Balancing Small Engines

Notes on basic principles and practical methods of procedureBasic Principles

by ET Westbury, 1951

Balancing Multi-cylinder Engines

Before dealing specifically with engines having more than one cylinder, it may be mentioned that there is one type of single-cylinder engine in which perfect dynamic balance is possible; namely, the opposed-piston type, in which two pistons moving in opposite directions are used in one cylinder. The advantages of this type, however, are somewhat marred by the fact that its mechanical arrangement is more complex, and often convenient or inefficient; it is much better suited for dealing with the heavy masses in very large slow-running engines than for those of small high-speed engines, where the improved dynamic balance may hardly be perceptible under practical conditions. Balancing problems may sometimes (but not always) be simplified by the use of more than one cylinder. A very common arrangement consists of placing two cylinders alongside, and parallel with each other, connecting the pistons of these cylinders to cranks disposed at 180 deg. as in Fig. 7. In practice, this is by no means a complete solution of the problem, because of the distance apart of the two cranks, with a corresponding offset in the plane of the pistons, which sets up a pronounced rocking couple. For an engine of given capacity, however, the pistons are smaller, so that the unbalanced forces are reduced in proportion, and another advantage (unconnected with balancing) is that the frequency of power impulses, at a given speed, is doubled, producing a more even torque at the shaft. The effect of the couple can be reduced to some extent by counterweighting the end crank throws.

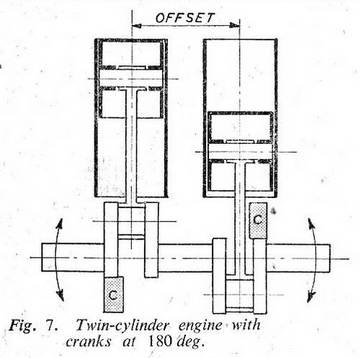

Balancing problems may sometimes (but not always) be simplified by the use of more than one cylinder. A very common arrangement consists of placing two cylinders alongside, and parallel with each other, connecting the pistons of these cylinders to cranks disposed at 180 deg. as in Fig. 7. In practice, this is by no means a complete solution of the problem, because of the distance apart of the two cranks, with a corresponding offset in the plane of the pistons, which sets up a pronounced rocking couple. For an engine of given capacity, however, the pistons are smaller, so that the unbalanced forces are reduced in proportion, and another advantage (unconnected with balancing) is that the frequency of power impulses, at a given speed, is doubled, producing a more even torque at the shaft. The effect of the couple can be reduced to some extent by counterweighting the end crank throws.

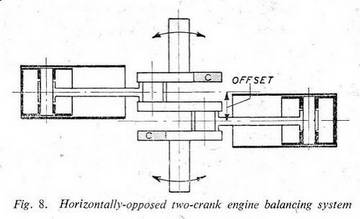

In the attempt to ,reduce the offset in the plane of the pistons, the cylinders can be located on opposite sides of the crankshaft, as in the popular "flat twin", and use a two-throw crank so that the pistons move in opposite phase. It is not usually desirable in practice to place the two cylinders in exactly the same plane, so that there is usually a slight couple as shown, in Fig. 8, but it is much less than in the side-by-side arrangement, and balance, on the whole, is fairly satisfactory. The same principle can be applied to any even number of cylinders, and "flat fours" and "flat sixes" have become increasingly popular in recent years,

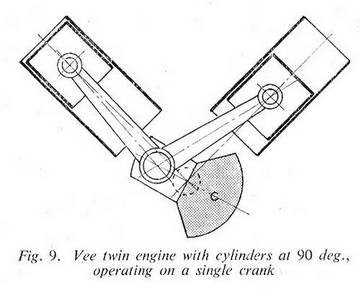

Yet another arrangement for a twin-cylinder engine is to place the cylinders at right angles to each other, and connect the two pistons to a single crank throw, as shown in Fig. 9. The crankpin is counterweighted as for a single-cylinder engine, counterweight is always acting in direct opposition to one or other of the pistons, and therefore it is practicable to balance completely the reciprocating weight one one piston (the other being of exactly equal weight). Such an engine is very well balanced, but the arrangement has its disadvantages, particularly in petrol engines, as it introduces unequal firing intervals, unless the pairs of cylinders are multiplied, as in the "vee eight" now popular in motor cars. Note that the complete state of balance is only obtained when the cylinders are set exactly at 90 deg.; the narrow-angle vee twin commonly employed in motor-cycles is not so good in this respect, being more of a compromise between the single and the two-crank twin. Radial engines having a symmetrical arrangement of cylinders may be balanced on the same principle as the 90 deg. vee twin, but it should be noted that when the rods do not all articulate on the crankpin centre, their order of motion is modified, and this may complicate balancing problems.

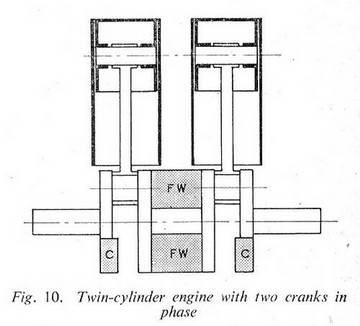

Side-by-side twins are often arranged with the pistons in the same phase, as shown in Fig. 10, the object being usually to obtain equal firing intervals, with smooth torque. From the balancing aspect, this may be considered a retrogression, as the problem is the same as that in a single-cylinder engine; but there is no doubt that the arrangement works well in practice, at least in engines of moderate cylinder capacity. The complete absence of a rocking couple, when the balance weights are symmetrically arranged relative to the reciprocating masses (which taken individually, are lower than those in a single of equal total capacity), is also a probable factor in the success of this type of engine. Sometimes a centre bearing is provided between the crank throws, but in other cases the space is occupied by an internal flywheel, which may be balanced in itself, or counterweighted to contribute to the partial cancellation of reciprocating forces.

In the attempt to improve the balance of this type of engine, a centre crank throw is sometimes introduced, opposite in phase to the other two, and this is used to drive a charging pump or compressor, or even simply reciprocate a counterweight equal in moment of mass to that of the two main pistons. Split-single two-strokes, having two cylinder barrels with a common combustion head, sometimes have two separate crank throws slightly different in phase, and may have an opposed centre throw which drives a "displacer" to increase the volume of air displaced in the crankcase, thereby acting as a supercharger. An example of an engine of this type was the 15 c.c. engine. of Mr. A. D. Rankine's Oigh Alba Junior, which unfortunately came to an untimely end in a fire at Kilmarnock some years ago.

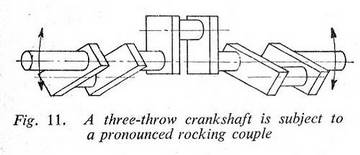

Three-cylinder Engines

These have never been very popular in small or medium sizes, despite the fact that they can be arranged to give equal firing intervals in either two-stroke or four-stroke types. In a three-inline engine with the cranks arranged as in Fig. 11, there is obviously a pronounced rocking couple which cannot easily be eliminated. Generally speaking, this arrangement is not well suited to high speed, but if it must be used, the best way is to treat each crank throw as a separate singlecylinder engine and counterweight the crank webs accordingly. Where it can conveniently be used, the radial arrangement of cylinders, acting on a single crank, is much to be preferred for high speed.Four or More Cylinders

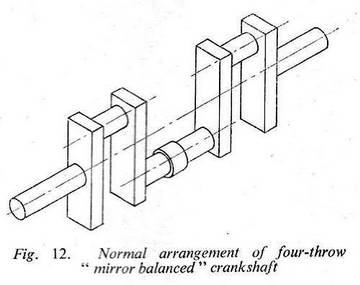

The orthodox four-in-line engine can be quite well balanced if the cranks are arranged in pairs at 180 deg., each pair being opposed to the other to cancel out the individual couples, as shown in Fig, 12. This arrangement is sometimes termed " mirror" balance, as each half of the engine resembles a reflection of the other as seen in a mirror. If the pistons and other working parts of such an engine are of uniform mass, the engine is capable of working smoothly, and with very little vibration. A similar arrangement can be used in a six-cylinder engine, with two opposed sets of three cranks at 120 deg., or eight cylinders, with two opposed sets of four cranks at 90 deg. It should, however, be noted that the stiffness of the crankshaft, and of the engine structure generally, has an important bearing on the success of such engines, 'as the cancelling of the two opposed couples has a tendency to bend the crankshaft in the middle.The shorter and stiffer the complete engine structure can be made, the more likely it is to be successful in practice. This accounts for the decline in the popularity of the once-favoured "straight sixes" and "straight eights", some of which were of prodigious length. It may here be appropriate to make some observations on the advisability of providing bearings between crank throws, as this matter has a pronounced influence on design from this aspect, and is often in dispute. Beyond doubt, it is a good thing to support the crankshaft between crank throws, provided that the bearings are held rigidly in true alignment, and the shaft also remains true under working stresses. But these conditions cannot be guaranteed in practice in an engine which must be kept as light as possible for a given size; moreover the provision of inter-throw bearings, if they are to be of any use at all, adds very considerably to the length of the engine, and therefore increases the effects of rocking couples. A further effect, not directly connected with balance, but capable of causing very troublesome vibration, is that of torsional deflection in a long and intermittently loaded shaft. As with many other things in engine design, a compromise is often necessary to get the best practical results from the most desirable features and avoid the worst of their disadvantages.

Primary and Secondary Balance

So far, I have dealt only with the means of dealing with the most important unbalanced forces in orthodox types of engines or machines; and quite frankly, I believe that if these principles are fully grasped, they will cover most practical problems encountered by "M.E." readers. There are, however, other forces of the second, third and further orders, ad infinitum, but it would be impossible to do so without taking up a considerable amount of space, and going very deeply in theory and mathematics, which I feel sure would be out of place in a practical journal.

It may, however, be observed that secondary unbalanced forces occur in mechanisms where the motion is not truly harmonic, and this applies where a connecting-rod of limited length is used to link reciprocating and revolving parts. As short rods, involving considerable maximum angularity, are common in high-speed engines, no simple system of balancing can eliminate these secondary forces completely, even in engines where the reciprocating masses can be directly opposed in identical planes. But as we have already seen, theoretical balancing systems do not always give the best results in practice, and again the importance of compromise must be stressed.

I have tried to assist readers to solve their own balancing problems in a strictly practical way, well knowing that nearly all model engineers are men of action, who would much rather spend their time at the lathe or bench than in working out theoretical problems on paper. I know from experience that these problems can be capable of purely practical solution, and I am not prepared to admit that this takes longer, or involves more labour, than the theoretical approach, always provided, of course, that basic principles are correctly grasped, and that one does not attempt to fly in the face of all physical laws.

I have tried to assist readers to solve their own balancing problems in a strictly practical way, well knowing that nearly all model engineers are men of action, who would much rather spend their time at the lathe or bench than in working out theoretical problems on paper. I know from experience that these problems can be capable of purely practical solution, and I am not prepared to admit that this takes longer, or involves more labour, than the theoretical approach, always provided, of course, that basic principles are correctly grasped, and that one does not attempt to fly in the face of all physical laws.

There is much more that could be said about practical balancing problems, but I trust that readers will be able to apply this elementary, and admittedly limited, information to advantage, and be encouraged to work things out for themselves by practical experiment. The mechanisms dealt with here are those most likely to be encountered in model engineering, but unusual types of machines generally embody combinations of simple motions which can be isolated and analysed. Perfection in the balancing of any machine is rarely attained, but the higher the speed and the more exacting the duty, the closer must be the approach to perfection if the machine is to be a practical success.

-oOo-

Previous page

Back to Balancing main page

This page designed to look best when using anything but IE!

Please submit all questions and comments to

[email protected]