The Atwood Story

Model Airplane News. January, 1979

Total involvement in all phases of the modelling hobby is the story of fifty years of Bill Atwood. Never satisfied, his was a constant search for a better engine, power and better reliability; nothing but the best.

As I write this account from information given to me by Bill, the world of modelers will be learning of the loss of one of its most prolific and successful engine designers. This article is a tribute to and a chronicle of the accomplishments of a man who was my friend for 32 years.

Behind William E. Atwood's mild-mannered, shy exterior was an intensely focused drive to win. At competitions he spent little time in conversation, for victory was his goal and careful attention to model performance was needed. People nearby would hear him mutter what, for him, was an eternal question, "Now, why did it do that?" Although Bill had other interests, flight was the chief one. At age 15 he built his first aircraft, a 20-foot Wright Brothers' hang glider, to fly with the Riverside, California, Glider Club.

Developing his flying skills, by 1930 he had earned some flight instruction in Curtiss "Jennies" and completed (in 16 months) a winning sailplane with a 60-foot wing. In 1946 Atwood decided to withdraw from competition in engine powered events, and he turned to indoor events. One of his peak achievements was qualifying for the V.S.F.A.!. indoor team of 1963, but unfortunately, the event was cancelled and he failed to make the team in 1964. The last years of his life he flew only R.C. sailplanes.

Other activity in Riverside of interest to young Bill was the new hobby of gasoline-powered model boat racing. A machinist friend, Bert Cundiff, was buying Westbury engine castings from England and making model boat engines. In 1928, after studying Westbury's articles and Bert's engines, Bill, with his perennial thought of "I can do better than that," designed his first engine. This 30cc displacement water-cooled boat engine was made with parts cast by Atwood in his back yard while still in high school. In Bert's shop he machined the castings and made other parts. The two-piece crankcase contained a crankshaft-driven rotary intake valve and supported a cast-iron cylinder with a screwed-on bypass passage. The aluminum piston had one ring and the combustion chamber of the head was contoured for better gas flow. For the next four years, he made and ran boat engines with local modelers, including Maynard Clark and Mel Anderson.

He also piloted "Jennies," flew indoor models, and competed at Pacific Palisades (near L.A.) in sailplanes he had built. Scaling down his aircraft in 1932, Bill built a nine-foot span model of spruce covered with butcher paper-for power, he designed a 30cc aluminum-case engine with cooling fins on the iron cylinder. This combination, consuming a quart of fuel, he flew for a 26-minute flight, even before Maxwell Basset gained notoriety with his gasoline-powered model. Unpublicized, though, especially in Riverside, was the fact that Atwood's plane made the flight carrying his neighbor's cat as cargo. His competitive nature spurred Bill to develop an improved aircraft engine in 1933, one which utilized an iron cylinder with a shrunk-on finned aluminum sleeve for cooling. He and Irwin Ohlsson took planes to the 1934 Nationals at Akron to challenge other engine-powered entries. Unfortunately, they mixed fuel using light grade oil and their engines failed to perform well in the hot weather there.

1935 was the year Bill Atwood won the California State Championship. He gave Mel Anderson half the credit for the use of shaft-rotary induction in the engine he designed to win the event. Major C. C. Moseley, an entrepreneur in the aircraft industry, bought the design and hired Bill to produce and develop the engine. Many student pilots at Grand Central Airport in Burbank, California, earned their instruction by working on Baby Cyclone production. Mel Anderson and Ira Hassad were employed there; Mel remained to design the Super Cyclone engine for Moseley. While working on Baby Cyclone production, Atwood continued in boat competition as well as improving his piloting skills.

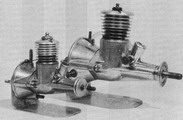

He took on the challenge of beating the 31 mph world record for boats held by Zukor of France. The engine Bill developed in his home shop was of 15cc displacement, air cooled, and had fore and aft dual-shaft rotary carburetion. In 1938 he achieved official record runs of 44 mph for % mile and 38 mph for one mile. These records remained unbeaten for five years.

Feeling financially unrewarded, Atwood left Baby Cyclones to Moseley in 1938 and went to work for Automatic Screw Machine Co. (Phantom Motors Division, Hi Speed Division). Here he made one of his most significant design innovations, first seen on the Phantom engine. Until then, induction bypass passages had been fastened to the outsides of cylinders by welds, clamps, or screws. BiII devised the "drop-in" cylinder, which utilized an extended crankcase casting to provide a passage for induction gas flow between crankcase and combustion chamber. This method reduced weight and distorting stresses upon the cylinder walls and is used on most present-day model engines, as well as on some industrial two-cycle engines. Production of the Phantom, Bullet and Hi Speed engines was so rapid that design flaws were ignored initially. Notable among these were too-thin heads, which frequently warped and leaked compression. To reduce corrosion of the magnesium castings, some models were given a crackle-finish paint coating. Until the Torpedo, Atwood's aircraft engines featured updraft intakes to prevent flooding by the gravity-fed fuel. When BiII left Automatic Screw Machine Company, he retained all rights to the Torpedo and Bullet designs. The Phantom P-30, Postwar Bullet 100 and Torpedo Special were not Atwood designs.

While still with Phantom Motors, he became interested in the race cars at the rail track of Tommy and Harry Dooling in nearby Culver City. Watching the Doolings and Dan Bunch running their Dennymite and Brown Jr. powered racers, he thought to himself, "I can do better than that!" In his home shop he built a 10cc engine which he installed in a Bunch car and proceeded to amaze the car buffs. By 1939 he had improved this design and was selling some completed engines, as well as casting sets. These engines were the Crown Champion series. Initially, he used sand castings with dual carburetors with drum type, and crank-shaft rotary valves. When dies were made, the "smokestack" single carburetor supplied both intake valves for car and aero versions. As a result of the success of the race car engines, two men, Shaw and Kaw, convinced Atwood to leave Phantom and join them to produce the latest Champions. Their association was brief. Bill then joined Wetzel to continue development and production until World War II intervened.

Bill worked as a toolmaker for a time, continuing with Champions as a hobby activity. When he became a glider pilot instructor for the Army Air Corps, Wetzel kept the dies and parts inventory, assembling a few engines from pre-war parts stock.

In early 1945, as war production was slowing down, metals were once more available in limited quantities. Atwood and Wetzel began producing Champion model engines. As this partnership split, each one thought that he had rights to earlier Atwood designs. During the war the dies for the Torpedo had been lost. Wetzel transferred the Torpedo to Miniature Motors; Bill sold the Torpedo name and good will to John Brodbeck (B of K & B), with a promise never to compete with John in the .29 class. In mid-1945, Bill set up shop in the Ace Model Shop in Pasadena, where he produced magnesium casting Champions. The Model H had a capped Meehanite piston and radial fins on the head. The change to Model J entailed streamlined fins on the head, a ringed aluminum piston and drilled cylinder ports.

Even with these alterations, production could not keep up with demand. Ken Adams had greater production facilities, so Atwood joined him in Burbank. A redesign at this time resulted in the model JH Super-Champion, with aluminum castings, higher compression, squared ports, and a smaller timer assembly. A straight-in carburetor was available chiefly for inverted operation.

The dissolution of this partnership resulted in reestablishment of Atwood Motors, at first selling Super-Champions, then, without timers and with the "inverted" intake, Glo-Devils. In 1948 Bill brought out the Triumph .49 and .51 in both spark and glow ignition versions. This design was used by Gene Stiles to bring to the USA the first Free Flight Speed record (81.587 mph) with his June 1949 flights. His plane was placed in the Smithsonian Institute.

Meanwhile, the appearance of the K & B Infant Torpedo opened up a new era in model power, made possible by glowplug ignition. Engine designers began thinking "small," Atwood included. Putting his head together with Bob Holland's resulted in design and production of the first Wasp .049's outstanding performers among the 1949 glow engines. When Wen-Mac and Jim Walker needed engines for their "toy" type airplanes, Atwood and Holland were the suppliers. They also produced B and B Timertanks (possibly inspired by the prewar Korda timertank). In 1953 Bill and Bob split over production philosophy, with Holland taking rights to the Wasp. Atwood continued to improve the basic design with versions named Atwood, Cadet, and Signature, all in .049 and .051 sizes.

He made a .15 version, but its power was not competitive and none were produced for sale. The Atwood outboard engine innovated coupling the air or water cooled power head (.049 or .051 ) to the propeller with a coil spring. They were marketed by Wen-Mac, for whom Bill designed a new engine. He also reworked Pagliuso's "Pogo" helicopter engine design. In 1955, to beat competing products, he designed the last of his own engines, the Shriek, first marketed in 1956. Following this, the shop was converted for production of the Jungle Queen, a steam-powered model launch inspired by the movie "African Queen." This venture ended in financial disaster and Atwood sold out in 1959.

Bill's ingenuity was thus available in 1960 when Roy Cox needed help with an .010 size engine he hoped to produce. Roy wanted to continue using reed-valve induction in all his engines, but the tiny one wouldn't work. He employed Atwood to find a solution. There might never have been a Cox .010 marketed if not for Bill's wish to coax enough power out of the reed-valved Olympic .15 to make Cox a competitive name in F.A.I. events. These experiments he did on his own time. He finally abandoned the reed valve and put a drum rotary (like Champions) in its place and used a different glow head. Because of the significant increase in power, Cox was persuaded to produce a few for use in F.A.1. competition. The front rotary experiment was almost abandoned during testing, because Bill was using a stock head instead of the "hot" one. He then sold Roy on the idea of the front rotary valve for competition engines, designated the Cox "TO" line. Applying this design change, Atwood's first handmade tapered-cylinder .010 prototype ran at a steady 26,000 RPM. To successfully produce this tiny engine called for holding tolerances up to 25-millionths of an inch. Toward keeping Cox engines in competition, Bill developed .35 and .40 engines, of which a few were given to prominent modelers for field testing in 1967 and 1968. Predictions for sales volume versus production cost were unfavorable; therefore, this excellent engine was never marketed. From 1970 on, Bill Atwood was Project Engineer for Cox.

During those years he designed a pull starter for cars, helped develop bicycle and industrial engines, and directed upgrading of the model engine lines. The Cox Conquest .15 was the last Atwood design to go into production. Bill retired in 1975 but remained a consultant to Cox as the Conquest production progressed. He was thus active as a competition pace-setter until his death on April 28, 1978, 50 years after he built his first engine.