MODEL

|

|

|

|

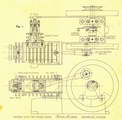

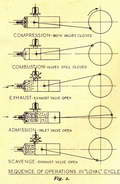

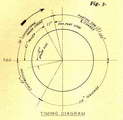

IN A RECENT BOOK on the history of the internal combustion engine, it is stated that its practical development "really began with the introduction of the four-stroke cycle". Though there were several engines which worked with a fair degree of success before this date, their efficiency and economy was limited, and they became obsolete when in 1876 Otto demonstrated the advantages of compressing the charge prior to ignition. This could most readily be accomplished by adopting the four-stroke cycle, in which the cylinder of the engine served half its working time as an air compressor. To adapt the principle of pre-compression to an engine which would fire once per revolution it was necessary to provide some extra means of charging the cylinder. The two-stroke engine by Dugald Clerk, patented in 1881, employed a single-acting charging cylinder, driven from a separate crankpin, suitably phased in relation to the main crank to transfer the charge to the working cylinder. James Robson, whose patent pre-dated that of Clerk by two years, employed a cylinder similar to that of a double-acting steam engine, in which the front end was closed so that it could be used as a charging pump. The structural design of these engines followed the traditional features of steam engines, including open cranks and other working pans (this incidentally applied also to the original Otto engine), but Fielding's engine of 1881 employed an enclosed crankcase which served as the charging pump, and this was followed up, with further simplification of working parts, by Day in 1891. These principles, with various modifications, have been the basis of nearly all two-stroke engine designs ever since. These historical facts have already been referred to in the first article of this series, but I repeat them here to avoid any possible misunderstanding regarding the distinctive features of the particular unorthodox engine I propose to describe. In the last decades of the 19th century, there was an abundance of inventions relating to internal combustion engines, most of which sought to exploit the advantages of pre-compression in some form or other. Some of them had a brief period of success while the Otto patents were valid, but failed to achieve a sufficiently high standard of efficiency to ensure their survival. They were however, a distinct advance on the earlier "atmospheric" engines which they superseded, and in a few cases their economy and reliability compared favourably with other forms of motive power. Some time ago, Mr Arthur P. Stone, of Elfers, Fla., U.S.A., sent me a photograph of an engine he had built, in which the working principle follows that of an engine manufactured in France some 70 or 80 years ago. It occurred to me that many readers of M.E. would find this engine interesting, and in view of its inherent simplicity, might be prepared to essay its construction. Mr Stone has kindly permitted me to copy his working drawings, which I reproduce, with only a few minor modifications and Anglicised details such as screw threads and part details. The prototype on which the design was based was defined as "Systemé Loyal", but despite many enquiries through museums and archaeological institutions, I have not been able to find out anything about the engine or the firm who manufactured it. Perhaps there may be some readers better informed in these matters who may be able to supply this deficiency. I may, however, mention that a small gas engine working on a very similar principle was manufactured in Britain by Messrs. Hardy and Padmore, under the title "Ideal", and I described this in a pre-war article. It differs from the "Loyal" engine in one more or less important detail, but its cycle of operations is identical. The general arrangement of Mr Stone's model is shown in Fig. 1. It has a horizontal cylinder, 1-3/4 in. bore by 4 in. stroke, (46 x 101.5 mm.), giving an effective capacity of 78 cc, and a compression ratio of 5.3 to 1. By modern standards, it is a slow-speed engine, achieving a maximum of 1,600 r.p.m., and a range of working speeds between 500 and 1,200 r.p.m. Mr Stone states that it runs very smoothly and reliably, and can be slowed down to 400 r.p.m., without misfiring—a feature which is exceptional for two-stroke engines of normal design. It is fitted with an inlet and an exhaust valve, both of which operate automatically and do not involve the need for cams or other mechanism. The sequence of operations in the "Loyal" cycle is shown in Fig. 2, and the first phase shows the piston nearing the end of the compression stroke, with the engine running in a clockwise direction and with both valves closed. In the second phase, the compressed charge is ignited by the sparking plug (not shown) and the resulting expansion produces the motive force. Shortly before the middle of the stroke, the exhaust port in the cylinder wall is uncovered by the piston, and the exhaust valve is lifted against its spring loading, to allow the products of combustion to escape. As soon as the pressure is released, it closes again, and for the rest of the outward stroke, a partial vacuum is produced, so that the lightly loaded inlet valve opens to admit a fresh charge from the carburettor or gas mixer (not shown). Mr Stone's diagram shows a fifth phase of operation, in which the return stroke of the piston produces sufficient increase of pressure to lift the exhaust valve a second time, and thereby scavenges or clears out more of the residual gases. My personal opinion is that this action is somewhat dubious, because the momentum of the incoming charge would keep it flowing till well past the outer dead centre, and if the pressure on the return stroke became high enough to lift the exhaust valve, it might just as likely cause loss of useful charge, as expel the exhaust, before being trapped by the piston. But this is a point which could only be settled definitely by indicator diagrams, or possibly stroboscope observations of the exhaust valve motion. There has always been debate about the extent to which stratification of the charge does or can take place in i.e. engines; and most of them, especially two-strokes, cannot be completely scavenged, but suffer some admixture of exhaust with the fresh charge. The timing diagram, in terms of crank angles, is shown in Fig. 3. The essential difference between the "Loyal" and the Hardy and Padmore engine is that in the latter, the exhaust valve is of the hinged flap type, and is gravity loaded instead of having a spring. But in ether engine, somewhat less than half the swept volume of the cylinder is effectively used for compression, combustion or induction. For this reason, the engine would inevitably have a low volumetric efficiency, but this does not necessarily mean that its economy or thermal efficiency would also be poor; and its mechanical efficiency is definitely good because of its simplicity. A larger cylinder volume is required to obtain comparable power output to that of orthodox engines, but unless any restrictions in this respect are imposed, that is not a disadvantage.

|

||

Edgar T Westbury, November 1968 |

||

Ref: ME 3357 |

||

Back to the ETW Home Page

Back to Model Engine News Home

Please submit all questions and comments to [email protected]