| Name | Alternate Firing Twin | Designer | Bob Chunn |

| Type | Spark Ignition, 2S | Capacity | .32 cuin |

| Production run | under 50 | Country of Origin | USA |

| Photo by | Bert S, Les S, Ron C | Year of manufacture | 1938/39 |

Background

The first (and only) advertisement for this engine appeared in Model Airplane News of June 1938 in which it was named merely (and I quite from the ad) "..an Alternate Firing Twin". It could be ordered direct from Southern Model Engineers of Nashville Tennesee for the not inconsiderable sum of $20.00, postage paid. As related by John H Krickel [1], the engine was the work of Bob Chunn, a barber by trade, but a talented modeller with a love of machines. Today it is most commonly called the "Chunn Twin" for obvious reasons.

In 1937, believing that a market existed for small engines, Bob had started Chunn Model Motors Incorporated with capital invested by a member of one of Nashville's 'first families', Henry "Boots" Tyne. Located over the barbershop, Chunn Motors produced the "Chunn", and the "Chum". Economic circumstances forced a stockholders takeover of the company shortly before the twin was produced. The reason his name was not formally associated with the engine was that his name was still tied up with the old company--who were now selling the "Chum" as the "Kaydet". Production of the Alternate Firing Twin continued into 1939, totalling less than 50 engines [2], or perhaps less [1].

Although the fabricated shaft arrangement would have permitted conventional conrods to be fitted before final assembly, the Twin used a bronze strap bent around the crankpin and secured to the rod proper by two 2-56 screws fitted from either side of the strap and threaded into the rod above the big end "shell" bearing.

It is believed Chunn chose this arrangement so that disassembly would be possible without driving out the crankshaft pins. Conceptualy, it is similar to that then used by Dan Calkin's Elf single (and later, twins, fours, and sixes), and later by ET Westbury's little Ladybird in-line twin, although the former used a detent/clip arrangement while the latter's strap was permanently held in place by two rivits, one above the other.

The edges of the baffle were chamfered, even though the CAD General Arrangement shows that at the TDC position, it comes nowhere near the truncated cone combustion chamber machined into the head.

The two cylinder castings are mirror-image to facilitate fitting of the T-shaped inlet manifold which was retained by a slit clamp in the cylinder casting. The manifold was fabricated by soldering the inlet into a drilled cross piece. A conventional design spraybar was also soldered up as part of the assembly. The needle valve made use of a small 0.030" sewing needle--a sound practice since followed by many, many small and not so small production run engines (Taipans and Glow-Chief, for example).

Technical Description

The engine is a quite conventional side port design with a bore of 5/8" and a stroke of 17/32". In common with automotive practice, the Twin used a "full" crankshaft supported at both ends and the middle by plain aluminium journals. The crankcase was split horizontally with the lower half attaching to the upper with six 4-40 screws. The steel crank shaft was fabricated from a number of parts, cross-pinned together.

It was cross-drilled 1/16" just ahead of the front bearing housing for a pin that fitted in a similar cross-drilled hole on the rear of the prop drive washer. This is not alltogether an ideal design as (i) it weakens the shaft at a most vulnerable point, and (ii), the pin presents a high stress contact on the drive washer. Such arrangements have been known to destroy themselves, even without a crash!

The engine is a quite conventional side port design with a bore of 5/8" and a stroke of 17/32". In common with automotive practice, the Twin used a "full" crankshaft supported at both ends and the middle by plain aluminium journals. The crankcase was split horizontally with the lower half attaching to the upper with six 4-40 screws. The steel crank shaft was fabricated from a number of parts, cross-pinned together.

It was cross-drilled 1/16" just ahead of the front bearing housing for a pin that fitted in a similar cross-drilled hole on the rear of the prop drive washer. This is not alltogether an ideal design as (i) it weakens the shaft at a most vulnerable point, and (ii), the pin presents a high stress contact on the drive washer. Such arrangements have been known to destroy themselves, even without a crash!

The timer/distributer was fully enclosed. A turned aluminium body carried a moving point actuated twice per revolution by flats on the end of the rear crankshaft projection. Provision for adjusting the advance/retard of the timer was provided by loosening two opposed, radial screws, adjusting and re-tightening. Not the sort of thing you'd want to try while the engine was running. The shaft end was threaded to permit the rotor arm to be positioned and secured. The distributor cap was cunningly machined from a "bakerlite" radio knob (today I groan to think of how many nascent distributor caps I consigned to the tip in days past...) Two spring clips retained the cap to the body, again in accordance with good, sound, automotive practice.

The timer/distributer was fully enclosed. A turned aluminium body carried a moving point actuated twice per revolution by flats on the end of the rear crankshaft projection. Provision for adjusting the advance/retard of the timer was provided by loosening two opposed, radial screws, adjusting and re-tightening. Not the sort of thing you'd want to try while the engine was running. The shaft end was threaded to permit the rotor arm to be positioned and secured. The distributor cap was cunningly machined from a "bakerlite" radio knob (today I groan to think of how many nascent distributor caps I consigned to the tip in days past...) Two spring clips retained the cap to the body, again in accordance with good, sound, automotive practice.

The cylinders comprised sand cast aluminium jackets into which were fitted steel liners. The heads were secured by six 4-40 screws. Engines were apparently produced in small batches (Chunn had no grinding facilities, so all parts were hand turned and honed), and while the same castings were used for all, minor differences appear between batches. Some heads were tapped for the large 3/8" Champion V-1 spark plugs; later ones used the the new, small 1/4" V-2 plugs.

Pistons were machined from cast-iron and had a 3/32" high deflector baffle machined in the top (biased towards the transfer side, naturally).

The cylinders comprised sand cast aluminium jackets into which were fitted steel liners. The heads were secured by six 4-40 screws. Engines were apparently produced in small batches (Chunn had no grinding facilities, so all parts were hand turned and honed), and while the same castings were used for all, minor differences appear between batches. Some heads were tapped for the large 3/8" Champion V-1 spark plugs; later ones used the the new, small 1/4" V-2 plugs.

Pistons were machined from cast-iron and had a 3/32" high deflector baffle machined in the top (biased towards the transfer side, naturally).

Performance

The original engines, bare, weighed in at over 12 ounces. The single MAN advertisement quoted 1/2 a horse power with a total flying weight of 18 oz including coil and batteries. Reference [1] suggests it turned a 14-8 prop at 5,000 rpm. The Fadden reproduction engines described below are quoted as turning a 10-6 at 5,600 rpm. In-line twins are great fun, and as I found out with my Prototype Taplin Twin repro, as they sound like they are going twice as fast because you are getting two bangs per rev.

Modern Chunn Twins

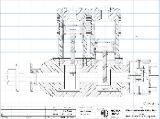

The Twin has been a relatively popular engine with model engine builders because of its straight forward design, simple construction, and strong appeal (yes, yes, not everyone shares my affliction with twins, but you've got to admire the period cham of this one, nea?) The ready availability of "factory" plans has also helped. Sometime back, I began a CAD set of Chunn Twin plans in preparation to commencing work. Over five years later, they are still 80% complete, requiring only final dimensioning and fiddly work that will require another 80% of the time to complete.

The Twin has been a relatively popular engine with model engine builders because of its straight forward design, simple construction, and strong appeal (yes, yes, not everyone shares my affliction with twins, but you've got to admire the period cham of this one, nea?) The ready availability of "factory" plans has also helped. Sometime back, I began a CAD set of Chunn Twin plans in preparation to commencing work. Over five years later, they are still 80% complete, requiring only final dimensioning and fiddly work that will require another 80% of the time to complete.

The castings are simple to produce and I'm aware of two sources: Art deKalb--as pictured here--and at one time, George Hellmer of Taylor, Michigan. The engine pictured in the Technical Description Section was made from a set of Helmer castings by Les Stone. If you have a full set of SIC, check out the rear cover of Volume 4, Issue #19. There you'll find no less than six beautifully made Twins built by Mr Morton himself, Dennis Fadden of Vancouver, BC. I'm reliably told that these are part of a batch of 13 he made--increasing the world's supply of Chunn Twins by over 25%.

The castings are simple to produce and I'm aware of two sources: Art deKalb--as pictured here--and at one time, George Hellmer of Taylor, Michigan. The engine pictured in the Technical Description Section was made from a set of Helmer castings by Les Stone. If you have a full set of SIC, check out the rear cover of Volume 4, Issue #19. There you'll find no less than six beautifully made Twins built by Mr Morton himself, Dennis Fadden of Vancouver, BC. I'm reliably told that these are part of a batch of 13 he made--increasing the world's supply of Chunn Twins by over 25%.

The engine at the head of the page was built by founder Motor Boy, Don McCluskey, from his own patterns and castings. This engine is now under the care of Don's life long friend, Bert Striegler. The photo here shows the last remaining set of Don's castings with one cylinder partially machined by Don himself. They sit under my bench awaiting the right moment to become a foreground job. I'd be tempted to make the shaft along the lines of the Prototype Taplin Twin shaft. This arrangement provides a degree of latitude in alignment and obviates the need for big-end straps, while still permitting easy disassembly (see the GA drawing above).

The engine at the head of the page was built by founder Motor Boy, Don McCluskey, from his own patterns and castings. This engine is now under the care of Don's life long friend, Bert Striegler. The photo here shows the last remaining set of Don's castings with one cylinder partially machined by Don himself. They sit under my bench awaiting the right moment to become a foreground job. I'd be tempted to make the shaft along the lines of the Prototype Taplin Twin shaft. This arrangement provides a degree of latitude in alignment and obviates the need for big-end straps, while still permitting easy disassembly (see the GA drawing above).

Conclusion:

The Chunn Alternate Firing Twin was not the first multi cylinder model engine to be sold commercially. The two-stroke Furgerson Falcon and Condor designs (opposed cylinders) had appeared years prior, though these were huge engines. Dan Calkin's diminutive opposed twin Elfs did not appear until 1940 however, so perhaps we can credit Bob Chunn with pioneering the market for a small sized multi cylinder model engine.References:

| [1] | Krickel, John H: History of the Chunn Engines Part 3, Engine Collectors Journal, Volume 3, Number 4, Jan-Feb 1965, p2. |

| [2] | Fisher, OFW: Collector's Guide to Model Aero Engines, Argus Books Ltd, 1977, ISBN 0 85242 492 2, p48. |

![]()