Model Engine News: April 2013

Special Features:

Vale: Dennis Fadden

Vale: Dennis Fadden

Another FTP Twin Runs

Another FTP Twin Runs

Flash! New Allbon Model Discovered

Flash! New Allbon Model Discovered

Clanford's A-Z Wrong (again)?!

Clanford's A-Z Wrong (again)?!

Gallery

Gallery

Regular Features:

Editorial

Editorial

New Books and Magazines This Month

New Books and Magazines This Month

Engine Of The Month: Dooling 61

Engine Of The Month: Dooling 61

Tech Tip of the Month

Tech Tip of the Month

Briefly Noted

Briefly Noted

Standard Stuff

Standard Stuff

|

Unless otherwise expressed, all original text, drawings, and photographs created by Ronald A Chernich appearing on the Model Engine News web site are licensed under a Creative Commons Attribution-Noncommercial-Share Alike 3.0 License. |

|

Editorial

Well, the "remote release" of the March issue of MEN went off without a hitch, and regrettably, I enjoyed the ocean cruise, which means I've no excuse for not going on another—which Ruthie is busy booking right now. The most amusing anecdote for the trip occurred as we were emerging from what passes for "customs" at a stop in Port Chalmers, outside Dunedin on New Zealand's South Isle. As we started to walk up the main street of this small and quaint, but rather attractive little village, a guy ran out of a building in front of us and yelled, "...hey everybody, they've got FREE WiFi!!". Must have been a dozen people, all from our cruise ship, stopped and made a bee-line for the door of the public library, including us! Time was, you'd need a call of free beer to cause this much of a stampede; how times change.

I've spent the last half of March in considerable pain, which I don't want to talk about, and which is now abating so I'll be grateful for small mercies. A consequence is slim 'pickins for the month, but Adrian more than makes up for that with his opus on the Dooling Brothers, and we have something on workholding which is rather basic, but I hope will be of special interest to beginners. I continue to receive emails from people who are now making quite advanced model engines and credit what they read here for getting them started and answering their initial questions. I really can't ask for more return than just that.

Vale: Dennis Fadden

We were saddened to hear the news, passed along by Paul Knapp, that Dennis Fadden passed away on March 17, 2013. I've always considered Dennis as "Mr Morton" due to his incredible variations based on the Morton M5 radial. Over the years, he has built 1, 2, 3, 5, 7, 10, and 14 cylinder versions, including cut-away models. His work, together with that of Bruce Satra, significantly improved the original, basic M5 design, resulting in higher power and greater reliability. The revised CAD plans appeared in June 2005 issue of Model Engine Builder (MEB).

Dennis, like many of us, was a self-taught machinist. A native of Vancouver (BC), Dennis was a pipeline welder who picked up a little Unimat lathe for something to do in his spare time. Enjoying a challenge, he had built radio controlled helicopters in the late 1960's, before the first kits for them started appearing. With the advent of commercial helli kits, Dennis switched to building aircraft engines, such as the Franklin flat-six, air-cooled, four-stroke seen here. He also ventured into small production runs of reproduction engines, such as the Chunn in-line twin, which were eagerly snapped up by collectors. In his short biography which appeared in MEB #3, September 2005, Dennis explained that his father had been a trapper in Ontario and owned airboats like those used in the Florida Everglades. By the time he was 14, Dennis was overhauling the engines, which seemed to grow on him.

His crowning achievement would be the unfinished scale model of the Pratt & Whitney R-4360, a four-bank, seven cylinder, air-cooled, supercharged radial (28 cylinders). This engine represents the pinnacle of piston engine aircraft engines to reach large scale production, and even unfinished, seems a fitting cap to Dennis' achievements. A few months back, Dennis sent the R-4360 parts to Paul Knapp who has restored and mounted the engine for display in the Carlsbad Craftsmanship Museum. Paul also supplied the photos for this small tribute to Dennis Fadden who will be missed by those who knew him, and admired by those who see his work, long into the future. More examples of engines built by Dennis can be found on this website (search on "Dennis Fadden", with the quote marks), and here on Flicker Vale, Dennis...

Another FTP Twin Runs

A long, long time ago, when my late friend, Russell Watson-Will and I were going over the CAD plans I'd made from his rough sketches used to construct his opposed twin cylinder diesel, he paused and said, Ron, do you really think anyone will ever actually build one of these? In all honesty, I was not. It is a complex beast, but for sure, if we didn't do the plans, nobody could build one. Well I was wrong and several have been built, and built as runners to a standard that would have pleased Russ, even though he did not live to see them. The latest is from Motor Boy, Les Stone, and you can follow the link to see Les' interpretation of the plans which appear, along with 12 other designs, in the Motor Boys' Plan Book.

Flash! New Allbon Model Discovered

Ok, that may be a bit overstated, especially as 75 years have elapsed, but Adrian Duncan has decided that sufficient evidence exists to propose a "Mk 1.5" version of the Allbon 2.8cc diesel. In support of this, we have added an entirely new section to the review (click the link to go direct to the new part). Adrian has also been corresponding with Gordon Cornell, who has been able to set the record straight on matters regarding the FROG 500 (see Briefly Noted), and the Allbon Arrow. This and other information received caused Yet Another Insertion into the Allan Allbon saga, so follow this link to The Allbon Arrow Re-evaluated.

Clanford's A-Z Wrong (again)?!

Unlikely as it may seem, another small error has been found in Mike Clanford's A-Z of Model Engines. Adrian Duncan has been researching racing engines and in an exchange with Don Sohn, who, as you can see from the photo here, is a very talented engine constructor, has discovered that the EDCO twin which appears in Clanford's book on pages 51 as "few made" was in fact made by Don in the early 1980's! Don states categorically that Hassad (on whose work he is an authority) never made twin-cylinder versions of the EDCO. Apparently Don made just one example which was sold in the early 1980's to Miguel de Rancougne. It's likely that Clanford obtained his images either by borrowing the engine from Miguel or getting the pictures he published from Miguel himself, or during the course of a visit to Miguel.

Gallery

I've always though that a disassembled model engine was far more interesting than an assembled one. I think this dates back to my earliest memories of engine reviews in model magazines. The British ones always disassembled the engine, while the American mags seldom did (at least until Peter Chinn began writing for Model Airplane News). The exploded shot here came from Keith Beaumont (UK), showing all the gory innards of his Sparey Vibrator—sorry, 5cc diesel. For more information of what it took to get it running, visit the Engine Gallery, page 19.

New Books and Magazines This Month

This month's new book for The Library gave me a sore neck; you can only shake your head side to side so many times before something gives! In 1940, a meeting took place between the President of Chrysler Corporation and the US Treasury Secretary which led to Chrysler being offered the opportunity to build the Rolls Royce Merlin, under contract, for the US. After Chrysler engineers had examined a disassembled and complete Merlin, they decided they could do better. The Merlin was a proven design which had and still was distinguishing itself in the skies over Britain. Chrysler had zero experience in building and designing aero engines, but were given a contract to design a high-performance (the Army called it hyper, now you know), liquid cooled engine. Is your head shaking from side to side in amazement yet?

Our book is Chrysler Aircraft Engines, by Kimble D McCutcheon, Weak Force Press, Huntsville AL, 2012, ISBN 0971084777. It is soft cover, 8-1/4" x 10-3/4", 186 pages, with numerous black and white photographs, illustrations, document images, and some color cross sections. It tells the saga of the development and testing of Chrysler's XI-2220 V-16 cylinder aero engine from the 1940 meeting (more than 18 months before Perl Harbor and the official entry of the US into World War II), to the termination of the project in January 1946, some months after cessation of hostilities. Some readers may recognize the author's name. Kim is President of the Aero Engine Historical Society (AEHS), and author of Tornado: Wright Aero's Liquid-Cooled Piston Engine, which we reviewed here way back in 2002.

Kim McCutcheon is a historian, so his writing is factual, extensively researched, and copiously end-noted. I have no issue with this as he presents verifiable facts, omits any conjecture, and reserves any of his own observations to a separate Conclusions chapter. If anything, his matter of fact delivery caused me even more amazement and head shaking as the story unfolded, though your mileage may vary. The story, like the engine, is complex, so the author has separate chapters which concentrate on a single aspect each:

- The project, politics, and contractual details

- Technical aspects and development of the V-twin, and single cylinder test engines

- Development, testing, and technical description of the V16 prototypes

- Details of the XP-47H flying test bed for the engine.

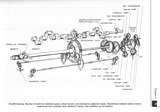

This approach means the same chronological ground is covered four times, and even though it requires some redundancy, I found that it worked excellently well. In fact, given the amount of ground to be covered, I don't think there could be a better way to tell the story. The engine itself is far from "conventional" in many aspects. Essentially, it is two inverted V-8's joined in the middle by a pinion gear that engages a bull-gear to the long prop shaft located between the V. This resulted in an engine over 10 feet long (3 meters), able to fit into a circle 34 inches (86cm) in diameter. The engine employed cylinders with a bore of 5.75 inches (146mm) and a stroke of 5.25 inches (133mm), and developed between 2,000 and 2,500 HP at sea level, depending of the type of supercharger.

Engine lovers will certainly appreciate the detail of the construction, and how Chrysler identified and overcame development issues. For example, the cylinders comprised a steel sleeve with an aluminum head, threaded and shrunk on with an interference fit of 16 thro. The cylinder screwed into the head and crankcase using a buttress thread (look at the cap of your toothpaste tube if you are not sure what this is). The cylinder was locked into the crankcase with a nut which had a bevel gear on its upper surface, tightened by a special tool and gear which engaged the nut's teeth. This list goes on, and on (is your head shaking yet? How would a battle-field mechanic cope with such a thing?)

Chrysler's inexperience with aircraft standards and military standards appears time and again, although not always with Chrysler causing the difficulty. At one point, Chrysler requested permission to deliver the first two engines with corrosion proofing, but not painted in accordance with the official painting specifications. They were told that the delay required to obtain approval would be greater than the delay posed by painting in accordance with the specification! More head-shaking is required in the chapter detailing flight testing of the engine in a highly modified Republic Aviation P47 Thunderbolt (called the "Pregnant Pollywog" by Republic, who where called the "Repulsive Aggravation Corporation" by Chrysler). The engine first flew on July 27, 1945, with Republic's chief experimental test pilot at the controls. He climbed to 2,000 feet, turned back to the field, and executed a slow roll, resulting in a loss of oil pressure and an emergency landing (eye witnesses say the roll was so slow, he flew the length of the field inverted even though the engine was not fitted with an inverted flight capable oil system), Amazement is insufficient; I must resort to astonishment...

Fortunately, the world was saved from the XI-2220 (and it's like in the US and Britain) by the gas turbine. As several other aero engine writers have explained, the piston engine had reached it's limit where demands for more horse power resulted in unsustainable and unreliable complexity. The first chapter of Kim's book on the Wright Tornado places this state firmly in context, explaining the US Army Air Corps/Force rationale for requesting high-power, liquid-cooled engines from engine manufacturers. One noteworthy difference between Curtis-Wright, Allison, Pratt & Whitney, Continental, and Chrysler is the latter billed the Army for all development costs, while the established manufacturers funded development in-house! In any event, none of their hyper creations saw service either.

I hope I've not given the impression this is a dry, academic read—it most certainly is not. The author has told a complicated story in a highly factual and detailed way which kept me reading far more avidly than I'd have thought it would. Copies are available from Weak Force Press for US$27.95. Buyers get on-line access to 1,600 pages of material used to produce the book, plus extra material not included in the book. Second hand copies of Kim McCutcheon's earlier Tornado book (now out of print) are listed by Amazon Sellers using telephone book prices and mine is going in the safe. Recommended to all who appreciate aero engine engineering and history: five stars  .

.

Engine Of The Month: Dooling 61

When I was a young lad in the 50's, the name Dooling has held in total awe. No kid I knew could afford one, nor was "man" enough to run one, I suspect. I was shown an example of one, mounted in a tether car, by the father of a school chum and remember feeling that it was close to being in the same league as real car engines; big, complicated, and way out of my reach and ambitions—a Taipan 1.5cc diesel being more my speed. This month, Adrian Duncan looks into the Dooling 61 with what he terms the first part of the Dooling saga, wherein you'll discover what part Norma-Jean, pictured here, has to play...

Tech Tip of the Month

One thing model engineers should never shy from is spending more time making a jig or fixture to hold a part for a machining step, than they will spend machining the part itself. I know this seems to cut across the grain for some beginners, but trust me, the time is well spent if it produces the perfect part while jury-rigged setups may cost you the part and perhaps expensive tooling into the bargain. This month we look at a very simple device generally called a "pot-chuck" which will hold things like prop-drive washers (and other washers), backplates, cylinder heads, and other thin-ish things for second operations. Correctly made and used, they provide good concentricity (where a thou, or two is of no consequence) while ensuring excellent alignment of flat faces normal to the lathe axis. So click the thumbnail, or follow this link to Workholding with Pot-Chucks.

Briefly Noted

This section is intended to alert you to little things that are hard to expand to a full news item, or cunningly wind into the Editorial, but are worthy of note never the less.

- The FROG 500 page has been updated following definitive information provided by Gordon Cornell, who worked on IMA engines for a time.

- A new entry/page has been added to People and Places for International Model Aircraft Ltd, seeing as we seem to refer to it a lot. The page merely redirects to the FROG book review, but as that is about as definitive as you can get regarding the company and all its works, it makes a good start.

- Likewise, a People and Places entry has been added for Reginald Denny which redirects to the book review that again is about the last word on the Hollywood actor's role in early model engines, and radio controlled target drones, although we may have more to say about the latter, later.

- The Bungay page has been updated in light of the shocking revelation this month that there may be an error in Clanford's A-z.