|

|

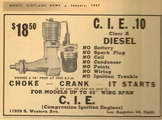

We historians don't know the designer of this neat little American diesel[1], the C.I.E. DIESEL 10. C.I.E. of course stands for Compression Ignition Engine and MODELCRAFT HOBBIES, 11929 South Western Ave., Los Angeles 44, CA was the seller/distributor. The "tall" appearance. similar to the ill-fated Deezil of America's Hobby Center fame[2] in the forties was most attractive due to the nice design. well cast materials and beautifully machined head. The aluminum cast body had no exhaust stack. with two openings either side. a cast in "nubbin" which held the aluminum intake with plastic tank and Gits cap equipped metal top. The pressure needle valve bottom screwed into a brass tube extending down into the tank.

The ten finned aluminum head covered a steel liner and was held to the body by four very long screws. A gasket was in between. The screw type adjustment on top of the flat. finless cylinder head has a small wire protruding arm. The back cover was removable and fastened to the body by three nuts and bolts and had a recessed back and gasket also. The steel, baffle-less piston utilized an aluminum, un-bushed conrod and the all steel crankshaft extend to an aluminum drive washer and steel prop-washer and nut. All in all a very neat package. Modelcraft is said to have sold a "few" thousand of the C.I.E.s. Note the discrepancy in the stated .10 displacement in the top title and the .144 stated in the "inside" story.

The ten finned aluminum head covered a steel liner and was held to the body by four very long screws. A gasket was in between. The screw type adjustment on top of the flat. finless cylinder head has a small wire protruding arm. The back cover was removable and fastened to the body by three nuts and bolts and had a recessed back and gasket also. The steel, baffle-less piston utilized an aluminum, un-bushed conrod and the all steel crankshaft extend to an aluminum drive washer and steel prop-washer and nut. All in all a very neat package. Modelcraft is said to have sold a "few" thousand of the C.I.E.s. Note the discrepancy in the stated .10 displacement in the top title and the .144 stated in the "inside" story.

At $18.50 it was fairly expensive and of course it is one of the very few American diesels to hit the market during that short period when they appeared to be on the "edge" of becoming popular in the 1940s. One of its best qualities, of course, was the fact that it had variable compression. Thus the Drones, and the C.I.E. were the most readily available with the advertised Micros, Mighty Midgets, Speed Demon, Delong, Edco and Kencraft most difficult to obtain. The Deezil, a .12, disillusioned most who bought them but are collectors items today along with the others.

In the early 1950s the McCoys followed the small Vivells all to vanish from the modeling scene as the all conquering glows took over.

Probably the single most important reason for the demise of the diesels in America was the lack of readily available fuel mixes on a nationwide basis. The large cities didn't suffer but the smaller towns where the modelers were did.

Diesels reigned supreme in England and on the continent in spite of the overwhelming American glows.

The C.I.E. is a most desirable addition to the American diesel collectors and increasingly hard to obtain in new condition. The $18.50 price originally has ballooned to over one hundred nowadays, joining the high cost of the other rare diesels. But the little gem is a beauty.

Model Engine News Notes:

| [1] | Yes we do! According to the late John Pond's research (second ref below), the designers and builders were identified and interviewed. They were Barney Snyder and William (Bill) A Ruff. This article states that the engine had a tubular steel connecting rod (possible), and a cast 356 aluminium alloy crankshaft. This is highly unlikely—perhaps a misprint for crankcase.

|

||||

| [2] | The Deezil was made by Gotham Hobby, not AHC, although there is a connection through the brothers Winston. Check out these links to the Deezil, and America's Hobby Center for The True Story. |

Other Variants

Outwardly, the CIE "10" is a very conventional example of the long-stroke side-port diesel. In the mid-1990's, it reappeared on the market for a short time as a small-scale reproduction "collectable" by Mr Taipan, Gordon Burford. The Burford engines can be easily identified. The most obvious differences are nine cooling fins, not ten; a translucent rather than transparent tank; and a subtle little compression friction device comprising a socket head grub-screw that pushed a nylon pad against the brass compression screw thread at the rear of the engine. No written evidence exists, but I have it on good authority that Gordon, with typical irreverent Ozzie humour, called his engine the "CIA". David Owen, who ground the cylinders, believes that less than a dozen were made.

Outwardly, the CIE "10" is a very conventional example of the long-stroke side-port diesel. In the mid-1990's, it reappeared on the market for a short time as a small-scale reproduction "collectable" by Mr Taipan, Gordon Burford. The Burford engines can be easily identified. The most obvious differences are nine cooling fins, not ten; a translucent rather than transparent tank; and a subtle little compression friction device comprising a socket head grub-screw that pushed a nylon pad against the brass compression screw thread at the rear of the engine. No written evidence exists, but I have it on good authority that Gordon, with typical irreverent Ozzie humour, called his engine the "CIA". David Owen, who ground the cylinders, believes that less than a dozen were made.

Tim Dannel's American Model Engine Encyclopedia listing for the CIE notes that production was taken over by HY-PRO Engines. These had both "CIE" and "HY-PRO" stamped on the front of the crankcase bypass. The same source records that HY-PRO also produced a "Race Car" variant. The spraybar was installed in the venturi mounting boss and the mounting lugs were ground off! This explains the engine pictured here from Eric Offen's collection. For the longest time, I had incorrectly assumed that the engine had been modified (butchered) by some past owner!

Tim Dannel's American Model Engine Encyclopedia listing for the CIE notes that production was taken over by HY-PRO Engines. These had both "CIE" and "HY-PRO" stamped on the front of the crankcase bypass. The same source records that HY-PRO also produced a "Race Car" variant. The spraybar was installed in the venturi mounting boss and the mounting lugs were ground off! This explains the engine pictured here from Eric Offen's collection. For the longest time, I had incorrectly assumed that the engine had been modified (butchered) by some past owner!

Here we see the engine lug region of Eric's lug-less HY-PRO race-car engine. If the lugs were removed, they've done a top-notch job of finishing the area and restoring an as-cast appearance! Dies are expensive things to make, so we can discount them making a second one. However this kind of change to the die would have been difficult and highly unusual. We will have to call it a bit of a mystery.

Here we see the engine lug region of Eric's lug-less HY-PRO race-car engine. If the lugs were removed, they've done a top-notch job of finishing the area and restoring an as-cast appearance! Dies are expensive things to make, so we can discount them making a second one. However this kind of change to the die would have been difficult and highly unusual. We will have to call it a bit of a mystery.

There was another CIE, but whether any examples exist to-day is questionable. The engine is pictured in this CIE advertisement from the January 1947 issue of Model Airplane News. It differs in several important details from the August '47 ad and from known examples of the actual engine. Note the engine mounting lugs are in line with the thrust line. The backplate is of the screw-in variety, the head has 11 fins, and the venturi/tank assembly was almost certainly borrowed from a "Brownie". If this was a prototype with a lower displacement used for early promotion, it could explain why a 0.147 cuin engine had to be known as a "10", having initially been announced as such. I must also point out that a 0.500" bore and 0.750" stroke as stated by all sources gives 0.147 cuin displacement, not 0.144 (see the "Inside Story" in the '47 ad above), and certainly not 0.10!

There was another CIE, but whether any examples exist to-day is questionable. The engine is pictured in this CIE advertisement from the January 1947 issue of Model Airplane News. It differs in several important details from the August '47 ad and from known examples of the actual engine. Note the engine mounting lugs are in line with the thrust line. The backplate is of the screw-in variety, the head has 11 fins, and the venturi/tank assembly was almost certainly borrowed from a "Brownie". If this was a prototype with a lower displacement used for early promotion, it could explain why a 0.147 cuin engine had to be known as a "10", having initially been announced as such. I must also point out that a 0.500" bore and 0.750" stroke as stated by all sources gives 0.147 cuin displacement, not 0.144 (see the "Inside Story" in the '47 ad above), and certainly not 0.10!

The Encyclopedia states that no examples of this model are known to exist, however the Blue Book (4th edition) lists and describes three different engines by displacement. For 1946, the .10 with the screw-in backplate and flared inlet. For 1947, two models are listed; the .14 of 0.144 cuin displacement with plastic tank, and the HI-PRO .15 with a 0.147 cuin displacement and no tank. The race-car variant is also noted. This enlargement of the bypass on a lugged version clearly shows a "Y", so we can award this point to the Encyclopedia. A serial number is evident on the end of the lug. Original CIE's do not seem to have carried serial numbers.

Contrast the HY-PRO bypass with the bypass of the CIE in Bert Streigler's collection. The front of the bypass has been machined—I use the term loosely—but not stamped. This occasional absence of lettering is also noted in the Encyclopedia for original CIE made engines. Quite evident is the difference in the way the area has been treated. HY-PRO has obviously milled the flat. Bert's CIE seems to have been introduced briefly to a grinder fitted with a cup wheel! One must ask, why? You can easily stamp the as-cast surface. Our most plausible theories are to make the marking stand out (so why then not stamp it?), or because this area was where the casting sprue was located, hence dressing was required. It's also been suggested that this treatment was necessary to remove cast-in marking that would identify the cases as being of Italian origin. Sadly, we just don't know.

Contrast the HY-PRO bypass with the bypass of the CIE in Bert Streigler's collection. The front of the bypass has been machined—I use the term loosely—but not stamped. This occasional absence of lettering is also noted in the Encyclopedia for original CIE made engines. Quite evident is the difference in the way the area has been treated. HY-PRO has obviously milled the flat. Bert's CIE seems to have been introduced briefly to a grinder fitted with a cup wheel! One must ask, why? You can easily stamp the as-cast surface. Our most plausible theories are to make the marking stand out (so why then not stamp it?), or because this area was where the casting sprue was located, hence dressing was required. It's also been suggested that this treatment was necessary to remove cast-in marking that would identify the cases as being of Italian origin. Sadly, we just don't know.

The photos inserted into the Janson review text above were kindly sent in by a reader who notes that the name originally cast into the front of the engine has been milled away. This may not be so; the Encyclopedia observes that not all CIE engines were stamped. When he received the engine it appeared un-run, but has evidence of having had fuel in it. He had to remove the compression stop to get the contra-piston into the running range which led him to wonder if the original purchaser may have given up in disgust!

Back to Model Engine News Home

Back to Model Engine News Home

Back to Janson Index

Please submit all questions and comments to [email protected]