|

|

Diesels of United States manufacture before and after WWII the spark ignition era were seldom used to power model airplanes. If one were to mention diesels during that time the venerable Drone 29s of Leon Shulman would invariably come to mind and then if one were really knowledgable, the C.I.E. 14, Micro 12, Mite 09 and especially the "cheapie" Deezil 12 would be chuckled over. Towards the end of that period, the tiny McCoys and Herkimers surfaced and an after market company made Arden diesel heads. Overseas the diesels were the "main thing" in Britain and Germany and Italy and later a few from Japan would appear via OS and Enya.

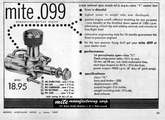

The subject of this report is the MITE .098 DIESEL. This fixed compression diesel was very light weight due to the use of magnesium castings for crankcase, backplate and cylinder head. Designed by one Howard Mandeville, and first introduced by Walt Schroeder's kit company, Eagle Mfg. Co. of Brooklyn; they formed a new company, Mite Mfg. Co. in 1947. It was not an attractive model (the advertising pic seen here was much better looking than the actual product)...it did not look "quality and pleasing design". The linerless steel upper cylinder had seven machined fins, square holes for dual exhaust, and a machined magnesium finned head held on by four 2-56 screws. This upper cylinder was secured to the cast magnesium lower case by four steel screws. It looked like a mushroom. The lower case had a short cast-in front intake through which the needle was secured, narrow beam mounts and a long nose with steel drive washer, prop washer and nut. The crankshaft was steel, as was the piston with an aluminum rod fitted by ball and socket to it. No bushings.

One of our well known "senior citizen" current old time flyers who worked early on in the back loft of the Eagle Mfg. Co. was Norman Rosenstock. He was a young machinest and modeler and struggled to fit piston and cylinder and eventually test run the Mite engines. Different thicknesses of head gasket, for "reworking" under or over compressioned engines as well as different sizes of pistons helped get the engines out the door after testing. An estimated 5000 Mite diesels were sold before the glow plug did away with them. In an effort to keep production going, a serious move was made to make the Mite into a glow engine. Arden glow plugs were fitted to the former diesel heads, but the rest of the engine was unchanged, resulting in blown heads as the small 2-56 screws were just unable to hold them on. The plastic gas tank was replaced with an aluminum one for glow fuel. As commercial diesel fuels did not work well the suggested Mite fuel was 50% ether and 50% heavy mineral oil.

This was a strange little "eastern engine", manufactured of course in Brooklyn, and little "western" usage and input is known about its acceptance out there. Undoubtedly a number of these engines found their way to the west coast and there are a handful of "testimonials" about those Mites but with reservations about power and reliability over their engine lives. To the writers knowledge, the Eagle Mfg. Co. didn't produce a kit design for their engine.

According to Norm Rosenstock's memory, the Mite Mfg. Co. assets and "good will" and name was finally sold to Mercury Model Co. also of Brooklyn where they assembled and sold the remaining glow engine models for as long as they could up into the late 1950s. No advertising was done specifically on the engine but word of mouth and city clubs provided successful sales. The original Mite 098 sold for around $15 and on down to $6 in the final days of availability.

Mite .098 compression ignition engines are seldom mentioned by collectors as "must haves" as few really pristine engines, boxes and instructions are known, but in the history of United Stated designed and manufactured diesels, the Mites were a genuine effort. They are very difficult to obtain today, especially in complete condition.

Back to Model Engine News Home

Back to Model Engine News Home

Back to Janson Index

Please submit all questions and comments to [email protected]