Building the Little Dragon, Page 8

The numbers on the photos correspond to the text.

Click on a photo to view it larger size.

Click on a photo to view it larger size.

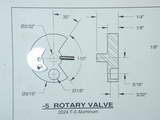

Rotary Valve

Another deviation from the plan: the original design turns the valve pivot pin integral with the valve. Alas, I could not force myself to do this for a number of reasons. One, I'm cheap, so turning all that barstock into swarf offends me. But more importantly, it prevents the face of the valve from being easily lapped flat, which aids sealing the valve while it needs to be closed off during primary compression and transfer. So I made a separate valve and pressed in a 3/32" diameter drill-rod pivot pin.

Piston 1.

Piston 1. |

Piston 2.

Piston 2. |

Piston 3.

Piston 3. |

Piston 4.

Piston 4. |

Piston 5.

Piston 5. |

- Being blessed with a mill, I've reduced some aluminium bar to the 9/16" valve diameter, then nibbled away the valve opening with a 1/8" slot-drill to a depth slightly greater than the final valve thickness. While setup for this, the blind recess for the drive pin was milled, then into a radial slot in case the position is slightly out of alignment with the crankpin when assembled.

- What can I say? The valve is parted off. It's also drilled #42 for a press fit of the pivot.

- After parting off, the rear face of the valve was lapped on a piece of 600 grit wet 'n dry, with some oil, on a flat surface.

- Here's the valve and pin ready for assembly. Some question the "fully floating" design, but this will not be a problem. Yes, it can be sucked off the mating face, but think about it. This could only happen while the piston is rising and the case is at lower pressure than the outside atmosphere. But during this time, the valve is open, so we don't really case. As the piston descends and primary compression builds up, the valve will be forced against the seat on an oil film, so good things happen. Almost like a reed valve, isn't it?

- And here's the stack of moving bits (the front case flange has not yest been drilled for the attachment screws). The rounded end on the valve pivot pin is just to make it easier to insert into the hole in the back of the crankcase. I've been quite cride on the valve opening sides. These could be feathered, as done on some racing engines, but I doubt you'll be able to measure any change in performance.