Editorial

Spring has sprung early in my little corner of the Wide Brown Land Downunder. Wait—forget spring, feels more like someone threw the switch to summer by mistake. What we laughingly call winter usually has it's last ghasp in August, but not so this year. The skies are deep blue and cloudless with temperatures rising as high as 27°C during the day (call it 80°F). It's my fault, you know. Just before the end of July, I ordered two cubic meters of firewood, then spent two days lugging it up our 1-in-1 slope driveway to the house. So far, haven't needed to burn any of it, and won't until next year. So, as we see here, I'm getting in some shop time before it becomes too hot!

This issue was produced almost entirely on my Macs; the only time MS Windows got opened was for driving the scanner, and I'll get around to moving that to the OSX world soon, too. For what are probably obvious reasons, before retiring from the academic life, I bought a copy of Adobe Creative Suite 5.5 for the Mac. One of the obvious reasons is you need to be retired to have enough time available to learn to use Photoshop! But I've made progress and all images included with this release have been "photoshoped", rather than the quick and dirty ACD photo editor I've been using since the beginning of time. I hope you don't immediately notice the difference as I'm trying for a subtle improvement, rather than the flashy and false look that can be all too easily created with this tool.

While making a minor correction to the May, 2007 Editorial page, I noticed a comment I made way back then (5 years seems like an age) about reading on-line. My, what a difference a few years can make. In 2007, I concluded that reading in bed using a laptop was too uncomfortable. Well who could have predicted touch-screen tablets? For bedtime reading—and all other times too for that matter—I use my iPad more than anything else, whether it's on-line via the household WiFi to text books on the O'Reilly's Safari service, reading magazines such as new and old issues of the Model Engineer and Model Engineer's Workshop, accessing the web, or reading downloaded material from Amazon (Kindle), Apple's iBook store, or making the odd eBay purchase. I'm so addicted, I've even downloaded novels from Amazon when I already have a paper copy in The Library! Using a tablet means I never loose my place by falling asleep, nor need a reading light that attracts grumbles from the Other Side. I've even been so decadent as to answer emails on it while relaxing in our spa! Perhaps it's not for everybody, but it sure works for me.

It also looks like I'll be needing a new digital camera. The Nikon Coolpix 950 I bought way back in 1999 on Bert Streigler's recommendation went walkies late in the month, courtesy of a brick through the window of our sun room at 4am. Looks like a prowler spotted the Macbook Pro and camera on the table and was overcome with envy. I heard the noise, said to myself, "bloody cats", rolled over and went back to sleep, to be woken again at 6am by the police, who'd been called by a neighbor. So far, that looks like all that's missing, hopefully. The Macbook will go into lockdown the next time it's connected to the Internet and I'll get an email with the location, so vengeance may yet be enjoyed. I sure hope so, as setting up a new laptop is lengthy and tedious. Will have to see what the insurance company says about a digital camera that cost nearly a grand, over ten years ago. Today, they seem to give them away in cornflakes packets, so I'm not hopeful of replacing the lost quality without dipping into my own pocket.

Vale, Robert Hughes

Australian born Time art critic, Robert Hughes, died last month at 74. Obituaries and tributes to him have flooded the media both here and in the US, so I won't bother detailing his achievements, except for one which, as far as I can tell, only the Sydney Morning Herald (on-line edition) hinted at; the young Robert was an aeromodeler! As we see in this photo, he is holding what appears to be a small control line model, powered, if I'm not mistaken, by a Mills 1.3. The design is not one I recognize, so perhaps it was his own, seeing he later became a drop-out architecture student at the University of Sydney. One tribute I heard on radio described how he became an art critic. His editor, returning from a long pissy lunch, exclaimed, "I've just fired the art critic. You! Cartoonist! You must know something about art—you're the new one!" And the rest, as they say, is history.

BJ Cicada Progress

During the past month, the neat little 1.3cc piston ported diesel designed by Chris Boll and Rob Jenkins has been fully modeled in Alibre (easy, quick), and fully dimensioned plans created from the 3D model (long, tedious). The image here has had many of the components rendered "translucent" to show how it goes together. As mentioned before, there's no thread cutting required—apart from tap and die work. However, it does require silver brazing. This is not hard, but some practice and experience are required—luck will suffice—to produce a neat job. The most complex part is the needle valve and spray bar assembly. I've simplified the design here by using a piece of threaded rod (2-56, rolled) for the needle. The super nice one on Rob's prototype was turned from stainless steel rod, reduced in diameter to produce a neat thimble on the end, and threaded M2.5x.4, roughly equivalent to a UNF 3-64, if such a thing existed. I'll show Rob's original as an option, but trust me, going the threaded rod rout is much easier and will do the job just fine.

As I see it, one advantage of 2D CAD over 3D "parametric" CAD is with 2D, you can produce precisely the drawing you want, with exactly the layout and information you want—even if you have to "lie" to do it. With 3D, you can't lie and must in some cases, accept what the package restricts you to. I'm not sure if this is good, or bad (ok, now I lie, it's bad). So the drawings look good, but they don't and can't contain all I'd prefer for a beginner. I've not been counting, but a quick scan suggests that I've produced over 70 engine drawing sets over the years, and if I've learned one thing, it's how easy it is to omit a critical dimension. So prudence will be the byword and I'm going to make one from my own drawings before releasing them to you. Naturally, photos will be taken and a construction series produced, in fact, I've already started as we can see in from the photo in the Editorial. Sad thing is, I've had to use my iPhone to do the crankcase construction photos and either I don't know how to use it, or it's just is not up to the sort of things we need for engine making pics. Hopefully the insurance company will come through with a new Nikon before long...

Firefly Developments

One set of plans which are now well and truly nailed down are those for Alex Whittaker's Firefly .46R/C. Alex tells me that sixty (60!) materials kits for this engine have now been sold, and that so far, every completed Firefly has run first time. Even better, he has generously offered to allow Model Engine News to operate as a "second source" for the plans so that they achieve the widest possible distribution and hopefully give others the urge to have a go at a proven and practical design. This seems like a superb idea, so we'll be adding the pdf planset to the MEN Plans page later this year.

But wait... as they say. Alex has a new design in the pipeline which is intended as a practical, 5cc old time R/C engine. The retro motor is piston ported (aka "side-port") that can be built as a diesel, glow, or spark ignition, using alternate heads. Meanwhile, the Firefly group is hard at work on variations of the basic design and are constructing a two-stroke Twin and a four-stroke Firefly. Alex himself will be giving a lecture on the SMEE stand at the Model Engineer Exhibition which this year, will be held on November 2-4 at Sandown Park Racecourse. The SMEE stand always demonstrates Model Engineers in action and word is, this year, they will be building Fireflys (Fireflies?), live, as you watch. I suspected that Alex's design would trigger an upsurge in model engine building and this is one of those times it looks like I got it right! Well done, Alex.

The Fox Twin

Continuing our expansion of the reviews written by the late David Janson, his ninety-second review was about Duke Fox and his 1978 Fox 1.2 cuin twin cylinder glow engine. The engine was not a terrific success, arriving just before the "chain saw" brigade gained strength, and having some initial carburation problems. Janson's review begins with an encapsulated biography of Duke Fox and Fox Manufacturing in which he pulls no punches, making mention of "that" incident, not generally spoken of in refined company. Still, facts are facts, and if we take it on ourselves to white-wash history, erasing mistakes, how can future generations learn? So enjoy his unedited story, as we segue neatly into the next item.

More Mixtures

Some more trolling through issues of Model Airplane News of the late 1980's has found two more instances of "Duke's Mixture" which engine people may find useful, or thought provoking, or both. First, there's his January 1989 column on engines which "sag" under acceleration, and an unconventional solution for them. Then, there's his December 1988 column on "crankcase stuffing".

Years ago when George Aldrich was still with us, he related (by email to our Motor Boys Group) how he and Duke had conducted experiments to see if reducing the crankcase volume actually did increase the power output of our crankcase-charged two-strokes. This was a practice supposedly used by some control line stunt fliers of note to "hot-up" engines like the Fox 35. Well, as you'll read in Duke's short article, and as related to us by George, it did not work. In fact, it resulted in less power. I believe the reason is that while increasing the primary compression may improve suction, the lowered crankcase volume reduces the weight of the available ideal fuel/air mix. The stoichiometric ratio for methanol is 6.45:1, so if we reduce the amount of air that can be held in the crankcase when the piston is at TDC, we have to reduce the amount of fuel in that air as well. This may explain why Duke found that increasing the crankcase volume resulted in a slight rpm increase. Duke's experiment was static. How an engine with increased crankcase volume and lowered suction was going to perform in a tight square corner turn might be another matter. However the take-away is that model engine design is full of trade-offs, and this is another of them.

Incidentally, while assembling this month's pages, I noticed that the site did not contain so much as a photo of the venerable Fox 35 stunt. Although the '35 has been done to death everywhere, this oversight has been redressed in a modest way. If you want more, I suggest you buy The Engine Collectors' Journal, Volume 36.

RepRap

Perhaps everyone on the planet knew about Reprap but me. Just in case this is not so, let me mention a model engineering device/project which blew me, if not actually away, then at least across the room and down the corridor a bit. The device in the photo is a 3D printer, and I'm sure you've all heard of those. What I was blissfully ignorant of was a project initiated by researchers at the University of Bath (UK) in 2005 under the guidance of Dr Adrian Bowyer. Their goal was to build a Rapid Prototyping machine (3D printer) which could "print" the parts required to replicate itself, hence "Rep Rap". The project has been a resounding success and how I missed knowing about it all this time, I've no idea. The device in the photo, named "Mendrel", comprises 8mm threaded rods and 8mm precision ground bars as axis sliders, held together with white plastic parts which were "printed" by another Mandrel. In fact, every white plastic component, including the gears, was made this way! The entire project, including the electronics and software is Open Source, and the software can be run by a Mac, Linux, or MS Windows. The control files are essentially G codes for 3-axis control, layered in 0.012" thick "slices".

If you want to build one, complete plans and instructions for different versions are on the Reprap Wiki. A check on eBay shows numerous entrepreneurial types offering Reprap parts printed on their own machines. Others offer complete or partially populated printed circuit boards for the controllers, so all you need do is to scrounge all the 8mm rod, the stepper motors, and all the other bits. Or you can order a complete kit of bits from numerous suppliers in several countries, most of whom also offer the ABS and PLA filament the machine uses to build up parts. I won't list the suppliers; there are too many and they are easy to find with a web search.

I came very close to ordering a kit, and still may. The blocker to the initial impulse was when I asked myself what I was going to make with it, not to mention where it would live when not in use—my house is just about full! The finish on the parts Reprap makes is not all that smooth. I can't see much use for it in model engine making, apart from novelty, and maybe the odd backplate, or carby body. ABS is reasonably resistant stuff. PLA is not and can be dissolved. There are "dual head" Repraps which allow you to load both types and "print" complex things—a ball race for example—as a solid part, then dissolve the PLA to free up the ABS parts. I don't think PLA as a wax substitute for investment casting would be practical due to residue and the solvents required which would make me very nervous about subsequently pouring molten aluminum into the investment! Still, you could make groovy fuel tanks in many colors with not much effort, or patterns for sand casting.

Another thing which astounded me as I dug further into Reprap and the many similar devices it has spawned is the dropping price of commercial 3D printers. I'd written them off as too expensive for the average model engineer's shop, but this is no longer the case. If you are interested in this technology—and I can't imagine any full blooded model engineer would not at least be a bit curious—start by googling "reprap" and fan out from there. Be prepared to loose a few hours in the process...

Persistence Pays

This little guy is a mini-Weaver made by Dave Miner. If you do a search for Dave on this website, you'll discover he has taken to the idea first employed by David Owen of making crankcases from an extrusion of aluminum in the shape of the cross section at the cylinder centerline (there's more on this in this month's Tech Tip. Dave Miner has a neat twist on the idea though, he used wire EDM to produce the crankcase blank in whatever size he pleases. The mini-Weaver follows his standard Weaver, and getting it running was not straight forward, but persistence has paid off, as you can read in the new Gallery entry on the engine.

Aircooled Aero V12 in 1/5th Scale

Last month, we added a link to a very practical V12 (meaning that it is intended to be flown, not looked at). It's called the Artus V12 and was so impressive that it deserves more than a quiet insertion into the Commercial section of the Links Page. The web site is multi-lingual with photos and videos, including one of a hand made, WWII era, German Tiger in 1/4 scale. One video shows a tread being removed, rolled up, and reinstalled. Looked like lifting the rolled up tread would cause back strain! Well worth a look to see what a pair of talented and dedicated model engineers can achieve.

New Books and Magazines This Month

For those out there who have chosen to make their home under large rocks in the desert, with no Internet connection, the Engine Collectors' Journal is the world's longest running publication dedicated to feeding the habit of, well, us! Since August, 1963, ECJ Editor, Mr Tim Dannels, has maintained a publishing schedule of six issues per volume, with a new Volume appearing almost every 12 months to 18 months, depending on when Tim's army of willing contributors could provide sufficient material to fill each issue's 14 pages. Tim assigned his first issue to Volume 2, since it carried on from pioneering efforts by Joe Wagner. The scan here shows the cover of Volume 2, Issue #1 which contained an article on the Feeney four-stroke, plus Tim's aims for the Journal's future. It's safe to say that forty-nine years on, these have been more than realized.

You can take your Journal as a subscription of six issues, or if you've the will-power for delayed gratification, order bound volumes. I prefer the latter format as it seems to make shelf storage and browsing easier for me. The latest volume is #36, covering issues 205 thru 210. Tim delivered this to me three times, with it being sent back twice. Since "here" is Brisbane, Australia, and "there" is Buena Vista, CO, USA, my volume must be one of the most well-traveled ever. But as always, the wait was worth it. There are too many goodies in Volume #36 to name individually. I've chosen two covers to give a hint, but if I have to mention one item in particular, it must be Bill Mohrbacher's coverage of the venerable Fox 35. In parts One through Four, appearing in Issues 206 through 210 (skipping 207), Bill describes the old Fox 35 stunt engine from it's "sand cast, 2-bolt" beginnings, to the 1980 model (as Bill explains in Part One, no Fox 35 was ever actually sand cast, it's just a label we're indelibly stuck with).

Tim sent me a sneak-preview of Volume 37 in the form of Issue #211 wherein Bill concludes his history of the engine with the "Anniversary" models. The first of these appeared in 1988 and had a "Blue Ribbon" cast onto the bypass, identifying it as the "40th Anniversary" model. Duke Fox passed away in 1991, so we could say that the 1998 "50th Anniversary Collectors' Edition" was a posthumous tribute. A special, serialized, "Collector's Edition" of this engine was produced with a black finish and gold plating on the NVA and screws. The tradition continued in 2008 for the 60th anniversary of this wonderful stunt engine. There have been many small changes over the years, and if you grab copies of the ECJ's mentioned and read Bill's work, you'll know all about it.

Volume 36 has a real international flavor, with engines from the US, Sweden, Germany, and Switzerland. There are aero engines, marine engines, two-strokes, four-strokes, Watzits, and Expo reports. A six issue subscription costs between US$20.00 and $25.00, depending on where you live. Bound Volumes run between $7.50 and $21.00 (plus extra for shipping outside the US). An up to date Index for all issues is available from Bill Bickel (must get me one of those). To order ECJ volumes, or subscribe, visit the Model Engine Collecting web site. As always, Five Stars  .

.

-oOo-

As mentioned in July, the Model Engineer has acquired the rights to publish all of the bar-stock four-stroke model engine designs by the late Malcolm Stride. The plans for the twin cylinder, air or water cooled 15cc Bobcat, and the companion 7.5cc single cylinder Jaguar are appearing now, having started in issue #4437. Even better, ME Editor, Dave Clark, has decided to present them as a full construction series, and as the Whittaker Firefly series has not yet finished, this means there are two IC engine construction series appearing simultaneously in the magazine. I could be wrong, but I think this is a first, and for a magazine that is more than 100 years old, that's saying something. For the impatient ones, paper copies of the plans are available from My Hobby Store (UK) for £49 + postage. As the drawings comprise sixteen A3 size sheets, that is a lot of paper, and does not include the machining instructions, which will add another 30 quid to the bundle price, and weight to the shipping. As I mentioned before, if this is beyond your budget, consider a digital magazine subscription for £29.95, including access to back issues. For a limited time, UK residents who subscribe will receive a free copy of Malcolm's Book, which contains nice things about me, plus some other stuff  .

.

Engine Of The Month: Bungay 600

Tether car engines were once big, meaning they were 60 sized and very popular. One which tried to compete with the rear rotary valve (RRV) Doolings and McCoys of the early 50's was front rotary valve (FRV) Bungay "High Speed" 600. Adrian Duncan's review of the engine includes a wealth of background information on the Bungay and the scene prior to and during it's brief moment in the sun. As well as the two famous names already mentioned, you'll meet Ira Hassard and learn about the FRV racing movement of the pre-WWII era. Adrian's report includes a test of a beautiful reproduction Bungay, which, as of August 2012, you can still order, New In Box (NIB)—I just checked and avoided spending dollars by the narrowest of margins...

Tech Tip of the Month

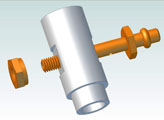

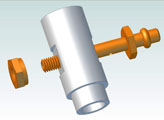

Wot's this, then? Easy. It's called a "manifold nut". They were once common in the auto industry, but progress seems to have put paid to that. The light aircraft industry, rather surprisingly, has not seen the same degree of progress—especially in engines—so the manifold nut is still common there. The one pictured here was lifted from the web catalog of Aircraft Spruce, a company which has been serving homebuilders and restorers since as long as I can remember (about 1968, when I started pilot training and found a copy of the EAA magazine in the flying club). If you live in the US, Aircraft Spruce is a great source for 2024 T3 aluminum bar stock, rod, and plate, and chrome-molly (4130) tube and sheet at good prices with fast delivery. Just the stuff for model engine building. End of unpaid commercial, and back to business: why have I drawn attention to the manifold nut, and what's special about it?

As a model engineer, experienced engine plan draftsman, and occasional engine designer, I appreciate elegant designs and solutions to problems. They provide healthy doses of humility induced by all the "why didn't I think of that?" moments, and sometimes allow me to solve similar problems in the same way. Here's an example: the venturi and spraybar designed by David Owen (see Owen Engines Australia), for his DIY Owen Mate 2cc diesel. David's design is loaded with innovation and ideas, starting with use of an extruded crankcase—made by the mile, sold by the yard, as an old mate used to say. As you can see on the Mate page, the extrusion is in the form of an engine cross section at the centerline of the cylinder. The nose is then easily machined by turning the extrusion down to a circular, tapered section. This is bushed for the crankshaft and drilled for the venturi, which is glued in.

Here's a CAD model of the venturi. Again, aiming at simplicity for first-time builders, Dave uses a simple, round design, drilled thru for the inlet, necked down for where it will glue into the crankcase, and tapered 60° at the inlet using a large center drill. The inspired bit is the two flats milled (or filed) on the sides. This provides a nice flat spot on which to spot the cross-drilling for the spraybar, and makes it easy to mark the center for the drill such that it will be in the middle of the venturi. Now look at the spraybar. This is turned from 1/4" AF (across flats) hex brass stock. The width of the milled recess is 6.4mm (.252"), so the spraybar is prevented from turning while the nut is tightened. Even better, David uses the alignment this provides to correctly orient the jet hole in the spraybar, making installation a no-brainer operation, as you can see in the illustration.

The down-side would have been tightening up the spraybar nut. This too is made from 1/4" AF hex brass, but in order to tighten a standard nut, the recess in the venturi would need to be at least 0.387" wide (to get the "outer diameter" of any hex section, multiply the AF dimension by 1.547). This would work, but means the spraybar could not be reversed. As you've probably spotted by now, David solved the problem with, wait for it, a manifold nut! This is shop made and is just a slice of 1/4" AF hex brass, drilled, tapped, and necked-down to a diameter of 6mm (.236") for a length such that the hex part will clear the venturi recess flat when tightened up. Works great and looks cool.

So cool in fact that I frequently draw up nuts this way on Motor Boy plans, even when they don't strictly need it—the jam-nut on the venturi of a side-port, for example. Well, not totally gratuitous as it turns out because as David explained when I asked him about this, there is another form of nut known as a "washer-faced nut". It's the same, except the height of the circular section is small, about that of a thin washer. The intent is to prevent it from digging in when tightened up. The Mate prop nut is designed this way, which is a really good idea when the prop washer is machined from aluminum, as it is on the Mate. To close off this tech tip with a pleasing sense of symmetry with other stuff contained in this issue, the photo here is not the Mate prop nut. Its a standard Fox 35 Stunt prop nut. Guess Duke liked the idea too!

Yet More Atom Minor

This month we continue Jan Huning's build of the Westbury Atom Minor Mk III with the Cylinder and cylinder head. Note the especially well made George H Thomas Universal Dividing Head being used to port the cylinder. I've made the headstock version of this amazing tool and have castings under the bench for the UDH itself. A lot of the parts are interchangeable between the two, so maybe someday...

Edward G Ingram on "Hot" Engine Design

In Yet Another of those serendipitous moments, while searching for something else entirely in a box of pre-1950 issues of Model Airplane News, I happened to spot an article on the design of "hot" engines by Mr Edward G Ingram. This made me look twice as Ed Ingram was mentioned in the text of Adrian's review of the Bungay which I'd just completed formatting. A quick scan of the material suggested it was well worth including in our Design Center topics, so it has been OCR'd to make the text searchable, and readable! As a footnote to this piece, and this month, I never did find what I was after during the old MAN trawl...

Briefly Noted

This section is intended to alert you to little things that are hard to expand to a full news item, or cunningly wind into the Editorial, but are worthy of note never the less.

- The Hornet page has been updated as a result of new information received from readers and a better images(s) of the engine fitted with the conversion kit.

- A link to the Ingram article on hot engine design has been added to the Design Center Index page—so has the index to Duke's Mixture.

- Seems I don't have the January 1961 issue of Model Aircraft, hence we missed the review of the KK Cobra in that issue when making the grand Model Engine Reviews Index. Our review, by Adrian Duncan, has been updated to reflect this omission (it used to say that Model Aircraft did not review the engine), but the Engine Review Index itself hasn't, yet.

- Last month, I said I was not completely happy with the answer to the Dual Ported Watzit. Well, I've split the "answer" off to a page of its own because the engine is interesting in and of itself, in both its two identities. The new page has been expanded to examine the technicalities of dual rotary valve engines. Still can't say I'm happy, but it's getting there.

- We've corrected the grievous error of calling Elmer Wall "Edgar" in the Suppliers Index page.

Vale, Robert Hughes

Vale, Robert Hughes

BJ Cicada Progress

BJ Cicada Progress

Firefly Developments

Firefly Developments

The Fox Twin

The Fox Twin

More Mixtures

More Mixtures

RepRap

RepRap

Persistence Pays

Persistence Pays

Aircooled Aero V12 in 1/5th Scale

Aircooled Aero V12 in 1/5th Scale

Yet More Atom Minor

Yet More Atom Minor

Edward G Ingram on "Hot" Engine Design

Edward G Ingram on "Hot" Engine Design

Editorial

Editorial

New Books and Magazines This Month

New Books and Magazines This Month

Engine Of The Month: Bungay 600

Engine Of The Month: Bungay 600

Tech Tip of the Month

Tech Tip of the Month

Briefly Noted

Briefly Noted

Standard Stuff

Standard Stuff

.

.

.

.