Henri Baigent

and the B.M.P. 3.5cc Diesel

by Adrian Duncan

Some years ago we presented an article on the relatively rare B.M.P. 3.5cc diesel from Bournemouth, England. Until quite recently, very little published information was available regarding the origins of this elusive motor and the company that made it. Accordingly, we were unable to include any substantial details regarding the engine's origins and development in the original article, contenting ourselves mainly with describing the engine as it exists today in small numbers.

However, that changed dramatically when our original article on the B.M.P. 3.5 was read by Richard Jackson of Dorset, England. Richard was kind enough to draw our attention to a web-site which throws an immense amount of light upon the personalities involved with the development and manufacture of the B.M.P. The extent and scope of the new information made available in this way fully justifies the wholesale replacement of the previous article with the text which follows.

It turns out that the B.M.P. engines were the brainchild of the outstanding model engineer and model car builder Henri Baigent (1909-1971). I'd run across Henri Baigent's name frequently when reading about car modelling in post-war Britain, but had failed to make any connection with the B.M.P engines. Thankfully, Henri's only son Ray has undertaken the very considerable amount of work involved in putting together an excellent website dedicated to the recording of his father's amazing achievements in the fields of model engineering, full-sized car restoration, photography and art (among others). You can find more at this fascinating site. Well worth a visit—be prepared to spend some time and be amazed! Our very sincere thanks to Richard Jackson for drawing our attention to this site and of course to Ray Baigent for putting it all together.

I'd also like to express my thanks to Eric Offen, who kindly provided several images for my use in connection with the preparation of this article. In addition, I'm most grateful to Kevin Richards for sharing some of his recollections with me. Such assistance alone makes our ongoing research into the history of these fascinating little creations possible.

The scope of Henri Baigent's talents and work extended far beyond the realm of model diesel engine design and construction. Here we will do no more than summarize the B.M.P. story and Henri's involvement with that venture, drawing heavily upon Ray Baigent's published work with full acknowledgement. Readers wishing to learn about the full scope of the accomplishments of this extraordinary individual are referred to the excellent website noted above.

As ever, while openly acknowledging my indebtedness to the above-named gentlemen for the information which they have so generously made available, I wish to state that any errors or omissions in what follows are my sole responsibility.

Henri Baigent—early life

Although his name has led many people (myself included!) to assume that he was born in a French-speaking region of Europe, the fact of the matter is that the designer of the B.M.P. 3.5 was as English as treacle pudding! He was born Henry (sic) Cyril Baigent in Dagenham, Essex, on January 5th, 1909 to William Baigent and Janet Bird. William Baigent was descended from the Baigents of Rotherwick, who in turn took their ancestry from a Huguenot family which had come to England around the middle of the 17th century to escape religious persecution in France.

William Baigent was a hard-drinking working man whose domestic behavior imposed quite a strain upon his family. The resulting tensions doubtless did much to shape the characters of Henry and his siblings, making them both tough and self-reliant. However, this unhappy situation did not stifle Henry's creative talents in any way. At school, he showed considerable artistic ability, demonstrating a high level of proficiency in both painting and drawing. These skills were to serve him well during his later adult years. He was to retain an active involvement with art for his entire life, always setting aside some time for this activity. He also became an accomplished photographer.

Henry's entry into the workforce came shortly prior to the onset of the Great Depression, a period during which work was very hard to come by. Following his marriage to Daisy May Osborne, Henry had to accept whatever work was on offer to support his family. He worked variously during the 1920's and 30's as a bus driver, a lawn-mower sales manager, a builders' merchant's manager, a 78 rpm record presser and a fireplace-surround designer and maker. The family lived in Tonbridge, Kent, until 1935, when a move was made to Bournemouth in Dorset, a little to the east of Poole on England's south coast.

Henry was intensely interested in machinery of all kinds, spending much of his spare time engaged in mechanical activities. Just prior to the commencement of WW2 he constructed a treadle-lathe from a converted sewing machine. On this he made a 0-1 inch micrometer which was accurate to less than half-a-thousandth of an inch over the entire one-inch range. The threads were cut with a hand chaser. It was this that opened the door to Henry's subsequent wartime mechanical career when the Armaments Inspectorate awarded him an A1 Certificate of Competence for this achievement.

Although a disaster for Europe and the world in general, the onset of WW2 and the consequent need for military supplies came at just the right time for Henry in terms of the development and application of his burgeoning engineering skills. He established and managed an experimental workshop making munitions for the war effort. During the course of his pre-war activities, Henry had established some useful contacts in the pottery towns and the 'Black Country'. Through these contacts, he located some used machinery which he was able to overhaul and put into service in the new workshops, thus increasing his production capabilities.

This facility was soon entrusted with work of a very exacting nature, operating at a frantic pace. Henry was frequently consulted to deal with difficult problems which other workshops had failed to resolve. Many members of his workforce put in long hours of overtime, while he himself worked most of the day and a large part of the night, except when he was periodically called for night duty as an Air-raid Warden. Needless to say, Henry's family saw relatively little of him during the war years!

At the conclusion of the war in Europe in mid 1945, the� British government elected to end its support for the workshop, assigning Henry to work in a radar establishment under the 'Directed Labour' scheme. Here he made experimental wave-guides. However, later in 1945 Henry was discharged due to some respiratory problems which he had developed as a result of his earlier involvement with the record-pressing industry. He thus became a free agent, able to pursue whatever directions seemed appropriate to him.

Developing interest in model aircraft

By late 1945, when Henry became master of his own destiny once more, his only son Raymond (always known as Ray) had developed a strong interest in aeromodelling. Now that he had more time to do so, Henry began to take an interest in the technical side of his son's hobby, initially through the provision of advice and support.

At this point, it's necessary to place our story in context by taking a moment to recall the period during which Henry's interest in models first became stimulated. Although there had been a growing power modelling movement in Britain prior to WW2, with a number of British engine manufacturers challenging the marketplace during the late 1930's, the outbreak of war had the immediate result of diverting model engine manufacturing facilities into war-related production. Indeed, the flying of I/C-powered model aircraft was prohibited by law during the wartime years.

As a result, model engines were in extremely short supply in early post-war Britain. As of late 1945, commercial model engine manufacture in Britain had yet to resume. Such engines as did become available during this immediate post-war period were mostly individually imported through contacts in the United States.

A number of spark ignition motors such as the FROG 175 and the Ten-Sixty-Six Falcon did begin to appear in early 1946, but British modellers had to wait until the latter part of that year for the introduction of Britain's first commercial diesel, the excellent Mills 1.3. The 2cc ED Mk. II did not appear in production form until early 1947, to be followed later in the same year by the 1cc FROG 100 Mk. I.

Accordingly, any British modeller requiring a diesel engine as of early 1946 was on their own. If you wanted such an engine, you either had to make it yourself or get some talented friend or relative to do so for you. Young Ray Baigent was in this very position as 1946 rolled around, and it was inevitable that he would turn to his mechanically-skilled father for help.

Naturally, the design and construction of a model aero engine presented a challenge which resonated very strongly with Henry's mechanical leanings. He was thus more than willing to promise that he would indeed make an engine for Ray. This commitment proved to be the seed from which the B.M.P. venture was destined to grow. Henry immediately embarked upon the development of a suitable engine design, becoming increasingly engaged in his self-appointed task as time went by. As his understanding of his subject grew, so did his ambitions, the result being that this engine progressively grew in scope until it became what must certainly have been the world's first 3-cylinder in-line model diesel engine!

This one-off unit had a total displacement of around 10cc. Initially it did not work, but Henry steadfastly pursued solutions to its various problems, finally resolving all of the difficulties by mid 1946. Ray has recalled the general excitement within the family when the engine was first successfully run! This initial effort was later converted to glow-plug operation and finally into a spark-ignition unit. In this form it was installed in a superb 1/8 scale R/C model of an Aston-Martin DB-2 which was owned for some years by the well-known motor racing enthusiast Rob Walker, subsequently spending time in the National Motor Museum at Beaulieu before apparently being sold on. Where is it now ... Ray would love to know!

From his experience in developing this powerplant, Henry gained a great deal of insight into model diesel engine design and construction. After sorting out all the problems with the 3-cylinder unit, in mid-1946 he returned to his original mission of building a practical model aero engine for his son Ray to use in a model which he was then designing. For reasons which are unclear today, Henry decided upon a displacement of 3.5cc, which of course placed the engine in between the recognized competition classes at the time. It's quite possible that the engine used a piston/cylinder configuration taken from the 10cc triple, but we don't know this for certain.

In any event, Ray recalls that the model design which he was then developing would have been overpowered by an engine of this displacement. He therefore pressed his father for the development of a smaller engine, with results which we shall review in the following section of this article. In the meantime, Henry persisted with his original design plan, developing a 3.5 cc single-cylinder diesel engine with a twin ball-race crankshaft. This was the first British model diesel engine design to use a shaft supported in this manner.

The resulting unit was of course none other than the prototype of the B.M.P. 3.5 cc diesel which is our main subject. It proved to be extremely successful in operation by the standards of the day, to the extent that many of the local Bournemouth-area modellers expressed a strong desire to own one themselves. This may seem surprising given the engine's substantial bulk and weight as well as its somewhat offside displacement in the context of then-current competition classes. However, we must recall once more that at the time in question there were still no commercial model diesels on the British market. Hence if a model diesel of any description was made available, modellers would snap it up!

The general enthusiasm with which the prototype engine was greeted led Henry to approach a local precision engineering firm in the latter part of 1946 with the suggestion that this engine would be a commercial success if they produced it in quantity, because the response to the prototype had shown that the market was wide open for a practical model diesel engine of this kind.

It was around this time that members of the local model club began to render Henry's name as Henri, pronouncing his full name in Continental style as 'On-ree Bay-jon'. This apparently amused Henry no end, the result being that it became quite the usual thing to address him directly in this manner. Doubtless Henri (as we must now call him!) recognized that this rendering of his name imparted a considerable cach�t, since it implied a Continental connection synonymous with such revered names as Bugatti, Hugo Tanin and other iconoclastic mechanical innovators of the day. However, it was quite a while before he traded officially by the name of Henri.

B.M.P. production commences

Henri's approaches to the afore-mentioned precision engineering company fell on fertile ground, resulting in a decision being taken to produce the new 3.5 cc diesel design in quantity. To carry out this program, a new company called Bijou Mechanical Productions (Bournemouth) Ltd. (or B.M.P. for short) was established, with the owners of the original engineering company and Henri himself as co-directors. The new company traded from an address in Bournemouth.

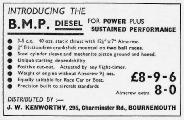

The introductory advertisement for the new engine appeared in the January 1947 issue of Aeromodeller magazine. The advertised selling price of the engine was �8 9s 6d (�8.47 in modern money), a very significant investment in early post-war Britain, when a man earning �8 a week would have been considered to be very well off. The same advertisement announced that a suitable matching airscrew was also available from B.M.P. at an extra cost of 8 shillings (40p).

The timing of this advertisement appears to confirm the right of the B.M.P. to be recognized as one of the earliest commercial diesels to enter the British marketplace, since it followed Britain's first such product, the Mills 1.3, by only some three months. The Owat 5cc from Bradford appeared at roughly the same time, while the ED Mk. II did not appear in its advertised production form until the following month. The FROG 100 did not make its commercial debut until mid 1947.

The initial B.M.P. production batch was very small, the idea being to test the market before engaging in expanded series production. The results of this exploratory stage were sufficiently encouraging that a second much larger batch of some 200 engines was soon produced. Local model shop proprietor and former Wakefield Trophy winner (1933) J. W. "Joe" Kenworthy was a great supporter of the B.M.P venture at the outset, advertising and distributing the engines from his model shop at 295 Charminster Road in Bournemouth.

The ongoing advertisements imply that by May 1947 distribution had shifted to Henry J. Nicholls Ltd. (HJN) of London. John Goodall, commercial model engine dealer and one-time editor/publisher of Model Engine World (MEW) has claimed that the engine was also distributed by Model Aircraft (Bournemouth) Ltd.—better known as "Veron"—but we are presently unaware of any evidence to support this assertion. In Issue #1 of MEW, Goodall relates how the engine introduced him to engine collecting and collectors, having such an influence that he named his own company BMP (Barton Model Products).

The manufacture of the B.M.P. engines was very much a hands-on affair as far as Henri Baigent was concerned. He was directly involved with all aspects of production, with his son Ray helping out as opportunity offered. All the casting work as well as the machining was carried out in-house. Ray has preserved many fascinating recollections of his time spent working with his father during this period, which may be found on the web-site to which reference has already been made.

It soon became apparent that the choice of the 3.5cc displacement had been a mistake in purely commercial terms. At the time, there was no competition class for 3.5cc engines in Britain, which had a considerably damping effect upon demand for the new product. Moreover, the physical bulk and weight of the engine told against it by comparison with some of the other designs which soon began to appear to challenge the B.M.P.

During the period when the B.M.P. 3.5cc model was being developed into its production form, Henri's son Ray had become interested in the relatively new sport of control-line flying and wished to build a C/L model to be powered by a far smaller diesel engine. This led directly to the development of the B.M.P. 0.9cc diesel, for which young Ray was largely responsible (at Henri's insistence!). In many ways, this engine followed the design pattern of its larger brother apart from the use of radial mounting as opposed to beam. The prototype used crankshaft rotary valve induction, but the production version reverted to the side-port pattern of its larger sibling. It was an excellent performer but was never produced in significant quantities.

The sole advertisement for this engine that we can find was a placement by J. W. Kenworthy in the February 1947 issue of Aeromodeller. This advertisement focused on the B.M.P. 3.5 but also stated that "production of the B.M.P. 0.9 will commence shortly" and invited orders. The selling price for this model was quoted as �5.

Despite the seeming absence of any further advertising, the B.M.P. 0.9 seems to have entered production on schedule and remained on the market for some time, since it was mentioned again in the British Diesel Summary by "Artifex" that appeared in the May 1947 issue of Aeromodeller. One of its purchasers was the redoubtable Col. C. E. Bowden, who mentioned it in his June 1947 Aeromodeller article summarizing his experiences to date with diesel engines. Bowden reported having used the little B.M.P. with great success in a 45" span free flight cabin model called the "Meteorite".

These smaller B.M.P. models are definitely about as rare as they get—there are hen's teeth, rocking horse droppings—and the B.M.P. 0.9, the latter being perhaps just a bit more difficult to find than the others! I've never so much as had a personal encounter with anyone who owned an example! But they do exist... One can see the family resemblance in several features, notably the exhaust porting and the use of twin ball races, the latter feature definitely being a first at this small size.

The B.M.P. engines remained on the market through 1947 and into 1948, with the B.M.P. 3.5cc model continuing to be the "flagship" offering. It's unclear whether or not the company actually made any further batches after the numbered run of some 200 engines which followed the un-numbered introductory batch. However, the scarcity of surviving examples together with the range of recorded serial numbers combine to suggest that only a few hundred were manufactured in total. I've only ever encountered a single three-digit serial number. That said, if any reader is able to add to our knowledge of B.M.P. serial numbers, we would be most grateful for such information. All contributions will be openly acknowledged.

Whatever the true production figures, the B.M.P. engines did not remain long on the market. HJN advertised the B.M.P. 3.5 sporadically during the period 1947-48, albeit seemingly with very limited sales success. A certain amount of work was put into the development of a 5cc version of the B.M.P. 3.5, resulting in a single prototype being produced for testing purposes. This prototype was used successfully by Col. C.E. Bowden to achieve several record performances, most notably a world endurance record for model floatplanes established at Poole Harbour, Dorset. It remains today in working order in the possession of Ray Baigent.

However, demand for the 3.5cc model was steadily falling as a result of increasing competition from other manufacturers, and the 0.9cc model had evidently failed to excite the marketplace. It was consequently becoming clear that the continuation of the B.M.P. enterprise was no longer economically viable. Accordingly, the business was wound up at some point during 1948, with the 5cc model never seeing production.

There is actually a strong possibility that production of the B.M.P. engines ceased prior to the end of 1947. The primary evidence for this stems from the fact that the B.M.P. engines were not included in Ron Warring's April 1951 table of data on the world's documented model aero engines produced during the period 1948—early 1951. This table was published in Model Aircraft and was re-printed in Vic Smeed's much later publication "Flying Models—Favourites of the Fifties" (Argus Books, 1988). A review of the engines which were included makes it quite clear that engines for which production had definitely ceased prior to 1948 were omitted, imparting some potential significance to the absence of the B.M.P. models from that table.

The other factor which is consistent with a very short production run is the seemingly small number of surviving examples. Even a one-year production period should have resulted in far more examples being manufactured than is suggested by the evidence. The number of survivors as well as their serial numbers seems to suggest that the numbered batch of some 200 engines recalled by Ray Baigent may well have been the final production batch, with the ensuing year or so being spent selling off the accumulated stocks.

The E.R.E. project

The dissolution of the B.M.P. enterprise was completed amicably between the various parties, leaving Henri free to continue his model engine development independently. By now he had become very interested in the then-burgeoning field of model car racing. Accordingly, his further engine development efforts were focused upon the production of an engine suitable for powering model racing cars. At this time, he was operating on his own account from a workshop at 10 Beverly Gardens in Bournemouth.

Ray Baigent recalls that a number of different one-off model diesel engines were made during this period, including one having a displacement of only 0.075cc—almost certainly the smallest engine to have been successfully constructed in England at that time. However, the most tangible result of Henri's ongoing model engine development work was a now extremely elusive 2.48cc diesel engine called the E.R.E. (English Racing Engine—a clear poke at the full-sized E.R.A. racing cars!). After some successful tests, this engine was put into limited production.

Our technical information regarding this model is presently limited to such facts as may be deduced from the attached images kindly supplied by Eric Offen of an example which he once owned. The E.R.E. was clearly a long-stroke design which utilized updraft crankshaft rotary valve induction along with a tall steel cylinder having integrally-machined cooling fins. The cylinder porting was interesting in that it reflected the system later used by Cox and others, with twin bypass passages and transfer ports fore and aft and twin opposed exhaust ports at the sides.

The E.R.E. was primarily intended for model car racing, many of the engines being supplied set up specifically for this purpose using a direct-drive trans-axle arrangement with two centrifugal clutches incorporated into dummy brake drums. John Oliver reportedly owns an example of the engine in this form. The engine was specifically designed to be applicable to model aircraft as well, a few of them being sold in this form as illustrated here. However, the number of aircraft units produced was evidently insufficient to warrant the inclusion of the E.R.E. in Ron Warring's previously-mentioned 1951 listing in Model Aircraft of model aero engines manufactured during the years 1948-51.

The E.R.E. did nonetheless rate a mention by OFW Fisher in his 1977 book Collector's Guide to Model Aero Engines. Fisher stated that while the engine was very well made, production figures were extremely small. The engine's present-day rarity appears to confirm this. Fisher also added the information that the E.R.E. was marketed by a firm called Replica of Sloane Street in London.

At this point, honesty compels me to admit that Fisher's comment regarding the E.R.E. being very well made is not unchallenged. My friend and colleague Kevin Richards recalls having owned one years ago that he recalls as having been "horrible ... not very well made at all"! Kevin admits that this is extremely inconsistent with Henri's demonstrated ability with the excellent B.M.P. engines as well as his superb car models, but there it is... Perhaps some of them weren't made under Henri's direct supervision?!?

Be that as it may, Ray Baigent recalls that the engine did well in model car racing against the Oliver and ED opposition of the day, and also achieved some fine results in aircraft applications. Southampton model shop owner and C/L stunt expert Peter Cock, who was a family friend of the Baigents, reportedly switched to the E.R.E. from the ED 2cc unit that had won the 1948 Gold Trophy for him and enjoyed continuing success. An E.R.E. powered control-line speed model built by Ray Baigent in 1949 unofficially achieved a British 2.5cc record performance in pre-contest testing but was unfortunately irreparably damaged just prior to the actual 1949 National contest during which an official record attempt was to have been made.

Despite these successes, the E.R.E. never made it into series production, being constructed mainly to special order in even smaller quantities than the former B.M.P. 3.5. In any case, by now Henri's interests were well and truly focused upon the world of scale car modelling, leading him to quickly abandon the model engine field. It is for his amazing achievements in relation to car modelling that he is best remembered today. But that's another story that has been very ably told elsewhere by Ray Baigent.

Henri Baigent died on April 13th 1971 at the age of 62 years following a series of strokes. The modelling world had lost one of its genuine masters.

The B.M.P. 3.5—Description

As noted above, the B.M.P. 3.5 cc diesel enjoys the distinction of being the first commercial English diesel to feature a twin ball-race crankshaft. Measured bore and stroke of the engine are 14.99mm x 19.40mm for a calculated displacement of 3.44cc. The engine is a bit of a lump at all of 10.125 ounces including tank—heavier than some much larger engines (and also heavier than the maker's claim of only 9.5 ounces)! The addition of the four extra holes at the front of the very substantial engine bearers (which also doubled as webs for the main bearing) did little to improve this situation and served merely to add some individuality to the engine's appearance! The motor is undeniably very sturdy, but the cost in terms of weight seems a little excessive.

According to O. F. W. Fisher's previously-mentioned 1977 book, the initial production batch of the B.M.P. 3.5 cc diesels (the small batch made to test the market) displayed no serial numbers, while the later series-production examples did have such numbers. My own illustrated example bears the serial number 34, stamped in rather small figures on the forward end of the left-hand exhaust "stack" (viewed from the rear) just to the side of the stamped initials "B.M.P." (as written, with periods) which appear on the front of the transfer port casting along with the stamped designation "3.5 cc" just below.

Another set of letters and figures appears on the crankcase below the right engine bearer (viewed from the rear). This series is cast in relief into the crankcase in very small letters and reads PM 909. It must be some kind of identifying mark for the casting rather than the specific engine. These letters are clearly visible in the right side view which appears above.

The engine is of the conventional side-port pattern. There are two exhaust ports set slightly towards the rear of the cylinder rather like those of the Series I ED Bee. These feed through substantial stub exhaust port "stacks" cast into the aluminum alloy cylinder barrel, which is separate from the lower crankcase. This cast alloy barrel also incorporates a "bulge" at the front to accommodate the single bypass passage. Mixture is transferred from the bypass into the cylinder by way of a single quite large transfer port cut through the steel cylinder liner at the front. This transfer port overlaps the exhaust port to a significant extent. Port areas are relatively generous and durations are unusually long for an engine of this type; clearly the makers were hoping for some reasonable operating speeds and were prepared to sacrifice a little low-end torque to get there.

Overall, the engine is very well made, especially where it counts. The crankcase appears to be a high-quality gravity die-casting. All fits are exceptionally good and the main castings are pleasingly polished. A nice touch is the fact that the engine bearers are milled on their undersides to ensure that they are both level and parallel, a refinement employed by ETA and others to help ensure a rigid mounting. Another classy feature is the provision of a cover plate over the front bearing. This is mounted just behind the prop driver and is held in place against the open end of the front bearing housing by three screws. It is clearly visible in the various photographs. The very laudable intent was clearly to exclude grit from the bearing. International Model Aircraft were to emulate this feature years later with their FROG 249 twin ball-race diesel, albeit with a non-metallic form of seal.

The fuel tank is also a heavily machined casting which is held in place by the same 4 screws which retain the crankcase backplate, thin paper gaskets being used to ensure a seal between the machined surfaces. The backplate thus doubles as the front wall of the fuel tank. The engine can readily be run without the tank—one simply removes the four screws, sets the tank aside and secures the backplate once more by re-installing the four screws. It would be necessary to adopt this approach in order to run the engine in anything other than an upright configuration.

The filler cap is interesting—it does not screw into its hole, but snaps in, being retained by the fact that its hollow spigot is split at four points on its circumference and has a small protruding ring of material surrounding its inner end. The splits allow this ring to contract to pass through the hole and then to spring open again to retain the cap in position.

One unusual feature for a British diesel is the fact that, on this example at least, an aluminum alloy contra-piston was employed. This was quite common practise on the Continent, but is a very rarely encountered feature in a British diesel. When the engine is cold, the fit is very easy, but when the engine really warms up the contra-piston sticks in place and cannot be shifted until the engine is allowed to cool down for a while. That said, it is true that once a setting is established the engine will readily start and run on the same setting, so this is perhaps less of a problem than it might otherwise have been. Nonetheless, a cast-iron contra-piston gives a far better measure of control while the engine is running. Perhaps this was a somewhat futile weight-saving measure!?

This example was equipped with a spring-loaded choke flap which is now missing, although its mounting remains brazed in place. Other examples of this engine, including the one previously illustrated on the MEN site as well as that illustrated by Fisher, are also missing this flap, but it appears to have been an original feature of my own motor. The example illustrated in Peter Scott's little book has the flap in place. The spring apparently held it in the open position, and a timer could presumably be arranged to snap it shut to stop the engine when desired.

Following the initial publication of this article, a reader kindly provided a photograph of B.M.P. 3.5 no. 68 which retained that delicate little shut-off clapper. The moving arm has what appears to be a rubber ring screwed onto a stub to provide an air-tight seal. It was also noteworthy for the fact that the attachment is on the opposite side to my own engine.

My example (engine no. 34) has a conventional compression screw with a tommy bar, as does the example which was illustrated by Scott. Others, including the example featured in issue #1 of MEW, the one in Fisher's book and previously-mentioned engine number 68, have a slotted head compression screw to accommodate the ubiquitous penny for compression adjustment (shades of E.D.!). All of these examples also feature the choke flap or provision for this accessory. However, reader Graham Phillips sent in a photo of his own example of the B.M.P. 3.5 bearing the serial number 105. This example also features the slotted comp screw, but lacks the choke flap. It would seem from this that engines with and without the choke flap and with either style of comp screw may have appeared more or less randomly throughout the production run. In fact, on the basis of the evidence to date, the slotted comp screw seems to have predominated.

The B.M.P. 3.5cc diesel—user impressions

I've run my B.M.P. 3.5 and have found it to be a fine starter and runner. It feels positively silky when turned over after a finger-choke—really nice! Fits are generally beyond reproach, although this example has been used and there is some very slight play just starting to develop in the con-rod bearings. This is only detectable when the engine is completely "dry" after cleaning.

The motor is dead easy to get going using standard procedures, but the aluminum contra-piston means that you need to be quick with the compression setting to get it right before the engine gets too hot! Under-compression won't harm anything—the tank can safely be run out in that condition. However, if you find out too late that you've set the thing over-compressed, it's necessary to stop it before it bogs itself down to a laboring halt (potentially doing itself all sorts of damage in the process), allow it to cool a bit, reduce compression as much as you judge to be required and then try again, noting the desired setting prior to starting and making sure that you get the compression screw to that setting before the engine warms up fully. Once a good setting is established, you can leave it alone—the motor will start and run on the same setting with no trouble at all. In effect, you can treat it as a fixed-compression diesel at this point!

The tank has an extremely generous capacity, giving a leaned-out run of over 4 minutes. This would be OK for control-line or model boat use, but is extremely excessive for free flight purposes. For the latter application, the use of the cut-out would be mandatory.

A slightly cut-down 10 x 6 prop seems to be a good match for the engine, which seems very happy in the 8,000-9,000 rpm range. Running is extremely smooth and torque appears to be excellent in this speed range. Generally speaking, the engine is quite a sturdy performer for its type and displacement, but its power to weight ratio is still rather less than stellar. By comparison with the soon-to-be-released Amco and ED 3.5 cc diesels and even the ED 2.49cc Mk. III, it was strictly no contest—the B.M.P. could never have survived their introduction for long.

Still, a quality piece of merchandise and a very worthy effort by Henri Baigent! It's really great to be able to assign due credit for the design and manufacture of this engine after all these years!

Conclusion

We hope that you've enjoyed this summary of the history of one of the more intriguing and capable pioneer British model engine manufacturers of the early post-war period. Once again, our sincere thanks are due to Ray Baigent for so generously sharing his recollections of his father's life and work, and to Richard Jackson for drawing our attention to Ray's efforts.