Feeney Four-Stroke

![]()

| Name | Feeney Four-Stroke | Designer | Casimir Leeja |

| Type | Four-stroke, spark ignition | Capacity | 10, 15, or 20cc |

| Production run | unknown | Country of Origin | USA |

| Photo by | Ron C and others | Year of manufacture | circa 1940 |

Hiatory: Feeney and Leja

The Feeney was one of the first, if not the first minature four-cycle engines intended for use in models to be manufactured and sold in the USA. The basic design was created by Casimire Leja. "Cass", to his friends, was a well known modeller recognized for his achievements in rubber powered events during the 1930's, although he had abandoned aeromodelling for motorcycles due to disillusionment with some contest judging practices in Chicago/Cleavland area [ECJ68]. However, by the late 30's, he had his own machine shop business and experience gained with 'cycles and his fondness for model airplanes led him to start development of a four-cycle, overhead valve design.During development, sources say he was assisted with alloy casting by Jack Feeney [RJH1]. Leja lacked the resources to take the design through to production, so the design and manufacturing rights were purchased by Feeney who developed and produced the engine now bearing his name. News of the engine seems to have reached the model press as early as 1938, although the engines did not follow until 1940/41. Three sizes of Feeney were manufactured:

| Model | Displacement | Bore | Stroke | HP |

| Model "A" | 20cc (1.18 cuin) | 1-3/16" | 1-1/16" | 2/3 |

| Model "B" | 15cc (0.814 cuin) | 1-1/16" | 1-1/32" | 1/2 |

| Model "C" | 10cc (0.617 cuin) | 15/16" | 7/8" | 1/3 |

Technical Details

The references indicate that all engines utilized identical castings, with only the bore and stroke changing with capacity. Mechanically, the Feeney was a straight-forward overhead-valve design, with a few unusual features. First, the crankshaft was made from an aluminium-bronze casting and ran unbushed in the aluminium crank case [ECJ63]--the latter being split vertically to permit assembly (think motorcycle). The case ran "wet", being filled to a drain plug with SAE 50 oil, lubricating the two shaft bearings, cams and piston by "splash". The case, as is common four-stroke practice, is fitted with a "breather" tube (that's the thing that looks like a police whistle poking up behind the valve push rods in the photo at the head of the page). The steel piston was fitted with two compression rings, the lower of which doubled to retain the fully floating wrist pin (!!). The piston ran directly in the aluminium cylinder--generally, this is not a recipie for a long and happy life.

No valve cages were employed (more gloom). The inlet and exhaust valves were also machined from aluminium-bronze castings and seated directly on the aluminium head. The rocker arms, again bronze castings, were of conventional design. It appears that rather than insert bronze bushes, moving parts were made from bronze in the hope they'd be thier own bush. Lubrication of the rockers was by dabbing a drop of oil on the shaft. The valves were held closed by rather unusual but artfully attractive hair-pin springs. Factory instructions recommended a tappet gap of 0.007"--rather large by today's standards. The cylinder head, valve guides, inlet and exhaust openings, and cylinder bore were all sand-cast in one piece with rather complicated coring.

The cam drive was provided by two spiral-cut gears; the smaller fitted to the rear extension of the crankshaft; the other (at right angles to the shaft) was cunningly used to hold together the two cam segments, which were--guess what?--bronze again. This was achieved by machining "D" sections on one stub end-shaft of each cam. The two D sections mated to form a shaft over which the cam drive gear could be assembled. Finally, the gear was fixed by soldering the three parts together (in a jig, one hopes). This assembly was inserted into a housing in the rear crankcase half which provided one side of the cam shaft journal. The other was provided by a cover plate that held the cam assembly in place and doubled as the timer case. The section of cam assembly that protruded through the plate was milled with a flat to actuate the timer points. These were fitted to a carrier that slipped over the cover mentioned previously. Retention and some friction was provided by a "finger" spring allowing the point assembly to be rotated for advance/retard (the photo at the top of the page shows adifferent arrangement, so it is probably of a re-touched prototype).

The tank mounted to a frame screwed to the top of the cylinder, placing it at close to the level of the carburator. This was a rather rudimentary "reverse butterfly" design: instead of a thin shaft carrying a flat butterfly, a thick barrel had a slot cut in one end which could be rotated to restrict the airflow. Fuel was admitted by a brass tube jet that protruded into the axis of the barrel within the "slot"--much like the standard drilled barrel of modern R/C carbies. There was no fuel metering. Yup. That's right. No needle valve, no nothing! The adds even bragged about it. According to one source [ibid] who visited the Feeney factory in 1940, or '41, engines were made to fire using an electric drill shoved over a splined driver on an engine mounted flywheel. The jet tube was raised, lowered and rotated until the engine ran unassisted. The jet was then crimped in place. Unsurprisingly, the article author was unable to get the engine to start at home, hand flipping a prop. Factory instructions wisely stated that "..to move the gas tank to another position or to fit a larger one be sure to have the gas levels in the same relative position, vertically, as the standard tank." In other words, the engine is effectively gravity-fed and any change in the hydrolic head of the fuel will be fatal to performance.

There were two different rod styles for the Feeney. As the crankshaft is of the "full" variety, both must have a split big-end with removable caps to allow them to be fitted to the crankpin. One is quite conventional. The other pictured here is what I'd be tempted to term a brilliant innovation that I'm pleased to say never caught on! The idea was probably to permit the compression ratio to be adjusted by extending/shortening the rod length half a turn at a time. The problem (apart from the lack of a jam nut) is that getting the axis of the holes even slightly out of line shoves friction through the roof. Accurate set-up would really require either a jig, or some close fitting, long rods, a pair of accurate parallels and a surface plate, followed by strong prayer that the setup did not move when the jam-nut was tightened. Altogether, quite a lot of trouble to go to for a non-problem, given how tolerant sparkies generally are of compression. But given the rather rudimentary carburation on the Feeney, maybe the assemblers needed all the adjustments they could get!

Advertising for the Feeney began appearing sporadically in Air Trails and Model Airplane News from 1938. The three models appear in the yearly M.A.N. Model Engine Market Review for 1941 only, so we could conclude that they were sold only during late 1940 and 1941. Still, by 1942, the US was turning all available manufacturing capacity to the war effort, and use of strategic materials for hobby use was prohibited. Prior to this, the Feeney had sold for $29.95 for any of the three models. A complete kit of un-machined parts was also available for $13.75. All indications are that comparitively few were made, making it a highly rare and desirable collectable today.

The Return of Leja

The National Defense build-up for WWII caused business to boom for many engineering companies, including Leja's (remember him?). Following the war, he collaborated with RJ Hoffman to develop the "Leja Engines 4 Cycle". This was a truly beautiful design; clean, streamlined, and functional (including fuel metering  ). Intended to sell at $35.00 on the 1948 market, the Leja was another design that was unfortunately run over by the glow-plug revolution and Leja and Hoffman, despite having expended $60,000 in development and dies, abandoned the project [ECJ68]. No other information has been found about Hoffman, although it is apparent that his association with Leja must extend back to at least the late '30's, since it is his name that appears as the author of the Air Trails article that introduced the Feeney prototype [RJH1].

). Intended to sell at $35.00 on the 1948 market, the Leja was another design that was unfortunately run over by the glow-plug revolution and Leja and Hoffman, despite having expended $60,000 in development and dies, abandoned the project [ECJ68]. No other information has been found about Hoffman, although it is apparent that his association with Leja must extend back to at least the late '30's, since it is his name that appears as the author of the Air Trails article that introduced the Feeney prototype [RJH1].

It is useful to compare the Feeney with a similar design from the same period, but from a different side of the pond. In 1935, British magazine Model Engineer published ET Westbury's 15cc "Kiwi" overhead-valve, four-stroke design. Superficially, the designs are similar, with a vertically split crankcase, two compression rings, and vertical poppet valves [ETW1]. Both utilize a "full" single throw crankshaft, although the Kiwi utilizes straight-cut gears to drive the cam shaft which is necessarily oriented fore-aft. Westbury's design however is more sophisticated in the lubrication and carburation departments--reflecting his greater experience. The ETW "Apex Minor" of a year or so later used spiral-cut gears, but did not feature the full crank. His "Channel Island Special" 10cc overhead-valve design also used spiral gear driven cams and was manufactured from 1948 through the mid 50's, making it a contemporary of the still-born Leja, and showing that the devistating effect the glow-plug had on the US engine market was not felt immediately outside of the USA.

Later-day Feeneys

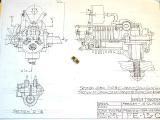

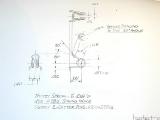

Comparitively modern-day Feeney casting sets were produced in the early 1980's by the Precision Service Company, run by Mr Arthur DeKalb. Art's casting sets reproduced the cast aluminium-bronze crankshaft, valves and rockers, the intricately cored aluminium cylinder, and other aluminum parts. The kits were quite complete and included a full set of machine screws, plus the spiral-cut gears required that are beyond the capabilities of even well-equiped home-shops. Like Art's other kits, the Feeney includes professionally drafted, full size drawings, running to 45 sheets detailing all components, including tolerences as required. Close examination of the drawings shows the addition of a small bushing to the front crankcase half, and an option to fit a thin-wall, cast-iron cylinder liner. The drawings also call out the piston as cast-iron, although the steel reference to the original [ECJ63] may be in error on this, and the lack of shaft bushing. The raw castings as supplied in the kit appear in the photographs below, along with a shot of drawing that illustrates the spring-winding challenge for the hair-pin valve springs.Twenty-first Century Feeneys

Although the Feeney casting sets are no longer available from Art, he is still in the casting business, concentrating on vintage outboard engine parts. However, Art is considering making another small run of Feeney kits. The cruncher is the spiral-cut cam drive gears. These are not your standard Boston Gear catalogue item and have to be specially made. To get the price of their manufacture for inclusion with the kits down to an acceptable figure, Art will need to take actual, hard cash deposits for eight to ten kits before committing capital to the venture. So if you are after a full kit for a very rare and historic engine, contact Art for details (and mention that you read about it here).

Art says that he will produce the 10 and 15cc versions which will sell for US$200, plus shipping and handling. Subscribers must state the size they want at the time of placing the order, which must be accompanied by an up-front deposit of US$75 per kit which is non-refundable unless he is unable to deliver within before January first, 2005. You can email Art at [email protected], or visit his web site at http://www.precisionserv.com/.

References:

- [ECJ63] Werve, Charles A: The Feeney 4-Cycle Model Engine, Engine Collectors Journal, Volume 2, Number 1, August 1963.

- [ECJ68] Nichol, Dr RE: The Engines of Casimir Leja, Engine Collectors Journal, Volume 6, Number 26, Winter 1968.

- [ETW1] Westbury, Edgar T: "Model Petrol Engines", Percivil Marshal & Co, London, (undated).

- [RJH1] Hoffman, RJ: A New Four-Cycle Gas Engine, Air Trials, (date unknown; reprinted by Suhr AG in "Model Engine Reviews: Selected Engine Article Reprints 1935-1955", no publisher stated, undated).

- [SUHR] Suhr, Arthur G: Antique Gas Model Engines: Pictures of Great Old-Timers 1934-1950, (no publisher stated, undated).

![]()