Editorial

Where are these months going? August already. Can't say precisely how many visitors we had this month because the hit counter was off line for quite a while (see my little winge at the end of this month's editorial for the sad tale). It was somewhere in the region of 2500+. Not as good as the month before—maybe a flaming logo will help...

However, there was some action in the shop at least, even though it was constrained to restoration work. So this month, you can read about a new way to make conrods, head slitting for beginners, and other stuff. Action at the CAD station saw plans for a 0.1cc miniature diesel completed (rendered in 3D at left), plus a start made on drawings for the Swiss Buchmann 0.6cc diesel by tracing over a scan from an old book. Other action was putting together a tutorial on metadata schema design for DSTC's Evolve 2003 Conference where the theme is Enterprise Information Integration. Our annual conference will be in Sydney again this year, so come along and I'll talk your ears off about metadata, software engineering, or engines, depending on whether you catch me behind the podium, on the floor, or in the bar.

However, there was some action in the shop at least, even though it was constrained to restoration work. So this month, you can read about a new way to make conrods, head slitting for beginners, and other stuff. Action at the CAD station saw plans for a 0.1cc miniature diesel completed (rendered in 3D at left), plus a start made on drawings for the Swiss Buchmann 0.6cc diesel by tracing over a scan from an old book. Other action was putting together a tutorial on metadata schema design for DSTC's Evolve 2003 Conference where the theme is Enterprise Information Integration. Our annual conference will be in Sydney again this year, so come along and I'll talk your ears off about metadata, software engineering, or engines, depending on whether you catch me behind the podium, on the floor, or in the bar.

Another Source for Westbury Plans

Readers of the late and very lamented SIC magazine will surly remember the name Bob Paule. I've sort of been aware for some time that Bob had some connection with Sulphur Springs Steam Models in the USA, but had never bothered to look over their web site as steam is not my bag. I should have though, as there are items in their price list of interest to model engine builders too.

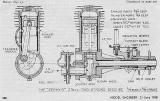

All this was sparked off by a request from a reader seeking the plans for Edgar T Westbury's Zephyr 2.5cc two-stroke, spark ignition engine pictured at the left here. I knew that Model Engineer had run a series by ETW in 1968 on model two strokes featuring (naturally) his designs as examples. That was easy to find. Just about every engine he designed appeared as a construction series in ME, the exceptions being some of his early, larger engines, and the Channel Island Special, I believe. Finding the actual issue is another matter, even with an index. Fortunately, my reader managed to quickly answer his own question by discovering that Sulphur Springs has a very good selection of the ME published ETW designs available from stock. Alas, they have no castings, but at least you now know where to find the plans.

All this was sparked off by a request from a reader seeking the plans for Edgar T Westbury's Zephyr 2.5cc two-stroke, spark ignition engine pictured at the left here. I knew that Model Engineer had run a series by ETW in 1968 on model two strokes featuring (naturally) his designs as examples. That was easy to find. Just about every engine he designed appeared as a construction series in ME, the exceptions being some of his early, larger engines, and the Channel Island Special, I believe. Finding the actual issue is another matter, even with an index. Fortunately, my reader managed to quickly answer his own question by discovering that Sulphur Springs has a very good selection of the ME published ETW designs available from stock. Alas, they have no castings, but at least you now know where to find the plans.

A Gaggle of Glow Chief

I've never really been a fan of the Glow Chief range of engines, even though I'm frequently accused of being a tad fanatical over their brother Taipans. Still, when offered the chance to get one in exchange for doing a little restoration on two others, how could I resist? The work required making new heads and NVAs, and may yet stretch to a piston or two. But as the techniques required to make the heads are not something I've covered elsewhere, I've documented it as a Work in Progress and you can read about it on the restorations page. Just click the link in the column opposite and select Glow Chief 19, or click on the photo for a direct link.

I've never really been a fan of the Glow Chief range of engines, even though I'm frequently accused of being a tad fanatical over their brother Taipans. Still, when offered the chance to get one in exchange for doing a little restoration on two others, how could I resist? The work required making new heads and NVAs, and may yet stretch to a piston or two. But as the techniques required to make the heads are not something I've covered elsewhere, I've documented it as a Work in Progress and you can read about it on the restorations page. Just click the link in the column opposite and select Glow Chief 19, or click on the photo for a direct link.

YAWT Radius Conrod Ends

There are some operations which, despite being relatively simple, I do not look forward to when building an engine. Making conrods and especially radiusing the ends of said conrods is one of these. There must be a squillion conrod designs, from the "dog-bone" to the simple flat plate. I'd also say that over the life of his Sabres, Taipans and Glow Chief engines, Gordon Burford tried every one of them, without a lot of repetition! When faced with making a new rod for a Series 66 Taipan diesel (look it up in the Engine Finder), I noticed some machining marks on the ends of the originals that indicated they had been radiused in a way I'd never thought of before. I've taken a few shots of the process (Yet Another Way To ...) which I now rather like and as this was a restoration job, you can find it under restorations, although it probably deserves more prominent display. Click the photo at the left for a direct link.

There are some operations which, despite being relatively simple, I do not look forward to when building an engine. Making conrods and especially radiusing the ends of said conrods is one of these. There must be a squillion conrod designs, from the "dog-bone" to the simple flat plate. I'd also say that over the life of his Sabres, Taipans and Glow Chief engines, Gordon Burford tried every one of them, without a lot of repetition! When faced with making a new rod for a Series 66 Taipan diesel (look it up in the Engine Finder), I noticed some machining marks on the ends of the originals that indicated they had been radiused in a way I'd never thought of before. I've taken a few shots of the process (Yet Another Way To ...) which I now rather like and as this was a restoration job, you can find it under restorations, although it probably deserves more prominent display. Click the photo at the left for a direct link.

The Zimmerman Valve

No, not a Bob Bylan tribute brass band, it's a variation on the rear rotary valve induction concept that I was blissfully ignorant of until Ken Croft visited a tether car track in the Black Forrest and sent back some pics. These tether car fanatics have been quietly having fun developing the humble two-stroke to astounding peaks of performance. I'd thought the little screamers in the nose of F1C and F1J models that spin at about 30,000 rpm for 7.5 seconds of vertical ascent were the peak, but the engines driving those blurs on the tether car track are achieving 44,000 rpm (that's forty-four thousand revs per minute) from a 1.5cc engine, tempting me towards a whole new range of adjectives!

Ken says that most of these high performance engines are using the Zimmerman Valve (let's call it the Z-V for short), and supplied a photo to answer my "watzat?" question. I think it's accurate enough to say that the vast majority of speed engines (two-strokes) are based on the rear rotary valve (RRV) concept. Think Dooling, K&B, McCoy, Bugel, Rossi, etc, etc. All these place the valve inside the crankcase cavity and drive it from the crankpin. The Z-V is similar, but resides in a separate cavity—the idea being that this isolates it from the pressure fluctuations in the crankcase, resulting in lower friction. Although it seems to me that the reduction in friction is not going to be great (there still must be an arm inside the case that is driven by the crank pin after all), I guess when you are chasing the last possible erg, anything helps. I did a web search and found a few references to commercial engines employing the Z-V. Surprisingly, all were intended for hydro use, both tethered and R/C. Yet Another engine development area which I, for one was totally ignorant of...

Ken says that most of these high performance engines are using the Zimmerman Valve (let's call it the Z-V for short), and supplied a photo to answer my "watzat?" question. I think it's accurate enough to say that the vast majority of speed engines (two-strokes) are based on the rear rotary valve (RRV) concept. Think Dooling, K&B, McCoy, Bugel, Rossi, etc, etc. All these place the valve inside the crankcase cavity and drive it from the crankpin. The Z-V is similar, but resides in a separate cavity—the idea being that this isolates it from the pressure fluctuations in the crankcase, resulting in lower friction. Although it seems to me that the reduction in friction is not going to be great (there still must be an arm inside the case that is driven by the crank pin after all), I guess when you are chasing the last possible erg, anything helps. I did a web search and found a few references to commercial engines employing the Z-V. Surprisingly, all were intended for hydro use, both tethered and R/C. Yet Another engine development area which I, for one was totally ignorant of...

New (and Not So New) Books This Month

If an indicator of a really good book is one that keeps you up late at night, still turning the pages, even when you know what's going to happen, then I've read a doosey this month.

First Flight by TA Heppenheimer (Wiley & Sons Inc,2003, ISBN 0-471-40124-2) is a combination biography, history and techno-thriller that traces in detail, how the Wright brothers went from having a casual interest in flying machines, to being the first to achieve heavier than air, powered, man-carrying flight in just four years of part time research and experimentation. Engine lovers will probably be a bit disappointed that the power plant of the 1903 Flyer does not get more coverage, but engines are apparently not a passion for Mr Heppenheimer—who gives what I'd thought to be a very poor explanation of the two-stroke cycle. I've revised my opinion upwards a little though after Bert Streigler pointed out that if you want to describe the action in a simple, single sentence, he'd done a fairly good job. Anyway, I really enjoyed reading this one, so make me rich, click on the photo and order a copy from Amazon dot com.

Building the Bentley BR2 World War I Rotary Engine

Building the Bentley BR2 World War I Rotary Engine

About an hour's drive north of me is the sleepy little town/area called Buderim (say "Bud-rum" with emphasis on the first syllable and you'll be close to our incomprehensible pronunciation). I mostly remember it from my vanished youth by a sign on the road to my favourite surfin' spot that proclaimed "Buderim Ginger Factory Next Right". It was to this sleepy hamlet that Lew Blackmore retired and proceeded to build his remarkable engines—most notably, the Bentley BR2 that won the coveted British Duke of Edinborough Cup for Lew—taking it out of the UK for the first time ever. Alas, Lew passed away before I could meet him, but not before self-publishing a book based on a long series that appeared in Model Engineer on building his scale Bentley BR2 rotary. Although the original, hard bound book sold out long ago, it has been reprinted with a soft cover by Camden Miniature Steam of the UK, and can be ordered through Amazon. The book contains full drawings and copious photos with words describing each part.

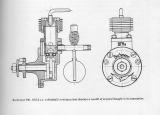

I mention this because it has a direct connection to the book describing the Clerget that was reviewed here last month. I decided to tinker about with scans of the Clerget to see just how practical a scale model of it might be (answer? even a 1:5 model would be too big for my present lathe). Somewhere in the back of my mind, I knew that Bentley had some connection with the Clerget, but it was not until I started looking closely at the Clerget cam gear that I knew I'd seen it all before—in the BR2 book! So some digging in the library led to the work Bentley (who had joined the British Navy at the start of World War I) did to improve the reliability of the Clerget. All sources agree that the "obdurator" rings at the top of the piston were the Achilles' heal of that engine. The cylinders were machined from steel and had walls only 3mm thick. To maintain a seal as they distorted under running heat, an odd, flexible ring (called the obdurator by the French inventor) was used. When this ring (actually a two-part affair) broke, the cylinder overheated, distorted and generally made life exciting for the pilot. If he managed to limp home, the cylinder had to be replaced (blue cylinders being an indication of a broken obdurator)—and this made life bad for the mechanics as the crankcase had to be split in half to replace the cylinder—a long and tedious procedure. Just what Bentley did varies with the source you read. Most say he replaced the Clerget iron pistons with aluminum ones. These had less heat retention, resulting in longer obdurator life and made the engine much more reliable. Another source suggests that the Clerget already had aluminum pistons.

Whatever, it is agreed that Bentley developed the AR1 (Admiralty Rotary engine number one) as a variant of the Clerget with separate, screwed in heads and other improvements. This engine was later renamed the BR1 in Bentley's honor. From there, he went on to design the BR2 which retained those aspects of the Clerget of which he approved, and replaced those he knew had shortcomings. The shaft, thrust bearings, maniton and epicyclic timing gear remained roughly the same, as did the head arrangement, master/slave rods and lubrication system. However the BR2 cylinders had aluminum cooling jackets over a cast iron liner (sound familiar?), with separate heads. These were secured to the case with four long bolts having conical heads in conical recesses inside the case. The nuts pulled the head down onto the cylinder, and clamped the cylinder skirt onto the case bore. The BR2, fitted to the Sopwith Snipe, is agreed to represent the peak of rotary engine technology, and the swan-song for the type.

All of the above is to say that after looking at the prospect of drawing up a Clerget, I've found that there are a couple of aspects that make the BR2 a far more attractive choice. The negatives for the Clerget are the blind bore cylinders (which would have to be thicker than scale) and their method of attachment to the case. They could be screwed in, like Les Chenery did on his Gnome rotary plans (the Gnome and Clerget both clamped a flange rim machined on the base of the cylinders in a grove between separate crankcase halves). But this gives the problems of having the intricate machining on top of the head line up at the fully tightened position. Not insurmountable, but the bolt-down BR2 is so much better. Then there's the oval section induction pipes of the Clerget. Not impossible to make drawing a die through annealed tube, or by electro-deposition, but still a challenge. So if you want a challenge, build a Clerget. If you want a sure-fire, practical, running rotary, buy the BR2 book and built it instead.

And Still More Multi-cylinder Sleeve Valve Engines

Ken Croft has the kind of neighbor that would drive me to stamp collecting. Not content to build other people's designs, he chooses his own subjects, and makes sure that they are unique and unusual. His name is Tom Pascoe and his latest is a 42cc, three cylinder sleeve valve, four-stroke radial, just for fun. Ken managed to take some shots of the internals of this engine when it had to be torn down during initial trials to clear up something that had tightened up. Pictures and words have been added to the

Engine Gallery

Ignition Systems and More Gallery Stuff

An email from Clive Longstaff in the UK this month arrived with photos of a very nice Westbury Craftsman Twin. Being a horizontally opposed twin of the conventional sort, it is simultaneous firing (previously, I'd thought all flat twins would be like this, but was proven wrong (in print naturally) by a Saito). Simultaneous firing sparkies need a special coil, or two coils and Clive reported difficulties running the Craftsman due to a week spark. Some web research led to site specializing in this sort of stuff. Mike Neal of MjN Fabrication provides basic and advanced ignition equipment and spark plugs for model engines. His prices appear quite reasonable (US$4 for a NGK CM-6 10mm plug) and his site has some beautiful automotive type scale (working) engines. For future reference, MjN appears in the Suppliers Page under Coils and Ignition Accessories. You can see pictures of the Craftsman in the Gallery.

An email from Clive Longstaff in the UK this month arrived with photos of a very nice Westbury Craftsman Twin. Being a horizontally opposed twin of the conventional sort, it is simultaneous firing (previously, I'd thought all flat twins would be like this, but was proven wrong (in print naturally) by a Saito). Simultaneous firing sparkies need a special coil, or two coils and Clive reported difficulties running the Craftsman due to a week spark. Some web research led to site specializing in this sort of stuff. Mike Neal of MjN Fabrication provides basic and advanced ignition equipment and spark plugs for model engines. His prices appear quite reasonable (US$4 for a NGK CM-6 10mm plug) and his site has some beautiful automotive type scale (working) engines. For future reference, MjN appears in the Suppliers Page under Coils and Ignition Accessories. You can see pictures of the Craftsman in the Gallery.

Dragonflea

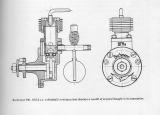

The Dragonfly was a small "diesel" of 0.1c, or 0.2cc capacity made in the early sixties. As far as I've been able to find out, it was never actually advertised, just available, presumably in small quantities from the famous HJ Nicholls model shop in London. I've never seen a "real one" and no one I know has one, although pictures appear in Clanford's A-Z. A news item about it did appear in Model Aircraft of January 1961, although the engine described there is different in some of the details from that appearing in Clanford's. From Ken Croft, I got some rough sketches he'd obtained from Tom Crompton, designer of the well-known EZE series that appeared in MEW. These have been turned into CAD drawings, and "made" into the 3D CAD image seen here. My version has enough differences that I feel justified in renaming it the Dragonflea. All this activity was prompted by the good experiences with the Allbon Bambi that has made me all excited about small diesels again following earlier disappointments with the Nano (perseverance and more cylinder/piston pairs is what's really required). Like the Bambi, I intend to use a steel piston in a steel liner for the Dragonflea to see if that is the "secret". Stay tuned, but don't hold your breath...

The Dragonfly was a small "diesel" of 0.1c, or 0.2cc capacity made in the early sixties. As far as I've been able to find out, it was never actually advertised, just available, presumably in small quantities from the famous HJ Nicholls model shop in London. I've never seen a "real one" and no one I know has one, although pictures appear in Clanford's A-Z. A news item about it did appear in Model Aircraft of January 1961, although the engine described there is different in some of the details from that appearing in Clanford's. From Ken Croft, I got some rough sketches he'd obtained from Tom Crompton, designer of the well-known EZE series that appeared in MEW. These have been turned into CAD drawings, and "made" into the 3D CAD image seen here. My version has enough differences that I feel justified in renaming it the Dragonflea. All this activity was prompted by the good experiences with the Allbon Bambi that has made me all excited about small diesels again following earlier disappointments with the Nano (perseverance and more cylinder/piston pairs is what's really required). Like the Bambi, I intend to use a steel piston in a steel liner for the Dragonflea to see if that is the "secret". Stay tuned, but don't hold your breath...

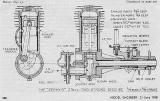

New Engine in the Finder: Buchmann 0.6cc

This little guy surfaced when I was passed the URL of a site in the UK pre-advertising plans and castings. I'll hold off giving the site as the plans and castings are not yet available. Beside, gives me something to write about when they are finally released. Anyway, it turns out the Motor Boy Tim Dannels (editor and chief of Engine Collectors Journal, in case you didn't know) has one of these. Tim has a world map on his Model Museum wall and has tried to find and attach an engine from all countries on the map (what have you got for Zanzibar, Tim? — only kidding

This little guy surfaced when I was passed the URL of a site in the UK pre-advertising plans and castings. I'll hold off giving the site as the plans and castings are not yet available. Beside, gives me something to write about when they are finally released. Anyway, it turns out the Motor Boy Tim Dannels (editor and chief of Engine Collectors Journal, in case you didn't know) has one of these. Tim has a world map on his Model Museum wall and has tried to find and attach an engine from all countries on the map (what have you got for Zanzibar, Tim? — only kidding  ). Well, you guessed it, Tim's artifact for Switzerland is a genuine Buchmann. I kinda like this little guy. Read why in the cardfile entry for it.

). Well, you guessed it, Tim's artifact for Switzerland is a genuine Buchmann. I kinda like this little guy. Read why in the cardfile entry for it.

From the What Will They Think Of Next File

I'm going to close off this month with yet another news item that I read of in

Sport Aviation, the

EAA journal. Bombardier has released news of a new, certified aero engine for light aircraft. If you are saying bomba-who? these is the Canadian company that bought, amongst others, Bill Lear's company (the Lear Jet), and Rotax who originally made the two-strokes that powered the Ski-Do snow-mobiles. They (Rotax, an Austrian company) started selling ski-do engines into the ultra-light market for powered hang-gliders and the like. Today, supplying this market is their main business line. For instance, the

Predator drone is Rotax powered, albeit by a four stroke of considerable sophistication. Well the latest offering is water cooled with some very advanced computer controlled features giving what they describe as "single lever" operation. No mixture control, no prop (constant speed) control, just a throttle; the computer does the rest. Sort of like a gas turbine, set the power required and forget the rest. The innovations don't stop there; this puppy will run on av-gas, or auto-gas, or a mix of the two with the computer figuring out the optimum timing required (Oz's leather-bound CASA bureaucracy would have apoplexy at the mere thought, let alone the actuality of such a thing). If you like engine developments, visit the

AVweb site and read all about it.

Averice

You may notice that my hit-counter went off-line this month, I certainly did! And you will notice that it has now changed somewhat, alas, not for the better. I use a free service for the counter that is provided by bravenet.com because even though writing one is not serious work, logging and graphing of hits is relatively serious work (Aside: I tend to avoid use the term "Rocket Science", because rocket design is not Science, it's Engineering!  Endof Aside) Well, the provider has decided to downgrade the free version and charge a not inconsequential monthly fee for the cooler versions. I sympathize with people having to make a buck, but as I don't, we'll have to put up with the ugly, yet free counter below. Sign of the times, I guess (grrr...)

Endof Aside) Well, the provider has decided to downgrade the free version and charge a not inconsequential monthly fee for the cooler versions. I sympathize with people having to make a buck, but as I don't, we'll have to put up with the ugly, yet free counter below. Sign of the times, I guess (grrr...)

Another Source for Westbury Plans

Another Source for Westbury Plans

A Gaggle of Glow Chief

A Gaggle of Glow Chief

YAWT Radius Conrod Ends

YAWT Radius Conrod Ends

The Zimmerman Valve

The Zimmerman Valve

And Still More Multi-cylinder Sleeve Valve Engines

And Still More Multi-cylinder Sleeve Valve Engines

Ignition Systems and More Gallery Stuff

Ignition Systems and More Gallery Stuff

Dragonflea

Dragonflea

From the What Will They Think Of Next File

From the What Will They Think Of Next File

Averice

Averice

![]()

Building the Bentley BR2 World War I Rotary Engine

Building the Bentley BR2 World War I Rotary Engine

). Well, you guessed it, Tim's artifact for Switzerland is a genuine Buchmann. I kinda like this little guy. Read why in the

). Well, you guessed it, Tim's artifact for Switzerland is a genuine Buchmann. I kinda like this little guy. Read why in the