An American Classic —

The Drone Diesel

by Adrian Duncan

2008-05-01

Revised:

2010-05-15

2010-07-07

2010-10-11

|

|

Click on images to view larger picture.

Hover over images for captions. |

Our subject this time is another of our beloved diesel engines, but one with a difference—in fact, several differences! For one thing, it was made in America, a country which produced relatively few diesel designs. For another, it retained fixed compression at a time when variable compression was fast becoming the accepted standard among diesel manufacturers. Finally, it was manufactured to the very highest standards and achieved a contest record which was second to none during its relatively short production lifetime.

With that introduction, no knowledgeable model engine aficionado could be in any doubt at all that we're talking about the famous Drone Diesel of 4.85cc (0.297 cuin) displacement. This fine engine was manufactured by Drone Engineering Inc, initially of 125 Broad Street, Elizabeth, New Jersey, but later giving their address as 851 Anna Street in the same city. It was in production during the years 1947-1949 and was arguably the most successful of all American diesels both in commercial and competition terms. Some 15,000 units were produced during those few years, a high figure for an American diesel. The engine was so well built and so durable that a substantial proportion of that total still survives today.

It's our intention in this article to summarise the genesis, development and untimely demise of the Drone as well as set the record straight in a few areas in which there has been a measure of misinformation circulated in the past. We will also provide some detailed operational notes based on present-day experience. However, it's always best to begin at the beginning.

Origins

As of the mid 1940's, spark ignition engines were dominant in American aeromodelling and the model diesel technology which had been evolving in Europe since 1941 was pretty much unknown. However, this began to change shortly after the conclusion of WW2 when returning US servicemen started bringing European diesels back home with them in increasing numbers. One of these was the French Micron fixed-compression diesel of 4.99 cc displacement, examples of which had begun to appear on American flying fields by 1946. It was this engine which inspired the design of the Drone Diesel which is the subject of this article.

The Drone Diesel was designed by the well-known modeller Leon Shulman, who had been born in 1920 in Brooklyn, New York. Although he was only 26 years old when the Drone was conceived, Leon was already a very experienced modeller with a high standing in the US competition arena and a visible presence in the US model trade. He had actually taken his first step towards an active involvement in the model industry in 1940 at the age of only 20, when he developed and marketed a folding prop for gas models. In 1941 he followed this up by marketing an "unbreakable" plastic prop. In addition, a number of his free flight model designs such as the Sky Scraper, Sky Rocket, Wedgy, Banshee, Zoomer and Zomby enjoyed considerable competition success both in America and elsewhere, and most of them were either commercially kitted or published in plan form.

Leon thus had something of a "name" to attach to any new modelling product with which he might become associated, backed up by a considerable amount of marketing experience. He was also blessed with an open and inquiring mind, and it's clear that he was very impressed with the 5 cc Micron fixed-compression diesel. That fine engine had achieved an outstanding contest record in early post-war European competitions, and this certainly made it a design worth studying.

By 1946, when he first became aware of the Micron diesel, Leon had become a regular competitor in control-line events, an activity with which he was to remain involved until 1951, winning several Regional and National competitions along the way. He was thus pre-disposed towards the development of better equipment for control-line use.

Viewed in a 1946 context (prior to the commercial advent of the glow-plug), the two big attractions of the diesel engine for control-line use were the elimination of the dead weight represented by the spark ignition system and the dependability of the engine once running. It's easy to forget today that prior to the widespread adoption of control-line flying, engines had for the most part been required to make no more than 20-second runs in the free flight models in which they were generally employed. The advent of control-line meant that repeated runs of up to 10 minutes duration were now routinely required, and this was taxing the capabilities of many of the spark ignition engines then in current use. Battery depletion, point fouling and vibration-induced electrical gremlins all militated against reliability in such service. By contrast, once running at the correct settings, the diesel would continue to run indefinitely as long as it was supplied with fuel because there was basically nothing to go wrong!

According to long-time Drone user Gus Munich, who was "there" during the engine's hey-day, the idea of designing and producing an American fixed-compression diesel along the general lines of the Micron had its genesis in coffee-shop discussions between Leon and others at the 1946 US Nationals. Following these discussions, Leon secured financial backing from a close friend and got started on the design work on the engine as well as the assembly of the required dies and tooling.

The Drone was Gus Munich's all-time favourite engine by his own open admission, and his personal reminiscences regarding the Drone were published in MECA Bulletin no. 71, issued together with swap sheet no. 88 in January 1981 (well over a quarter-century ago—how time flies!). Gus's insights still make fascinating reading today, and I freely acknowledge that both my personal enthusiasm for the Drone and the basic material for the following article stemmed from my reading of Gus's text. I advise anyone who can gain access to a copy to read Gus's original comments. Where my information differs from that set out by Gus, it is only on the basis of persuasive evidence and later experience which have become available since Gus's time of writing.

The First Model (plain bearing)

Leon Shulman's initial design concept for the Drone followed the general layout of the Micron pretty closely, in functional terms at least. However, the original version of the engine with cast-in-place upright front intake and the word "Drone" cast onto the front of the cylinder barrel apparently never actually reached the hobby shops. We only know what it looked like from a pre-release advertisement which was placed in "Air Trails" magazine in early 1947. The engine was christened in this advertisement with the name Drone "B"ee by which it is still sometimes known.

One significant departure from the Micron was the bore/stroke relationship. The Micron used a bore and stroke of 17.00 mm x 22.00 mm respectively, giving that engine a displacement of 4.99 cc in keeping with the European Class B standard of 5 cc. However, this worked out as 0.304 cuin, which was just over the limit of 0.299 cuin allowable in American Class B competitions, and Leon naturally wanted an American Class B engine. Accordingly, the Drone utilized a modified bore and stroke of 16.67 mm x 22.22 mm, making it slightly more under-square than the Micron and giving it a displacement of 4.85 cc or 0.297 cuin These rather long-stroke measurements were well suited to the relatively low design operating speeds which the use of fixed compression pretty much dictated.

The model that finally reached the marketplace in early 1947 is generally referred to as the first model Drone, or the Drone plain-bearing model if you prefer. It was basically similar to the design illustrated in the early advertisement, but the cast-on word "Drone" was moved from the front of the bolt-on cylinder barrel casting to the bypass bulge opposite the exhaust. In addition, the original cast-in-unit venturi was replaced by a separate screw-in item which could be positioned to set the needle in any desired orientation using a lock-nut.

At 275 gm (9.7 oz.) complete with tank, the Drone was certainly no lightweight. However, it dispensed with the cumbersome and heavy spark ignition equipment and seriously out-torqued the spark ignition opposition which was all that it had to contend with during the pre-glowplug era in which it was introduced. In terms of its effective power-to-weight ratio, it probably at least equalled the best of the opposition and certainly had far less to go wrong.

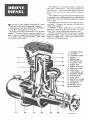

The main crankcase casting incorporated the main bearing in unit, and a separate cylinder casting was attached to the top of the case with four screws. This cylinder casting incorporated the exhaust stack, the bypass passage and the machined cooling fins. The steel cylinder liner was a simple drop-in item which was retained by the gold-anodized head. The head in turn was secured by four screws and sealed to the liner with one or more gaskets. The fixed geometric compression ratio could be adjusted between runs by adding or removing head gaskets as required. It's only a fixed compression engine if you allow it to be!

The cast iron piston was stepped on the transfer side much like that of the Micron. It was carried on a sturdy forged alloy rod with a bronze bushing in the big end. The steel gudgeon pin was equipped with flat brass end-pads. These are not infrequently missing in present-day examples that have been disassembled and re-assembled by less-than-careful owners, and this is a point well worth checking before you try to run one of these engines. No sense scoring a good bore!

As assembled by the factory, the exhaust was located on the left side of the engine (looking at it in the direction of flight from the rear). This was because the recommended control-line mounting position for the engine was in the sidewinder configuration, and locating the exhaust on that side theoretically reduced the amount of dirt potentially ingested during landing of models that were not equipped with landing gear. The design was such that the engine could be re-assembled with the stack on the right as long as one remembered to switch the piston around as well! It's astonishing how many Drones are encountered today with their pistons reversed.

The sturdy one-piece steel crankshaft had a plain disc crankweb and a generous journal diameter of 0.471 in. It was provided with a rectangular induction port which gave very rapid opening and closing of the induction system. The shaft ran in a main bearing which was cast integral with the crankcase and incorporated a bronze bushing. The front of the shaft had a short extension of reduced diameter with a pair of flats milled into it on opposite sides, and the alloy propeller driver keyed onto this extension. A further threaded forward extension accommodated the prop itself as well as the prop-nut and prop washer.

Unusually, the backplate was a light alloy stamping which was held in place in a rather distinctive manner. The unthreaded backplate simply plugged directly into the case with a thick gasket for a seal. The tank had a flange which bore against the rear of the backplate rim, again sealing with a gasket. The entire assembly was held in place by a flat plate retainer of light alloy which incorporated a large hole for the spun aluminium tank and was secured by four screws at the corners. This bore upon the rear face of the tank flange and "clamped" the entire assembly with the gaskets in a compressed state for good sealing. It was neither necessary nor desirable to over-tighten the screws to achieve a good seal—doing so merely bent the corners of the retaining plate. If it was desired to run the engine without the tank, one simply removed the flat plate retainer, discarded the tank and replaced the retainer.

The back tank appeared on most examples of the first model Drone, although a few of the later engines in the high 9000 serial number range were apparently sold without this fitting— the odd tankless example has been encountered in a box in which the insert lacked the required cut-out to accommodate a tank in the first place. Presumably, stocks of the tank were exhausted before all of the other first model components had been assembled into engines for sale, and there was no point in making more tanks because the engine was scheduled for replacement anyway by that time.

Most tanks had a Gits cap on the filler hole, but a few of the later models lacked this fitting—the engine which appears in most of the attached illustrations is a NIB example of one of these late models (s/n 9796). They must have run out of Gits caps shortly before they ran out of tanks! Once again, there was no point in re-ordering since the Gits caps were not required for the second model Drone which was soon to replace the first model.

The serial numbers for the first model Drone were stamped on the upper surface of the right-hand mounting lug (looking forward in the direction of flight). They went from 1 to around 10,000—this statement is supported by the fact that I own first model Drones 441 and 9796 from opposite ends of this range as well as several in between.

The engine sold for the then considerable price of $21.50. It wasn't cheap, but the quality and performance were both high. In fact, the standard of workmanship throughout was of the very highest order, putting many contemporary British makers to shame. Gus Munich mentioned having met a former employee of Drone Engineering who had been responsible for fitting the piston/cylinder units for the Drone engines. He recalled using Bon Ami to produce the ultimate fit between the two components. If the typically excellent fits on surviving Drones are anything to go by, he was a real craftsman!

The engine was most attractively finished, with the black-anodized main castings contrasting nicely with the plain metal highlights and gold-anodized cylinder head. It was packaged in a sturdy black cardboard box with gold lettering.

The instruction sheet provided with the engine was both comprehensive and accurate. If followed, the very clear instructions which appeared on the sheet could scarcely fail to ensure good results.

The guarantee provided with these engines was interesting—there was no time-limited guarantee of the more usual kind. The document first made the statement that "this engine has been run at the factory and was started by hand as a final check. Only Drone diesel fuel was used." The actual guarantee itself was limited to a specific assurance that the engine was "free from material defects at time of purchase". Nothing was said about defects that might develop after purchase!

Basically, Drone Engineering guaranteed that the buyer received an engine that had been tested and found to be in perfect working order and was therefore capable of performing up to standard as supplied. The company clearly felt that this was the extent of their obligation and that what happened thereafter was up to the new owner! The guarantee warned that dismantling the engine or using a non-specified fuel invalidated the guarantee.

I can envision a few "material defects" that might not become obvious unless the engine was dismantled! However, the ruling criterion was the performance out of the box—the very clear message was that if the engine failed to start and run properly using the specified fuel and procedures, it would not be due to the factory sending out an inoperable engine! The fact that all engines were test-run at the factory meant that there was little or no chance of inoperable engines getting out to the public, and the company was clearly and expressly relying on this.

Still, if the engine failed to perform for its new owner there must be a reason of some kind and the company's preference was to have it returned to the factory for inspection and repair if necessary rather than have the owner try to fix it for himself. One wonders how many of the engines returned (assuming that some were) proved to have no defects, more or less demonstrating that the problems were owner-related. What would the company have done in such a case?

The lack of long-term warranty protection meant that if the engine performed OK out of the box but developed a problem later on, claiming on the guarantee might be a bit of a challenge!! However, there's a great deal of logic in the above wording—any manufacturer's primary obligation to the customer is surely to supply an item that will perform as the customer expects, and that's what Drone Engineering were specifically guaranteeing. Moreover, they claimed to have established this fact through a hands-on test of the engine, so they were on pretty firm ground. What happened down the road was out of the maker's control, hence the absence of any guarantee beyond the original condition of the engine. In particular, they did not feel responsible for any user-related problems!

The manufacturer's recommended fuel (specified both in the instructions and on the guarantee) was either the pre-mixed Drone fuel or a blend of 75% ether, 25% SAE 20 mineral oil—presumably the two were more or less the same. The addition of a little SAE 30 oil was suggested during the break-in process.

The recommended airscrew for control line stunt flying, for which the engine was primarily intended, was an 11 x 10. Using this combination, starting was foolproof (present-day urban legends to the contrary) and running extremely consistent, as I can personally confirm from extensive first-hand experience. By comparison with the spark-ignition alternative which was all that was then available, the Drone really stood out in these respects, especially in the context of control-line flying where dependable runs of up to 10 minutes were the standard requirement as opposed to the short runs typical of free flight operation.

Leon Shulman was very active in promoting his new product, making a number of extremely successful demonstrations of the motor at various trade shows as well as sponsoring a series of contests with Drone engines as the prizes. As a further promotion, he even produced a limited number of custom pith helmets having a Drone cylinder and head on top along with Drone decals on the side! Boy, would I love to have one of those today.

The Drone cause was further aided by several positive commentaries which appeared at various times in the contemporary modelling media. An extremely positive review of the engine was published in the August 1947 issue of "Flying Models" magazine, and the rival magazine "Air Trails" published an equally positive evaluation at around the same time. The latter review specifically stated that the engine "was easily started and ran very consistently".

The September 1947 issue of "Air Trails and Science Frontiers" featured an article by Jim Noonan entitled "The Development of Diesels", in which the Drone received high praise for its "high speed, smooth running and lots of noise"! The latter comment was somewhat contradictory to the claim in the factory instruction leaflet, which implied that the engine was unusually quiet! Based on present-day testing, it was in fact somewhat quieter than the spark ignition competition.

In addition, a contemporary user's view of the Drone appeared in the December 1947 issue of "Model Airplane News". Author Jack Bayha commented as follows:

"We have been flying with the Drone for several months now and find its .297 displacement gives adequate power to handle ships which would be considered as excessively heavy for an equal displacement gasoline engine. We have had particular fun with Drone-powered P-39 scale models. The Drone can take these plastic prefabricated ships along at a lively 60 mph and has adequate power for stunts and emergencies. Leon Shulman's peppy little diesel runs equally well with a 10x12 or an 11x10 prop."

In view of all this promotional activity, it should come as no surprise to learn that the Drone quickly achieved a high level of acceptance among control-line stunt flyers, and users of this engine cleaned up at major stunt contests in America during the year of its introduction. The 1947 US Nationals and the prestigious Mirror Meet both fell to the Drone, along with numerous other lesser contests. The factory was kept busy keeping up with demand, and life was good!

The Drone even managed to cross the Atlantic and appear in small numbers on flying fields in Britain and elsewhere. The pioneering British power modeller Colonel C. E. Bowden included a very positive description and an illustration of the first model Drone in the 1949 second edition of his classic book "Diesel Model Engines". He reported having used the engine successfully to power an 8 foot span free flight model—an impressive feat for a 5 cc motor.

However, all was not perfect. As the operating hours built up on some of the first-model Drones which reached the hands of active competition modellers who did a lot of practising, it became apparent that the main bearing was not up to the job in the long term. The journal was very large by the standards of the day and one would have expected the shaft to wear very well in conjunction with its bronze bushing, but apparently it didn't.

In hindsight, the problem likely arose from the fact that the fuel tank arrangements used at the time were such that part of every run in a model was unavoidably spent in a lean-running condition, and lean running of the Drone was accompanied by a considerable amount of detonation of the rather volatile ether fuel. This detonation clearly gave rise to internal shock loadings which the best of bearings could not absorb forever. In addition, there is a suspicion that a higher percentage of slightly heavier oil might have done a better job of protecting the bearing. I usually run my first model Drones on 30% oil of SAE 30 viscosity.

As the main bearing wore, the shaft was no longer constrained at right angles to the bore, and accelerated rod bearing wear naturally followed. As this occurred, the piston location at top dead centre became progressively lower, resulting in a decrease in the geometric compression ratio of the engine. This in turn naturally affected performance to some degree. In short, the engine would not hold peak performance over the long haul, although some of the lost performance could doubtless be recovered at least temporarily either by lowering the head or increasing the oil content in the fuel.

Having said this, we must point out that based on considerable personal experience of the engine, a first model Drone which is run in the optimum condition without detonation and with an adequate supply of good-quality oil appears to be good for many tens of hours of strong running. Even so, the bearings will likely wear out long before the piston fit is worn anywhere near to the point where a rebore is required—Drone pistons seem to last forever, and it's extremely rare to find one that is anywhere near clapped out.

Regardless, this wasn't good enough for Leon Shulman—he prided himself (with considerable justification) on building his engines up to a standard rather than down to a price! So he set to work to re-design the entire engine with a view towards rectifying the problems which long-term use of the first model Drone had uncovered.

The result was one of the all-time classic model diesel engines, regardless of origin. Let's take a close look at it.

The Second Model (ball-bearing)

The second model Drone, often referred to as the Drone ball-bearing model, was far from being a minor revision of the first model. As can be seen from the attached promotional view of the two designs, it was in fact an all-new production throughout. Difficult though it may be to believe, the only interchangeable part between the two models was the prop washer!

The new model, which was introduced in the second half of 1948, had the same bore and stroke as its predecessor but was changed in almost all other respects. It featured a completely revised one-piece main casting incorporating the crankcase, the backplate, the bypass and the cylinder barrel together with a left-hand side exhaust stack. In addition, the engine bearers were considerably stronger. The word "Drone" was cast at the front of the cylinder barrel rather than at the side.

The main bearing was now mounted on a separate cover plate which bolted onto the front of the crankcase with three long bolts and nuts. A gasket was used to ensure a seal. This arrangement allowed for the possibility of mounting the engine radially if desired. The venturi intake was cast integrally with the main bearing rather than being a separate screw-in item as on the first model.

The crankshaft journal diameter was unchanged from that used on the first model Drone, but the induction port was now a simple round hole, which gave slightly slower opening and closing of the induction system but was probably an improvement in terms of strength and was certainly simpler from a production standpoint. Given the engine's relatively low operating speed, the slightly less responsive induction system was probably not an issue in any case.

The same means of securing the alloy prop driver to the shaft were employed. However, the keyed shaft extension with its two flats had a larger diameter, with the centre of the driver modified accordingly. The former forward extension of the shaft to accommodate the actual prop was replaced by a separate prop bolt which screwed into a threaded hole in the front of the shaft. This was a good move, since a hard crash would now merely result in a bent prop bolt rather than a bent or broken shaft.

The most significant design change was the incorporation of a single ball race at the rear of the main bearing. It might be thought that this was done to reduce bearing friction and allow a higher operating speed, and this was no doubt a factor. But the main reason for this change was undoubtedly to extend engine life by eliminating the problem of excessive radial wear at the rear of the main bearing. In this respect, the change was extremely effective. The balance of the main bearing, which was of course far less heavily loaded, was left plain.

However, it didn't stop there—a further benefit conferred by the addition of the ball-race was even easier starting. Much of the challenge involved in starting large diesels of the pioneering era was due to their admitted tendency to "self-brake" during starting as a result of the relatively high compression resistance and bearing drag. This resulted in a tendency for the engine to fail to swing all the way over from the initial firing stroke to the next unless a sufficiently large prop was used and/or a really sharp flick was employed. Ron Warring actually included an accurate retrospective commentary on this issue in his March 1955 "Aeromodeller" test of the 5 cc Miles Special diesel.

Although the first model Drone was a perfectly straightforward starter, the ball bearing greatly improved the second model's ability to "carry over" during starting. The improved "flickability" of the new model also facilitated an increase in the nominal fixed compression ratio from 18:1 to 18.5:1, no doubt to bring it into line with the higher operating speeds of which the engine was now capable. However, fuel and propeller recommendations remained unchanged—the idea was to turn the same props at a higher speed.

No tank was supplied with the second model, probably because the first model tank was unsuitable for control-line stunt use and most had likely been discarded by their owners in any case. Many of the tanks seen today on Mk I Drones are latter-day replicas.

In terms of weight, the elimination of the tank was offset by the addition of the ball race, with the result that the new model weighed 278 gm (9.80 oz), a fraction more than its predecessor. The new model came in a rather flimsy fold-up box as opposed to the sturdy high-class box formerly used. The introductory price remained unchanged at $21.50.

The serial numbers for this model were relocated to the outer end of the left-hand mounting lug (facing forward in the direction of flight). The numbers for the second model Drone started at around 10,000 and went up to around 15,000. All examples of my past and present acquaintance are within this range.

The instruction leaflet issued with the revised model was if anything superior to that for the first model—it's hard to see how the manufacturers could have been any clearer regarding the correct approach to using the Drone. Anyone who read and followed these instructions should have experienced no difficulty in starting and running one of these units.

The second model Drone got off to a very promising start when a model powered by a pre-production prototype finished third in the control-line stunt category at the 1948 Mirror Meet. However, at this event the new model had to give best to its plain-bearing predecessor! Frank McElwee not only won the control-line stunt event using his "Defender" design powered by a first-model Drone (mounted in the upright position!), but also took first place in the radio control event using a first-model Drone-powered airplane! Needless to say, this was good enough to give McElwee the outright Mirror Meet championship for 1948! The old plain-bearing Drone "B-ee" still had a sting in its tail.

Despite its failure to defeat its predecessor on this occasion, it was immediately obvious to one and all that from the standpoint of its running and wearing qualities, the revised model of the Drone stood head and shoulders above the first version, and even that model had set a pretty high standard. Another extremely positive review soon appeared in the October 1948 issue of "Flying Models" (by which time the price had been reduced to $14.95) and many confirmed Drone users hastened to replace their Mk I engines with the new model. Life was still looking good for Leon Shulman and Drone Engineering!

From the purely selfish perspective of a present-day collector, this had one very beneficial effect—a lot of dedicated Drone users laid aside their first model Drones in favour of the new version, long before their first models had worn out and in some cases before they had even been run in! As a result, many first model Drones survive today in excellent running condition, never having come close to the end of their working lives during the year or less in which they were in use.

Gathering Clouds

So far, we've been chronicling a story of unbroken success! During its first 18 months, the Drone had achieved a contest record that was second to none and had been refined into a product that seemed capable of producing contest-winning performance indefinitely. Sales of the engine confirmed the extremely positive marketplace view of its qualities. Leon Shulman had every reason to feel proud of his accomplishments!

However, this happy situation was destined not to last—even while the Drone was maintaining its competition pre-eminence in 1948, a large black cloud was looming ever-larger on the horizon. At the very same 1948 Mirror Meet which had been so completely dominated by the Drone, contestants took note of a number of models which were flying very well indeed using engines which resembled the old spark-ignition models but appeared to run without any form of on-board ignition system. One of these was an unpretentious-looking sand-cast prototype of a motor which some initially took for just another slag engine but which was soon to become widely known as the Fox 35—the glow-plug had arrived!

The December 1948 introduction of the Fox 35 in production form, along with other similar glow-plug motors suitable for stunt flying, heralded the doom of the Drone Diesel. Not only were these engines significantly lighter than the Drone, but they pulled at least as well in flight and ran just as dependably. Moreover, they were cheaper. The Drone was still built very much up to a standard rather than down to a price, and quality of the Drone level doesn't come cheap. The June 1948 introduction of the $14.95 O&R 23 glow-plug model quickly forced Drone Engineering to reduce their price to match, but Leon Shulman was not prepared to countenance any accompanying reduction in quality to offset this. As a result, the profit to be made on the engines dropped to zero.

The blow was initially somewhat cushioned by the fact that Drone Engineering were not totally dependent on their engine manufacturing—they had diversified considerably by this time and were also producing kits, propellers, fuel and accessories to match their engines, including variable-compression diesel heads for the second model Drone and glow-plug heads for the first model Drone. It's a little odd to note in the latter context that complete engines were never sold by the factory as either variable-compression or glow models. One wonders why... but this information is authoritative since it came from Leon Shulman himself.

Bert Striegler has had some experience with the variable compression head for the second model Drone. He comments that the Drone factory head used a very short contra piston and most of them leaked excessively. Bert fitted one of his own second model Drones with a variable compression head of his own design and construction. This head has a brass contra piston which is fitted with a high temperature O-ring and is contained completely inside the head—a very similar system to that employed in the 1990's by Webra in their .09 and .28 bluehead diesels. The whole thing works extremely well with standard diesel fuel mixes. Bert's head does not leak and the compression control works smoothly. Bert finds starting much easier than with a fixed head and feels that the performance of the engine is enhanced by this fitting, although he agrees that a well set-up fixed-compression Drone was a strong runner.

Turning now to the Drone glow head, there's a fair bit of confusion surrounding the accessory glow heads that were supplied by Drone Engineering. This is due in large part to the fact that a fair number of second-model Drones were converted to glow operation by their owners—a very simple operation indeed for anyone having access to a lathe. Indeed, a number of individuals reportedly offered conversion services for these engines to assist those who were not equipped to carry out the work themselves.

Second-model Drones converted in this way still show up fairly regularly on eBay and elsewhere. This has led to a common belief that such heads were supplied by the factory for the ball-bearing Drone. However, according to Gus Munich, an original Drone user who drew much of his information from direct long-term contact with Leon Shulman, the accessory glow head was only supplied by the factory for the 1st model Drone. The intent was evidently to provide owners of the then-redundant 1st model Drone with an opportunity to breathe new life into the design through the switch to glow-plug ignition.

The genuine Drone glow heads were simply standard 1st model heads which had a centrally-tapped and smoothly contoured recess added to accept a standard glow plug. They also incorporated an internally-machined groove surrounding the glow plug hole in order to lower the compression ratio. The resulting combustion chamber configuration could scarcely have encouraged efficient combustion, however the engines did apparently run reasonably well in this form. Thanks go out to Bob Allan for the attached image of an original example of one of these heads.

The converted heads were not anodized, being left in their plain aluminium finish to distinguish them from the diesel heads. The selling price of these heads was $2.25. There have been a few previous reports that such heads were also supplied in red, but Gus stated directly that this is incorrect—only the plain finish was supplied by the factory. Any red-anodized heads are therefore the work of later owners.

There was also a so-called "free-flight attachment", the price of which was $2.00. This was not an R/C throttle but rather a device to allow the operator to control the engine's power output for free flight testing purposes. Because of the absence of a compression control, the Drone was pretty much a one-speed engine on a given prop, so this was a useful accessory.

The device clamped onto the venturi much like an R/C carburettor. It had a coarsely-threaded plunger which could be adjusted on the ground to partially close off the venturi air and slow the engine for initial test flights. The unit also doubled as a timer, since the plunger could be fully released by activating a spring clip, thus completely closing off the air supply and stopping the engine. This function could be activated using a pneumatic timer or similar device.

The End of the Road

The Drone didn't die overnight following the introduction of the all-conquering Fox 35. It was after all an established winner which had swept all before it during the previous two seasons. The substantial army of dedicated Drone users had become well versed in the engine's unique operating requirements and initially stuck with what they knew. As far as they were concerned, the new type of engine had yet to prove itself.

Consequently, the market for the engines and accessories was maintained at least for a while, and the fuel in particular continued to be a steady money-maker for the company. The kits had some ongoing success as well.

This kept the Drone Engineering company going for a time, but it didn't take long for the new-generation glow-plug engines to prove themselves even to the satisfaction of dyed-in-the-wool Drone enthusiasts like Gus Munich. As the 1949 season got into its stride, more and more people progressively (and in some cases reluctantly) switched to the new glow-plug models. Naturally, the demand for the Drone engines, fuel and other products dropped accordingly.

By mid 1949 the writing was on the wall, and Leon Shulman wound up the Drone Engineering business in that year, having produced only some 5,000 second model Drone Diesels.

Reminiscing years later, Leon recalled that some of the later second model Drone castings never received the black anodizing treatment and ended up being sold as complete engines in their natural finish. Accordingly, it is possible that one may encounter the occasional second model Drone with natural finish castings. I've never seen one myself, despite looking long and hard, so there can't be many such engines out there. However, the possibility exists.

Once again, the present-day collector is well served by the fact that the second-model Drones were practically bullet-proof and also had an even shorter working existence as a leading contest engine than their plain-bearing predecessors. Accordingly, many of the 5000 engines that were produced remain in circulation today in excellent operating condition.

Gus Munich reported that just before Drone Engineering ceased operations they made a single prototype of a Drone 49. This apparently had an un-anodized case which resembled that of the first model, the main difference being that it accommodated a ball-bearing shaft. A screw-in venturi was used, again like that of the first model Drone. The engine retained the familiar tapered cylinder and head, but the head was held on by 8 screws instead of the former 4. "Drone 49" was cast onto the surface of the cylinder. Sadly, this new Drone model never saw the light of day in production terms.

The wind-up of the Drone Engineering business was by no means the end of Leon Shulman's involvement with the model aircraft hobby. On the contrary, when viewed in the context of his lifelong achievements in the field the Drone venture appears as merely an interlude! Leon continued a very successful career in various capacities connected with the marketing side of the model industry, rising to the position of Vice-President of Monogram Models at one point in his career. He also continued his successful participation in model flying competition, primarily in the R/C field after 1951. A pdf file of his AMA autobiography may readily be accessed on-line by Googling "Autobiography of Leon Shulman" and hitting the "Quick View" option. Reading this document leaves one in no doubt at all regarding Leon's stature as a major figure in US modelling!

The Drone story didn't quite end at this point. In 1949, the late and much-missed Australian manufacturer Gordon Burford produced a fixed-compression diesel known as the GB Stunta-Mota. This engine was basically a direct copy of the second-model Drone with a few minor changes. It looked just like a Drone except for its plain aluminum head, a more rounded exhaust stack, a stiffening web cast behind the venturi, and the letters "GB" instead of "Drone" on the front of the cylinder. Far fewer of these were made than the original Drone, and the Stunta-Mota is a highly prized collector's item today.

Even on the home front, the Drone didn't die overnight. Gus Munich recalled that although he bowed to the inevitable by switching to the Fox 35 for competition use, he retained several Drone-powered models for purely fun flying. He was probably not alone—Gus was still using the Drone in 1980, having built an R/C model which was fitted with a throttle-equipped Drone, still running on ether with its fixed-compression head! A lot of his fellow fliers spent time wondering where in tarnation the plug was hiding!

The Drone story is a classic saga of a technically-successful product which achieved great things for a short while but undeservedly died before its time due to a sudden unforeseen change in the nature of the marketplace. This does not alter the fact that it was a very fine engine indeed which did (and still does) great credit to its designer and manufacturer Leon Shulman.

Using the Drone

We may as well start right out with a direct challenge to one of the most enduring myths about the Drone. This is its reputation as a "difficult" engine to start and operate. As we shall see in due course, nothing could be further from the truth provided the business of operating the engine is clearly understood and approached correctly from the outset. In the following section of this article, we'll do what we can to help would-be Drone operators get things off on the right foot.

In doing so, we recognize that we will have a fair measure of scepticism to deal with!! I recently ran across a thread on a US R/C site which discussed the Drone, mostly in very uncomplimentary terms which actually annoyed me very much! One poster claimed that the Drone simply would not start by hand but responded well to an electric starter (AAARRRGGGHHH!!! On a diesel; I ask you...).

Another claimed that it wouldn't run at all and that most buyers consequently threw them out in disgust as useless boat anchors! If that's so, why are there still so many of them in circulation today—who raided the trash bins of America? How did they win all those high-profile contests? Why, without exception, did all the reviewers rave about how good they were? And how did Leon Shulman manage to persuade 15,000 punters to buy them? Negative reputations travel fast if they're well founded, but good reputations travel faster!

The truth of course is that all of this is complete and utter nonsense, as the contest record of the Drone surely reflects. Such comments simply reflect the fact that the people making them were present-day R/C flyers who were tied to their electric starters and consequently lacked the required "feel" and specialist flick to start a diesel engine and/or failed to understand the special needs of the particular engine that they were maligning. The nay-sayers also probably used the wrong fuel—the Drone absolutely needs its special brew and doesn't respond at all well to more conventional present-day diesel blends.

Too much glow-plug operation can certainly rob you of your "flick", especially if you come to rely upon electric starters, but please don't jump on me for saying that, because I use and enjoy glow engines too, including several large and powerful units which I routinely hand-start because I don't own an electric starter! It's all in the "feel" and the flick, and there's no substitute for the direct feedback regarding the engine's condition that you get through your flicking finger! Heck, I've always hand-started my old McCoy and Nordec glow-plug racing 60's!

In reality, starting a Drone is almost absurdly EASY if (and only if) the correct fuel and prop are used and the appropriate procedures are followed! Having owned no fewer than 10 Drones in my time and having run most of them and flown a few of them with no problems at all, I feel well qualified to say that! And I'm not alone in my assessment—long-time Drone user and fellow enthusiast Gus Munich fully supported this view, as do the engine's stellar contest record and uniformly positive media reviews.

In his previously-mentioned 1981 MECA Bulletin article about the Drone, Gus recalled that stunt competitors during the Drone's heyday were allocated three flights, the third of which followed no set schedule but instead was specifically designated as a "novelty flight" in which competitors could basically strut their stuff in any fashion that they chose. According to Gus, who was himself a participant, most winning fliers elected to put on a "two handed" display of formation stunt flying using two models at once. The Drone was greatly favoured for this event in large part because of what Gus characterised as its "easy instant sure start" which guaranteed that both models could be started simultaneously—not always possible with the spark ignition competition of the day! Reconcile that with the negative views noted above.

OK, let's get on with an examination of the starting issue based on long personal experience. In actual fact, the techniques outlined in the manufacturer's instruction leaflet are both completely appropriate and clearly expressed, but it may help if we add a little background to those instructions.

As noted earlier, the two models of the Drone are quite distinct. The original plain bearing model was supplied with a fixed compression ratio of 18:1. This is on the low side for model diesel operation—even with ignition improver added to the fuel, high-speed diesels frequently require compression ratios of up to 20:1 to achieve the ignition timing advance necessary for optimum performance. But the Drones are definitely not high-speed engines, so the compression ratio adopted is well suited to their normal operating speeds and tailored fuel.

Despite these differences, the starting procedures for the two models are essentially identical. Therefore, the following remarks apply equally to both models except where noted.

The first point to bear in mind is that a conventional diesel fuel with kerosene and ignition improver should not be used in these engines—quite apart from the starting difficulties which will be experienced, serious damage will result if this advice is ignored. Readers who wish to know more about the reasons for this and other fixed-compression diesel anomalies are referred to our companion article on this subject and the MEN FAQ section.

The manufacturer's recommended fuel consisting of 75% ether and 25% mineral oil works well. The manufacturers recommended straight SAE 20 oil, but I've found that 20/50 mineral-based motor oil works just fine and probably improves cylinder lubrication due to its ability to polymerize to a higher viscosity at elevated temperatures. Straight SAE 30 mineral-based oil also seems perfectly satisfactory. The engines are very clean-running on this fuel—no castor gum to worry about!

The 25% oil content should be viewed merely as a starting point, since a degree of effective operating compression adjustment is possible by simply altering the oil content—more oil effectively raises the operating compression ratio, and vice versa. You may find by experimentation that your particular engine is happier on a modified oil content. However, any Drone in good condition will at least start on a 25% oil brew.

The greatest threat to our continued enjoyment of fixed-compression diesels like the Drone is the fact that pure ether has become extremely difficult to obtain today due to restrictions upon its availability arising from its use in illicit drug-manufacturing. Once again, the criminals win and the legitimate users lose.

The only alternative source of ether is automotive starting fluid, which seems to work reasonably well as a substitute provided it is of the high ether-content variety. In years gone by, more or less any starting fluid would work, but in recent years the ether content has dropped, in large part because of the use of such products as a source of ether for illicit purposes. Many such products (like the appropriately-named and doubtless-effective Australian product "Start, Ya Bastard!") have very low ether contents and are therefore unsuitable for this purpose. Check the official product information sheet before you buy.

Present-day starting fluids generally have a significant heptane component. Although heptane is a relative of ether which is a useable base fuel in its own right and has a relatively low self-ignition temperature (albeit higher than that of ether), its presence in the brew nevertheless seems to upset the apple cart by raising the self-ignition temperature of the overall fuel mixture. A recent test using Gunk Liquid Fire, which has 60% ether, revealed that the engine would start and run on this fuel but was not at all happy and showed clear symptoms of under-compression.

A further test using a fuel based on the Canadian-made starting fluid Kleen-flo Kleen-Start (manufacturer�s stock no. 730) gave far more promising results. The MSDS sheet on this fluid gives the ether content as between 40% and 70% ether—a pretty wide margin! Based on performance, the higher figure seems far more probable, at least in the tested sample, because the Drone started and ran very well indeed on this fuel, behaving exactly as if it was operating on a straight ether/oil mix. According to the information on the container (but oddly enough not on the MSDS sheet), the balance of the fluid is aliphatic naphtha rather than heptane. Perhaps this makes a difference.

At the present time in North America, the best available product is John Deere starting fluid, which has 80% ether and zero heptane. This appears to work as well as straight ether for all practical purposes. How long it will remain available is anyone's guess. I suppose that if ether ever becomes totally unavailable, we'll all have to make variable compression heads for our Drones and run them on conventional fuel, but it won't be the same.

North American users do have a further alternative at the present time. Allen Heinrich of Aerodyne in the USA remains willing and able to supply ready-mixed Drone fuel, just like the factory used to sell! He can make regular Drone fuel as per the original maker�s specification, but also mentioned an interesting alternative blend which he claims worked well in his own fixed-compression Drone. This blend consisted of 65% ether, 25% castor oil and 10% kerosene. I�d expect this fuel to run a little hotter and perhaps allow slightly higher revs. It appears that there may be room for further experimentation! Allen may be contacted at [email protected].

As of May 2010, Allen also still had a few of his very good variable compression heads for the Drone. These are available at a cost of $32.95 each plus postage. It�s not the same, but these are a good alternative if you want to run a Drone without all of the fixed-compression anomalies!

The one thing to be avoided at all costs when starting a Drone is flooding, because you can't back off the compression to clear the cylinder. This is another reason why the use of an electric starter is virtually a death sentence for any Drone—you may get lucky for a while, but sooner or later it will lock up or detonate and destroy its power train. I acquired one (cheap!!) that had been destroyed internally in that way (by the previous owner's own rueful admission). I made a new shaft and rod for it, and it remains my favourite "flying" example today, with many hours of trouble-free running to its credit!

To start from cold, it's actually best to set the needle if anything a little on the lean side (the opposite of the usual approach!). The makers recommended around 4 turns of the needle for starting, and this recommendation appears to work quite well for the most part if the needle valve assembly is original. At least it's a good setting from which to begin.

With the needle set and fuel in the tank, give one or two choked flicks on a full fuel line (just a whiff of fuel in the cylinder is enough given the very wide explosive limits of ether) and then flick smartly, putting a bit of energy into it. That's the secret—the flick has to be quite sprightly. If the needle is anywhere near right and the fuel is up to specification, one or two such flicks get it going every time—one of the easiest starting engines of them all, in fact, putting other contemporary large diesels like the notorious "K" Vulture to shame! Anyone who can't hand-start a Drone should stick to glows or electrics!

The Drone's response to the needle when starting is rather individualistic, like all fixed-compression diesels using an all-ether fuel. If the needle is set too lean, that's usually not a problem unless it's way too lean—the engine will start but will misfire and detonate while emitting puffs of white smoke. Despite this, it will keep going, allowing you the opportunity to open the needle for best performance. On the other hand, if the needle is set too rich for starting the engine may fire up briefly but will immediately stop. If it's way too rich, it may not even fire. This is why a slightly lean mixture is better than a rich setting for starting. Once the correct setting is established, the engine will generally start at its running setting.

Once running, fixed compression diesels respond very differently to the needle than their variable-compression successors. Misfiring and detonation with puffs of white smoke mean a lean mixture—pull the needle out until the engine runs smoothly without detonation and the exhaust clears. Go too rich and the engine stops abruptly with no warning whatsoever! The best setting is right in the middle between misfiring and cutting out. This setting is quickly found by trial and error. In this condition the engine will run extremely smoothly and will keep this up seemingly forever with no trace of sagging and a remarkably clear exhaust with little visible smoke.

Restarting when hot is more problematic—the residual heat in the cylinder tends to create a serious pre-ignition condition which can't be good for the engine's internals and is pretty hard on even an experienced diesel finger like mine! These engines are best allowed to cool almost completely between runs. Tales of using blow-torches or car exhausts to pre-heat the cylinders should be devoutly ignored! Remember that when used for their intended purpose as stunt engines, they were not required to make the instant hot re-starts expected of team-race engines, so this was not a problem in the context of their intended use.

I've found that the first model Drone actually operates best on a 30% oil mixture. This raises the effective operating compression ratio a little and the extra oil reduces the tendency of the fuel to detonate. Moreover, the plain bearing benefits from the application of the extra oil since wear in this bearing is devoutly to be avoided given the previously-noted effect which any such wear would have on the geometric compression ratio. Fortunately, the bearing is very substantial and it will take many hours of running to wear the bearing to the point where a problem develops as long as detonation is avoided, dirt and dust ingestion are minimized and the oil content is of sufficient quantity and quality.

The main limitation of fixed compression is that the compression ratio necessarily has to be set at a suitable level for easy starting. This means that it is bound to be too low for high-speed running. The ignition timing does advance somewhat as the engine warms up, with a consequent improvement in running at the upper end of the range, but the effect of this is limited. So fixed-compression engines have a very definite and rather narrow speed range in which they will operate efficiently, and this tends to be very much on the low-speed side.

The first model Drone seems to run very smoothly in the 5500—7500 rpm range, but starts to struggle with under-compression above that range, even when well warmed up. One contemporary tester reportedly rated it at 8,400 rpm on a 9 x 4 wooden prop and 4,400 rpm on a 14 x 8. The 9 x 4 is definitely operating past the engine's peak, which is probably around 0.2 BHP in the region of 6,500 rpm or so, and the 14 x 8 is unquestionably lugging the engine—a very bad thing to do with a fixed-compression design since pre-ignition is almost certainly occurring in this state and nothing can be done to alleviate this while the engine is running. I obtain around 6,800 rpm on the bench on a 10 x 8 wood prop (somewhere around 0.19 BHP), and would recommend that or an 11 x 7 as a very suitable bench test prop for this engine.

For control-line flying (for which these engines were primarily intended), one should aim for a ground speed of around 5,500 rpm or so. The makers recommended 10 to 12 inch diameter props for control-line stunt, with pitches ranging from 8 inches to 10 inches. The purpose-built stunt prop manufactured by Drone Engineering for this engine was an 11 x 10, and the present-day 11 x 10 Zinger wood prop seen in the earlier image appears to be a very acceptable equivalent. Failing that, a slightly cut-down 12 x 8 works fine. Or you may be able to cut down a larger prop of higher pitch. The trick is not to under-prop the engine and to use a high pitch for good airspeed at the relatively low revs at which the engine will deliver its best performance. Such large props will shift a lot of air—you'll be amazed at the static thrust developed! I don't recommend running a Drone below 5,000 rpm under any circumstances—at lower speeds the condition of premature ignition sets in, with potential harm to the engine.

The advantages of the second model Drone have been set out above. If you plan to do some serious fixed-compression running and/or flying, this is the motor with which to do it! In his previously-mentioned 1981 write-up, Gus Munich (whose all-time favourite engine this was) reported that he had a second model Drone which had over 500 running hours on it with no replacements! Only a man like Gus with 34 years of continuous experience as a Drone user at his time of writing could credibly make such a claim! My own "flyer" second model Drone has around 25 hours in my hands, and who knows how many hours before that? It looks its age but shows virtually no signs of internal wear.

The second model Drone has a slightly higher geometric compression ratio of 18.5:1, which allows it to keep running evenly at slightly higher speeds than the earlier version or alternatively allows the use of a fuel with a slightly lesser oil content—I generally use 25% oil in the fuel for my second model Drones, as recommended by the manufacturers. The same prop sizes as for the first model generally work, the difference being that the second model seems to be about 500 rpm up on the first model using the same prop. It probably peaks at around 6,800 rpm as supplied. Results from calibrated test props indicate a peak power output of around 0.22 BHP at this speed.

Gus Munich recommended setting the engine a little lean for take-off and allowing centrifugal force to richen the mixture in flight to smooth out the running. Personally, I've found that the use of a well-located Uniflow or chicken-hopper tank greatly alleviates the need for such measures since such tanks maintain a constant fuel head pretty much throughout the flight except insofar as manoeuvres may affect mixture. The trick is to locate the tank at or near the centre-line of the spraybar so that centrifugal force actually plays a minimal role in influencing fuel head relative to the spraybar.

If anything, the tank should be a little inboard of the spraybar centre, since (as Gus rightly pointed out) it's easier to adjust for a slight richening in flight than it is for a slight leaning-out. In a sidewinder mounting as used on a profile stunter (the recommended mounting position for the Drone), placing the tank in the usual position on the outside of the fuselage achieves this pretty well. The tank should also be tucked in as closely as possible behind the motor to shorten the fuel line and minimize the effect of manoeuvres on the mixture.

The motor should run smoothly throughout the flight using this approach, although it will begin to run lean just before the tank runs out, thus giving you plenty of warning that the flight is about to end. If it momentarily crackles and sends out white smoke during manoeuvres, this is merely a symptom of temporary leaning-out. Nothing to worry about—it won't stop and will pick up smoothly as soon as the anomaly passes! A slightly richer take-off setting may cure this as long as the setting stays within the rich-running limits of the engine.

However, the opposite effect can also occur—the engine may suddenly cut out altogether if it is run too near the upper limit of fuel mixture richness and a temporary manoeuvre-induced fuel surge makes it go even richer. If this occurs, you'll have to adjust the fuel system or take off at a slightly leaner mixture. But the engine actually has pretty good suction, and troubles of this nature can generally be overcome by test-flying and appropriate adjustment.

The other matter which may require adjustment is the prop. If the engine picks up on take-off to the point where it runs past the limitations of its fixed timing and misfires no matter how you set the needle, then you'll have to add a little more blade to the prop to slow things down to the optimum speed.

Being somewhat musically inclined, I use (of all things) a pocket harmonica to match the note of the engine as heard from the center of the control line circle. You want to be operating in the air at between 6,000 and 6,500 rpm, so you're looking for an airborne engine note somewhere close to A natural (6,400 rpm).

It all sounds rather complicated, doesn't it? However, you have to remember that the Drone dates from a time when modellers expected to have to expend a bit of effort to get things just right rather than having perfection supplied in a box. Indeed, the tinkering was considered part of the fun, a viewpoint which we seem to have lost in this age of instant gratification. In reality, once the overall system is fine-tuned, flying a Drone becomes smooth and trouble-free, as you'd assume when looking at the engine's contest record. It just takes a little time and patience, that's all.

The Drone as a Variable Compression Diesel

Following the original publication of this article, I contacted Allen Heinrich of Aerodyne to confirm the ongoing availability status of his Drone diesel fuel mix and his variable-compression heads. The fuel remains available to special order (June 2010), and Allen still had a small stock of his variable-compression heads as well. He was selling these at a very reasonable price of US$32.95 plus postage.

On confirming the latter point, I immediately ordered one of the variable compression heads to satisfy my own curiosity regarding their effect on Drone operation and performance. This arrived promptly by mail and proved to be a very well-made item. It was supplied complete, all ready to fit, and I immediately set about removing the fixed compression head from one of my well-used second model Drones and fitting the new component.

The Aerodyne head turned out to be a fairly close visual copy of the original variable-compression head made by Drone Engineering for the second model Drone. The Aerodyne component will fit both the first and second model Drones equally well, and my choice of the second model Drone for the test was prompted purely by the fact that it was this model for which the original factory variable-compression heads were produced.

The Aerodyne head is more or less typical of the kind of unit often used to convert glow engines to diesel operation. It consists of an aluminium alloy head member which is externally tapered and finned to conform to the overall Drone styling and is internally blind-bored to accept an aluminium alloy contra-piston with a synthetic O-ring seal. This unit sealed extremely well, with no trace of leakage when assembled. The head itself seals to the top of the cylinder liner with a gasket which is supplied with the kit.

A set of four 5-40 screws is also provided to secure the head to the engine, although Allen's instruction sheet correctly notes that many Drones encountered today are threaded 6-32, whether by the factory or by owners is unclear. The example that I chose to use for this test had 6-32 screws (as do most of my examples), and the holes (but not the sockets) in the Aerodyne head had to be very slightly enlarged to accept the Allen head items that I elected to use.

One somewhat irritating feature of the Aerodyne head is the use of an Allen-head �-28 UNF set screw for compression adjustment. Inserting an Allen wrench into the socket of this item on a large diesel which is vibrating quite noticeably is not easy, and making fine adjustments as the engine warms up is not facilitated by this system! I elected to make a conventional L-shaped compression lever typical of those used on many large diesels of the period. This looks good and works well.

I had seen postings on several model engine forums to the effect that the set screw on the Aerodyne head had a tendency to wander from its setting when the engine was running. One suggested solution was to drape a short length of thread (dental floss apparently works well) down the threaded hole prior to inserting the set screw. I have always preferred the solid assurance of a compression locking lever, so I made one up from aluminium alloy.

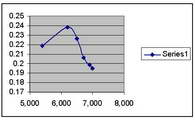

I arrived at the testing site on a fine sunny morning and soon had the fixed-compression example in the test stand. I used a fuel consisting of 75% John Deere starting fluid (80% ether) and 25% SAE 30 motor oil. As ever with these fine engines, it presented no difficulties in starting—all that was necessary was a few choked flicks on a full fuel line with the needle set a little on the lean side, followed by a series of hard un-choked flicks. Once running, it was extremely easy to set and ran very smoothly within the limits imposed by the use of fixed compression. The engine delivered a very stout performance> The following table and graph show the RPM figures measured and the power curve obtained after applying the power coefficients for the various airscrews.

|

The above curve implies a peak power output of around 0.240 BHP @ 6,300 rpm—somewhat above the manufacturer's claim for both figures. This is actually a very respectable performance for a 5 cc diesel dating from mid 1948! Running at the peak on the 12x8 was extremely steady and smooth, with no tendency to sag even after 5 or more minutes of continuous running. It was only on the smaller props in the vicinity of 7,000 rpm that some evidence of under-compression began to creep in, but this speed is well past the peak in any case. The fixed compression ratio seems well matched to the engine's performance characteristics on this fuel.

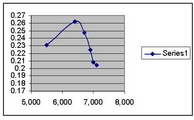

Next up was the variable compression version, which I tested on conventional diesel fuel with kerosene and ignition improver. Once I established the correct compression setting, I discovered that the starting technique for this one was pretty much the same as for its fixed-compression brother—a few choked flips and then a few more hard un-choked flicks, and away it went! In typical fashion for large diesels, the compression had to be raised a little above the running position for cold starting and then backed off as it warmed up. But this technique never failed to produce a quick start. Hot re-starts were very prompt with the compression left at running setting. Overall, in either fixed compression or variable compression form, the Drone must rank as one of the easiest-starting large diesels of them all!

One very pleasant surprise was the fact that my worries about the compression screw unwinding during running proved groundless. The compression setting held firm at all speeds tested while remaining fully adjustable at all times, and the locking lever that I had made proved to be quite unnecessary. As the earlier image shows, I had drilled out the center of my home-made compression lever and flattened the remaining surface to eliminate point contact with the upper surface of the contra piston, and perhaps this made the difference.

The fact that the conventional diesel fuel contains a substantial proportion of kerosene means that the fuel has a higher calorific value than the all-ether brew, and we would accordingly expect a little more power. We would also expect an improvement in the range of practicable speeds given the fact that we can adjust the compression to suit the speed on a given prop.

In practise, that's pretty much exactly what we get! The engine delivered an excellent performance, turning in the figures below.

|

As can be seen, the variable-compression Drone produced a peak output of some 0.265 BHP @ 6,500 rpm. The fact that the compression can be optimised at all speeds results in the engine being limited by its induction and transfer systems rather than by the compression ratio in combination with the other factors. It appears that the engine's pumping efficiency is at its maximum at around 6,500 rpm, which explains the fact that the peak is found at that speed using variable compression. The higher-energy fuel also doubtless played a part in achieving this result.

It's worth noting that this performance is at least as good as that of a K Vulture Mk II tested a few months previously. That engine delivered 6,500 rpm on the same 11x7 Zinger wood prop, 6,900 rpm on the TF 10x8 wood and 7,200 rpm on the 11x6 APC. So the Drone was definitely "in there" in the performance stakes for 5 cc diesels of its generation. There's no question that it delivers more low-end torque than the Vulture, just as you'd expect from its relatively long-stroke design.

The main limitation of the Drone for higher speed operation is the vibration factor. The use of a long stroke in combination with a relatively heavy piston and a plain un-counterbalanced crank disc means that vibration levels are starting to become fairly severe as 7,000 rpm is approached. Fortunately, the power curves show that there's nothing to be gained by running a Drone in either fixed or variable compression form above around 6,500 rpm.

On the basis of this test, I'd rate the Aerodyne variable compression head as an excellent accessory for the Drone diesel and as first-class value for money. It appears that the same props should work for the engine in either configuration, the difference being that the variable-compression version will most likely produced a few hundred extra rpm on a given prop.

I intend to leave my newly-converted example as a variable compression engine just so that I have the option. But I feel obliged to confess that I retain a perverse preference for running the engine on fixed compression, just to be different! The power differential isn't that great, the handling is excellent and there's something about seeing those puzzled faces and hearing those bemused questions: "Where's the plug? Oh, it's a diesel. OK then, where's the comp screw?

Conclusion

The Drones can best be summed up as well-made, powerful and dependable engines which are one or two-flick starters and will run forever if approached correctly and well looked after. If you follow the above procedures, they can be run with complete confidence. Examples in good condition remain relatively available at not too-outrageous prices, so by all means track one down, get some proper fuel together and give it a go—you'll be pleasantly surprised if you do!!

This page designed to look best when using anything but IE!

Please submit all questions and comments to

[email protected]

|

Unless otherwise expressed, all original text, drawings, and photographs created by

Ronald A Chernich appearing on the Model Engine News web site are licensed under a Creative Commons Attribution-Noncommercial-Share Alike 3.0 License. |

|