Editorial

What a month! No sooner had November started, it was over, and I—to use the good old Australian vernacular—am positively knackered. There was the conference mentioned last month (where my paper was very well received, thankfully), red-eye departures to interstate meetings, a sudden grant application to prepare and submit with four days warning, and the December MEN to write. And being December, tradition requires the drawing, dimensioning, and checking of a new Free Plan. To cut a long story short, all objectives have been met; all pigs fully fuelled and ready to fly, Sir! Add to this, I ended up with a stack of stuff in the way of book reviews. The sensible thing to do would have been to hold one over for later, but as there seemed to be a lack of "news" items as such, you get three items in the New Books and Magazines section this month.

Looking back to this time last year, I see we'd had a wet November around here and were no longer in danger of expiring from water riots. This one has been dry, dry, dry. Storm activity has been high with no rain, but lots of wind and property damage. Thankfully, there have been no injuries, so in comparison to some places, we are not doing too badly. My health is as good as ever (all Model Engine News Life Members breath a collective sigh of relief) and the only thing I could wish for is more hours in the day. As that is not likely to happen, I'll do the best with what I've got and wish the very best to everyone during this totally non sectarian, gender neutral, politically correct, Festive Season of your choice, and down to business...

Your December Free Plan: The Schroeder 09

Some time back, Roger Schroeder sent me his folder containing all drawings and other material for a spark ignition engine he had designed way back in 1974 for readers of ECJ, bidding me do what I liked with them. I decided we should make them publicly available and put the project on the To-Do Real Soon Now list, where it sat. Now, needless to say, I regret not completing the process while Roger was still alive to bask in the glory and answer the questions. My penance will be to answer any question as best I can. Note that while this is the anticipated December MEN Free Plan Set, it is available to everyone, not just members—just click the thumbnail picture, or follow this link to the Schroeder 09 page. Members take heart though. I am part way through a 3D CAD set for a very historic diesel dating back to Sweden of 1944. Not only that, we've made a surprise contact that will enable us to document the story behind the design and provide unique information about the model engine scene at the berth of the diesel era.

Ivan Rogstadius

Tucked inside the folder of material Roger had sent for the Schroeder 09 were some photocopied pages showing a Dyno-like diesel. They were of non-English origin, but it was a simple job to pick an obvious engineering term, plug it into Google, and find it was a Swedish word. One date appeared clear enough, "1944", and a name, "Ivan Rogstadius". As the printing looked more modern than 1944, I assumed Mr Rogstadius had written the article about a pioneering war-time design. It was a nice engine, so a full 3D model was quickly created from the original drawings (the easy part) in preparation for deriving a modern CAD plan set (the lengthy, tedious part). Scans of the article also sent out to fellow Motor Boys to see if any knew more about the design. Then the surprises came flooding in!

Adrian Duncan had a friend in Sweden who could translate the pages. On seeing them, his friend, Lars Gustafsson, immediately knew the design and knew that Ivan Rogstadius was the actual, original designer of the 1944 engine. Then he discovered Ivan was alive and well, and living nearby! To chop a long story short (for now  ), Lars has translated the original article, spoken with Ivan over the phone and in person, and is transcribing answers to some questions our group had regarding the origins of the design, the effect on the Continent of the release of the Dyno and other "diesels", and other early reminiscences related to model engines then and over the years. You'll get to read these next year, and Members will get the full 3D CAD plan set. For now, the picture shows a photo of Ivan taken by Lars. In front of him are two engine he has made. The diesel is a one-half size copy of the Swedish Mikro-Diesel. The spark ignition engine has aspects of Original Ohlsson, or Brown Junior/Ranger B about it. Both are immaculately executed and are fitted with props carved for clockwise rotation—not uncommon in the early days. Ivan is 95 and does not look a day over 70 to me; I can only hope to wear so well, and so gracefully. Maybe I should move to Sweden too.

), Lars has translated the original article, spoken with Ivan over the phone and in person, and is transcribing answers to some questions our group had regarding the origins of the design, the effect on the Continent of the release of the Dyno and other "diesels", and other early reminiscences related to model engines then and over the years. You'll get to read these next year, and Members will get the full 3D CAD plan set. For now, the picture shows a photo of Ivan taken by Lars. In front of him are two engine he has made. The diesel is a one-half size copy of the Swedish Mikro-Diesel. The spark ignition engine has aspects of Original Ohlsson, or Brown Junior/Ranger B about it. Both are immaculately executed and are fitted with props carved for clockwise rotation—not uncommon in the early days. Ivan is 95 and does not look a day over 70 to me; I can only hope to wear so well, and so gracefully. Maybe I should move to Sweden too.

London 2010

To quote the press release, Alexandra Palace will be transformed into the model engineer's paradise for the annual London Model Engineering Exhibition from 22nd – 24th January 2010, when the Great Hall is filled with the smell of steam and the sound of whirring engines. It goes on to note that the exhibition will feature exhibits from more than 40 national and regional clubs, and over 60 suppliers of machinery, kits, components and tools. Like the Model Engineer Exhibition mentioned last month, you can save a pound or more pre-purchasing your tickets from the Meridienne Exhibitions web site. This makes for two really major English Model Engineering exhibitions within weeks of each other—break out the chequebook and sound the overload alert.

New and Updated Stuff

Website page access statistics show that the Model Engine Gallery is one of the most popular series of pages on this site. They sort of started without any plan at all and if I could change them now, I would, but this would cause total chaos with all the links scattered throughout this site, not to mention existing references held by others, so we are stuck with it. There is no rule as such for when a new page gets started. Having some new stuff to add, Page 15 was looking a bit long in the tooth, so this month we have a brand shinny new Page 16 which includes shots of how a New Zealand Member made a model engine project the focus for a senior year high school class he teaches—really great to see.

The other popular section is the Watzits and we have two new entries there this month. The first is rare, but well known to those who know their early Continental designers. The second is a total mystery. It appears home-made, but from a time when many home builders didn't think twice about doing a spot of casting, making their own spark-plugs, and generally experimenting.

Adrian Duncan's BWM Review from last month drew a good audience including two knowledgeable gentlemen able to add extra information and pictures to the story. The page has now been updated and our thanks go to Jim Dunkin and John Malkin. As well as this Dennymite book reviewed here a while back, Jim is an expert on 2.5cc engines and is getting near to completing a revision of his book on this subject. John has a BWM 250D which was awarded to him as a prize at a long ago New Zealand Nationals. He still has it, complete with box an papers and has sent us a scan of the instruction sheet which enhances the page nicely.

A reader emailed with positive things to say about the spark ignition related components being sold by a UK company called Just Engines. A reference to them has been in our Suppliers Page for some time, but apparently their web site has moved since the entry was added, so this has been corrected and if you are looking for 1/4-32 spark plugs, Capacitive Discharge Ignition (CDI) modules for one and two cylinder engines, we know they have at least one satisfied customer!

On-line Estate Auction

We've been advised of an auction comprising the first part of the late Bert Hartshorn's model collection (Australia). Bert spent his life building and collecting models. The first part of the auction comprising some beautifully built and finely detailed flying scale models along with quite a number of highly collectable "tin" toys will take place on-line on December 15, 2009 with a live webcast (see Auction 362 for details). These are delicate models, so have a good idea of how you plan on taking possession of your prize if you plan on bidding. The next auction will take place sometime in February and will contain some rather rare engines. We'll have details when available.

New Books and Magazines This Month

This month we link two names that have appeared previously in isolation. The Workshop Practice Series is a venerable institution produced through the various publishers of the Model Engineer commencing with Argus in 1984. The concept has been to produce small, inexpensive volumes, each dedicated to some specific aspect of model engineering that are written for model engineers, by model engineers. The first in the series was titled Hardening, Tempering & Heat Treatment, by "Tubal Cain", aka Tom Walshaw. Have a look in the Book Review Index to see other titles in the "Workshop Practice" series that have been reviewed to date. The other name is Dave Fenner, a current writer for the ME and MEW who has authored several series in those magazines on model IC engines, related tools, and totally unrelated but interesting subjects. Dave is also the author of the latest addition to the Workshop Practice Series, specifically, number 43, The Mini-Lathe.

I had seen the new volume advertised and was under the mistaken assumption that it dealt with the current crop of really small, table-top lathes of Chinese manufacture; ones with a swing over bed of about 2 inches (or 4 if you use the US measure of the largest diameter work that can be accommodated rather than the distance between bed and centerline, as preferred in the old Commonwealth countries). But it turns out I was wrong. The Mini Lathe in question is about the size of my Myford ML7A, having a capacity to turn work of slightly over seven inch diameter between centers distance of 10, 12, or 14 inches, depending on which model you choose. The major difference from the Myford, apart from the much lower price, is the lack of a gap in the bed and the somewhat shorter between centers capacity. But for the sort of work most frequently depicted on these pages, the mini lathe described in Dave's book is an excellent choice for the beginner model engineer wanting to get into the hobby on a budget. But as you'd expect, the low price imposes some constraints on quality and features. This is where I believe the Mini-Lathe book shines as Dave pulls it down and rebuilds it to a higher standard than is possible at the street price, adding features along that way that improve the usability of the machine.

The Mini-Lathe: Workshop Practice Series 43, by David Fenner, Special Interest Model Books Ltd, Dorset UK, 2008, ISBN 9781854862549, soft-bound, contains 132 pages with numerous black and white photographs and illustrations. Like other titles in the series, it is "pocket book" size, measuring approximately 6x8. It is divided into ten chapters arranged in a logical progression that takes the reader from knowing nothing, to fitting digital readouts and replacing the headstock ball-race with an angled roller bearing. In between, the reader is informed on workshop safety aspects and simple projects to improve the overall usability and capability of the lathe. For example, in Chapter Two, Dave un-crates the machine and pulls it down to inspect, lubricate, and correct things like gear train misalignment, slide surface finish, interference of covers, etc. He shows ways to test alignment and ends up with a machine that is in the general class of the Myford. I should note that as it has a MT3 taper in the headstock, it actually has a greater headstock capacity that a standard Myford.

Other chapters deal with improving rigidity with saddle clamps, adding headstock indexing capability, adapting a "mini-tool" to a toolpost milling and grinding attachment, and adding a handwheel to the lead-screw, just like the Myford (and a feature that I find to be extremely useful when cutting cylinder head fins and other operations requiring precise and repeatable movement along the bed). He even replaces the ugly but functional plastic handwheels with nice, spoked, cast ones and describes the construction of a simple center height gauge as a "first project". This is an indispensable gadget that every model engineer should make. Mine was made to the GHT design; Dave's is much simpler and every bit as effective, even if it does not expand the builders' skill set as much as George's version which requires between centers work, cross drilling, and hardening and tempering.

I'm glad to have had the chance to read this book and correct the ignorant, mistaken assumption I held about it when I first saw it advertised. In fact, if you are a beginner thinking of how to best spend your hard-earned on equipment, you could do no better than to read this book before committing to any particular lathe. It's not perfect. There is no index (a specialized job and expensive for publishers, so the absence is somewhat understandable) and the size of the oil holes added to to the lead-screw bearings is not mentioned. I would also have liked to see a photo of the modified lathe in its final, "all-tricked-out" form, but those are minor nit-picks. Dave has produced a very valuable reference for the modern model engineer and is to be congratulated. The machines in question are available in England, Australia, the USA, and probably everywhere else for all I know—maybe even China! Workshop Practice Series 43: The Mini-Lathe is available from Amazon for $23.50 and MEN rate it at four and a half stars  (I still have no clear idea of how to remove the chuck from a mini-lathe apart from knowing there are three screws involved

(I still have no clear idea of how to remove the chuck from a mini-lathe apart from knowing there are three screws involved  ).

).

-oOo-

Last month I mentioned the LBSC biography I had acquired and started reading. I sort of thought that I understood the status "Curley" Lawrence has in the live steam world, but looks like I was wrong: he's much bigger than that (think of the standing that ETW has in our model engine world, then raise that by an order or magnitude, or two)! The upshot was a very nice email to let me know that just about all of what author Brian Hollingsworth wrote regarding how Lillian Lawrence came by his name turns out to be wrong!

The current thinking on the subject appeared in the January 2006 issue of the English magazine Engineering in Miniature. The authors of the article do however point out that they had the benefit of the Internet and digitised records to assist them in their genealogic research, plus some experience in tracing family trees. To summarise their findings, Curley was born on September 27, 1883 and named William Morris Benjamin. He became William Morris Mathieson around 1894 when his father decided to change the family name. The authors conclude that the change from Bill to Lill (their words) occurred sometime between 1902 and his marriage in 1908. The inescapable conclusion is that the name change was his own adult decision. If this strikes you as a trifle eccentric, descriptions of Curly's preferred mode of dress in later life, as strongly hinted at in Hollingsworth's book, tend to support it all the way—none of which detracts, in my opinion, from his ability, achievements, and absolute dedication to his chosen corner of model engineering.

So leaving aside a large part of the first chapter, has reading "LBSC" His Life and Locomotives, by Brian Hollingsworth, Croesor Press, 1982, ISBN 0953652351, hard-bound, changed my opinion or broadened my horizons any? Well, now that you come to mention it, yes, it does rather seem to have. Building a working live steam loco in any gauge is a truly non-trivial task and over his life, Curley made 55 of them. Perhaps just as impressive, he designed and documented 112 models in gauges 0 to 5, and penned 3,000 magazine articles, and several books on the subject. The book is a really enlightening read, suffering only from an apparent assumption that the reader is already well versed in locomotive terminology and perhaps some LBSC lore as well (someone is just going to have to explain to me what the frequently mentioned famous monkey gland treatment might be, because although it was mentioned a number of times, the author never did).

I said in the lead-up to this review last month that I'd found LBSC's writing style an acquired taste, thus praising it with feint damns. I think I've changed my mind. Hollingsworth frequently quotes LBSC, often at considerable length. At first I skim-read these, but soon found I was going back over them. They are very, shall I say, "folksy" when describing actual and fictional incidents relating to engine driving and the like, with characters like "Inspector Meticulous", "Bert Smiff", and "Brother Wholesale", with whom I assume his regular readers were intimately familiar. But when he gets to describing how to machine some component, he exhibits an enviable economy of words, managing somehow to remain clear and concise while avoiding descent into terse, ungrammatical, "workshop operation sequences". His audience probably had nothing more accurate than a ruler for measurement, making his descriptive talent at describing such a complex subject all the more remarkable as he manages to do so using just fractions. The language does reflect a bye-gone era and may now require some shift of mental gears on the part of a modern reader, but it's nowhere near the challenge I'd previously thought it was.

Then there's the story of how Curley challenged popular wisdom of the 1920's, as well as big business and some even bigger egos, asserting that a coal fired boiler could perform as well or better than a spirit fired water-tube boiler in 2-1/2 gauge (see all these new terms I can now bandy about with alacrity?  ). He proved his point most publicly in a contest now known as the Battle of the Boilers. In the process, he made some life-long enemies, showing that full-size practice could be scaled down and still work efficiently, and be made by your average model engineer on a treadle-powered lathe. I could go on. Instead I'll just give the book four stars

). He proved his point most publicly in a contest now known as the Battle of the Boilers. In the process, he made some life-long enemies, showing that full-size practice could be scaled down and still work efficiently, and be made by your average model engineer on a treadle-powered lathe. I could go on. Instead I'll just give the book four stars  if you are a model engineer who loves to read about other model engineers regardless of their subjects. Make that five

if you are a model engineer who loves to read about other model engineers regardless of their subjects. Make that five  if your thing is live steam models, the history of their development in the UK and USA, and some of the people involved. The book is out of print, but copies are not hard to come by. At the time of writing, Amazon Sellers list several copies available. I really enjoyed this book! (too bad about Chapter 1).

if your thing is live steam models, the history of their development in the UK and USA, and some of the people involved. The book is out of print, but copies are not hard to come by. At the time of writing, Amazon Sellers list several copies available. I really enjoyed this book! (too bad about Chapter 1).

-oOo-

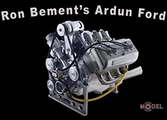

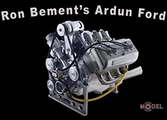

Issue #20 of Model Engine Builder arrived during November and on opening it up, I was really chuffed to see a nicely made example of the Mills 1.3 made by Heinz Beutler from my plans which appeared in Issue #1, all those years ago. There was also a picture of a nicely executed VAL, designed by Brian Fairey that appeared not that long ago in the magazine. All this shows that the plans Mike slaves over at a hot CAD terminal to include with each issue are being used as intended. The issue contains the usual good spread of workshop tips, construction articles, and jaw-dropping center spread. This time around, the latter is Ron Bement's amazing Ardum Ford V8. Ok, so there was CNC involved—lots of it. Get used to it. Besides, producing the codes to machine out a water cooled head in two halves by measuring a full size one takes real skill. Visit the MEB website and click on issue #20 to see and hear this engine in action.

Engine Of The Month: OS 29 Twin-stack Ignition

We have two engines to feature this month, or perhaps three if we include the Schroeder 09 as part of the package. The first is the OS "Twin-stack" ignition engine from 1948. A glow version appeared the following year and remained in production until 1954, after which the company changed their models to a loop scavenged design with a single exhaust port. What immediately strikes me about the engine is the fine quality and light weight of the castings—something always associated with the loop scavenged Max engines, but not so evident on early OS sparkies like the K6.

The other review is for a very rare bird: the Hope 09 for which our tireless Hope archaeologists could only obtain one photo and no actual example. This one concludes the story of the Japanese Hope range begun with the Hope Historical Overview some time back. The series was extensively researched by Adrian Duncan and Alan Strutt who have done everything humanly possible to ensure the story presented is as accurate and complete as they could make it. But we always welcome additions and corrections, so let us know if you believe you have something to contribute and have reasonable corroboration for it. We are never above making, admitting, and correcting mistakes, crediting sources, or admitting to it where popular but contrary, unreconciled views exist.

Tech Tip of the Month

Last month's tip on Camshaft Grinders for Model Engines was a bit of a surprise hit with readers. I got a lot of email, including a reminder (Doh! I knew that!) from Joe Martin and Craig Libuse at the Craftsmenship Museum that Joe had been developing a computer controlled machine based—naturally—on Sherline components. The grinder has recently been used to produce the camshafts for the Museum's latest collaborative project (see MEN October, 2007). It came through with flying colors and the boys have even posted two videos of it in action on uTube. Joe says that the hard part was accounting and compensating for the wheel geometry when grinding a cam to numerical values entered for the base circle, flank radii, duration, etc. See the CamCalc page if you want to see how all these inter-relate, but be sure to visit the Howell V4 page on the Craftsmanship Museum web site to see the finished camshaft and how it was case hardened after grinding. The page includes the links to the uTube videos which are well worth watching. I especially liked the neat and simple but precise way Joe worked out for dressing the wheel during a production run, then compensating for it. You can't buy one of these Rolls-Royce cam grinders yet, but Joe is thinking about it.

By the way, last month's page on the subject has been updated with pictures of the rather ingenious way Chris Dunn devised for setting the cam angles without resort to a DTI, as I'd incorrectly assumed.

-oOo-

Remember the Dynamic 049 featured here a few months back? The new owner's tests on the engine were just not coming up to what Gordon Cornell designed and built these engine to deliver, so he set about finding out why. Suspecting the ball races, he obtained a new set from Gordon. Aside: how's that for after sales service? It's only been 48 years and Gordon was not even the manufacturer! What makes this Tech-Tip quality work if that he set about installing them correctly. It has been noted in a number of articles on the subject that just pushing them home into a press fit cavity, no matter how precisely it may have been machined, is most likely not going to give you the full potential for friction minimisation. To get this, you really need special assembly tooling. So using more sage advice from Gordon, David made the required tooling and replaced the bearings. There turned out to be even more to it than that, but the engine is now right in the ballpark delivering a healthy 18,500 rpm on an APC 6x2. The Diedesign page has been updated, so visit it to see photos of this rare engine in bits, and the correct tooling for bearing alignment used during reassembly.

Your December Free Plan: The Schroeder 09

Your December Free Plan: The Schroeder 09

Ivan Rogstadius

Ivan Rogstadius

London 2010

London 2010

New and Updated Stuff

New and Updated Stuff

On-line Estate Auction

On-line Estate Auction

Editorial

Editorial

New Books and Magazines This Month

New Books and Magazines This Month

Engine Of The Month: OS 29 Twin-stack Ignition

Engine Of The Month: OS 29 Twin-stack Ignition

Tech Tip of the Month

Tech Tip of the Month

Standard Stuff

Standard Stuff

), Lars has translated the original article, spoken with Ivan over the phone and in person, and is transcribing answers to some questions our group had regarding the origins of the design, the effect on the Continent of the release of the Dyno and other "diesels", and other early reminiscences related to model engines then and over the years. You'll get to read these next year, and Members will get the full 3D CAD plan set. For now, the picture shows a photo of Ivan taken by Lars. In front of him are two engine he has made. The diesel is a one-half size copy of the Swedish Mikro-Diesel. The spark ignition engine has aspects of

), Lars has translated the original article, spoken with Ivan over the phone and in person, and is transcribing answers to some questions our group had regarding the origins of the design, the effect on the Continent of the release of the Dyno and other "diesels", and other early reminiscences related to model engines then and over the years. You'll get to read these next year, and Members will get the full 3D CAD plan set. For now, the picture shows a photo of Ivan taken by Lars. In front of him are two engine he has made. The diesel is a one-half size copy of the Swedish Mikro-Diesel. The spark ignition engine has aspects of

(I still have no clear idea of how to remove the chuck from a mini-lathe apart from knowing there are three screws involved

(I still have no clear idea of how to remove the chuck from a mini-lathe apart from knowing there are three screws involved

if you are a model engineer who loves to read about other model engineers regardless of their subjects. Make that five

if you are a model engineer who loves to read about other model engineers regardless of their subjects. Make that five  if your thing is live steam models, the history of their development in the UK and USA, and some of the people involved. The book is out of print, but copies are not hard to come by. At the time of writing,

if your thing is live steam models, the history of their development in the UK and USA, and some of the people involved. The book is out of print, but copies are not hard to come by. At the time of writing,