the Midlands show this year will be Barry Hares, who will also display his 1/5th scale Merlin. As mentioned previously, a sight and sound video of this being put through its paces can be accessed from the AEHS web site. Also on exhibit will be the George H Thomas collection of inspired lathe tools and accessories, including George's actual modified Myford Super 7 lathe.

While talking about auctions, if you've been looking at the eBay listings this past month, you can't fail to have noticed the large number of placements under the name glowplugboy. This is Mike McGraw, who specializes in managing estate sales of model airplane engine collections (how's that for a job!) Mike says he has 4000 items to dispose of from a single collection. You can visit Mike's web site for more details. He also produces a 25cc chain-saw engine conversion in his own machine shop, and sells an RTF model to go with it. The qualifies him for mention on at least two counts. Sadly, Mike had to flee hurricane Rita, but hopefully he will be back in business again soon. Oh, and the picture here is a Mark II Enya 15 diesel that I got up at 3am to to bid on. It has been added to the Engine Finder.

External Combustion

I'm told that it is never a good idea to tell any Royal personage that it is wrong. But it is permissible to utter something like, "Remarkably, your Majesty, that turns out not to be the case..." Where is this going you ask? Well, the May 27-June 9 issue of the Model Engineer related the experiences of Mr Edward Perara, a Shri Lankan model engineer who has constructed and flown a flash-steam powered R/C model in a land where there are no hobby shops. The article began by saying:

"Once upon a time there were designs for steam-powered aircraft. As far as is known none actually flew."

Years ago while I was living in Portland Oregon, a most kind gentleman sent me a copy of an article describing a flash steam power-plant that had been fitted to Travel Air and successfully demonstrated on many occasions. As I recall the story contained in the article in question, the designer ultimately obtained a position designing power-plants for steam locomotives. This had been his intent all along. The aerial engine had been his way of drawing attention to his abilities (this being The Depression era when jobs were scarce), and the Travel Air flew no more.

Sadly, I lost both the article and the name of the engineer who sent it to me in the move back to Oz. But a quick email to Kim McCutcheon of the AEHS got back this entry from the 1939 Aerosphere. While it's not the same article, it is the same engine and gives the designer's name as one William J Besler. Now having the name of the inventor (which I'd quite forgotten) a web search turned up lots more references to the achievement. The Model Engineer is a most august publication, with an enviable reputation, but their assertion regarding steam powered, man-carrying flight turns out not to be the case...

Sadly, I lost both the article and the name of the engineer who sent it to me in the move back to Oz. But a quick email to Kim McCutcheon of the AEHS got back this entry from the 1939 Aerosphere. While it's not the same article, it is the same engine and gives the designer's name as one William J Besler. Now having the name of the inventor (which I'd quite forgotten) a web search turned up lots more references to the achievement. The Model Engineer is a most august publication, with an enviable reputation, but their assertion regarding steam powered, man-carrying flight turns out not to be the case...

New Gannets

Last month's Engine of the Month, the Nurthan and Muirhead Gannet, has elicited some mail. A UK reader sent in a picture of a pristine example he has managed to acquire, posed here in front of the nice stained wooden presentation box that all Gannets arrived in. Included was a picture of his almost complete Sea Queen and even though it is not fitted with a Gannet, it has been added to the Gannet Page. A second and more surprising email arrived from Mr Mike Prodage who was a close friend of George Nurthan and who has, time permitting, continued with the production of the engine on a one-off, made to-order basis.

Back to the Future

By the time you read this, it will be too late to visit the 2005 Gas Engine Antique Reproduction (GEARS) show in Portland, OR. This show was held for the first time last year (the Sherline web site has a show report you can read) and replaces the Pacific Rim International Model Engineering (PRIME) show which was first held in 1997. I attended that show and snapped a roll of 35mm film as fast as I've ever done before. So to commemorate the occasion, the photos have been digitized and posted on a brand new, old? PRIME 97 Page. The page is a bit scant on text as I've forgotten all the names and other details, but they are worth a look.

Kiwi Progress

For the past year, Nick Jones (England) has been making steady progress on a Westbury Kiwi. More photos arrived this month showing that he is now getting close to the Moment of Truth. The additions to the Kiwi Construction page show the cam grinder Nick built, and the changes he made to the piston rings after consuming the entire SIC oeuvre in one go! The update to the Kiwi page includes his findings on piston ring material selection.

Nick is already planning his next project: the Whittle V8, at original (1/9th scale) size, and a 217% size increase to produce a 108cc monster with 1" cylinder bores.

Whittle V8

This beautiful CAD model of the Eric Whittle V8 was built by John Downie (England). John is building an engine and modeling parts as he progresses to validate the plan dimensions, and prepare tool paths for his HNC (Human Numerical Control) system—ie, winding the handles. John says the engine is nearing completion asymptotically  . He also forwarded animated gifs showing the engine being "assembled" around the crankshaft, and a rotating view. These are large files, so they will be put in the Members area to preserve the bandwidth allocation on this website.

. He also forwarded animated gifs showing the engine being "assembled" around the crankshaft, and a rotating view. These are large files, so they will be put in the Members area to preserve the bandwidth allocation on this website.

New Books and Magazines This Month

Two new entries in the Library Catalogue this month. Both are old, but one is available in reprint, so we'll deal with it first: Small Internal Combustion Engines, by ET Westbury, reprinted by TEE Publishing 1993, ISBN 1 85761 029 6. Westbury was a prolific author. You may be lucky enough to hunt down an original copy of his books on the Internet, but TEE have been doing a good job of making facsimiles of the books available at a modest cost. The process used tends to lose a little definition in the photographs, but it's not serious.

The work in question was first published in 1950. It describes not model engines, but small internal combustion engines (hey, what a coincidence; that's the title of the book!) of up to 2-1/2 HP. These are the type that were applied to tasks like driving the layshaft for a modelers' lathe, or water pumps and small electric generators for the home before electric power became universally available. Westbury covers the types of engine, theory, aspects of carburetion, ignition, etc. The material is very dated, but quite germane to a modeler contemplating building a historical subject, or someone who is curious about once popular engine types that have totally disappeared over time; the "hit-and-miss" engine for example. It's typical Westbury work; purposely targeted at the "non-technical", 11 chapters and 120 pages. My copy was purchased from Plough Book Sales, US readers should try Wise Owl Magazines. British readers can go straight to the source.

The work in question was first published in 1950. It describes not model engines, but small internal combustion engines (hey, what a coincidence; that's the title of the book!) of up to 2-1/2 HP. These are the type that were applied to tasks like driving the layshaft for a modelers' lathe, or water pumps and small electric generators for the home before electric power became universally available. Westbury covers the types of engine, theory, aspects of carburetion, ignition, etc. The material is very dated, but quite germane to a modeler contemplating building a historical subject, or someone who is curious about once popular engine types that have totally disappeared over time; the "hit-and-miss" engine for example. It's typical Westbury work; purposely targeted at the "non-technical", 11 chapters and 120 pages. My copy was purchased from Plough Book Sales, US readers should try Wise Owl Magazines. British readers can go straight to the source.

-oOo-

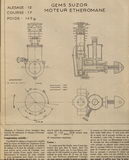

The second subject is most rare and prized. It was very generously provided by a reader in England (who received a complimentary MEN CD in gratitude—thanks Malcolm!) This is a large 'magazine style' book by none other than Gems Suzor titled Mechanique et Modeles en Reduction, and naturally, the text is French. Suzor was France's Westbury. Both were engine designers with a keen interest in tethered hydroplanes. Both wrote on internal combustion engines, steam, and model engineering in general. In fact, this volume contains a chapter on magnetos featuring Westbury's work, referring to him as the "le technician bein connu et attache a la redaction celebre revue anglais The Model Engineer".

The second subject is most rare and prized. It was very generously provided by a reader in England (who received a complimentary MEN CD in gratitude—thanks Malcolm!) This is a large 'magazine style' book by none other than Gems Suzor titled Mechanique et Modeles en Reduction, and naturally, the text is French. Suzor was France's Westbury. Both were engine designers with a keen interest in tethered hydroplanes. Both wrote on internal combustion engines, steam, and model engineering in general. In fact, this volume contains a chapter on magnetos featuring Westbury's work, referring to him as the "le technician bein connu et attache a la redaction celebre revue anglais The Model Engineer".

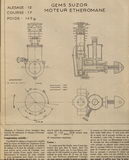

The reason that I prize this library addition so highly is for one of the construction features it contains: the Suzor Moteur Etheromane, examples of which have been built by Motor Boys Ken Croft and Les Stone (both the Etheromane and another of Gems Suzor's books were described in the November 2004 Model Engine News). This is a charming engine that features an unusual ratcheted compression adjusting wheel, an elegant external transfer pipe, and a front rotary induction valve that breathes through an extended tube that passes axially through the rather Victorian front mounted fuel tank. As the publication date for the book is 1946, it again illustrates how compression ignition designs were well established on the Continent before Sparey's pioneering efforts appeared across the Channel. Both Ken and Les hogged their Etheromane crankcases from solid aluminum, although you'd never know it just by looking. *Sigh* Another engine to add to my growing Must Build Someday list...

The reason that I prize this library addition so highly is for one of the construction features it contains: the Suzor Moteur Etheromane, examples of which have been built by Motor Boys Ken Croft and Les Stone (both the Etheromane and another of Gems Suzor's books were described in the November 2004 Model Engine News). This is a charming engine that features an unusual ratcheted compression adjusting wheel, an elegant external transfer pipe, and a front rotary induction valve that breathes through an extended tube that passes axially through the rather Victorian front mounted fuel tank. As the publication date for the book is 1946, it again illustrates how compression ignition designs were well established on the Continent before Sparey's pioneering efforts appeared across the Channel. Both Ken and Les hogged their Etheromane crankcases from solid aluminum, although you'd never know it just by looking. *Sigh* Another engine to add to my growing Must Build Someday list...

Engine Of The Month: Hybrid Hornet

Bert Streigler has been busy restoring what he thought was a modified Hornet with a broken exhaust. It turned out to be a little more than that. I was just going to quietly drop it in place here, but the story seems more like a Watzit, except we know what it is! Next thought was a Gallery entry, but that's not quite right either. The solution is obvious. Writing up the Sugden construction feature has drained my MEN time budget for the month, and I've got no feature engine yet, so... thanks Bert! You're a life saver! Click the pic, or here to read Bert's tale of the Hybrid Hornet.

Tech Tip of the Month

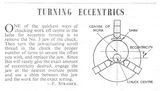

A couple of months back, I added the unusual way Dave Sugden approached turning offset crankshafts to the Crankshafts: How To page. I had a suspicion that this technique would have been well known in days past, so was not that surprised to chance on a paragraph describing it in a 1953 issue of the Model Engineer. Obviously it applies to all sorts of eccentric turning and may be of use to some who do not have a 4 jaw independent chuck, or are too lazy to change to it  .

.

The full description of applying this technique to making a crankshaft, along with the advantages and disadvantages offered are written up on the new page: Building the Sugden Special. On this page, we look also look at how to make an Oliver-type cylinder liner, and a couple of other techniques that have not appeared on these pages before. Aspects of construction that are well covered on other projects are omitted, but hopefully you'll find something useful amongst the text. The page also gives suggestions for changes to prospective Sugden builders.

The "Ideal" First IC Project

This is a question I'm frequently asked and it's a difficult one to answer. I lean towards a compression ignition (CI) type, purely from an ideological predisposition (and because I love the smell of ether fumes in the morning  ). This is probably an actual negative to modern builders who have no experience with operating this type of engine, compounded with the increasing difficulty of obtaining the correct fuel, or even the ingredients to mix your own! But all that aside, let's look at characteristics that are important:

). This is probably an actual negative to modern builders who have no experience with operating this type of engine, compounded with the increasing difficulty of obtaining the correct fuel, or even the ingredients to mix your own! But all that aside, let's look at characteristics that are important:

- A proven, developed design with enough prototypes made to iron out bugs due to manufacturing tolerances, etc.

- A displacement of somewhere in the 0.09 to 0.15 cuin range (1.5 to 2.5 cc). Much smaller than this and the parts require watchmaker skills; larger and mistakes become expensive. Additionally, the bore of engines in this range is "sweet"; beginners will have no great difficulty achieving the required finish and uniformity. Above and below though, extra care and effort are required.

- No screw-cutting required. While I believe the ability to cut accurate threads is ultimately mandatory for all model engineers, reports from some first-time builders suggests that removing it from the equation for the first attempt is a distinct positive.

- Just simple turning, drilling, and tapping operations required—no special tooling, milling, or slitting required. These things too should be part of a model engineer's skills inventory, but they can come later.

- No bush for the crankshaft; simply a reamed hole in the crankcase makes for one less thing to worry about. Pressing in a bush presents some 'gotchas', as does using a Locktite fit. Easier to skip it. Engine life and performance will be reduced, but we can live with that—many commercial engines have!

- Builders' choice for ignition type: glow, CI (diesel), maybe even spark. Some early English engines like the ED Mk III offered both CI and glow heads out of the box. This would let the builder use the system they are most familiar with, then try the other after confirming that the engine will run.

The question of using a casting for the crankcase verses one hogged from a lump of aluminum is contentious. A casting simplifies things. Machining it is generally the first task as other parts will be made to fit it. This provides the beginner a grand opportunity to have an expensive mistake when skills and confidence are at their lowest. On the other hand, a "hogged" case requires even more skills, but permits a few stuff-ups at an acceptable cost in material and time (to obtain a replacement that is, not in the overall effort invested). But this comes at the expense of either a dependency on milling operations, or a lot of sawing and filing—both of which are skill requirements we wanted to avoid.

If pressed, right now I'd recommend the ML Midge, or the Schroeder Deezil. The Midge is smaller than I'd prefer, and requires hogging the case. The Deezil is the right size, but requires screw cutting. The Owen Mate would be another contender, but as the crankcase extrusion is no longer available, a builder is faced with both hogging and screw cutting! All these engines are proven designs and have been successfully tackled by many first time builders with positive results. But late this month, two alternatives surfaced that have all the features on the list, provided you accept that castings are an acceptable risk. What are they? Wait for next month...  .

.

ETW and the Deltic

ETW and the Deltic

New Watzit and Gallery Entries

New Watzit and Gallery Entries

Estate Auctions

Estate Auctions

External Combustion

External Combustion

New Gannets

New Gannets

Back to the Future

Back to the Future

Kiwi Progress

Kiwi Progress

Whittle V8

Whittle V8

The Ideal First Project

The Ideal First Project

Editorial

Editorial

New Books and Magazines This Month

New Books and Magazines This Month

Engine Of The Month: Hybrid Hornet

Engine Of The Month: Hybrid Hornet

Tech Tip of the Month

Tech Tip of the Month

Standard Stuff

Standard Stuff

Please be patient; we'll get there eventually).

Please be patient; we'll get there eventually).