|

|

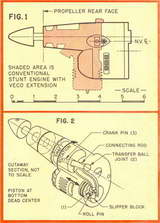

There had never been a model engine like it before or since, reported "Wild Bill" Netzeband in the Sept/Oct 1963 issue of American Modeler, and the "Dean" of model engine reviewers, P. G. F. Chinn in his "Engine Review" in the Jan. 1964 Model Airplane News asked and answered "doesit or doesn't it...it does!" The subject was the Aero Horizontal Piston Engine, without a doubt the most unique of model engine designs to the 1963 date, offered for sale to the modeling public. It was unorthodox and broadly classified as an "axiel" engine, one in which the cylinder and piston are arranged with its axes parallel to the crankshaft!

So howinhell does it all work? The aluminum shaft (not steel) is lightly stressed operationally as no crankpin is used. Instead the deep "flywheel" section of the shaft has an inclined bronze bushed socket. The steel connecting rod can be roughly described as being of an obtuse inverted "L" shape, with a ball at the corner of the L. The horizontal portion of the L terminates in a crank pin which fits the inclined shaft bushing which generates a "cone" action which moves the piston fore and aft. (It's really much more complicated). It starts, sounds, runs and powers just like a "normal" two-cycle engine of .30-.35 cid but is much slimmer for hiding in a cowl, and thus its design purpose. Over 20 years and 45 prototypes of development by its designer, August Savage and his partner John Piston (who better to design engines) in their AeroResearch and Development Co., Inc., 51-53 Great Arrow Ave., Buffalo, NY had resulted in its public offering at $35 std and $40 R/C, June, 1963. Just over a year later it was closed out at reduced price because it was too "different" and expensive alongside the "normal" engine offerings. This little "gem" was very well made, attractive, practically custom built. Using the best Perfect Circle piston rings and needing no breakin the ad said...revolutionary new engine design! And it was!

The company touted the possibilities of "hopping up" the engine and that a number of other sizes and displacements were being planned. All to no avail it seems.

In the design of internal combustion engines, the American engineers had not usually gone out of their way to be different, as they had in Europe where the taxes and expensive nitromethane encouraged designers to indulge in the smaller diesel model engines. For those of us who seek more engine facts, the Aero 35 is an air-cooled, single-cylinder, two-stroke cycle, glow-plug ignition, horizontal cylinder, loop-scavenged, rotary valve model engine. It has a cast aluminum case, cylinder and head with a removable back plate. The side mounted (either std. or R/C) carb. enabled a peak power of .42 bph at approximately 11,500 rpms, on an 11/4 propellor, or about 20% below a typical stunt type model engine of the 1963-64 years.

In the design of internal combustion engines, the American engineers had not usually gone out of their way to be different, as they had in Europe where the taxes and expensive nitromethane encouraged designers to indulge in the smaller diesel model engines. For those of us who seek more engine facts, the Aero 35 is an air-cooled, single-cylinder, two-stroke cycle, glow-plug ignition, horizontal cylinder, loop-scavenged, rotary valve model engine. It has a cast aluminum case, cylinder and head with a removable back plate. The side mounted (either std. or R/C) carb. enabled a peak power of .42 bph at approximately 11,500 rpms, on an 11/4 propellor, or about 20% below a typical stunt type model engine of the 1963-64 years.

It almost goes without saying that model engine collectors go literally "bananas" with offers in the hundreds of dollars when an Aero 35 is found or comes on the market, as production was well under 1000 units in its short market history.

Back to Model Engine News Home

Back to Model Engine News Home

Back to Janson Index

Please submit all questions and comments to [email protected]