Editorial

Seasons' Greetings to all of you out in Model Engine Lovers Land. And if any of you happen to know where 2005 went, please tell me! This month's issue (and the associated pages) is a new record for word count, so you will have a lot of reading to catch up with. MEN Members will find a CD update in the Members Area towards the end of December. This will bring your local copies of this site up to "current" status. About this time, you'll also find your *Free Christmas Plan* ready for downloading—my way of saying thank you for your support of this site. I've a few things to sort out on it, but I hope to have it available in time for you to put it under the tree, as it were.

As I've mentioned before, I get to turn the lights out here at DSTC on December 31st and I've been surprised and honored the number of readers who have emailed expressing concern for my professional future! Fortunately I've had enough options to give me a sense of comfort and have selected the one that is both the easiest and the most challenging, all at the same time. On January first, I will officially join Extensia Solutions. Extensia is DSTC's last spin-off company, incorporated to commercialize the research we've done in the electronic health record management space. It's challenging because it is a start-up company in a hot, new area, and it's easy because I don't even have to move out of my current office—not for six months anyway. And with the new Model Engine News web site now operating smoothly, there will be no interruptions to service, even when I switch off the DSTC servers.

So allow me to wish you all the very non-denominational, politically correct "Best" for the Festive Times. If you are taking a break, enjoy it and I'll see you back here in the New Year. By the way, unique visitors per month is now running at over 10,000.

Watzit Update

As well as having two new Watzits for us to puzzle over, I've done maintenance on the Watzit page itself, splitting it up and separating out the index. The server access logs show that the old Watzit page is responsible for a large part of the monthly bandwidth consumption. Now either this is due to Watzits being popular, or the page being too bloody big! So it's been made more manageable and we'll see which of the explanations is the correct one from next month's logs. In the mean time, click the photo to go direct to the page containing the new Watzit entries, or click here or use the Nav-bar at the left for the Watzit Index where new entries appear at the top, and are marked "new" until the list is updated..

Guildings Auction Results

Last month, Model Engine News reported on the impending auction of a large number of model engines by Gildings. Looks like this has become an annual event, with this year being particularly notable due to the Gerald Smith Collection going under the hammer. Motor Boy Ken Croft went along to observe and place a few cunning bids on my behalf—a skill at which he has proven significantly adept, as now I must speak with my bank manager! Now the question I'm sure you are all wanting answered is how much did the eighteen cylinder, dual bank radial go for? The answer (drum roll please, Mystro): a whacking 15,500 pounds Stirling!! Yes, you read that right. Fifteen thousand-five hundred pounds! That's US$26,520, or A$36,165 (dammit, I've run out of exclamation points again). The buyer, says Ken, was the same gentleman who bought just about all the radial engines on offer at the Christies auction of the Miguel de Rancougne collection. For a limited time, the terminally curious may view the results of the auction on the Guildings web site.

ER32 for the Myford

I've become a big fan of collet use in the lathe. The standard Myford collets use the #2 Morse Taper of the headstock spindle to achieve closure. This limits the workholding capacity to 1/2". Myford collets also close at one end only, so unless the stock being gripped is close to the collet size, there is a chance of bad run-out at extended distances from the collet end. This is common to all "end-closing" collets such as 5C, R8, etc. The more modern "full grip" type ER collets (DIN 6499) are designed to close at both ends, providing better gripping with less run-out.

There are a number of types that have different external dimensions, limiting the maximum size that can be held. The maximum diameter of the collet is usually quoted as a suffix, but does not relate directly to the maximum diameter that can be held. For example, the ER32 series has a maximum diameter of 32mm and will grip material in the range 2mm to 20mm. Each collet has a grip range of only 1mm, so 18 collets are required to cover the full grip range. Other ER series include ER16 (0.5mm to 10mm) and ER40 (3mm to 26mm).

There are a number of types that have different external dimensions, limiting the maximum size that can be held. The maximum diameter of the collet is usually quoted as a suffix, but does not relate directly to the maximum diameter that can be held. For example, the ER32 series has a maximum diameter of 32mm and will grip material in the range 2mm to 20mm. Each collet has a grip range of only 1mm, so 18 collets are required to cover the full grip range. Other ER series include ER16 (0.5mm to 10mm) and ER40 (3mm to 26mm).

Where is this leading? John Strachan of Hobby Mechanics, the Australian producer of Quorn cutter grinder casting, has produced a replacement tool-holder bracket for the Quorn that can be machined to take large spindles capable of using the ER series collets (or 5C, R8, etc if you already have them). John has provided me with a prototype casting to machine and evaluate, so before starting on this, I had to make a decision on the collet type to use. I've chosen ER32 and decided to make a holder for the Myford as an experiment. The ER collet nut is a bit complex, with an eccentric internal annulus that really requires hardening, so I've used a commercial one. It has a 40M 1.5 thread which required change wheels to cut, but all has gone well and the ER series can now be used to grip most of the cylinders I commonly make, accurately and without danger of distortion (like that which would be induced by a 3 jaw chuck). I'll report on the new Quorn tool-holder bracket in due course. The design I have in mind will incorporate the standard Quorn 30 degree quick-indexing feature, plus special detents for four and six facet drill sharpening and a revised system for work-spindle locking.

Where is this leading? John Strachan of Hobby Mechanics, the Australian producer of Quorn cutter grinder casting, has produced a replacement tool-holder bracket for the Quorn that can be machined to take large spindles capable of using the ER series collets (or 5C, R8, etc if you already have them). John has provided me with a prototype casting to machine and evaluate, so before starting on this, I had to make a decision on the collet type to use. I've chosen ER32 and decided to make a holder for the Myford as an experiment. The ER collet nut is a bit complex, with an eccentric internal annulus that really requires hardening, so I've used a commercial one. It has a 40M 1.5 thread which required change wheels to cut, but all has gone well and the ER series can now be used to grip most of the cylinders I commonly make, accurately and without danger of distortion (like that which would be induced by a 3 jaw chuck). I'll report on the new Quorn tool-holder bracket in due course. The design I have in mind will incorporate the standard Quorn 30 degree quick-indexing feature, plus special detents for four and six facet drill sharpening and a revised system for work-spindle locking.

Benzinmotor

There's been a new addition to the Les Stone Tribute Page of The Engine Gallery. This is Les' latest engine, the German Frank of 1940. Remember that WWII was well under way for Germany at that time, so it is interesting that model engines were still being produced in Germany. In comparison, all IC powered aeromodeling in England had been effectively banned. Even rubber was unobtainable and balsa had been declared a "strategic material". Yet Germany and German occupied Holland (as evidenced by the Nova) continued to permit model engine design and construction.

It's EDM, Mate

This photograph comes from Dave Miner who is building an Owen "Mate" diesel without the aid of the crankcase extrusion. This has been done before and involves some heavy duty milling, but Dave has found another approach. Having access to EDM (Electrical Discharge Machining) facilities, Dave simply programmed the outline of the extrusion as shown in the Motor Boys Book plan and turned the machine loose on a sheet of 2" thick aluminum plate! This approach is very practical and would allow cases to be made from the plate with minimal waste. Dave even programmed in the bore for the crankshaft bushing so it would be perfectly centered—although this then required that the case be mounted on a true-running mandrel to bore out the case cavity.

If you would like an EDM Mate case (raw outline, not machined; bushing hole optional), email Dave Miner [davem(at)machinistsinc.com]. Dave says that the price will be about US$40, plus shipping. That's for the raw case only—no plans included. Please note that the Mate drawings remain under David Owen's copyright and the only legal way to obtain them is to buy the Motor Boys Plan Book from the AMA. But as all proceeds from sales of the book go to the AMA juniors' program, you are aiding a good cause—we Motor Boys have never and will never receive anything from sales but satisfaction! Similarly, the Mate machining instructions remain under David Owen's copyright, but Dave has upgraded them and given permission to Model Engine News to make them available for private use on the web—which leads neatly into the next item:

The Ideal Beginners Engine (3)

Continuing on with our examination of engine designs for the first-time builder, this month we look at a design from Motor Boy David Owen that incorporates a unique feature, namely and extruded crankcase! Dave produced the die and had a length of 6061 extruded in 1989 at his own cost. The bar was cut up and distributed all over the world as raw material kits. Dave designed his engine to incorporate modern features and be perfectly flyable. So click the photo to read how he set about achieving this.

As a bonus, Dave has generously allowed Model Engine News to reproduce his machining instructions for the Mate. While directed at the Mate (obviously!), they contain techniques that are perfectly applicable to just about any shop made engine you can think of. Please note that copyright for the instructions remains with Dave and they may not be reproduced except for personal, private use without his permission. Click the Mate picture, or this link for observations on the Mate as a beginners' engine project.

Tiny Jewels

How about this? A case full of tiny jewels—miniature diesel engines in this case (ouch, please excuse bad pun). This pic was snapped by Ken Croft at the Guildings Auction. The engines were not part of the auction. There were made by expatriate German engine builder now living in the USA whose name we both know but cannot remember and were being shown by a collector. There appear to be two basic sizes, with the larger also being used as the basis for the multi-cylinder models. Cases look like vapor blasted barstock, contrasting nicely with the anodized parts. More if our memories ever start working again.

New Books and Magazines This Month

Apart from the latest issue of Model Engine Builder, new stuff this month was a bit ho-hum. Since MEB #3 contains an embarrassment of yours truly, with an awful blooper from the same source, I'll skip over it at this time except to say well done to Mike and Toni Rehmus. Next, the Model Engineer continues to give coverage to IC engines on alternate issues (ie, monthly as they publish on a 2 week cycle) and have done a good job reviewing Gordon Cornell's book. This was reviewed here a few months back in the July issue. Their sister magazine, Model Engineers Workshop also covered it and the ICE performance modeling program in issue #109 (October 2005), so Gordon is getting good exposure. The presenter of the IC column in the ME does not provide an email contact which is unfortunate, as I could provide answers to several questions he is asking of the readership. Anyone out there know if his is reachable electronically?

So with nothing great added to the library, we will look at an indispensable workshop aid that I term the "ready reckoner". There are lots of these, all taking the same general form: pocket sized (6" x 3-1/4" in this case) with plastic covered pages containing tabulated data on threads, drill sizes and other more (and less) useful things. As you can see, mine exhibits signs of frequent use in a harsh environment and is called "Kenwells Engineering Data Charts and Reference Tables". It is printed right here in my home town (Brisbane, Australia) by Gamecastle Pty Ltd, PO Box 26, Greenslopes 4120, and has no ISBN.

So with nothing great added to the library, we will look at an indispensable workshop aid that I term the "ready reckoner". There are lots of these, all taking the same general form: pocket sized (6" x 3-1/4" in this case) with plastic covered pages containing tabulated data on threads, drill sizes and other more (and less) useful things. As you can see, mine exhibits signs of frequent use in a harsh environment and is called "Kenwells Engineering Data Charts and Reference Tables". It is printed right here in my home town (Brisbane, Australia) by Gamecastle Pty Ltd, PO Box 26, Greenslopes 4120, and has no ISBN.

In its 28 pages, the reference lists nearly all of the thread types a Model Engineer is likely to encounter, namely ISO course and fine (metric); American UNF, UNC; the British Standards: Whitworth (BSW), Fine (BSF), Pipe (BSP), British Association (BA); and American National Taper Pipe (NPT) for good measure. The BA table seen here is a good example. Each thread is neatly tabulated, one per page, for all sizes with corresponding pitch, major/minor diameters, and drilling and tapping sizes quoted in metric. Now I still find thinking in metric difficult, but the metric value can be treated merely as a look-up index as the first two pages tables all the standard drill sizes, metric, number, fractional, and "letter", in ascending order. So finding the nearest you have to the metric tap or clearance size is quick and easy. The only thing omitted that I would have liked to have on hand is the "Model Engineer" series (32 and 40 TPI), but as these are 55 degree threads, the data from the BSW and BSF threads for thread depth can be used to calculate the important numbers.

In its 28 pages, the reference lists nearly all of the thread types a Model Engineer is likely to encounter, namely ISO course and fine (metric); American UNF, UNC; the British Standards: Whitworth (BSW), Fine (BSF), Pipe (BSP), British Association (BA); and American National Taper Pipe (NPT) for good measure. The BA table seen here is a good example. Each thread is neatly tabulated, one per page, for all sizes with corresponding pitch, major/minor diameters, and drilling and tapping sizes quoted in metric. Now I still find thinking in metric difficult, but the metric value can be treated merely as a look-up index as the first two pages tables all the standard drill sizes, metric, number, fractional, and "letter", in ascending order. So finding the nearest you have to the metric tap or clearance size is quick and easy. The only thing omitted that I would have liked to have on hand is the "Model Engineer" series (32 and 40 TPI), but as these are 55 degree threads, the data from the BSW and BSF threads for thread depth can be used to calculate the important numbers.

There are lots of equivalent pocket references published like this, but this is the only one I've encountered that provides such a wide range of thread data (some tend to be a bit parochial and omit the threads to "standard" in their country of origin). As our engines come from all over, a very non-denominational reference like this is quite handy. The 28 pages also contain data on tapers, "speeds and feeds", and other things I find I seldom need. But it's nice to know they are at hand when they are needed—saving me having to wash the grime off my hands before consulting a "library" text. My copy came from COMAG Pty Ltd for A$9.95. And I had not noticed until looking at the scanned picture of the cover, but the display in the digital calipers, 25.4, is the metric/Imperial conversion factor. Cute  .

.

Mia Culpa 2005

It's been a good year. I've not had to publish monthly True Confessions inserts as has been necessary in previous years (either I'm getting better at research, or cover-ups). But there were two from last month that must not go unpunished; let's do the worst first. In the latest issue of Model Engine Builder there is a little article on making D-Bit cutters by moi. On page 9, in the right hand corner, I say "Making the size across the 'D' slightly greater than the diameter achieves this...". Short of a hammer and anvil, it's hard to machine round stock to larger than its diameter. Obviously I meant to say smaller. Apart from that, MEB #3 is a great issue and all you subscribers should send Mike your renewals for 2006.

The second blooper was calling an Elfin 2.49cc updraft an Elfin 1.8cc updraft (mega-ouch). The real 1.8 has two horizontally disposed mounting ears and either no integral tank (the so-called "C/L" model pictured here), or a drop in clear tube arrangement for the F/F version. As penance, I'll review both early in the new year (and the Elfin 149BB article wherein the booboo appeared has been corrected).

Engine Of The Month: PMC-IMP

All right, I confess: I've been obsessing over this thing ever since Ken Croft awarded it most horrible status in the September Model Engine News. In an attempt to get over it, we've produced our standard CAD drawings and a full review of it's good and bad features (the good feature is that it actually runs). So click the pic, use the Engine Finder, or even use this link to see what the inside of a certified MH engine looks like.

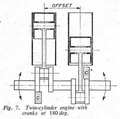

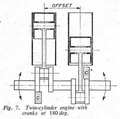

Tech Tip of the Month: Static Crankshaft Balancing

I've covered simple crankshaft balancing before, but recently re-discovered an ETW series on balancing that deserves preservation. So the series has been OCR'd, which is more work, but consumes less space and bandwidth than a straight scan. The result has been added to the Westbury Tribute page. The Crankshaft How-to page in the How-to section has been updated to include the cross reference.

Watzit Update

Watzit Update

Guildings Auction Results

Guildings Auction Results

ER32 for the Myford

ER32 for the Myford

It's EDM, Mate

It's EDM, Mate

The Ideal Beginners Engine (3)

The Ideal Beginners Engine (3)

Benzinmotor

Benzinmotor

Tiny Jewels

Tiny Jewels

Mia Culpa 2005

Mia Culpa 2005

Editorial

Editorial

New Books and Magazines This Month

New Books and Magazines This Month

Engine Of The Month: PMC IMP

Engine Of The Month: PMC IMP

Tech Tip of the Month: Static Crankshaft Balancing

Tech Tip of the Month: Static Crankshaft Balancing

Standard Stuff

Standard Stuff

.

.