Editorial

September already! Someone please tell me where August went, or the year, for that matter. Looking back, I feel not much has been accomplished in the workshop. I'd be tempted to make a New Year Resolution to do better, except that the only New Year's resolution I've that ever kept was the one to make no more New Year's Resolutions.

There has however been some workshop activity during August. The photo shows most of the progress to date on a gadget I've been promising myself since 1994, and no, I'm not going to tell you what it is until it's finished—although some Model Engineer readers will recognize it, especially seeing that the article describing it has appeared in those pages twice. The urge to finally make an actual start on it arose from writing the piece on Kitting Up To Make Model Engines (Part I). That made me think on an expensive purchase which I've never been entirely happy with, but which may be recoverable with the assistance of the "thing". We'll see...

It's been a busy month for me, work-wise, with the iPhone app for submitting algal bloom sightings has just about been completed to the stage of preparing for submission to the Apple App Store—a process almost as complicated as writing the app! I've rather enjoyed the experience, even if the learning curve was rather steep for the first few months. The development language for the Mac, iPhone, iPad, etc is something called Objective-C which is not hard to learn if you are a C or Java programmer. As usual, it's becoming familiar and proficient with the supporting libraries that takes the time, but eventually it clicks and progress speeds up, as does the level of satisfaction. In fact, it's just like making model engines. The first one will take a while and involve a few errors and trips down wrong paths, but it gets better with experience.

Incidentally, while browsing a 2000 issue of the ME (4118), I noticed a review of the Sherline mill. The following statement by the author positively leapt off the page at me:

"I soon discovered that 2BA, a current UK thread, was a commonly used size among the fasteners on the milling machine, a fact which will come in handy as accessories are made, and different lengths of holding bolts are required for the table."

EH!? I don't think so. In fact I'm absolutely positive that Joe Martin would use only US threads on his machines. What has happened is our rather inexperienced author has managed to screw a 2BA screw into a 10-32 UNF nut. This will work for short lengths because the major diameters are close and the pitch of a 2BA thread works out to be about 31.35 TPI. But—and it's a Big But—the included angle of UNC and UNF threads is 60° while British Association (BA) threads use 47.5°! So while the screw might fit over short distances, the load is being taken on the crests of the threads, not the flanks. Not a good idea because wear will be high, as will the possibility of the thread working loose. A good Model Engineer should be aware of the differences between threads as used by different countries. UNC, UNF, NTP (tapered pipe), and metric threads have an included angle of 60°. British Standard Whitworth (BSW), and British Standard Fine (BSF) use 55°, as do the British Pipe threads (BSPT, BSPP), while British Association (BA) have an included angle of 47.5°. Mixing can work, but it's not a great idea.

Myford

Last month we reported the demise of the English lathe manufacturer, Myford, promising more information when it became available. According to the Model Engineer and Model Engineers' Workshop, the name, rights, and spares inventory has been purchased by a company called RDG Tools of Halifax, UK who will be setting up to trade under the Myford name through a Myford e-commerce web site, though this will take a while. RDG has been selling copied versions of Myford parts and will continue to do so under their own name. I've had both good and bad feedback on these non-original spares. One reader gave them full marks for quality and service while another bought a quadrant arm with posts too large to fit genuine Myford change wheels. Also, while RDG now has the rights to make Myford lathes, there are no immediate plans to do so. Neither is it clear whether they will make new spares to the plans and rights they now own, or just sell the purchased spares inventory, so I guess we are still watching this space, but there is genuine hope at least.

Classic Engine Kits

Most Model Engineers will have a casting kit, or two (or six) under the bench for a rainy day and I'll bet a lot of them came from Roger Schroeder. Roger's casting kits sold widely due to their low cost, simple design, and the great after-sales service Roger provided. Roger himself was the first to admit that the surface finish was not as smooth as he'd like, but working in green sand in his basement, some surface dimpling was to be expected. On the plus side, Roger used high quality alloy and de-gassed his melt so that the castings were strong, heat-treatable, and free from porosity, voids and other traps that would discourage a first-time builder.

This past month, photos arrived of engines finished from Roger's Classic Kit series from two builders about as far apart as you can get. From Jim Frew (Dorset UK) we have a Mk I ED Baby, while from Rob Jenkins (Sydney, Australia), we have a Gotham Hobby Deezil, the latter coincidentally being our Engine of the Month! Click the links for the Engine Gallery entries, and for completeness, images and links to both gallery entries have also been added to the end of the Roger Schroeder Tribute page.

K.6 Update

If you know your early post-WWII English sparkies, you'll probably know the Kiel K.6, but what about the K.3 and the K.10? The texts that we generally use to check if such beasts existed are Ron Warring's Miniature Aero Motors, Clanford's A-Z, and Peter Fisher's Collector's Guide to Model Aero Engines, all of which list the K.6, but none of which mention a K.3, nor a K.10, so did they exist and why ask? The reason is the 1946 Keil Kraft Handbook, scans of which were kindly provided by a UK reader and added to the rather scant and old page for the Keil K.6. As well as a delightful cut-away rendering of the K.6 from Model Aircraft, the Handbook mentions the 3.8cc K.3 and 10cc K.10 spark ignition engines. This may be a case of over enthusiastic promotion (the reverse Field of Dreams: if they come, we'll build it), or just perhaps, some were actually made. If anyone can provide evidence one way or t'other, we'd love to hear about it.

Huck V-8 Running!

Automotive V-8 fans will no doubt recall mention of a new design by Steve Huck which we announced here in July. At that time, Steve mentioned that the prototype had not yet run, but was close, as were plans for a suitable blower for the engine as a separate plan set. Well, all issues have been addressed. The final plans (v1.01, 68 pages) have been released, as has the extra plan set for a Roots type blower. Even more significant, the prototype has been completed and has run! You can watch (and listen to) a video of the Huck V-8 in action on Youtube.

Sugden (ish)

What do you do when you happen to be the proud owner of one of Vincent Chai's magnificent die cast Sugden Special crankcases, but have already built one from the amazingly inferior sand-cast cases that did the rounds way back when? This was the problem confronting Motor Boy, Les Stone, whose Chenery Gnome Rotary we saw here last month. Well Les managed to put the case to good use in an innovative way. For the results, click thru to the Les Stone Tribute page.

Jim Dunkin's Second Edition is Out

Jim Dunkin emailed to let us know that the Second Edition of his book on model engines of 2.5cc (.15 cuin) displacement is now available. As you can see from the image, this is one good looking book containing details of 1646 model engines from 36 countries in its 460 pages. The cost is US$100.00, plus $6.00 for postage and handling in the USA. Canadians will have to pay $29.00 for P&H, while Rest of World will need to pony up $US46.00, but for that you can ship two books at once (or four for $59.00), so the shipping cost becomes reasonable if you have three friends who want one too, and get 20% off the unit price for ordering four copies at once. Details of where to send payment are on the flier image and be sure to mention Model Engine News when ordering  .

.

New Books and Magazines This Month

My favorite web site for out-of-print and second hand books is called the Advanced Book Exchange, or "ABE Books"—somthing long time readers will already know. They act as a clearing house for book sellers all over the world and it's not often they fail to have what I want, most times at a very reasonable price. Last month, they provided me with a replacement for a biography I'd stupidly loaned out and will never see again, and an old autobiography which I'll report on when I've finished it. The biography recounts what Steve Jobs did next after being forced out of Apple in 1985. It's aptly titled Steve Jobs & The Next Big Thing (Randall E Stross, McMillan Publishing, New York, 1993, ISBN 0689121350) and if you remember the Next black cube computer, you'll understand the title pun, and the colors chosen for the book jacket title. I bought and read this book when it came out and remember shaking my head in wonderment at the collective stupidity of people who should have known better. My pristine replacement copy—unread, unopened, and unmarked, cost $1.75 from ABE.

Back when this book came out, Steve Jobs was a bit of a joke. His subsequent re-invention of himself, first through Pixar, then his remarkable return to Apple and the way he reversed its fortunes would appear to say there is something to his personal Reality Distortion Field generator after all—Apple having surpassed the worth of Microsoft, and as reported recently, now has more money than the US Government Treasury! I wanted to read it again because of the iPhone App I've just about finished for the University of Queensland eResearch Lab and the utterly perverse API of the classes in the libraries it depends on, many of which are prefixed "NS" for "Next Step". The underlying windowing system of today's Mac, iPad, iPod, and iPhone is Next Step, so Next lives on and prospers even. Coincidentally, last week's announcement from Steve Jobs was announced here on National radio as "iResign". Made me smile...

Ok, apart from the autobiography, none of that has much to do with model engineering, so let me tell you about a couple of magazines that arrived during August. First is Issue #25 of Model Engine Builder. Mike and Toni have done a super job on this issue, not forgetting their contributors who have delivered interesting and useful material on a diversity of subjects, some detailing model engine construction, some on useful tools and techniques applicable to building model engines as well as to model engineers in general. As well as new styff, the plan supplement contains the instructions for Todd Snouffer's Pip three cylinder radial. Todd put a lot of effort into the plans and instructions, so it's great to see them getting wider distribution through MEB.

Speaking of which, MEB can't exist without subscribers, so if you are not one, give it a try. In the US, a subscription costs $36.00 per year (four issues). Canada and Mexico pay $46.00 and the Rest Of World air mail subscription is US$54.00. I feel confident in saying there will be something for everybody in each issue.

Last month, I mentioned the Double Size Whittle V8 construction series being serialized in the Model Engineer and the lack of dimensioned drawings. Having now seen seven parts of this series, I've come to the conclusion that there will be no plans as such, ever. The series is an extended "How I Did It" with lots of good photos and text detailed enough to enable another advanced model engineer to produce something similar, after they've drawn their own plans essentially from scratch. It would be rather hypocritical of me to criticize this approach, seeing this web site is full of exactly the same thing, though it does represent a departure from tradition for the ME. How I Did It's have not all that unusual in the ME over the years, but a series of this length and detail would generally be blessed with plans, so it is a change of sorts.

Another thing I'm seeing more and more are articles with "photos" that have been produced by photo-realistic light-ray rendering of 3D CAD models. This trend has now appeared in ME and MEW in place of photos of "The Real Thing". Call me old fashioned, but I like to think that the thing I'm reading about has actually been built, unless the text make it clear up front that it has not, and why it has not. For all that, I look forward to issues of MEW and the ME, especially as the latter has started republishing some of the prolific writings of good old LBSC. This is not page filling by regurgitation. The series was written for another long defunct magazine, so it's effectively "new" to the pages of the ME. Currently they are replaying the words and music for LBSC's Rodean, a three cylinder 4-4-0 in 3-1/2 gauge from English Mechanics magazine of 1948. As I've said before more than once, if you read outside your speciality, you're sure to learn things you can apply within it. It works for me.

Engine Of The Month: Deezil vs AHC

Both the Gotham Hobby Deezil and the AHC Diesel are engines that have been covered here for quite some time. The Deezil page dates back to pre-digital camera days, while my friend and mentor, the late Roger Schroeder described a replica in the pages of Strictly Internal Combustion magazine back in 1994, and covered what was known of the AHC Diesel in his regular Engine-uity column for The Engine Collectors' Journal in 2001. Despite all this Adrian Duncan asked if I thought a more in-depth piece on the Deezil which included all the various commercial replicas would be of interest to readers, especially if he worked a comparison with the AHC into the picture as The Competitor That Never Was? I'll admit to being only slightly better than luke-warm at the prospect, but said yes anyway. Having read the result, I'm glad I did as this one of Adrian's best ever reviews, IMHO of course. I enjoyed it immensely and hope you do too. Adrian says it's one of the hardest he's tackled to date, but thinks it well may spark some extra action and argument on the various forums which in turn may elicit more information. Let's hope so.

Tech Tip of the Month

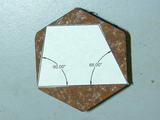

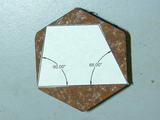

I'd originally thought that this month's Tech Tip would be distinctly high-tech until the penny dropped and I realized that the same result could be had with a very low-tech approach—one I'd used before and almost forgotten. The problem boiled down to how best to fit a shape—in this case, a trapezoid—onto a piece of available stock. The plans suggested a piece of 1" x 1-1/2" rectangular steel bar 2" long for the raw stock, but my scrap bin did not have anything remotely like that. I did however find several offcuts of 1-1/2" AF hex steel. Could the trapezoid be made to fit inside that? Being a bit of a nerd, I fired up the 2D CAD and found yes, it could if I could live with the height being about 1/32" short of the 1" specified. As this dimension was not critical, the reduction was deemed ok and you saw the result in this month's Editorial image.

But there's a simpler way. Draw the "thing" full size on a piece of paper, cut it out with scissors, the see how it can be rotated to fit, or not, on the available stock. In some cases, it will help to actually glue the paper to the stock and use that as a cutting guide for the band-saw while roughing-out. This approach was taken years ago when making the crankcases for the Weaver-Ransom 1cc diesel, as seen here.

Other places where scissors and paper are a good solution are things like bypass covers to be soldered to cylinders. After trimming and folding the paper version, flatten it out and use it as a template for the metal version. You'll probably save yourself from wasting metal this way too. So remember that scissors and paper are model engineering tools too and at times, very useful ones.

Briefly Noted

This section is intended to alert you to little things that are hard to expand to a full news item, or cunningly wind into the Editorial, but are worthy of note never the less.

- The Vic Smeed Tribute Page has been updated with more of Vic's flying model designs. I'm sure there are still more we've messed. If you know of one, let us know.

- Peter Chinn's review of the Gannet 15cc OHV four-stroke has been OCR'd and a hyperlink added to the page reference, or click here for a direct link to the new page.

Myford

Myford

Classic Engine Kits

Classic Engine Kits

K.6 Update

K.6 Update

Huck V-8 Running!

Huck V-8 Running!

Sugden (ish)

Sugden (ish)

Jim Dunkin's Second Edition is Out

Jim Dunkin's Second Edition is Out

Editorial

Editorial

New Books and Magazines This Month

New Books and Magazines This Month

Engine Of The Month: Deezil vs AHC

Engine Of The Month: Deezil vs AHC

Tech Tip of the Month

Tech Tip of the Month

Briefly Noted

Briefly Noted

Standard Stuff

Standard Stuff

.

.