Model Engine News: December 2011

Special Features:

Regular Features:

Editorial

Editorial

New Books and Magazines This Month

New Books and Magazines This Month

Engine Of The Month: 1066 Conqueror

Engine Of The Month: 1066 Conqueror

Tech Tip of the Month

Tech Tip of the Month

Briefly Noted

Briefly Noted

Standard Stuff

Standard Stuff

Editorial

A significant part of this issue comes to you from a resort in Caloundra with a balcony providing 180° panoramic views from the Pacific Ocean in the east, through Bribie Island and the Pumicestone Passage to the south, to the Glasshouse Mountains in the west (extinct volcanic cores of stark beauty). Ruffie decided we needed a couple of days off to recover from the stress of retirement, so after an abortive start waiting for a wayward cat to come home (he was inside, asleep), we left a day late for a quick vacation. All this comes at a cost, and not just the room charge: no Internet! So if the December 2011 issue seems a day late, sorry 'bout that, Chief. With luck, I'll still get it out before December One changes to December Two, in the USA, at least  .

.

This being our last issue of MEN for 2011, Members get a new Free Plan. We also have what is probably the most in-depth analysis of the 1066 Conqueror ever written, and a well researched article on yet another rare and forgotten Aussie engine marque. I was almost tempted to make this a second Engine of the Month, but decided—due to high embarrassment on my part—to make it a News Item instead so it will stand out more.

So Happy Whatever to everyone, everywhere. To the many who continue to ask, my health is good, and so is life. MEN will be back in 2012 for the ten year anniversary issue of our current format. And if the temperature drops below what we ozzies call "boiling 'ot, mate!" I've got a list of old and new shop projects in mind for the New Year. In the meantime, back to the pool...

QSMEE Trophy Day

Each year on the second Sunday of November, the Queensland Society of Model and Experimental Engineers (QSMEE) holds their annual Trophy Day. Last year I managed to attend, with camera, but without memory card. This year I did better and so a new page dedicated to the QSMEE 2011 Trophy Day has been added to the Shows Index page. As usual, I've confined the report page to IC engines and related gizmos being exhibited by the members; naturally there was a lot more to see as the show is conducted at the Society's extensive outdoor track which caters to all "rideable" gauges. I took Cirrus along and had no sooner put it down when a passer by stopped and said "Is that the broken tap Cirrus?", which of course, it was! Gave me quite a kick...

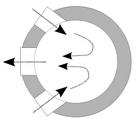

More Schnuerle

Our recent news items on Schnuerle porting has resulted in quite a bit of mail, and I suspect it is far from over yet! Among others, Leif Ryden (Uppsala, Sweden), pointed out that there is a Wikepedia Schnuerle page, and went on to point out that the "boost" port now commonly associated with modern Schnuerle ported model engines was not part of Adolph Schnürle's 1926 invention. Geoff Sheppard (UK, former MEW editor) wrote to say that Professor Dennis Chaddock had written on the subject of deflectorless two-Stroke engines in the Model Engineer back in September 1943. As well as the content of the article, I'm impressed by the way Prof Chaddock's article casually references the journal "Automobiletechnische Zeitschrift" No. 14 - 1940. That he had access to a 1940 German journal and reported on it during 1943 is impressive as the two countries were somewhat at odds with each other at the time. Still more thoughts on Schnuerle porting of model engines as a discriminator in engine selection for model competition use was received from Maris Dislers. It's all mounting up to about enough definitive data to put together a page dedicated to the subject. Maybe next month...

Your December 2011 Free Plan

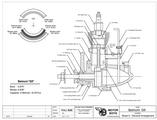

For the annual Thanks To Members gift for 2011, I've chosen an old sparkie, known variously as the G9, Belmont, and IMP G9. Work on this plan set actually began several years ago—how many I can't tell as I did not fill in the Date block of the 2D CAD sheets at the time, as I should have. As is often the case, I worked not from an actual example, but from measurements provided by fellow Motor Boys. If I recall correctly, Bert Streigler took photos of parts, printed them, hand annotated the prints with measurements, then emailed me scans of the annotated prints to work from. Saves time having to prepare rough sketches, works well enough, and provides fast turn-around.

As work progressed, knowledge of the engine's history grew and it became evident that there were at least two somewhat different variants—possibly more. Being an incorrigible perfectionist (I've been told this often enough to almost believe it), I grew unhappy with the plan set because we did not have the data to include details of both cylinder variations. So work slowed and finally stopped in the hopes that details of the later cylinder variation might emerge. It didn't, and the plan set languished, unfinished.

Recently, something reminded me of the old lump and even though I still don't have the data required to detail the second cylinder style (presumed to be a later model), there was full data for one variant. Feeling that all the work already done by The Boys needed to be at least completed as best could be done, the plan set was finally polished up to releasable state.

Continuing a tradition I fondly recall from my youth when Aeromodeller and Model Maker rewarded their readers with free plans included in the "Bumper" Christmas issues, the G9 is our end-of-year free plan, so, MEN Members: click on the GA illustration to view and print the five page pdf plan set. If you've forgotten your login details, email me. If you are not a member, consider joining to get this free plan, along with the other fifteen (15) plans issued so far.

Building an engine from these plans would be a challange, but not impossible. The cylinder was a giant cast-iron piece which I doubt anyone would be able to produce in a back-yard foundry, but I'll bet that does not stop some enterprising Model Engineer from taking a big C-I block and producing more swarf than part to end up with a brand new G9. And if anyone can supply dimensions for the later type of cylinder, I'd be happy to update the plans and declare them fully complete.

McCulloch Engines

If you know the name at all, you'll probably associate the name with pilotless drone engines made for the US military during World War II. These later found their way to the homebuilt market and were the engine of choice for the original Bensen homebuilt gyrocopter. Well, it's time that you knew better; there was another McCulloch associated with engines—model engines this time, in the Land Downunder, just after WWII. David Owen and Maris Dislers, have extensively researched the engines made by Alan (Billy) McCulloch. The material from them reached me last December, just in time for this issue (can't rush these things, 'ya know, and sorry guys, your hard work should have seen light of day long before now). So click the misleading drone engine image to read about the model engines of Alan E McCulloch.

Chenery and Whittle

Last month, we mentioned that many of the plans by the late Les Chenery are available once again through his son, John. By coincidence, the latest newsletter from Paul and Paula Knapp announces that they have managed to acquire four engines built by another English legend, Mr Eric Whittle. These now reside in the Knapp's magnificent Miniature Engineering Museum. These are the 1.25cc, single cylinder Robin four-stroke, the PeeWit flat-four boxer four-stroke, and both of his Cirrus Mk I engines, the 1/6th scale Zimmerman version, and the 1/9th scale bar-stock engine. Plans for the first three of these engines appeared in SIC (back issues still available). The 1/9th scale Cirrus appeared in Engineering in Miniature and back issues for that are available too, although the series ran for over a year.

Mike Cole (Cambridge, UK) emailed regarding the absence of the DH Gypsy from the list. The reason is because John Chenery did not include it in his original list to us, but John has updated his list so it now includes the 1/4 scale Gypsy I (which also appeared in SIC). The DH Gypsy was a successor to the Airdisco Cirrus and the larger scale allowed Les to design a model that is much closer to scale than either Cirrus version. Mike provided photos of his own Chenery Gypsy, seen here, along with other Chenery engines he has built.

New Books and Magazines This Month

Since retiring, my Kindle e-Reader has been getting quite a hiding and consequently, The Library is getting a rest. I've come to think that for reading novels, or other "pure text" works, the portable e-reader can't be beat. This conclusion is based on the low cost and instant delivery of media, and zero physical storage requirements for permanent storage of things you've read. The Kindle has excellent text presentation even in the brightest direct sunshine, however for anything with drawings or illustrations, the Kindle's E-Ink display (which has poor gray scale capability) just can't cut it. An Apple iPad fixes this little problem, but it fares less well in direct sunlight, and the 10 hour battery life just does not compare to Kindle's one month per charge (Wi-Fi off). All this preamble is a cunning way of saying that apart from magazines, nothing new of note has arrived in The Library during the past month, so I'm once again going to select something from the shelves which is still in print and which I think engine lovers may enjoy.

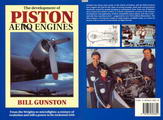

Our selection is Bill Gunston's The Development of Piston Aero Engines, Haynes Stephens Ltd, Somerset, UK, 1993, ISBN 1852603852, hard-covered, 222 pages, profusely illustrated with black and white photographs and illustrations. As mentioned previously, Gunston is a most prolific aviation writer. His book on the development of piston engines aero engines takes a most pragmatic approach to a subject which is now essentially a closed book. By that I mean that the story of piston engines for aircraft use is largely over. Gas turbines have now taken over in just about all categories. Yes, piston engines for light aircraft continue to prosper, but apart from minor changes to improve efficiency and power to weight ratios, even "new" light aircraft engines just copy designs optimized half a century ago. The advantage to our author is his book is not going to date and he can cover development from go to woe.

The book is divided into two sections: How It Works, and How Engines Developed (plus an appendix of abbreviations, bibliography, index, and introduction). Gunston states that he has tried not to make Section One too much like a dry classroom textbook, and I believe he has succeeded admirably in this regard. At the same time, he does not dumb-down necessarily complex but essential subjects. For example, he presents the molecular structures of some basic constituents of hydrocarbon fuels and explains clearly how fuel development led and drove engine development. Pressure-volume diagrams get a fair work out too as he describes the Otto-cycle four-stroke, the two-stroke, and the diesel cycle. Both sections are written chronologically, though section one tends to consider an aspect of engine design, air cooling for example, and follow its development. In essence, Section One is setting the scene for Section Two by providing technical knowledge so the reader will have the background to follow his descriptions of specific, significant engines selected to illustrate how aero engines went from the Wright Brothers 3.29 litre, 16 HP engine to the 71,553.0 litre, 3,000 HP Pratt & Whitney R-4360 Wasp Major in roughly 40 years.

In his Introduction, Gunston notes the impossibility of mentioning the many hundreds of types of piston aero engines that have been built. He also mentions how politics, personalities, and "fashion" can over-ride engineering when it comes to development, not infrequently leading to opposed techniques being adopted in different countries during the same time period. It has always amazed me that British engines during World War II persisted with carburetors in spite of their intolerance to negative G-loads while Germany were mass producing reliable fuel injected engines (fashion). Then there's the remarkable effort and expense Sir Roy Fedden expended on the development of sleeve valve radials because he was convinced (partly by Riccardo) that poppet valves could not produce the higher BMEP he required (personalities). All this we get in Section Two which comprises chapters titled, The Dawn of Powered Flight, Between the Wars, The Big-Engine Peak, and Piston Engines Today and Tomorrow.

Gunston has done a good job of condensing virtually the entire history of aero engine development into a manageable number of pages, illustrating his story using items of technical or commercial importance. This means he inevitably has had to ignore literally hundreds of odd-ball and unconventional items. Earlier, I made the gutsy call that piston engine development as such had ceased and I stand by that belief. Gunston notes that the history of aero engine development is littered with radical ideas, few of which make it to a running prototype form, while even fewer still have flown. I believe that the number of "out-there" IC ideas has increased in the last decade as affordable 3D CAD has matured while the number progressing to actual test items has shrunk. But as he says, this does not mean that the next radical idea to come along may not sweep the field and "restart" piston engine development history. For those who want a broad spectrum understanding of piston aero engine technology and the key drivers of development, I strongly recommend this book (which you can order from Amazon using this link); four and a half stars  .

.

-oOo-

Of the magazines arriving during November, one was Issue #26 of Model Engine Builder. In the Editorial, editor, Mike Rehmus, notes that age and childhood Rheumatic Fever has conspired to place him in the queue for heart surgery. All being well (and we most sincerely hope all is well, and Mike has a speedy, trouble-free recovery), Issue 27 will be published on schedule in January, 2012. The plan supplement in this issue completes the instruction section for Todd Snouffler's Pip three cylinder radial, and the conclusion of the long running series on magneto design for hit and miss engines by Don Grimm.

The article I think will evoke the most controversy is one on building a low-cost 12VDC EDM, by Lynn Anfinson. The design uses a concept I've seen before in Model Engineers' Workshop magazine (UK). In fact it must be more common than I thought because Lynn credits the basic idea to a Youtube video where the "Jiri the circuit girl" uses a doorbell buzzer and a 5v power supply to erode a hole in a razor blade. The idea is simplicity itself, and I think the best place for it, and my misgivings about it, are in this month's Tech Tip.

Back to MEB #26. The centerfold is a magnificent automotive V8 by Dwight Giles and Ken Hurst. The article states that a future MEB will contain an article on how the team molded the custom spark plug wires, which is one I look forward to, having had satisfactory if not brilliant results myself in this endeavor. As usual, if you don't subscribe, you should. Four issues per year for US$36.00 domestic, $42.00 in Canada and Mexico, and $54.00 for air-mail delivery elsewhere.

Engine Of The Month: 1066 Conqueror

The 1066 company and its products has been mentioned more than once in these pages, but never to any great depth, even though the Conqueror was our Engine of the Month in October, 2004. Recently, our Adrian Duncan got together (electronically) with Hugh Blowers, editor of On The Wire, a website dedicated to tethered hydroplanes and cars and a mine of information on all matters related to 1066 Products. Now armed with The Facts, Adrian has done his usual thorough job on the 1066 Conqueror. We are especially grateful to Hugh and Kevin Richards for the information they provided and their generous support.

Tech Tip of the Month

Ahh... simple, cheap, effective EDM: a paradox, or contradiction in terms if ever there was one. Yes, you can build a spark erosion machine very cheaply and relitively simply, but what do you want, or need it to DO!!? Consider the simple EDM in MEB #26. A DC power supply—a 12v car battery in this case—has its negative terminal connected to an electrode (say a piece of brass). The positive terminal in connected to the workpiece. The electrode is allowed to fall under gravity towards the target of the workpiece. When they meet, everything shorts out and things would get ugly, but we've cunningly placed a solenoid coil in the negative lead, arranged such that when it is energized (by the short circuit), it snatches the electrode away from the workpiece. The solenoid in an inductor and one property of an inductor is to resist a change in currnet flow, so as they break apart, an arc forms generating a plasma which erodes a few particles of workpiece (and electrode). This does not last long, so the circuit is broken and the solenoid de-energised, thus allowing the electrode to fall again. The cycle then repeats (and yes, I've simplified what's causing the plasma a little).

Will this work as an EDM? Absolutely. Can it be made simply, quickly, and cheaply? Yes, yes, and yes. Is it "efficient" and can it provide precision? Absolutely not. Does that matter? Well maybe no, and maybe yes. It all depends on what you are trying to achieve. If you want to burn a hole in something very hard and precision is not greatly important, look no further. If you want to burn out a broken 2-56 tap from a blind hole and preserve the thread in the work, I think you should look elsewhere. I fact, I have concerns at attempting the burn on a 6-32 tap without damaging the thread, unless you were prepared to drill out and tap a larger size afterwards.

The problem as I see it is repeatability of position, and flushing of particles. The article suggests a high flow rate (of de-mineralized water) will overcome the particle problem. The reason this is a problem is because if allowed to hang around, they disturb the path of least resistance which is where the plasma will form. The result is that more of the target is eroded than desired and the hole will be bell-mouthed. Serious EDM uses hollow electrodes to carry a specially formulated electrolyte into the cavity and thus force metal particles out as best possible. This is complicated, and not cheap. A high velocity stream directed at the top of the burn is not bad, but can impose side loads on the electrode, which is bad too, as we'll see in a moment.

The solenoid of our simple EDM winds houshold plastic sheathed copper wire (solid) around a PVC pipe former. Another piece of pipe slides inside this forming the movable electrode. It must have enough iron in it that the magnetic field formed when the solenoid coil is energized can retract it from the work, yet not be so heavy that the field can't lift it. Got that pictured in your mind's eye? I'm not going to illustrate this—if you need to, buy MEB #26 for Mike's excellent CAD renderings of the arrangement.

Now let's consider a broken 4-40 tap in a hole, blind or otherwise. The minor diameter will be about 0.09, assuming a normal thread engagement. Allowing for EDM "kerf" and taking advantage of the fact that the flutes in the tap are deeper than the true 4-40 minor diameter of 0.081, we might select an electrode of say 0.075 to 0.080 diameter and have at it, flushing madly as we go. If we are not to erode the work, this means that every hit has to be in almost the same place. Wander sideways by just 0.005 and we will be eroding the thread, along with the tap. So our EDM sinker "ram" needs less than 0.005" of free-play. Can you achieve that with PVC pipe that needs to be free enough to fall free under gravity, but be light enough to be retracted by our 12 VDC coil, which has a high velocity stream of water hitting it on one side? Maybe, but I have some doubts.

If the hole with the broken thing-a-mabob can be redrilled and retapped larger, way to go. If it can't, and if that tap is 2-56 and the last hole of 216 in your P&W Twin Wasp, you need absolute precision in the EDM ram assembly to achieve the repeatability and rigidity required. The burn is going to take a while too and I'd have further concerns about how the discharging DC battery is going to effect the burn.

So, in summary: I've no doubt that the MEB low-cost, simple EDM will work, and deliver on the "simple" and "low-cost" parts of the equation. The question is what do you want to do with it and how much positioning precision does that require? If you've got a 1/4 bolt sheared off in your lawn mower, one of these gizmos, a magnetic stand to hold the solenoid, an electrolyte dam made of blu-tack, and a garden hose will have you back in business (after you've re-tapped 5/16). If your needs are "finer", proceed with caution.

Briefly Noted

This section is intended to alert you to little things that are hard to expand to a full news item, or cunningly wind into the Editorial, but are worthy of note never the less.

- Registered owners of Steve Huck's auto V8 plan set should have received an update late last month. If not, be sure to email Steve.

- The Belmont page has been revised and updated with extra images and the GA from our December free plan.

- A linking error on the How-To page which caused "Kitting Up" to goto "Cast Pistons" has been fixed.