A Modern Deflectorless Two-Stroke Engine |

|

|

|

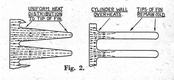

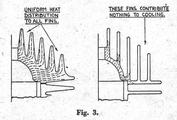

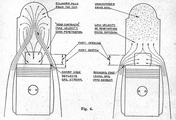

AS information on modern flat-top piston . two-stroke engines is scarce, the following details of a description which appeared in the "Automobiltechnische Zeitschrift" No. 14, 1940, are particularly interesting. Fig. 1. A cut-away view of the engine, copied as closely as possible from the original, shows many points of interest. One of the problems in a high performance two "stroke engine is to provide adequate cooling. In this respect the flat-top piston, cross-scavenged engine with its symmetrical arrangement of ports .is at an advantage. Light alloy cylinders permit increased performance with low weight. Plain cast-iron liners pressed in a light .alloy jacket are unsatisfactory, because capillary attraction draws oil into the interface where it carbonizes and forms a heat barrier; such a liner was found to be 300 C. hotter on the working face than a plain cast-iron cylinder with cast-iron fins. Screwed-in liners are equally unsatisfactory, owing to the lack of intimate contact between the two metals, and to differential expansion, causing distortion. . In the 250 c.c. "Ardie"� engine, a light alloy jacket is cast around an iron liner with longitudinal ribs. This arrangement increases the contact area by over 100 per cent, thus compensating for the" heat barrier," permits the liner to expand longitudinally without distortion, and the radial distribution of the ribs maintains contact during differential expansion. A reduction of liner temperature by 40� C., and of piston clearance from 0.0035 in. to 0.0023 in., for a 61.05 mm. bore cylinder, was achieved by these means. The fins cast on the light alloy jacket are proportioned to take advantage of the high thermal conductivity of the material, and increase to a depth equal to the cylinder bore on the leeward side of the cylinder. The thick base fins also contribute to uniform circumferential temperature distribution. Fig. 2 shows the approximate heat path in two cases, and proves that paradoxically the coolest cylinder is really the hottest. The same principle of heat flow is observed in the cylinder head, Fig. 3, and the eccentric disposition of the cylinder fins blends harmoniously with a " streamline" or "teardrop" elevation. The crankcase is called upon to heat dissipation by raising the joint face to the level of the transfer ports and 'liberally finning the upper portion. This arrangement, used by Mr. Westbury in his" Kestrel" and several other engines, permits the ports and transfer passages to be machined, an important point in utilizing the inertia of the gas columns to secure maximum volumetric efficiency. In this way the efficiency of the crankcase as a pump can be doubled. Perhaps intentionally, the least clear part of the original drawing is the exact shape of the transfer ports. Obviously they are steeply upswept, 60 deg. or more, and carefully blended into the transfer passages. The exhaust ports are 27 per cent stroke deep and the transfer ports 30 per cent. As the former have 5 per cent lead the effective height of the latter is reduced to 22 per cent., the remaining area not being uncovered by the piston. An explanation for this state of affairs is offered in Fig. 4. How each of these details contribute to the final result can be judged from the power curves for three 250 c.c. engines shown in ' Fig. 5. Those for the normal two-stroke and the four-stroke have been verified as representing average results by first-class makers of normal commercial engines, that is not specially tuned. The deflector-less two-stroke is of the same category. The normal two-stroke gives more power at low speed than the four-stroke, but the flattening off of its power curve puts it at a disadvantage at high speed. The deflector-less two-stroke is markedly superior over a substantial speed range, and only slightly inferior at its maximum. In a 30 c.c version 3 b.h.p. should be developed at 11.000 r.p.m. One day it will be tried out, probably in 05 c.c. capacity.

|

||

Dennis H Chaddock, 1943 |

||

Ref: ME 2201, P 282 |

||

Back to the Schnuerle Page

Back to Model Engine News Home

Please submit all questions and comments to [email protected]