Fergusson Condor

The Fergusson Condor was designed and manufactured by the John T Fergusson Company of South Bend, Indiana, circa 1936. It has a bore of 1.0 inch and stroke of 0.750 for a four cylinder displacement of 2.356 cuin (38.63cc) making it one big engine, right up there with the monsters powering modern R/C giant models. Fergusson also produced a two cylinder engine called the Falcon which shared the cylinder and piston assembly and some other small parts with the flat four. Factory documentation indicates that water cooled marine versions were available "to order".

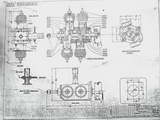

Internally, it's a rather conventional spark ignition two-stroke. The engine used a single, massive casting for the crankcase; most everything else being turned from barstock. The cylinders were turned from steel with a blind bore and brazed-on bypass covers. They were attached with nuts and studs that were a bit unusual being threaded 8-32 on the insert end and 6-32 on the nut end. The lapped, ringless pistons were fitted with bronze conrods that had a split big-end for assembly to the forged, one-piece crankshaft.

The four-throw crank was supported by single ball races positioned close to the two end crank-webs with plain bronze bushings where the double ended shaft extends from the front and rear covers. The rear end carried the twin breaker assembly which had to be easily removable to facilitate mounting using the bulkhead flange integral with the crankcase. In the center of the crankcase, the shaft was supported by a split "spool" which is relieved between the end faces to provide an inlet plenum. Once clamped around the shaft and inserted into the crankcase, the ends of the spool sealed against the crankcase bore to complete the inlet annulus and to isolate the front and rear cylinder pairs. Ports cut into the fore and aft flanges of the spool ends register with inlet ports in the crankshaft webs that bear against the spool. The crank throws are arranged so that when the forward pair are at TDC, the rear pair are at BDC. With appropriate arrangement of the ports, the end result is a pair of simultaneous firing twins that alternate, 180° apart.

The carby is centrally positioned over the crankshaft spool to alternately feed the front and back cylinder pairs. It is fitted with a rotating choke, but no throttle. Observant readers will probably have noted that the fore-aft, death-defying position of the needle differs from the safer transverse location shown on the factory 3-view. The position is dictated by bosses on the base casting, so the orientation is not optional. I can't guess why—surely no manufacturer could hate their customers this much.

The original engines were specified as weighing 56 oz and producing 1.6 BHP at 7,500 rpm. The ones in the photos are owned by Motor Boys, Eric Offen, and Les Stone. Les built his own engine—the one with the plain silver crankcase—from reproduction castings he managed to track down. Eric's came to him from the Miguel de Rancougne Collection and may be original, although he also has a set of castings under the bench for a rainy day. Strangely, so do I. Unfortunately, or perhaps fortunately, Australia is a rather dry continent.