Editorial

I finally got the Cardinal trimmed to reasonable competition trim by the rather extreme expedient of taking a knife to the flaps. After trimming half an inch from the trailing edge, the ability of the model to turn a square corner and track predictably out of it improved out of sight. With the smaller flaps, I was then able to remove some of the weight that had been added to the tail to restore the level flight "groove" quality and was finally quite happy with the model. Now settling down to some serious pattern practice, I managed to run out of ideas and altitude all at the same time in the last loop of the Four Leaf Clover. That's the first model I've lost to pilot error in the past twenty years of pattern flying—something to do with pride, and falls, I suspect. The model probably could have been repaired, but it would have gained weight in the process, so better to expend the effort on a new model—one that will actually fit in the back of a modern station wagon. I still like that Stalker 61, though.

One of the side-tracks blundered down this month involves the Westbury Zephyr 2.5cc two-stroke RRV ignition engine. In the process of reverse engineering the timing from the components, a small (ahem) error was found in the RRV Timing Calculator code which, in special cases, could give some rather unexpected and totally, totally wrong results. This has been fixed and apologies to anyone who may in the past have muttered what's with this thing anyway!?

Another change has been made to the navigation buttons at the bottom of the Model Engine Development pages. The next/previous links now have an "Index" button in the middle so you can go from any page to any other with only two or three mouse clicks. Gordon has completed the drawings for the reed valve variant of the Super Fury and we will present these in the fullness of time.

Some may have noticed that the web site went totally 404 for a short period around the middle of March. This was caused by a hardware failure at my host provider which has now been corrected and Will Never Happen Again, they say. Seems I've heard that one before, or used it myself on some customers; one of the two...

Dynamic 09 BB

As well as providing the monthly parts for his series on Model Engine Development, Gordon Cornell is finding the time to continue development of his Dynamic range of engines. The one pictured here is the Dynamic 09 BB, a Schnuerle ported, front rotary induction, dual ball-race, high performance 0.09 cuin diesel. If you've been following the MED series, you will know Gordon favors the all-machined crankcase for development work as castings, by their nature, tend to limit development scope. The modern Dynamics feature a CNC machined case and clearly show Gordon's mastery of the modest CNC mill he uses. Even so, Gordon reports that a well fitted Super Fury produces more torque than the Dynamic 09, allowing larger props to be fitted. In his testing, he concludes that piston fit in an iron/steel combination is very critical and that the piston height should be at least equal to the stroke to prevent the piston wearing into a barrel shape, leading to oscillation and RPM loss.

This month's MED part describes the Super Fury crankshaft and provides some considerations in relation to the selection of ball races for model engines. The latest release of drawings detail the multiple crankshaft types, two styles of prop driver, and the fully machined conrod option. If you prefer, forged Super Fury connecting rods are still available. The forging process results in an increase in strength. I've always found forging aluminum a bit magical; effectively, you hit it with a big hammer and that makes it stronger! Ok, I over-simplify, and most aluminum alloys do work-harden. Graham White's book on the R-2800 documents how a 35% increase in crankcase strength was obtained through forging—a rather significant change.

ETW Plans in Model Engineer

We mentioned in the December 2008 issue of MEN that the Model Engineer and sister publication Model Engineers' Workshop now had a common editor, wondering what this might hold for IC content in the ME. Well, so far, so good! Editor Dave Clark announced in MEW issue #148 that the ME would begin to carry full size plans as a pull-out bonus beginning in issue #4346. These will be double sided. One side will carry part of a five sheet series for a Martin Evans' Metro live-steam tank locomotive. The reverse side will reproduce some of the venerable Edgar T Westbury plans, both IC and steam, of years past. The ones announced were the Zephyr, Trojan, Corsair, Cygnet Royal, and Centaur (see the ETW IC list and steam list for details of these designs). The issue of castings for the Centaur aside, this is good news and MEN compliments Mr Clark on his efforts to ensure that IC continues to have some weight in a magazine that has become a bit steamy in recent years, despite Nemett's best efforts. Then again, any editor can only print what their largely amateur and part-time authors provide, so I'm sure Mr Clark is doing the absolute best he can to provide modern, balanced content.

Zephyrs, Timing, and Things

All this led to some discussion with Nemett regarding ETW's Zephyr RRV, bar-stock, two-stroke petrol ignition engine from 1946. As should be expected, Model Engineer's decision to include this plan as a free supplement has sparked (if you'll pardon the pun) a sudden interest in the old thing, together with some scrutiny of the plans. It soon became evident that the piston was not fully opening the exhaust port at BDC; neither did the transfer port in the piston align with that in the cylinder liner, leading to some question regarding the accuracy of the 1946 plans. Had the connecting rod length somehow been shown too long? Sadly, errors of this sort, and far worse, are not unknown in the old ETW designs, so I ran the numbers for the Zephyr through the MEN Design Center Timing Calculators.

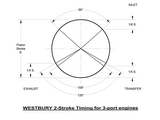

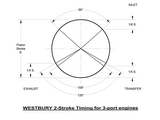

The results, with the rod length as drawn, are rather awful. The calculated inlet events are also different from those printed on the sectioned view that appeared in ETW's two-stroke design series of 1968, but these are at least acceptable, while the exhaust duration of just 101°, and a transfer of 81° are very restrictive. The 1968 two-stroke series mentioned earlier included a normalized representation of what he believed to be "good" numbers for a side-port engine. I've re-drawn them here to show the events in a more usual angular notation. These are "mild" numbers and we might expect a rear rotary valve induction engine to open exhaust and transfer quite a bit earlier.

The results, with the rod length as drawn, are rather awful. The calculated inlet events are also different from those printed on the sectioned view that appeared in ETW's two-stroke design series of 1968, but these are at least acceptable, while the exhaust duration of just 101°, and a transfer of 81° are very restrictive. The 1968 two-stroke series mentioned earlier included a normalized representation of what he believed to be "good" numbers for a side-port engine. I've re-drawn them here to show the events in a more usual angular notation. These are "mild" numbers and we might expect a rear rotary valve induction engine to open exhaust and transfer quite a bit earlier.

So is the rod length wrong? Let's assume that the piston and liner ports are correct. The bypass scheme is of the type where the new charge passes through registering ports in the lower piston skirt and the cylinder, then up a channel covered by a screwed on cover plate to the other transfer port (by coincidence, the same scheme used by the Dennymite mentioned in this month's new library item). A little bit of CAD work shows that if the connecting rod length between centers is reduced from 1-3/8" to 1-5/16", then at BDC, the port in the piston will be sort of aligned with that in the liner, and the piston crown will be just below the lower exhaust and transfer openings. the timing now becomes 135° for the exhaust and 120° for the transfer.

This seems better, but previously the piston crown had been level with the top of the liner at TDC; now it is 1/16" below which has the effect of reducing the compression ratio significantly. This is not so simply cured. Fortunately, the Zephyr is hogged from solid, so at least we are free to make any change required. If the liner and crankcase are reduced in height, the fin arrangement has to be changed. If the case is left as is, the liner reduced in height, and the cylinder head adjusted to restore compression, retaining the external shape, we run into problems with the spark plug reach. Another option would be to retain the conrod as drawn, raise the liner ports by 1/16", and reduce the fin spacing by ten thou so the bypass cover still fits. Of all these, I think the latter is the better option. Whichever choice a builder makes, it appears that there may have been multiple errors in the drawings and that these are not attributable to the editor, drafting department, or the printer. A search of the ME following original publication has not uncovered any correspondence on the subject, but that is not to say none exists.

The buttons above will draw timing event diagrams for a Zephyr as it would be if it was built to the plans given in the ME 63 years ago, with the conrod length reduction, and the raised port positions.

Large Felines

And since we've been mentioning Malcolm Stride, here's a picture of progress he's making on the Bobcat design. Back in December last year, we mentioned that that plans for his Lynx (aka NE15S were now being sold by him direct. I know many have bought "the music", then had trouble locating "the words" to go with them. Well Malcolm can now supply both. Visit the Nemett Engines website for details.

David-Andersen

I know there are many model engine enthusiasts all over the world fascinated by the engines made by Jan David-Andersen. The Bodø Aviation Historical Society (Norway) has a very comprehensive coverage of the various types, displayed in chronological order. At the moment, you will need to run the pages through a translator unless you read Norwegian, but I've been informed that English text will be added soon. Click the thumbnail to go direct to the Modellfly page.

Anodizing and Fatigue

Here's one from the "you have been warned" file: A recent issue of Sport Aviation, the Experimental Aircraft Association (EAA) journal, contains an article about the crash of a previous Grand Champion rotary wing aircraft due to fatigue failure of a control rod in flight. The rod appears to have been part of the cyclic controls. Although the crash appears un-survivable, thankfully the pilot/builder suffered only a sprained ankle. The airframe was still low-time and many other examples of the type have been flying for far longer without incident. The article attributes the failure to a reduction in strength of the control rod due directly to the anodizing which had been applied purely for appearance, and to appeal to the Grand Champion judges. References and numbers are quoted suggesting anodizing and the preparatory cleaning stage can reduce the fatigue life by a factor of 5.7 from the "natural" state. We anodize model parts principally for appearance, or sometimes to provide a better bearing surface as with the old Cox engines, so fatigue is not generally a concern. But model engine builders seem to like motorcycles too and I'm noticing an increase use of color anodizing on custom motorcycle parts. As the failure of say a wheel, at speed, would be nasty to say the least, this obscure piece of information is worth keeping in mind. For those feeling suddenly sober, a PDF of the article can be read at:

http://www.experimentalhelo.com/Anodizing&Fatigue.pdf

Watzat?

Not a Watzit, per se (as in What is it), more like a Watzat, as in What the devil is THAT! The object in question adorns the top of Les Stone's latest show quality model and looks to me like a cross between the hood ornament of an Austin and a Buck Rogers, rocketman helmet. Regardless, I love it. The engine itself should be recognizable to many engine builders and antique light plane enthusiasts; it has also been mentioned in passing here before. Les completed it this past month, although at the time of writing, weather precluded him taking it outside for a first run. Click the thumbnail, or visit the Les Stone Tribute page of the Engine Gallery for full details.

Be sure to have a look at the new entries in tha Gallery, too.

New Books and Magazines This Month

Last month I mentioned Jim Dunkin's Dennymite and Drones book, promising a review for this month which I'm pleased to deliver. Another new addition worthy of mention is a small, old volume which arrived early in March after more than two months in transit from the UK, as is a chalk and cheese reprint version of it—the reprint is the chalk—so two, or perhaps three book reviews this month, depending on how you count your chickens. First, the Dennymites.

Dennymites, Drones & More, sub-titled A Biography of Walter H. Righter ISBN 0-9767541-1-8, Dugout Publications USA, 2008. by James E Dunkin, is a 208 page, soft cover, printed in full color on glossy paper that describes precisely what you'd expect from the title. The author is an experienced model engine historian, having contributed to material to The Engine Collectors' Journal since late 1968. His first piece appeared in ECJ issue #30 of Jan-Feb 1969 and it detailed the pre-war Dennymites, so you could say that this book has been 40 years in the making. Let me tell and assure you, the wait has been worthwhile.

Even though the Righter name appears in the book sub-title, this is really his story. But the name Dennymite is more well known on model engine circles so it's quite right that this take top billing. Although Walter Righter designed it, built it, and prepared the advertising material, he wisely arranged distribution through a retailer who already had a reputation. This was film actor, Reginald Denny, hence the engine name. Through Jim's well researched and documented text, we learn that English born Denny had, like his father, chosen an acting career and was touring the USA in 1914 when war was declared between England and Germany. He enlisted in the Royal Flying Corps (RFC) and saw action in night intercepts where he was wounded by his own side. Despite this, he developed a life-long love of flying and later, returned to the USA to further his acting career, became an aero-modeler and opened a model shop in Hollywood, California. Reg either liked his name, or knew how to leverage his screen presence (he appeared in 37 movies between 1935 and 1939—these are listed in an Appendix). So we have the "Dennymite" engine, the "Dennyplane" and "Dennyplane Junior" and "Denny Bullet" airplanes, amongst others. In a somewhat similar vein, a long-ago colleague of mine named Hopper, called his boat the "Sea Hopper" and his car, the "Land Hopper". We suggested he call his lawnmower the "Grass Hopper"—but I digress...

The association between Denny and Righter continued after war was declared for a second time in the 20th century, producing a series of radio controlled, target drones for the US Army and Navy. The story of these had been researched and documented by Russell Naughton, of Monash University, Australia. You can read this on the Father of the UAV page of the Lawrence Hargrave tribute web site. Jim Dunkin was fortunate to meet with Walter Righter several years before his death in 1982 and much of the material in his book was made available by Frances Righter Tucker, Walter's daughter. Other material comes from the AMA Museum, Russell Naughton, and numerous model engine collections. Of all of it, I find the drones and the engines that powered them the most fascinating. It's tempting to précis them here, but I (and probably Jim too) would prefer you to buy the book and read it in full.

As well as covering the history of Righter's engines, the book includes a comprehensive set of Appendices that detail the various engine models and variations in parts. Scattered through the twenty-one chapters are extracts from the many patents Righter was involved with. These include everything from a rocker arm system developed for the Kinner engine company, through strain resistance gauges, to vacuum operated break systems for automobiles. The quality of the photographs and illustrations is extremely high, although a couple of the of old photographic print reproductions show evidence of having been digitally enlarged just a tad too much to fit with the format of the book. A Table of Contents is provided (naturally), but no Index. Understandable as this is a big job usually undertaken by specialists who do nothing else brought in by the publisher. The book is available only from Jim. You can contact him by writing to:

James E Dunkin,

PO Box 695,

Grain Valley, MO 64029,

USA

You can also telephone him on +01 816 2299671, or send Jim an email as

[email protected]. The book costs US$60.00 plus $6 post and handling within the USA, or $11.95 for most other countries. Jim accepts PayPal, but passes on their rather large "cut" of each transaction. Model Engine News loves this book, unfairly knocking off half a star for the lack of an index, but gives

Dennymites & Drones an otherwise unqualified endorsement: four and a half stars

and you'll spend hours and hours enjoying this one—I sure am.

-oOo-

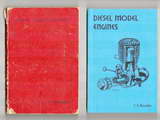

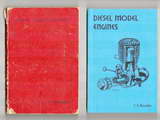

The second book is Diesel Model Engines, by CE Bowden. This was published by Percival Marshall & Co Ltd, London, back when they were the publishers of the Model Engineer. The first edition appeared in 1947, sporting 161 numbered pages (the red volume). This went to a second impression in 1948, then two revised editions which appeared in 1949 and 1951. The blue, 216 page softcover volume on the right in the picture is a 1993 reprint of the 1951 revision put out by TEE Publishing, ISBN 1-85761-035-0. I paid £10.95 for the reprint. Fifteen years later, I tracked down a copy of the first edition in quite nice condition for £5.00, so they are out there, if you are patient. Overall, I like the first quite a bit, but am less chuffed over the reprint.

The second book is Diesel Model Engines, by CE Bowden. This was published by Percival Marshall & Co Ltd, London, back when they were the publishers of the Model Engineer. The first edition appeared in 1947, sporting 161 numbered pages (the red volume). This went to a second impression in 1948, then two revised editions which appeared in 1949 and 1951. The blue, 216 page softcover volume on the right in the picture is a 1993 reprint of the 1951 revision put out by TEE Publishing, ISBN 1-85761-035-0. I paid £10.95 for the reprint. Fifteen years later, I tracked down a copy of the first edition in quite nice condition for £5.00, so they are out there, if you are patient. Overall, I like the first quite a bit, but am less chuffed over the reprint.

TEE should be thanked for making old works like this one available again and they always choose (and probably destroy) a good condition copy as the master. The problem for them is the process used to copy the pages. It ends up looking like a photocopy of a photocopy. The print is "wispy" and the photographs lacking in grey scale. I'm sure there must be better processes available, but I guess if you are reprinting a book for a small market and are going to have to warehouse a print run while they sell, economy and what the market will bear must be kept in mind. Don't get me wrong, the print is perfectly readable, the line drawings excellent, and you can sort of see the subjects in the photographs, although they lack definition, as this example shows. To me however, the reprints lack a certain something.

Ok, never mind the quality, feel the width: what does it contain? The first edition had five chapters; the third has six, accounting for some of the extra 55 odd pages. The new chapter in the third edition is titled British and Continental Diesel Engines, Plans and Castings. This subject was part of Chapter 1 in the first edition and Bowden notes in his foreword to the 1951 revision how much progress had been made in just a few years, accounting for what could be covered in a few pages in 1947 requiring a whole chapter in 1951. Not only were there many new manufacturers and models, some mentioned in 1947 were no longer in production—the the MAS ACE for example, which receives no mention in the later edition. The remaining chapters follow the same general themes, even if there is some re-arrangement. The first chapter describes how a compression ignition works. Later chapters cover fuel, starting and operation, timing devices, and suitable models for land, sea, and air. Some material from the first edition was retained, although the differences are sufficient enough to call the third edition almost a completely new book.

For model engine historians and the just plain curious, the first edition contains more esoteric information from the early days of diesels, while the reprint has broader scope. Complete-ists will want both. I rate the original at Four Stars  , the reprint at three

, the reprint at three  . The first edition was chased down using the Advanced Book Exchange. Strangely, some copies of the reprint are turning up there at rather outlandish prices, considering you can still buy the TEE "Past Masters" reprint from Amazon, though British readers could and should go direct to the publisher.

. The first edition was chased down using the Advanced Book Exchange. Strangely, some copies of the reprint are turning up there at rather outlandish prices, considering you can still buy the TEE "Past Masters" reprint from Amazon, though British readers could and should go direct to the publisher.

Tech Tip of the Month

What can I say? It's cams again, all the way down. And I've managed once again to side-step the task of concocting a Tech-Tip, this month through the generosity of MEN reader, Graham Meek (UK) and Engineering in Miniature, the British magazine where Graham's article first appeared. EIM have generously given permission for it to appear here for all to consider and enjoy—for which we thank them. In his article, Graham demonstrates Yet Another Way of machining cams in the lathe to produce fabricated camshafts. A link to it has been added to the general Harmonic Cams How-To page, or you can click on the picture of Graham's finished cam shaft to go directly to the page.

ACE Tanks

How could I let a month go by without mention the the ACE? )really observant readers will have spotted the subtle reference in the Bowden Book Review  ) Full construction plans for making your own ACE replica were released to Model Engine News Members last month as the march Free Plan. Non-members can order a set of plans for $US15, airmailed anywhere in the world. Castings will be available through Roger Schroeder's Classic Model Engine Kits, and the last part of the puzzle—the highly distinctive ACE fuel tank can be ordered from David Owen by sending him US$10.00 or UK£5.00 in a plain brown wrapper.

) Full construction plans for making your own ACE replica were released to Model Engine News Members last month as the march Free Plan. Non-members can order a set of plans for $US15, airmailed anywhere in the world. Castings will be available through Roger Schroeder's Classic Model Engine Kits, and the last part of the puzzle—the highly distinctive ACE fuel tank can be ordered from David Owen by sending him US$10.00 or UK£5.00 in a plain brown wrapper.

(and no, the prototype ACE replica is not running yet—still have piston lapping to go, so maybe next month...)

Dynamic 09 BB

Dynamic 09 BB

ETW Plans in Model Engineer

ETW Plans in Model Engineer

Zephyrs, Timing, and Things

Zephyrs, Timing, and Things

Large Felines

Large Felines

David-Andersen

David-Andersen

Anodizing and Fatigue

Anodizing and Fatigue

Watzat?

Watzat?

ACE Tanks

ACE Tanks

and you'll spend hours and hours enjoying this one—I sure am.

and you'll spend hours and hours enjoying this one—I sure am.

, the reprint at three

, the reprint at three  . The first edition was chased down using

. The first edition was chased down using

) Full construction plans for making your own ACE replica were released to Model Engine News Members last month as the march Free Plan. Non-members can order a set of plans for $US15, airmailed anywhere in the world. Castings will be available through

) Full construction plans for making your own ACE replica were released to Model Engine News Members last month as the march Free Plan. Non-members can order a set of plans for $US15, airmailed anywhere in the world. Castings will be available through