The Dart: 31 years of double top diesel history

OFW (Pete) Fisher reviews the Dart story

Editorial Note:

The following text, written by OFW (Peter) Fisher, appeared in the Aeromodeller, March 1985, p123.

Read it in conjunction with the D-C Story to gain a deeper understanding of the Allbon and DC Dart,

and if anyone can explain "double top" to us, we'd appreciate it!

ALLAN ALLBON, who produced his first diesel, the 2.8 cc Allbon side-port, at the Old Forge, Cople, Beds, subsequently manufactured the 'Javelin', 'Spitfire' and 'Dart' at the Allbon Engineering Co., in Sunbury in 1950-53. In 1953 the Allbon 'Dart' retailed at �3. 4s. 2d., including Purchase Tax. Shortly after this, Allbon Engineering was amalgamated with Davis-Charlton Limited in Barnoldswick and the above engines continued in production, together with the D-C 350 diesel, which Mr Davies was manufacturing. The Barnoldswick factory employed about 30 workers.

In about 1957, Davies-Charlton Limited, with Allan Allbon as chief designer, moved to the Isle of Man into a new 12,000 sq. ft. factory at Hills Meadow; and they also operated a neighboring factory of about 4,000 sq. ft., which was entirely used for model aero engine production. In about 1969, D-C Limited were operating all three factories, totaling about 31,000 sq. ft., and employing 140 workers. During this time they were probably the largest engineering company on the Island.

In 1972 the Barnoldswick factory, which had been doing sub-contract precision engineering work, was closed, and about 1974 the engines were moved to the large main factory of 21,000 sq. ft. at Hills Meadow. The lucrative sub-contract work for Rolls Royce and others terminated; so that by 1977, the D-C range of engines was the sole product of this works.

Following the demise of Mr. Davies; the works manager, Mr. Bill Callow, took over the production of all D-C engines, and a new company, Dav-Cal Limited was formed in April 1983. The old Davies-Charlton factory being sold. In 1984, Dav-Cal Limited moved to a new works, at the Loop in Douglas, where it is located today.

Allan Allbon left D-C Limited and in 1959 formed Allbon-Saunders Limited in Milton, Nr. Abingdon, where he produced the excellent AS 55 diesels until 1964. This firm is still very much operative, but sadly is no longer involved with engine production. It is celebrating its 25th year this summer. Performance Kits, who distributed the AS 55 to the model trade, were their first customers; and were pleased to be able to supply them with an original Allbon 'Dart' for their 25th anniversary Open Day.

At the time of writing Dav-Cal Limited are still making 'Dart' and P K 'Dart Special' engines, but in much smaller numbers than in the past. The last P K 'Dart Special' engine sold was serial number 97 and there is a long waiting list for this motor and also for the standard D-C 'Dart', the latest of a long line.

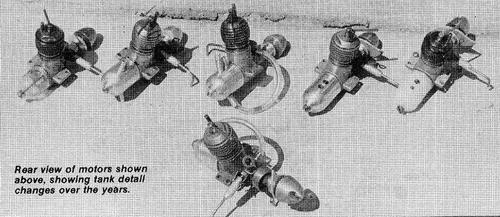

The top photograph, shows the 'Dart Collection' from left to right, and No.1 to No.6. The following chart identifies the main 'Dart' variants.

| Type | Head Shape | Color | Crankcase | Venturi | Tank | NVA |

|---|---|---|---|---|---|---|

| 1. Allbon | Barrell Fins | Green | Natural gloss | Reamed | Small clear | Brass |

| 2. D-C Ltd | Barrell Fins | Pink | Natural gloss | Reamed | Alloy/3 vents | Alloy |

| 3. D-C Ltd | Barrell Fins | Red | Vapour blue | Reamed | Alloy/3 vents | Alloy |

| 4. D-C Ltd | Parallel Fins | Pink | Vapour blue | As cast | Alloy/2 holes | Alloy |

| 5. Dav-Cal | Parallel Fins | Red | Vapour blue | As cast | Nylon/2 holes | Alloy |

| 6. PK Special | Parallel Fins | Gold | Blue anodized | As cast | Alloy or Nylon/2 holes | Alloy |

No.1, the Allbon 'Dart' has a readily identified large diameter drive plate. The spinners, featured in the photo, were supplied as an extra, when new, except for the 'Dart Special' which has an anodized gold spinner as supplied. The P K 'Dart Special' was introduced in December 1982.

The differing cylinder head fin profiles are due to the various lathes used in their manufacture. The earliest engines were made using Capstan lathes; Davis-Charlton then used Cam-Auto types, and these could have many tools fitted to the tool posts.

When the works changed to Plug-bored Controlled Autos, only four tools could be fitted simultaneously to the tool posts, and thus a change of head profile became necessary.

The early Allbon 'Darts' all had green anodized heads, the Davis-Charlton and Dav-Cal models using red. A few Davies-Charlton made 'Darts' had a pink head, and Dave, the current works manager at DavCal told me that Mr. Davies had a personal preference for these, which were first produced on a whim. . .

During the peak production of Davies-Charlton in the old factory, between 120-300 engines, of all types, were produced per day and every engine underwent a stringent pre-delivery test programme. The engines were firstly started using an air driven starter and then started at least four times by hand.

When the correct setting had been determined, the end of the compression screw was filed, so that it was in the correct position, relative to the stop-pin in the head.

Finally, they were washed in paraffin, before packing, Dav-Cal adopt a similar procedure today and all engines are hand started before dispatch. Dav-Cal recommend D-C 6 x 4 prop for general sports flying and easy handling of the 'Dart'. At their peak production, 20 workers were employed in the final assembly and test department.

In conclusion, I would like to thank Mr. Bill Callow, the current Managing Director of Dav-Cal Limited for the invaluable information which has made this brief article possible and also to thank him for his help in the restoration of our works museum 'Dart' engines, as illustrated. It is hoped that the D-C 'Dart' and P K 'Dart Special' will find appreciative homes for long into the future. The 'Dart' is perhaps the world's longest running production model aero engine, surely 31 years is a record!