Editorial

Welcome to the Sixth Anniversary Issue of Model Engine News, and Happy Fourth to all readers in the USA! The current monthly magazine-like format with the first of the month release schedule went live on July 7th of 2002. Prior to that, the front page had been fixed, with new pages added on an as and when basis, with changes (mostly) noted on a What's New? page. This became unmaintainable (a regular PIA, actually), so I decided to go "monthly" and see how long it would last. Well, despite a thankfully tiny number of sour incidents from a very small set of money hungry individuals who have taken exception over some content, we are still here (and still resisting the urgings from one of our earliest supporters to change to a two-weekly format!  ). For the record, as of this date, this web site comprises 735 HTML pages in 179 directories, with 1,184 images, 20 pdf documents, three sound files, two movies, and 138 things that defy simple classification.

). For the record, as of this date, this web site comprises 735 HTML pages in 179 directories, with 1,184 images, 20 pdf documents, three sound files, two movies, and 138 things that defy simple classification.

Following the fine get together with Adrian Duncan in Canada last month, Motor Boys Dave Owen and Vincent Chai dropped by for a visit in Brisbane during June. The photo shows, left to right, David, Vincent, and moi in the MEN Only Library and Engine Fondling Den. We went out to the Thunderbirds C/L Club field in the morning so they could watch me get blown out of every vertical maneuver I was foolish enough to try in the wind, then we had a fine lunch, followed by some engine fondling. Both Dave and Vincent ran their twin ball-race, side-port diesels at over 18K rpm, a speed which many believe no side-port is capable of! Vincent's screamer is a refinement of a venerable Model Engineer design he calls the Battiwallah Spacial. Dave's was one of his 2.8SP Limited Edition diesels described here way back in the December 2003 issue. The photos below show the latter bolted to my Bar-B-Q plate. It's not as evil as it sounds—that plate can no longer be used for the stated purpose as open, out-door fires of all types have been banned by our nanny-state. I wonder if the legislators involved have a connection with any of the gas fired Bar-B-Q supply business that have sprung up like mushrooms? But then again, perhaps I'm just too grumpy, old, and cynical.

Following the fine get together with Adrian Duncan in Canada last month, Motor Boys Dave Owen and Vincent Chai dropped by for a visit in Brisbane during June. The photo shows, left to right, David, Vincent, and moi in the MEN Only Library and Engine Fondling Den. We went out to the Thunderbirds C/L Club field in the morning so they could watch me get blown out of every vertical maneuver I was foolish enough to try in the wind, then we had a fine lunch, followed by some engine fondling. Both Dave and Vincent ran their twin ball-race, side-port diesels at over 18K rpm, a speed which many believe no side-port is capable of! Vincent's screamer is a refinement of a venerable Model Engineer design he calls the Battiwallah Spacial. Dave's was one of his 2.8SP Limited Edition diesels described here way back in the December 2003 issue. The photos below show the latter bolted to my Bar-B-Q plate. It's not as evil as it sounds—that plate can no longer be used for the stated purpose as open, out-door fires of all types have been banned by our nanny-state. I wonder if the legislators involved have a connection with any of the gas fired Bar-B-Q supply business that have sprung up like mushrooms? But then again, perhaps I'm just too grumpy, old, and cynical.

The difference in volume and pitch between the silenced and unsilenced state of the Owen 2.8SP is nothing short of remarkable. The muffler just pushes over the circular exhaust with a piece of silicon tube. This allows it to be pulled off to drain the oil (it's a baffle chamber type) and Dave says he's never had one fall off while running. Would be a great crash resistance feature on a combat model too. The device on the rear is a cut-off, not a throttle as the engine is intended for Texaco events. Dave has a batch under construction and we'll let you know when he's ready to accept orders.

And, finally, Yes!! The Myford is motor powered again! While I really wanted to install a phase converter, a sudden need to do some urgent plumbing work under the sink in the kitchen demanded a lathe, so the repaired single-phase AC unit went back in and the breeding pen for strange new life forms, otherwise known as a long defunct garbage disposal, got replaced with straight pipework (and more gender benders than I really want to think about). Next time the lathe motor blows up, I'll look more seriously at a nice, new, speed controlled motor. Anyway, there can be no more excuses for not finishing the last Whippet and firing them up now...

Stunt Engine Drawings

Remember Brian Turner's rear exhaust F2B engine mentioned here stating in the February and March 2008 issues? The kind gentleman who took the photos and posted them to Stuka Stunt Forum has now collected all and made a series of pages available on his web site. The pages are not yet fully complete, but the URL should be stable. I've added this to the non-commercial links section of the Links page, or you can click the thumbnail pic to go direct to Mikes web site.

AAO Cox Cylinders

AAO cylinders? Why would such a fine, upstanding citizen like Aaron Novak want an aluminum, Adults-Only cylinder for his Cox 049? Obviously the "AO" must stand for something else, and it does: aluminum oxide. As anyone who has used an aluminum oxide abrasive will know, this stuff is hard! Aaron (who's day job is in high speed marine engines) found a company able to apply the oxide as a cylinder liner coating that is very hard and offers low friction. So as an experiment, he has turned up a number of cylinders to the Cox pattern which will be so coated, then mated with pistons cast from a 24% silicon aluminum alloy, fitted with a conventional wrist pin and rods made from 7075 alloy. The rod will be thicker than the Cox ball-end steel rod, but the lower pivot point means it will still swing in the space available. His mass estimates indicate the result will be about 15% less than the Cox parts. Aaron is doing this for his own amusement and the confusion of future engine historians, so no use flooding him with orders. We'll report the results here in the fullness of time, but regardless, I think he deserves a big round of applause for the outside the square thinking behind his project.

Updates to Friends Old and New

Some changes for the better have been made to the Sparey 5cc Construction and the Allbon Bambi pages. In both cases, some errors have been fixed and the display font brought into line with current standards. The Bambi page contained a dreadful error where I had the surname spelling wrong for Ray Malstrom (aka, "Flair Phill"). The changes in the Sparey piece are to improve readability and (ahem) correct the odd type and spelling error, or two. Changes in the Gallery are new entries on the Les Stone Tribute page and the Darrel Peugh page. In the latter case, Darrel has supplied pictures of some unusual engines that I rather think you'll enjoy and thanks go to Darrel for his efforts. Les Stone has taken more details shots of his Les Chenery designed Aero V-Twin. Be sure to check the New entries in the Finder and the updated pages lists as well.

New Members' Free Plan

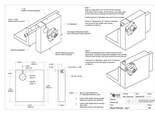

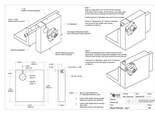

July 2008 marks the tenth anniversary of this website and the sixth anniversary of the current "monthly web-zine" format. To mark this grand occasion, Members receive a bonus free plan set, downloadable in PDF format from the Members' Update page. And no surprise, it is the Black Mamba, a KK Cobra clone based on Cox 049 parts. The plan is a little different from our usual fully detailed, model engine construction set, but still runs to eight 3D CAD pages even though the stock Cox parts are not detailed. The plans show two different styles for backplate machining to suit the old beryllium copper reed with wire circlip retainer, or the newer synthetic reed and plastic retainer cage. The letter style makes for much easier machining, so would be the one to scavenge if you can. I'd also try to get a Cox Black Widow cylinder and piston assembly in preference to the old single transfer Baby Bee, or even the twin slit QZ exhaust version.

The plans include details of a jig that will greatly simplify one of the critical areas, namely how to align and drill all the holes for the needle valve bush, fuel jet and fuel nipple using a lathe only. All work could be easily accomplished on a small tabletop machine like the excellent little Sherline and the jig drawing has been dimensioned for this lathe. Owners of larger machines can easily adapt the jig from the data provided. Builders will need castings for the crankcase and backplate. Dirk Tollenaar who supplies the Bob Shore PeeWee kit is looking into supplying these, and an option, if practical, to include a finished needle valve bush tapped with the unusual and very fine 4-80 thread.

There are some technical issues to be worked through in relation to the patterns for sand casting, but provided all can be overcome and a proof of quality engine machined, we will announce here when they are ready. I must add that aside from preparing the plans, neither Model Engine News, the Motor Boys, nor I have any connection with this enterprise—the idea and initiative are all Dirk's, so he gets to do all the hard work and receive all the rewards—although as Ivor F once said, the only way to make a small fortune out of building model engines is to start with a large one!

Super M-7 Nearing Completion

Rather than hide this one away in The Gallery, I thought it rated a news entry all of its own. The subject is Otis Baker's rendition of the Super Morton M-7 radial, based on design work being done by Bruce Satra, and Bob Roach, with input from several others, including Otis himself (he's just uncovered a slight interference problem between the mounting lug behind the number seven pot and the inlet tube to that cylinder). As well as Otis' beautiful machining on the gearcase, take special note of Bruce's latest modification to the old Morton cylinder design: an extra pair of cast-in pads allow the builder to choose between rear or side entry pipework. The SM-7 uses the rear pads which allows the inlet pipes to be a simple "L" bend, secured with lovely, scale-like castle nuts. This is far superior to the pipe-benders' nightmare and wring-in fit required by the original. We should see this engine running real soon now.

New Books and Magazines This Month

Apart from some magazines (Model Engineer, and Model Engineers' Workshop), nothing new came into the Library in June. However, I has made aware of a new two-stroke book by Dave Gierke. I've not got my hands on a copy yet, and it has not managed to filter down into Amazon either, but from the cover, it would appear to follow directly on from his older and excellent book on model two-strokes. Having covered history, development and basic concepts earlier, the focus of this one appears to be fuel and fuel systems related. Dave wrote an excellent series on model engine testing which appeared in Flying Models way back, including details of his torque reaction dynamometer and the lengths he went to in order to produce repeatable results. I have a lot of respect for him and his efforts, so while I can't make sight-unseen recommendations, I'd expect to like this one. More when I've actually seen one (he designed and build some damn fine control line stunters too).

Engine Of The Month: Kalper

The target under Adrian Duncan's microscope this month is a pair of diesels from Brighton: the 0.32cc Kalper and the 1.2cc 4-Some. Both date from the period 1948 through 1951 and are considered quire rare birds today. As well as originating in an area not exactly known for model engine manufacture, there are visual similarities and both have low bore to stroke ratios. Both were, at one time, sold through the same outlet: Arthur Mullet's Model Shop. Adrian looks at the engines to see if there might be a closer tie between them.

Tech Tip of the Month

Every month, we respond a model engine builders who email in with questions and problems. There is no charge; we just do it because we love engines and want to help others like us (although non-members might get a gentle hint that contributing to the cost of running the site through purchasing the MEN DVD would be greatly appreciated  ). Last month, a reader—who is now a Member—asked about ways of producing a square hole in a prop driver for and engine he wanted to restore. As it turns out, this is disgustingly easy, once you know how, and is something we've described twice: once in an SIC magazine article (Volume 12, Issue 70, page 9) by Roger Schroeder and myself titled the Stroke-a-Genius Square Hole Broach, and a second time as a photo sequence in the Morton M-1 build article I wrote way back for Model Engine Builder magazine. Seems like the trick really should appear in these pages too, so this month's Tech Tip is a new page in the How-To section that describes how anyone with a lathe and a bit of ingenuity can produce small, square holes with high precision and very little effort.

). Last month, a reader—who is now a Member—asked about ways of producing a square hole in a prop driver for and engine he wanted to restore. As it turns out, this is disgustingly easy, once you know how, and is something we've described twice: once in an SIC magazine article (Volume 12, Issue 70, page 9) by Roger Schroeder and myself titled the Stroke-a-Genius Square Hole Broach, and a second time as a photo sequence in the Morton M-1 build article I wrote way back for Model Engine Builder magazine. Seems like the trick really should appear in these pages too, so this month's Tech Tip is a new page in the How-To section that describes how anyone with a lathe and a bit of ingenuity can produce small, square holes with high precision and very little effort.

Now for something mentioned in these pages before, but well worth revisiting: the adjustable, external hone. The subject was prompted by a wonderful little innovation David Owen pulled out of his goodies box during his recent visit. It's one of those things you look at for the first time and think,

how obvious, and why didn't I think of it!

The little hand-held Delapena external hone is an indispensible tool for piston and crankshaft finishing. Sadly, the original product has not been available for many, many years and it is even a rare event to see one crop up in the tooling section of eBay. This photo shows what you got for not a lot of money back in the 50's: a set of guides with matching stone holders to cover a range of external diameters ideally suited to making small engines, a holder for the stones and guides, and some all-important "truing sticks" for the stones.

The little hand-held Delapena external hone is an indispensible tool for piston and crankshaft finishing. Sadly, the original product has not been available for many, many years and it is even a rare event to see one crop up in the tooling section of eBay. This photo shows what you got for not a lot of money back in the 50's: a set of guides with matching stone holders to cover a range of external diameters ideally suited to making small engines, a holder for the stones and guides, and some all-important "truing sticks" for the stones.

An article describing a kit built Delapena Hone Clone appeared in the Model Engineers' Workshop in the June/July 1997 issue. I was lucky enough to move quickly for once and secure one of these kits before the company making them disappeared. As you can see, it is close to an exact copy, although the article failed to mention the "truing sticks" which are used to true the stone to the guide, thus ensuring that the hone produces a cylinder with neither taper, nor barrel distortion.

An article describing a kit built Delapena Hone Clone appeared in the Model Engineers' Workshop in the June/July 1997 issue. I was lucky enough to move quickly for once and secure one of these kits before the company making them disappeared. As you can see, it is close to an exact copy, although the article failed to mention the "truing sticks" which are used to true the stone to the guide, thus ensuring that the hone produces a cylinder with neither taper, nor barrel distortion.

Nick Jones (Uk) made his own version of the tool, details of which appeared here in the April 2006 issue. Nick, with tongue firmly in cheek, dubbed it the Nikkapena Hone and built a magnificent fitted wooden case to go with it. The result looks almost too good to actually use. Through his business, Nick is blessed with a CNC shop and the knowledge of how to actually use it, hence making three tools to cover the range of sizes is not the chore it appears, although you don't produce quality like this without significant effort regardless of the tools that you use to do it.

Nick Jones (Uk) made his own version of the tool, details of which appeared here in the April 2006 issue. Nick, with tongue firmly in cheek, dubbed it the Nikkapena Hone and built a magnificent fitted wooden case to go with it. The result looks almost too good to actually use. Through his business, Nick is blessed with a CNC shop and the knowledge of how to actually use it, hence making three tools to cover the range of sizes is not the chore it appears, although you don't produce quality like this without significant effort regardless of the tools that you use to do it.

And finally we come to David's version. Instead of using castings, or CNC, Dave has simply fabricated the adjustable frame from flat aluminum plate, screwed together with button head Allen key screws. The guide and stone blocks fit into carefully milled channels, just like the prototypical tool, and the spring loaded adjusting screw works in precisely the same way as the original (the adjustment is so the tool springs apart enough to clear the work; closing pressure is applied by finger pressure). Dave has made a range of guides and truing sticks to cover the size of pistons he normally expects to work with.

And finally we come to David's version. Instead of using castings, or CNC, Dave has simply fabricated the adjustable frame from flat aluminum plate, screwed together with button head Allen key screws. The guide and stone blocks fit into carefully milled channels, just like the prototypical tool, and the spring loaded adjusting screw works in precisely the same way as the original (the adjustment is so the tool springs apart enough to clear the work; closing pressure is applied by finger pressure). Dave has made a range of guides and truing sticks to cover the size of pistons he normally expects to work with.

We discussed drawing plans for David's hone and may eventually do so, but I'm sure any relatively experienced model engineer could make their own just from the picture. If you make engines and don't have an external hone, you can't imagine what you are missing until you use one.

The End of eBay

Since it opened the "doors", eBay has been generally a good thing for model engine enthusiasts. Collectors found the engines they were after from sellers all over the world. Sellers got Crazy-Ivan prices as bidders who decided that they simply must have it at any price went into their feeding frenzy. Well it looks like that is destined to come to an end, or at best severely decline, due to new regulations imposed by eBay that will drive out, or worse, lock out the small seller.

What's happened is sellers can no longer leave negative feedback about a buyer, but buyers can trash a seller through unsubstantiated negative feedback and that seller has NO way of disputing, nor will eBay discuss the issue! (privacy issues, you understand) The final nail is the way a seller's "ranking" is defined as the positive to negative feedback percentage ratio, and the policy of disbarring sellers who fall below a very, very high threshold. Any person who thinks about this for ten seconds will see that it's a numbers game. A high volume seller can stand a lot of negative feedback, but a small volume seller will be out the door real quick. Guess what kind of seller typically sells model engines? And look at the how easy it would be for a small number of collaborators to get such a seller black-listed.

Now look at all the "business traders" that are permeating, if not dominating eBay these days. Not infrequently, they are located in the cheap manufacturing countries—virtually side door factory outlets, as shown by the multiple identical items with a "Buy It Now" price. Finally consider eBay's business model where their fee comes from the initial listing; the more listings, the more profit. Too bad there are all these small volume sellers cluttering up the lists... ...but wait! If we can create an environment where small volume sellers get squashed out... Ok. Maybe my grumpy old man cynicism is showing through again, but mark my words and keep an eye on this one. See you next month.

Stunt Engine Drawings

Stunt Engine Drawings

AAO Cox Cylinders

AAO Cox Cylinders

Updates to Friends Old and New

Updates to Friends Old and New

New Members' Free Plan

New Members' Free Plan

Super M-7 Nearing Completion

Super M-7 Nearing Completion

The End of eBay

The End of eBay

Editorial

Editorial

New Books and Magazines This Month

New Books and Magazines This Month

Engine Of The Month: Kalper

Engine Of The Month: Kalper

Tech Tip of the Month

Tech Tip of the Month

Standard Stuff

Standard Stuff

). For the record, as of this date, this web site comprises 735 HTML pages in 179 directories, with 1,184 images, 20 pdf documents, three sound files, two movies, and 138 things that defy simple classification.

). For the record, as of this date, this web site comprises 735 HTML pages in 179 directories, with 1,184 images, 20 pdf documents, three sound files, two movies, and 138 things that defy simple classification.