The ED Pep

Forgettable Fiasco,

or Successful Failure?

by Adrian Duncan

-

Background

Background -

Motivation for the Pep's Development

Motivation for the Pep's Development -

The British 1/2-A Revolution of 1959

The British 1/2-A Revolution of 1959 -

Development Problems with the Pep

Development Problems with the Pep -

Re-enter Gordon Cornell, Stage Left!

Re-enter Gordon Cornell, Stage Left! -

Marketing History

Marketing History -

Exit Gordon Cornell

Exit Gordon Cornell -

Looking back at the Pep

Looking back at the Pep -

The Pep re-visited—general description

The Pep re-visited—general description -

Identification and Serial Numbers

Identification and Serial Numbers -

The Pep on Test

The Pep on Test -

The Legacy of the Pep

The Legacy of the Pep -

Conclusion

Conclusion

Here we take a close-up look at one of the more poorly-documented and certainly least-appreciated members of the Electronic Developments Ltd (ED) family of model diesel engines—the 0.81 cc Pep. This little powerplant appears to have been not so much a carefully-considered ED initiative as it was a knee-jerk response to one of the repeated "fads" which afflicted the British model engine industry from time to time. This evidently did much to shape the process through which the Pep was developed and the form which it took in its final production version.

In many ways, the Pep was a product which stood well apart from the rest of the contemporary ED model engine range. Among other factors, the company's approach to its design and construction was unique among their various products. Moreover, it was their sole offering to take an American prototype as its basic design inspiration. For these reasons, it forms a more than usually interesting subject for detailed study—it's always the exceptions that prove the rule! In particular, the Pep offers an ideal opportunity to examine some of the challenges facing ED which cumulatively led to the eventual failure of the "original" company in 1963.

Before getting started on our main subject, it's both my duty and my very sincere pleasure to acknowledge the unfailing assistance and encouragement which has been accorded to me by my valued friend and colleague Kevin Richards. It would be quite impossible to write with any authority about any aspect of the ED enterprise without consulting Kevin, who has devoted more time and effort to the study of the ED range than anyone else of whom I'm aware. As always, Kevin has been unstinting in his willingness to help in the present instance. Muchas gracias, amigo mio!

I'm equally indebted to former ED chief engineer Gordon Cornell for generously sharing his recollections of his time at ED with me. Such a first-hand viewpoint is invaluable to any researcher, and Gordon's input has done much to clarify matters which might otherwise have remained forever obscure. Many thanks, Gordon!

I must also thank David Owen for sharing a number of images and serial numbers with me. The preservation of model engine history is a shared responsibility, a fact which David has invariably recognized and acted upon. I'm fortunate indeed to have such assistance always at hand.

In order to understand the history of the Pep, it's essential to grasp the context within which it was produced. So here we go with a bit of previous history!

Background

The ED company got its start in 1946 under the formal name of Electronic Developments (Surrey) Ltd. As the name suggests, its initial focus was as much on electronics as on model engines, but it soon achieved a strong market position on the strength of both its R/C gear and its ever-expanding range of model engines. We have covered the history of the ED enterprise in great detail elsewhere.

The company maintained its position throughout the 1950's despite a number of setbacks which are covered in our separate history of the venture. New and improved model engines continued to appear regularly throughout the first half of the decade before ED entered into a two-year period of reappraisal in 1956. During this period no new models were introduced, although minor detail improvements continued to appear on some of the established ED models as the company strove to address a number of design and production issues, albeit on a somewhat piecemeal basis.

In May 1958, ED announced their first all-new model for some time, the 1.46 cc reed-valve Fury. This was released with high expectations but proved to be uncompetitive both in terms of price and performance. It was by no means the success that it was hoped to be, hence doing nothing to bolster ED's somewhat flagging fortunes.

The design of the ED engines from the early 1950's through until 1958 had been entrusted primarily to Basil Miles. Interestingly enough, there is no evidence whatsoever that Miles was an ED employee at any time—certainly, he never appears to have held any official position within the company. Rather, his work for ED seems to have been undertaken through some form of design consultancy. His name was first openly attached to an ED product in connection with the 2.46 cc ED Mk. III Racer which appeared in March 1951, although there is evidence to suggest that he may have had something to do with the design of the earlier 3.46 cc ED Mk. IV Hunter which appeared in October 1949.

Miles' name continued to be openly associated with the ED model engines until some point in 1953, when some personal problems forced him to distance himself from the company. Even then, he continued to work for ED behind the scenes, also producing a number of engines under his own name at the same time.

Motivation for the Pep's Development

There had always been a certain tendency among British manufacturers to respond to the moves of their competitors rather than strike out boldly on their own account. An example from the early 1950's was the 1/2 cc "revolution" of 1951/52, which was triggered by the late 1950 release of Allbon Engineering's deservedly famous 0.55 cc Dart model. The Dart was an immediate and overwhelming success which prompted the release of competing 1/2 cc models by no fewer than three other competing British manufacturers (Aerol Engineering (Elfin), International Model Aircraft (FROG) and of course ED).

The attraction of these small engines to British modellers was based on a number of factors. Firstly, they were relatively cheap, a significant factor for the thousands of young people who were active in British modelling at the time (as well as their gift-buying parents!). Secondly, models for these small engines were themselves both easy and inexpensive to build (this was in the days when aeromodellers lived up to the name of their hobby by actually building their own models!) as well as highly transportable. Thirdly, the fuel costs of running these little powerplants were far lower than those of the larger engines favored by competition fliers.

However, the little 1/2 cc powerplants undeniably had their limitations. They were not notable for their handling qualities, being somewhat "fiddly" to start and adjust and also being far easier to damage through mis-handling than their larger and hence sturdier counterparts. Moreover, the power outputs of even the best of them were a bit on the marginal side in absolute terms, especially when it came to the control-line field which was then so popular in Britain.

Accordingly, Davies-Charlton (D-C) Ltd., who had taken over the manufacture of the Allbon range by this time, soon developed a slightly larger model (the Allbon Merlin of October 1954) which gave a bit more urge while retaining much of the compactness of its 0.55 cc companion in the range. International Model Aircraft followed suit in January 1957 with the first version of their FROG 80 model which replaced their earlier 50 offering. The iconoclastic Mills .75 had of course been there all along.

As a result, by early 1957 Mills, FROG and D-C Ltd. all had successful and well-received model diesels in the "3/4 cc" category, more or less corresponding with the American 1/2-A class which allowed engines of up to 0.050 cu." (0.81 cc) displacement. These models were very steady sellers, making it inevitable that ED would sooner or later begin to entertain thoughts of developing their own entry into this displacement category.

The initial decision to develop an ED 0.75 cc (.046 cu. in.) diesel model was apparently taken in 1957 while Basil Miles was still active as ED's primary engine designer. This decision was likely prompted by the January 1957 release of the FROG 80. Certainly, Miles did do some work on this engine, to the point of producing at least one prototype which was constructed very much along the lines of the existing ED Baby 0.46 cc diesel albeit a little bigger, as the attached image will confirm. Internally, the engine is more or less just a slightly enlarged Baby. This prototype is preserved in the collection of Kevin Richards today (2013).

The Miles 0.75 cc prototype appears to have represented a good first step towards the development of ED's own 3/4 cc entry. However, the development of this model was not pursued with great vigour. Moreover, the consultancy arrangement under which Miles was working for ED at this time seems to have come to a rather precipitate end in the latter part of 1958, for reasons which will likely remain forever obscure. Work on the 0.75 cc project was evidently sidelined as a result of this development.

Miles' departure from the scene left ED facing a situation in which development of their range had stagnated and their production program was in a very shaky state, with an increasing frequency of quality control issues along with a growing inability to met demand for certain models. All of this was causing a perceptible erosion of ED's formerly strong market position, a fact of which neither the Directors nor their bankers were unaware. Clearly they needed help, and needed it quickly!

As matters transpired, such help was available in close proximity to the ED factory in the person of Gordon Cornell, who had been working on the FROG range with George Fletcher over at International Model Aircraft (IMA) in nearby Merton. Following the completion of his National Service in 1954 (during which he served in Germany as a member of the RAF), Gordon had been working for Dodge Brothers (Britain) Ltd. before being invited by Fletcher to join him at IMA in 1957 to assist in the upgrading of the company's FROG model engine range. This proved to be a very fruitful collaboration.

During late 1958 George received a letter from Jim Donald, then Managing Director of ED, suggesting that Fletcher join them to fill the gap left by Miles' departure. George did not wish to leave IMA at that time, suggesting instead that Gordon Cornell contact Jim Donald. Gordon was quite happy to do so, resulting in an offer from ED

Accordingly, in late 1958 Gordon moved over from IMA to become the chief engineer for ED It quickly became apparent to Gordon that there were many problems at ED, the state of their finances being merely one such issue among others. All of the key players were very nice people to work with, but there did not appear to be any defined company plan or direction. This became very apparent when Jim Donald, who had been asked by the company's bank manager to develop a plan to reduce the overdraft which had been created by the Purchase Tax fiasco of the early 1950's, transferred this responsibility wholesale to Gordon.

Once having settled in and assessed the many design and production problems facing the company, Gordon prepared a plan as requested. The first step was to address a number of production-related matters. Gordon's efforts in this regard soon resulted in a 300% increase in the company's production capacity. He then took on the first of a number of engine design challenges by redesigning the somewhat lackluster Fury to produce the first in the long-lived series of disc-valved Super Fury 1.46 cc engines that were to come. This design was developed during 1959 and finally appeared in February 1960. It was a great success, having an outstanding performance by the standards of the day, especially in tuned form.

Meanwhile, outside events were shaping up which were to goad ED into re-activating their 0.75 cc diesel project which had been sidelined as a result of Basil Miles' departure.

The British 1/2-A Revolution of 1959

Prior to 1959, British modellers had for the most part been committed to the use of diesel engines, at least in the small and medium displacement categories. However, as 1959 rolled around the success of the American and Japanese glow-plug motors then reaching Britain in ever-growing numbers had created a situation in which many British modellers were at last ready to give glow-plug operation a fair trial in these lesser displacement classes.

The previously-noted attractions of small engines had by no means diminished over time—what had changed was the willingness of British modellers to experiment with glow-plug operation. D-C, Mills and FROG already had well-established diesel models in the 1/2-A displacement category, but the British marketplace was now receptive as never before to giving small glow-plug motors a fair trial.

Accordingly, beginning in mid 1959 the "revolution" of 1951/52 was repeated in almost every detail, the contestants this time being British-made 1/2-A glow-plug models rather than 1/2 cc diesels. The main contestants this time were D-C Ltd, Allen-Mercury (A-M) and FROG, all of whom released 1/2-A glow-plug models in the second half of 1959. KeilKraft also joined in the fun with their Cox-influenced Cobra .049 glow-plug unit, although this did not appear in production form until October 1960, by which time the small-engine craze had largely run its course in Britain and the market had become over-supplied. We have covered all of these models in separate articles on this web-site.

ED must have become aware of the above initiatives on the part of their competitors at a very early stage. The initial manifestation of the coming competition for 1/2-A sales was the appearance of the FROG .049 in July 1959. This was simply a glow-plug conversion of the well-established FROG 80 diesel model. It was followed almost immediately by the widely-publicized release of the Allbon Dart-based D-C Bantam in prototype form to selected reviewers in the following month. The impending release of the A-M .049 (a straight Wen-Mac clone) was also public knowledge by July 1959, while the Cox-influenced KeilKraft Cobra .049 was rather unconventionally announced before the end of the year through its inclusion on the plan for the new KeilKraft Firefly control-line stunt model.

If all of these plans came to fruition (as they eventually did), this would leave E.D as the only established British volume manufacturer lacking an entry of any kind in the 1/2-A field. It's abundantly clear from their subsequent actions that the ED management team did not take a favorable view of this situation—they wanted a piece of the action!

So a decision was taken to revive the still-born 0.75 cc diesel project which had become side-tracked when Basil Miles departed. Kevin Richards' in-depth research indicates that it was only at this stage that someone at ED (not Gordon Cornell!) had the bright idea of shaving some corners from the required development program by producing what would amount to an Anglicized version of the American OK Cub .049 diesel of 1954. The OK model had been a very worthy effort, as detailed elsewhere on this web-site, and ED clearly felt that they could do at least as well themselves with what would effectively be an Anglicized version of that engine.

This decision was clearly driven by the fact that ED did not have an existing 3/4 cc diesel design upon which to base their new offering. Allen-Mercury were in the same position, leading them to sidestep the development stage altogether by simply marketing a clone of an existing American design, the Wen-Mac .049. ED acted in a parallel fashion by electing to use the American OK Cub .049D as their design inspiration, although they appear to have decided from the outset to Anglicize the OK design rather than simply copy as A-M had done. Despite this, the application of the broad design concepts embodied in the OK Cub would save on valuable development time, or so went the theory.

One of the unresolved mysteries surrounding the introduction of the Pep centres upon the basic fact that it was a diesel. The OK Cub .049 had been marketed in both diesel and glow-plug guises, so an ED model based on that design could easily have been developed in either form. Moreover, the .049 craze of 1959 had been stimulated by a growing interest among British modellers in giving small-displacement glow-plug motors a trial. This being the case, it's very hard to see the introduction of a new 1/2-A diesel model as representing an appropriate response to emerging market forces. All that such a move would really accomplish would be to position ED as Johnny-come-lately competitors with the three other British manufacturers who already had well-established diesel models in this category. It seems that ED were in effect gambling upon the idea that after a brief flirtation with glow-plug models, British modellers would quickly return in droves to their diesel roots. A woeful misreading, if so!

Be that as it may, the decision was taken that the new model would be developed and marketed as a diesel. However, there was a problem in terms of resource allocation. As of mid 1959, Gordon Cornell was hard at work sorting out ED's existing production problems, finalizing the design of the Super Fury and thinking about possible new models, including some exciting further developments in relation to the Bee and Racer which had been ED's flagship products for some years. It's apparent that the ED management was extremely reluctant to divert Gordon away from these valuable efforts with respect to upgrading their existing range—after all, that was precisely what they'd hired him to do!

Accordingly, in addition to their adoption of the general design of the OK Cub they took another somewhat radical decision which was to have far-reaching consequences—they elected to outsource many aspects of the detailed design and production of the new model. They clearly believed that this two-tiered approach was the only way in which they could get a new design onto the market within the required time-frame without disrupting the other concurrent initiatives being pursued by Gordon Cornell.

To accomplish this objective, they entered into a contract with a precision engineering firm called Bardsley's located at Town Meadows in High Street, Brentford, Middlesex, just a short distance across the River Thames to the north-east of the ED factory at Island Farm Road, West Molesey. According to Gordon Cornell's recollection, this company was one of ED suppliers, although their exact previous relationship with ED remains obscure. The terms of the contract are also unknown, but they seem to have covered at least the assembly, testing and servicing of the engines. It's entirely possible that the contract went further than this, but we have no hard evidence at present.

As we shall see, the new model was designed to utilize as many existing ED components as possible. According to Gordon Cornell as related to Kevin Richards, ED had plenty of in-house production capacity available at this time. Output had fallen below demand prior to Gordon's arrival, but we have already noted that he had moved quickly to raise production capacity by some 300%. Accordingly, the agreement with Bardsley's could not have been in response to a shortfall in this area. It seems likely that it had more to do with a desire to avoid deflecting Gordon away from his work in connection with the upgrading of a number of established ED models as well as keeping the bank manager happy.

In effect, ED were taking their first step into the realm of "badge engineering"—the new model would bear the ED name but would in reality be a product of a collaboration between ED and a different company altogether. They were to repeat this pattern again in the future ...

Unfortunately, on this occasion they omitted one vital step—they failed to consult with their own newly-appointed chief design engineer Gordon Cornell with respect to the design or production criteria relating to the contract. In fact, it seems that Gordon was not even informed of this initiative, at least until considerably later. Therein lay the seeds of later dissent ...

Development Problems with the Pep

The new model was soon under development by ED and the Brentford company in accordance with the terms of the contract. Time was of the essence, since ED were already set up to become the Johnny-come-lately among British 1/2-A manufacturers. The key marketing target was the 1959 Christmas season with its greatly enhanced sales potential

It appears that the contract required ED to more or less pay as they went—they had to meet all design and development costs as they were incurred. Accordingly, a considerable investment was evidently made in these areas as well as in the production of the necessary dies. All of this work was pressed to the utmost given the time constraints with which ED felt themselves to be faced.

Throughout this period, Gordon Cornell remained in ignorance of the very existence of the Pep project, being kept hard at work getting the Super Fury ready for production, considering his proposed improvements to the Bee and the Racer, contemplating a number of possible new models and sorting out some existing production problems. Because of this, there seems to have been no appropriately-qualified individual within ED who was keeping track of the way in which the project was developing. All that was happening was that money was being spent in significant quantities!

Given the considerable investment which had been made in design, tooling and die-making by the time the Pep reached the prototype stage in the latter half of 1959, it must have come as a great shock to the ED management to find that the prototype engines fell well short of meeting their expectations. Among other problems, they would only run with gravity feed and even then not consistently. The design team hadn't realized that the�OK .049 glow and diesel models had different-sized venturis, that of the diesel being smaller to maximize suction�and provide better fuel atomization.

Re-enter Gordon Cornell, Stage Left!

ED management now found themselves in a trap of their own making—they had made a considerable investment in a project which was apparently failing to meet their expectations and was falling behind schedule, largely due to inadequate project supervision on their part. At this point, they finally did what they should have done at the outset—they brought their own chief design engineer Gordon Cornell into the picture.

Accordingly, Gordon was diverted away from the various engine upgrade programs upon which he was then engaged, being tasked instead with the job of sorting out the dog's breakfast into which the Pep program had evolved. Quite apart from his natural frustration at having been called in after the fact, Gordon was not best pleased to learn that the new model was to bear his own nickname of "Pep"!

Be that as it may, this was very much a case of too little, too late. A large number of finished components were already in existence, and economic considerations said that they had to be used in order to recover the investment which they represented. In Gordon's view, both the crankcase and connecting rod were inadequate for a diesel, but these were among the existing components that management insisted be used regardless. The time factor was also limiting—there simply wasn't the time available to re-develop the engine from scratch if ED were not to miss the boat altogether.

All of this tied Gordon's hands to a very large extent. He made a number of suggestions, but most of these were not implemented, presumably because in the view of management they would have increased the cost to unmarketable levels, would have extended the development time unacceptably or would have required the scrapping of too many finished components.

Gordon's most direct "statement" to the ED management took the form of a prototype twin ball bearing disc valve version of the Pep, using the Pep cylinder assembly along with the ED Bee forged conrod. This unit was tested by the well-known expert Jack North in a free flight model and found to be the best .049 in existence at that time. However, this design was not compatible with ED's desired price range, nor did it utilize the existing Pep crankcases. This resulted in a management decision to stick with the Pep as it had then evolved.

One issue which did receive some attention was the venturi throat diameter. We saw earlier that the initial engines were lacking in consistency, largely due to the venturi throat diameter being too great to provide adequate suction. Gordon realized this immediately, the result being the addition of a venturi insert to reduce the internal diameter and improve suction, a modification which worked well.

There may also have been an issue with the port timing, since some (but by no means all) examples have a spacer inserted beneath the cylinder location flange to raise the cylinder and hence increase the opening periods for the exhaust and transfer ports. But a number of other issues remained unaddressed.

Marketing History

The end result of all the above shenanigans was inevitable—the version of the Pep which finally reached the market was a compromise, with a number of design flaws left unresolved. Worse yet, even these compromises did not enable the engine to meet its marketing deadline, since it was not until January 1960 that the Pep was formally announced. It seems possible that a few examples were available in time for Christmas 1959, but in promotional terms ED had undoubtedly missed the boat.

Nonetheless, the engine was announced with great fanfare in the January 1960 issues of both Aeromodeller and Model Aircraft magazines in the form of a full-page advertisement devoted solely to the Pep. Ironically, this same issue of Aeromodeller featured a comparative test of the three previously-released British 1/2-A glow-plug models with which the Pep would have to compete!

The engine sold for the very competitive price of �1 18s 6d, making it the most inexpensive model diesel ever sold in Britain. It's hard to believe that this selling price allowed much headroom for profit, especially given the teething troubles which the engine had experienced. However, ED were forced to match the prices of the competition, so their hands were tied.

During the early stages of its existence, the Pep was promoted very aggressively by ED in a somewhat desperate effort to recover as much as possible of the considerable investment which it undoubtedly represented. It was still the main feature in their advertisement which appeared in the June 1960 issues of both Aeromodeller and Model Aircraft, six months after its release. Oddly enough, the recently-released Super Fury was not featured in this advertisement despite the fact that it was the subject of Ron Warring's engine test for that month, having been released in February 1960—for reasons which must remain unclear, the advertisement only showcased the now-discontinued Fury. ED's advertising strategies often defy comprehension ...

By September 1960 the Pep had slipped back into equal status with ED's other models. Its appearances in ED's advertising thereafter became increasingly sporadic—many months went by without the Pep putting in an appearance at all. It's clear that ED management had already accepted the fact that the Pep was not destined to be a winner in sales terms...

One of the oddest aspects of the Pep's marketing history is the fact that despite ED's very serious advertising efforts during the first half of 1960, it seems to have been completely ignored by the contemporary modelling media. Apart from the ED advertisements, I can find absolutely no commentary regarding the engine in the pages of either of the major contemporary British aeromodelling periodicals Aeromodeller and Model Aircraft—the Pep was never so much as mentioned in the "engine news" columns of either magazine, nor was it ever the subject of a published test. How the engine failed so completely to attract any coverage whatsoever in either of those two publications remains a complete mystery—all of the other contemporary British .049 models received ample coverage, as did competing models like the A-S 55. There must be a story there if one could only uncover it ...

Whatever the reason, the result was that ED received no help at all from the contemporary modelling media in their efforts to promote the Pep. To rub salt in the wound, ED's unaided efforts failed from the start to generate much interest in the engine. In large part this was no doubt due to the fact that by mid-1960 the British small-engine market had become saturated. This was an inevitable consequence of so many manufacturers all targeting the same market niche at the same time. Indeed, few of the 1959/60 crop of British 1/2-A models were to last long in production—the D-C Bantam was destined to be the sole glow-plug survivor together with the long-established D-C Merlin and FROG 80 diesels.

There were of course other factors involved. Although it was a perfectly useable engine (as we shall see), the Pep possessed no real edge over the competition, either overseas or domestic. In addition, it was "just another diesel" alongside the well-established D-C Merlin, Mills .75 and FROG 80 models. The revolution of 1959 had been triggered by pent-up domestic demand for small glow-plug models rather than diesels. In this respect, ED had woefully misread the market. Finally, it can't be denied that ED was already seen as "yesterday's company" by many British modellers.

There were also a few of those niggling design issues in the mix as well. Although the con-rod material was advertised from the outset as hyduminium, Kevin Richards recalls that his own new example from early 1960 had a phosphor bronze rod which burned off its big end bearing during the running-in process! This was apparently a characteristic failure of the early bronze rods, which Gordon Cornell had recognized immediately when consulted about the Pep project after the fact. The material was quickly changed to RR56 aluminium alloy, but a number of engines had reached the market before this change was implemented. The reputation of the engine was not enhanced by this issue.

This brings up yet another oddity with respect to the history of the Pep. Although Gordon had recognized the inadequacy of the Pep con-rod (hence his use of a forged aluminium alloy Bee item in his twin ball-race .049 special), and despite the fact that the rod material was initially advertised as being hyduminium, examples from both ends of the Pep production cycle are routinely encountered with bronze rods. Apart from Kevin Richards' previously-noted example from early 1960, my own engine numbers H 2.69B and B. 95C from August 1961 and February 1962 (if our hypothesis regarding serial numbers is correct—see later discussion) both feature bronze rods. In fact, examples with the bronze rod greatly outnumber those with the hyduminium component. Moreover, one of the later Pep advertisements (from May 1962) specifically refers to the con-rod being made of bronze. At present, we have no explanation for these inconsistencies other than to suggest that ED management may have been completely serious in their insistence that all components manufactured prior to Gordon Cornell's involvement be used. It's also possible that a bronze con-rod having a more suitable alloy specification was adopted.

The net result of all these factors was that the Pep failed to achieve any great sales success, claiming a place in the record books by becoming ED's least successful model in commercial terms. This evidently became apparent to ED quite early on. By November of 1960 the Pep was no longer regularly featured in ED's advertising, although it remained in small-scale production throughout much of 1961 and into early 1962, continuing to be available at least until September 1962 when it made its final appearance in an ED advertisement placed in that month's issue of Aeromodeller. However, it seems almost certain that by that time the company was simply selling off existing stocks of the engine. As far as can be ascertained today, the bulk of Pep production took place in relatively small batches during the years 1960 and 1961, with perhaps one small batch being produced in early 1962 (see further discussion below).

With the above background in mind, it should come as no surprise to learn that overall production figures were relatively low—at the very most, probably only a couple of thousand or so were sold in total. One direct consequence of this is the fact that examples of the Pep in good condition are few and far between today, changing hands on the collector's market for quite high prices.

Exit Gordon Cornell

It should be clear from the above account that the commercial failure of the Pep must have left a bad taste in a good few mouths. One of those mouths undoubtedly belonged to Gordon Cornell. A number of fundamental problems within the ED company had by now become painfully apparent to Gordon, and his consequent frustration levels had undoubtedly been elevated by being tasked with getting the Pep to perform at a stage when it was already too late to do anything meaningful about its problems. There were also the issues of management inertia with respect to both his proposed twin ball-race .049 diesel and his very promising upgrade programme for the Racer.

Despite all of this, Gordon continued his development work, which included a 3.5 cc drum-valve prototype model. While very powerful, this had some limitations as an aircraft unit due to its weight and other factors. Gordon accordingly re-developed it into the very successful marine Sea Otter 3.5 cc diesel. He also introduced some major design changes to the venerable ED Bee 1 cc model which transformed that rather lack-lustre performer into one of the most powerful 1 cc diesels then on the market, as amply demonstrated by Peter Chinn's test which appeared in the February 1961 issue of Model Aircraft. A further example of ED's inexplicable approach to advertising is the fact that the company failed completely to promote this vastly-improved design in any way.

At the same time, ED were casting about for new product lines. Gordon recalls that they had been approached by the Ministry of Defence to manufacture small diesel-powered generators for lifeboats—Ministry staff evidently did not appreciate that ED "diesel" engines were not true diesels! Given the fact that ED did not have the financial capacity to undertake such a project, Gordon judged it to be not feasible at that time.

It was at this point that Jim Donald introduced Gordon to a certain Alan Dye to discuss the possibility of ED undertaking alternative engine production such as chainsaw engines. Unfortunately for Gordon, Alan Dye was basically a smooth talker who was looking to create a work opportunity for himself—he was in fact nothing more than a competent draughtsman, although he evidently presented himself as something more. He persuaded Gordon to leave ED to join his company Dydesyne Ltd. of Slough in Buckinghamshire to produce what became Gordon's legendary Dynamic .049 twin ball-race diesel. This wonderful design had its roots in the twin ball-race version of the Pep mentioned earlier. As such, it certainly belongs in our Pep story. It's a sobering thought to realize that if ED management had shown themselves to be a little more forward-thinking at the outset, the Dynamic .049 could have been released as the ED .049!

Unfortunately, Gordon was unaware that Alan Dye did not have the necessary financial capacity to underwrite such a project. After working all hours to complete engines, the bailiffs turned up unannounced one morning, putting an end to the Dynamic .049 project and leaving Gordon high and dry. To make matters worse, it turned out later that Alan had not been paying Gordon's insurance and tax liabilities. Gordon was forced to return to his pre-IMA employment working for Dodge Brothers (Britain) Ltd. By an ironic twist of fate, Alan Dye later ended up working for Gordon at Dodge Brothers, thus reversing their former positions!

Looking back at the Pep

No doubt the members of the ED Board of Directors as well as their bankers acquired a highly negative view of the Pep given the financial drain upon the company coffers which it must have represented. It seems highly unlikely that ED ever came close to recovering their investment in this model, which doubtless contributed towards ED's slowly-accelerating slide towards marginalization in the British model engine manufacturing field.

All of this has contributed to a subsequently well-entrenched view of the Pep as a second-rate production that was cobbled together in far too much of a hurry and failed completely in the marketplace as a result. The engine has carried the stigma of having been one of ED's least successful designs from that day to this.

Now it's undeniably true that the engine failed in commercial terms. But that is only one yardstick of failure—many factors can contribute to such an outcome, some of them having nothing to do with the engine itself. How bad was the Pep in purely practical terms? The engine was never the subject of a published test in the modelling media—in fact, we saw earlier that its coming and going were pretty much ignored altogether! This being the case, we'll have to rely upon our own recollections and observations to gain a retrospective view of the engine.

In assessing a model diesel in a strictly utilitarian sense, it's perfectly legitimate to draw upon actual experience with the engine in operating terms. I'm in a position to do this because I actually owned and used a blue-headed Pep for a few years beginning in the mid 1960's. This engine was of course obtained second-hand, as were most of my engines at the time (I was still attending Grammar School in England), but I bought it not as a collector's item (a status which model engines had yet to acquire in those far-off days for all but a few prescient individuals) but as a useable engine that was available at a good price. Unfortunately, I never recorded its serial number ...

I used my little Pep in several models, one of which was a small free flight sport model with the others being compact small-field control line designs. One of the latter models had previously been fitted with my faithful old D-C Merlin, which had moved on to other applications. I still have that Merlin today ...

All of my personal recollections of the Pep in actual service are positive and are confirmed by the log book that I've kept since my early years of modelling. I recall the engine as being perfectly straightforward to start and as having a quite acceptable performance. I don't remember feeling that the model which had formerly used the Merlin had suffered at all through the engine switch. Although it was a long time ago now, I can honestly say that I found the Pep to be a perfectly acceptable unit in actual service. My notes from the time in question bear this out completely.

Interestingly enough, my notes also confirm my very clear recollection that my Pep had the infamous bronze con-rod, which acquired a reputation for wearing very rapidly. The rod in my Pep gave no trouble at all in service, a fact for which I have no explanation at this stage! Indeed, I have no record or recollection of any problems with the Pep during the period in which mine was in use.

Far more recently, I discovered that one of my compatriots in my present-day Western Canadian model club (an ex-patriate British resident like myself) had also owned a Pep way back—in fact, he had received his example brand new as a birthday gift from his parents in 1961! It was his first model engine, which he used both to learn how to operate a model diesel engine and to power a series of models during the period when he was just getting started. He too has nothing but positive memories of the engine, including the fact that it seemed to him to be well up to par with other competing British productions at the time.

Both of us moved on to other spheres of modelling activity which required larger engines, and in the course of time our respective Peps were sold on. But we both retained our positive recollections of the engine which have lasted until the present day. The fact that we had no trouble selling them way back then indicates that they retained some attractiveness as useable engines—I know that I sold mine to a fellow club-mate who had seen it run many times and was favourably impressed. Where is it now ...?!?

Anyway, my own memories of the Pep are entirely positive, and my friend's recollections are very much in line with my own. This being the case, could the engine really have been as bad as its latter-day reputation suggests?

To find out, it was necessary to renew old acquaintance by getting my hands upon a reasonably good example of the Pep for present-day examination and testing. As noted earlier, this isn't as easy as it might be, but thanks to the kindness of Kevin Richards, my good mate and mentor on all things ED, I was finally able to get my hands on a nice example. Moreover, a second example fell into my hands not long afterwards.

So we're now in a position to re-visit the Pep and undertake an objective hands-on re-evaluation, 50 years on. Let's get on with it!

The Pep re-visited—general description

The Pep is basically a completely conventional crankshaft front rotary valve (FRV) radial-ported diesel engine. However, it does possess a few features which set it apart from other contemporary designs of similar displacement.

The influence of the OK Cub .049 diesel upon the Pep's design is immediately obvious when one looks at the two engines both side by side and internally. Despite the clear architectural differences, there is an unmistakable similarity in the crankcase design. In addition, the cylinder porting arrangements are identical, as is the FRV induction employed. There are differences, of course—the Pep's steel cylinder is hardened in keeping with normal British practise and has thicker (and hence stronger) fins. The contra-piston is of cast iron and is lapped into the cylinder as opposed to being a steel item fitted with an O-ring and a "shock absorber" as in the OK. But generally speaking, the Pep is very much the Anglicized version of the Cub .049 diesel that it was intended to be.

Bore and stroke of the Pep are 10.41 mm (0.410 in.) and 9.52 mm (0.375 in.) respectively for a displacement of 0.81 cc (0.049 cuin.). The engine was clearly designed to take maximum advantage of the .050 cuin. upper limit for American 1/2-A competition, perhaps indicating a degree of daydreaming on ED's part regarding the possibility of marketing the engine in the US. The engine weighed in at 2 ounces (57 gm) exactly, with tank.

The Pep is built around a pressure die-cast crankcase which includes provision for both screw-in cylinder and backplate components. The major difference between the Pep case and that of the OK Cub is the omission from the Pep of the radial mounting lugs which were a feature of the OK model. This doubtless reflects the fact that British modellers were generally far more committed to beam mounting than their American counterparts. The tank is missing from both of my own examples, but it was made of aluminium alloy which would have been anodized blue to match the cylinder heads.

The hardened steel cylinder features integrally-machined cooling fins. The top flange is made thick enough to accommodate tapped holes for the three 8 BA screws which secure the alloy head to the cylinder. This head is centrally tapped 4 BA to accommodate the L-shaped steel compression screw.

Surviving examples of the Pep most commonly feature blue-anodized head and tank components. However, examples are regularly encountered having green and red anodizing, as well as several examples which were never anodized at all! It would appear that the engines were made in small batches and that different anodizing colours were applied (or not!) to different batches, blue being merely the most common.

Cylinder porting is essentially conventional, following the OK Cub pattern exactly. Three sawn slits form the exhaust ports, while three small holes are drilled at an upward angle through the pillars which separate the exhaust ports. These holes function as the transfer ports. This arrangement allows for a small degree of overlap between the exhaust and transfer ports, yielding a reasonably generous transfer period without the need to open the exhaust ports unduly early. There is no supplementary sub-piston induction. The flat-topped piston and matching contra-piston are both of cast iron, being very well fitted indeed on my two examples.

The transfer ports are fed via two milled bypass passages which interrupt the female cylinder installation thread, one on each side. A portion of the upper thread is relieved to form an unthreaded annular passage completely surrounding the cylinder just below the exhaust port belt. The three transfer ports are supplied with mixture from this annular passage, which is in turn supplied from the lower crankcase by the two bypass passages mentioned previously. Again, this precisely reflects the design of the American OK Cub models. The advantage is that transfer efficiency should be relatively unaffected by the annular position in which the cylinder ends up when fully tightened.

One possible indication of a design compromise is the previously-noted presence in some (but by no means all) examples of a 0.040 inch thick alloy spacer between the top of the crankcase casting and the lower surface of the cylinder flange. This gives the appearance of having been an afterthough which was added following a reconsideration of some aspect of the design, most likely the cylinder port timing or just possibly the con-rod length. While this is possibly a result of the initial re-appraisal of the Pep project by Gordon Cornell, the fact that it seems to be confined to the later examples (including both of my own engines) makes it appear more likely that it was a subsequent afterthought. A desire to improve the engine's top end performance by increasing the exhaust and transfer periods would explain this feature, as would a switch to a longer rod to reduce piston side-thrust. Kevin Richards has seen these spacers made from both aluminium and bronze alloys.

As noted earlier, the engine was advertised at the outset as having a con-rod made of hyduminium, although the early 1960 example once owned from new by Kevin Richards definitely had a bronze alloy rod. The con rod in both of my own examples from later production batches is also of bronze alloy, as was the rod in the example of the Pep that I owned and used many years ago. Indeed, the previously-noted advertisement which appeared in the May 1962 issue of Aeromodeller specifically referred to the rod being made of this material. Although it seems that both materials may be randomly encountered, I have to say that the bronze rods appear to predominate.

The one-piece hardened steel crankshaft features a circular disc crankweb with no attempt being made to provide any counterbalance. The induction port is a drilled hole which is extended fore and aft on the journal surface to increase the interface area between the port and the venturi base. The central gas passage in the shaft has a diameter of 0.109" Main journal diameter is 5.54 mm (0.218 in.).

These measurements support an observation which I had already tentatively made prior to my detailed examination of the engine. The crankshaft of the Pep appears to be very similar to that employed on the companion Baby 0.46 cc model! That engine had a bore of only 7.94 mm to go with the 9.52 mm stroke and was thus a long-stroke design. The use of a 10.14 mm bore in the Pep along with the same stroke of 9.52 mm still left the engine only slightly over-square.

The Pep crankshaft is some 1/8 inch longer than that of the Baby, while the induction port is considerably extended. However, the basic design is more or less identical, implying that the Pep crankshaft was likely simply a modified Baby item. The fact that an off-the-shelf component that was already in ED's production program could be used in slightly modified form must have been seen as an obvious cost-cutting measure. Doubtless the commitment to the use of this shaft design was one of the constraints which tied Gordon Cornell's hands when attempting to sort the Pep out at the pre-production stage.

As soon as one recognizes this connection, other similar connections become apparent. The prop driver also appears to be a Baby component, fitting to the front of the shaft on a taper. The prop-nut and washer also appear to be Baby items, as does the comp screw. This seems to confirm that maximum use was made of components for which tooling and/or inventory already existed. It actually appears possible that the original plan had been to use the Baby con-rod as well but that a longer rod had been found desirable after the crankcase die had been finalized.

The vertical intake is fitted with the previously-mentioned insert, which once again bears a possibly more than coincidental resemblance to that used on the Baby. This was one of Gordon Cornell's improvements which was implemented, as noted previously. Unusually for a British motor, the spraybar on many examples follows the OK Cub pattern by being press-fitted into the transverse hole provided for the purpose, rather than being secured with a nut in the more usual British style. Other examples have conventional spraybars with nuts for security.

The thread for the needle valve on a number of examples is an unusually fine 60 tpi American thread, presumably to reduce the engine's sensitivity to this control. Although many of them are pressed in rather than being retained by a nut, some of the 60 tpi spraybars do feature a retaining nut. This thread was not by any means a universal feature—other examples are encountered with a 5 BA spraybar thread and retaining nut. In either case, needle tension is provided by a rather sturdy coil spring which fits over the thimble and bears upon the side of the intake. This is very effective in practice.

One less than praiseworthy feature of the engine was the fact that the main crankcase casting incorporated a circular expansion at the rear to accommodate the rim of the screw-in alloy backplate. The presence of this expansion meant that the engine bearers in the model had to be quite deeply notched to accommodate the expansion. Coupled with the presence of the mounting holes, this significantly weakened the bearers. The accompanying illustration should make this clear. This is undoubtedly a highly annoying feature, as I well recall myself. Indeed the contemporary A-M .049 glow-plug model came in for published criticism as a result of having the same inconvenient feature.

Apart from that, the above examination confirms that the Pep was a completely conventional model diesel of its type which showed strong OK Cub influence. All fits and finishes are excellent, in my own two examples at least. That said, it's apparent that efforts were made to keep costs down through the maximum use of components that were already available from the existing production inventory.

Nevertheless, the ultimate test must always be the way in which the final product performs. But before we look at that aspect of the matter, let's consider the question of identification.

Identification and Serial Numbers

The letters "ED" are cast in relief onto the underside of the Pep's crankcase. Apart from that, the only other identification is a hand-engraved serial number on the lower surface of the case on one side. As of early 1960 when the Pep first appeared, ED serial numbers on their other engines were invariably stamped on, so the Pep was an anomaly in this regard. It appears to have been the first designated ED product to be numbered in this way.

There is some uncertainty regarding the issue of serial numbers applied to the Pep. The numbering appears to bear some relationship to ED's usual system of having a letter indicating the month of manufacture—A for January, B for February and so on, with I being omitted to avoid confusion with 1 and L also being omitted, presumably to prevent an unintentionally inverted strike being mistaken for a 7. This letter was followed by the number of the engine in that month's batch and finally (from January 1960 onwards) a further letter indicating the year of manufacture, A standing for 1960, B for 1961 and C for 1962.

However, there appear to be a few anomalies in the case of the Pep. For one thing, the year indication letter at the end is missing from a significant number of reported examples. For another, my own engines bear the numbers H 2.69B and B. 95C, both as written. In each instance, the decimal point is unquestionably there and appears to be a quite deliberate inclusion rather than a striking error. Both of my engines have blue heads but are missing their tanks.

Kevin Richards owns engine numbers G 52.B (plain head and tank), E102 (blue head and tank) and E147 (red head and tank—all numbers as written), while David Owen reports owning engine number C 2 (plain head, red tank) with no decimal point. Kevin also reports that he formerly owned engine numbers F41B (blue head and tank), H278B (blue head and tank) and A341 (red head and tank). The numbering and coloration are all over the shop, with those pesky decimal points moving about freely or being absent altogether!

As far as dating goes, the guarantee card confirms that NIB engine number E102 was sold on June 11th, 1960. This date is completely consistent with the hypothesis that at least some elements of the previous ED numbering system still applied, since the month indicator letter E on this engine would date its manufacture to May 1960. By the same reasoning, engine number G 52.B should be from July 1961, while my own engine number H 2.69B would date from August 1961.

However, there are some clear inconsistencies in these numbers, particularly with respect to the letter suffix issue as well as the decimal points. A case in point is provided by engine number E102 , which is known to have been made in 1960. On this basis, it would be expected to carry an A suffix, which is missing. Indeed, it's noteworthy that up to now we have yet to see an example of the Pep which carries an A suffix.

The most logical explanation for this would be that the year signifier was missed off the entire 1960 production, only commencing in 1961 with the addition of the B suffix. It also appears not unlikely that the letter prefixes which are invariably present are month indicators as per the usual ED system. Hence engine number C 2 from the above list would date from March 1960. That number would also appear to confirm that the batch numbers started from 1, this being only the second engine from that batch.

The missing year signifier may be down to the fact that much of the production was outsourced. Some support for this notion is found in the fact that ED's�in-house production range during 1960 and most of 1961 when the Pep was in production retained stamped numbers which invariably included the year indicator. The clear implication is that the Peps were numbered by Bardsley's rather than by ED It would also appear that Bardsley's omitted the year signifier during the engine's first year of production. The reason for its addition in 1961 is clear enough—if this had not been done, there would have been a whole range of duplicate serial numbers.

Reviewing the above discussion, the best that we can do for now is to propose the working hypothesis that the numbering system generally followed the main ED system with the exception that the year indicator (the A suffix) was omitted from the engines manufactured in 1960, only being re-instated in 1961 with the appearance of the B suffix to avoid the creation of duplicate serial numbers. The significance (if any) of the decimal points remains obscure. Regardless, it appears probable that any example of the Pep lacking a letter suffix dates from 1960, with the month of production being indicated by the letter prefix in the established manner.

In terms of production figures, Pep manufacture appears to have been largely confined to the years 1960 and 1961, although we do have presumptive evidence for the production of at least one batch in early 1962 in the form of my own engine number B. 95C, which would date from February 1962 if our working hypothesis has any validity.

The fact that engine numbers E102 and E147 feature blue and red anodizing respectively despite the fact that they are apparently only 45 engines apart raises an interesting point. If our working hypothesis regarding the numbering system applied to these engines is correct, both of these examples belong to the batch produced in May 1960. The different colours may simply reflect a lack of synchronization between the production of the heads and tanks and the assembly of the engines. If this was the case, then coloration would essentially be independent of the batch to which a specific engine belonged. The assembly staff would simply use whatever anodized components were on hand, trying as far as possible to match colours between heads and tanks (and not always succeeding if mixed-colour engine C 2 is any guide!).

The Pep generally appears to have been produced in relatively small batches by ED standards, sometimes not even reaching three figures. Indications that the engines were produced in somewhat larger batches during certain months come from engine numbers A341 (from the very early January 1960 batch if our earlier suppositions are correct regarding the missing year indicator) and H278B (from August 1961 if our working hypothesis is valid). We'd expect a pretty high figure for January 1960 when the engine was released with high hopes, but the high figure for August 1961 does require reconciliation with our working hypothesis, especially given our understanding that the engine never achieved high levels of consumer demand.

To me, such a figure as that implied for August 1961 would best be explained by the notion that prior to that point in time monthly production had been more or less tailored to demand. Given the engine's failure to attract much sales interest, there would have been many months in which production was very small indeed—in fact, the two August 1961 figures are currently the sole three-digit numbers which we have after 1960. The sudden "spike" in batch size which appears in August 1961 may well be due to a management realization at that time that the small two-digit batches which appear to have become the norm were uneconomic to produce and that it would be better to produce fewer but larger batches, holding off on further production until the available shelf inventory had been significantly depleted.

A direct consequence of such a decision would be that there would have been subsequent months during which no engines were produced at all! Further production would have been strictly confined to the manufacture of the odd batch on an "as required" basis to replenish the wholesale stock shelf. The frequency of such batches would be entirely dependent on how fast the previous batch approached the sell-out point at the wholesale level. Given the engine's apparently lacklustre sales record, this would in turn imply that batches such as that of August 1961 were few and far between. It's likely that only two or three further batches at most were manufactured after August 1961.

Whichever way one slices it, production figures for the Pep appear to have been well below average by ED standards—perhaps�around 400 or so monthly during the first few months of production as part of the introductory stock build-up, but tapering off sharply to far lesser figures in the two-figure range thereafter, with most months after August 1961 seeing no production at all. When we consider that ED are known to have produced well over 2000 examples of certain other models in some months, we can see that Pep production was on a very small scale indeed by ED standards.

An extrapolation from all of this over the engine's two-year production run would seem to indicate a maximum total production of�somewhere between 2000 and 2500 examples. This estimate could of course be in error either way, but the present-day scarcity of surviving examples is certainly consistent with a relatively low total production figure. Speaking personally, I'd be very surprised indeed to learn that the total number manufactured exceeded 2500 units.

Regardless of the truth, it appears that the serial numbering system applied to the Pep stands somewhat apart from that applied to the other ED models and is not yet securely understood. More serial numbers please, preferably with firm dates from guarantee cards!

The Pep on Test

Since the Pep was specifically intended to compete with the other British 1/2-A models (both diesel and glow) which were on the market at the time of its release, it seemed only fair to undertake a comparative test for the purposes of this evaluation. Accordingly, I elected to test the Pep against the very engine which it had replaced in my long-ago control-line model—the D-C Merlin.

I already knew from past experience that the Merlin would bury the D-C Bantam, which was the main British glow-plug competitor in strictly commercial terms. Naturally, no-one who was specifically interested in switching to glow-plug operation would consider buying either a Pep or a Merlin, regardless of any performance differential! However, diesel-minded modellers might well linger over a choice between these two offerings. So this comparison between competing diesels seemed fair enough to me.

The Merlin which I chose for this test was not my old faithful warrior from years gone by, since I had successfully modified that one years ago to release a considerably enhance performance. Instead, I selected a bog-stock example which had been flown but nonetheless remained in excellent condition. The Pep which Kevin Richards had so kindly made available also seemed to have had relatively little use, so this appeared to represent a level playing field.

First up was the Merlin. Every time I re-acquaint myself with one of these little units, I'm reminded of what an excellent powerplant it was for a neophyte modeller like myself in the old days! The engine was a very dependable starter, just needing a couple of choked flicks as a preliminary to a quick start. Response to the controls was very positive without being at all critical, making the establishment of optimum settings very straightforward indeed.

Once running, the little Merlin quickly settled down into a very steady rhythm, running without a trace of a misfire and holding its settings perfectly. It proved to be a very solid performer, swinging a wide range of props with no problems whatsoever. The range of speeds achieved was entirely consistent with previous experience as well as with published test figures for the engine.

Then it was the turn of the Pep. Like the Merlin, it proved to be a very easy starter, although in this case I found that a small prime was a considerable aid to a quick start—choking alone was less effective. This is probably a reflection of the very different transfer porting arrangements.

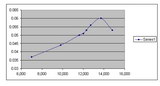

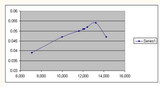

Once the appropriate technique was established, the Pep invariably started with just a few flicks. It was every bit as smooth a runner as the Merlin, being just as easy to set for optimum performance on a given prop. A wide range of prop-rpm figures was readily obtained, as follows:

| Prop | ED Pep | BHP | D-C Merlin | BHP |

|---|---|---|---|---|

| APC 8x4 | 7,100 | 0.039 | 7,000 | 0.037 |

| KK N 7x4 | 10,000 | 0.047 | 9,800 | 0.044 |

| KK N 6x4 | 11,600 | 0.050 | 11,600 | 0.050 |

| APC 6x4 | 12,000 | 0.051 | 12,000 | 0.051 |

| Cox 6x3 | 12,100 | 0.051 | 12,300 | 0.053 |

| Cox 5-1/2x4 | 12,400 | 0.052 | 12,700 | 0.056 |

| APC 6x3 | 13,200 | 0.054 | 13,700 | 0.060 |

| Cox 5x3 | 14,200 | 0.047 | 14,800 | 0.053 |

It will be immediately apparent that the Pep failed to match the Merlin across the entire tested speed range. If anything, it was actually a little stronger at the lower end of the speed range below 12,000 rpm, but fell somewhat behind at speeds above that point. However, it could not fairly be said that the Pep was completely outclassed by the Merlin—the difference in performance implied by this test would not be overtly apparent in an actual sport-flying situation.

The derived power curve for the Merlin is very consistent with test figures published in the leading British model magazines at the time of the engine's October 1954 release. The implied peak of 0.060 BHP @ 13,700 rpm is by no means out of line with either Ron Warring's figure of 0.058 BHP @ 13,000 rpm (Aeromodeller, December 1954) or Peter Chinn's figure of 0.062 BHP @ 13,000 rpm (Model Aircraft, January 1955). The higher peaking speed is most likely a reflection of the fact that this used example would logically be expected to be better freed-up than Warring's or Chinn's test models.

As far as the Pep goes, the above figures imply a peak of around 0.054 BHP @ 13,200 rpm. At this speed, the Merlin is developing around 0.057 BHP, a difference which would have little noticeable effect in a sport-flying situation. This doubtless explains why I never noticed any drop in model performance when I switched from my original Merlin to the Pep all those years ago!

It's worth noting in passing that the tested example of the Pep (engine number H 2.69B) is fitted with the infamous bronze con-rod. I checked the rod bearings following the conclusion of this test, finding that there was very little discernable wear despite the in-flight service which this example of the engine has clearly seen in addition to my own test running. It appears that not all of these rods failed in service. My original Pep of bygone days also had this rod, and it never gave me any problems. Perhaps the bronze alloy specification was changed at some point ...

Reviewing the above comparison, it becomes objectively clear that for all its rather hurried and poorly-coordinated development, the production version of the Pep that was somehow salvaged from the mess actually turned out to be a quite good little motor—far better than its subsequent reputation would suggest. It certainly outperformed the contemporary British glow-plug competition in the 1/2-A class. Notwithstanding its troubled genesis, it begins to appear far more in the light of a successful salvage job which was a commercial failure than as the complete fiasco throughout that it is generally portrayed as having been.

The Legacy of the Pep

It remains for us to look into the aftermath of the Pep's failure to penetrate the marketplace to any significant extent. We already saw that the Pep saga almost certainly contributed to the eventual resignation of Gordon Cornell as ED's chief engineer in early 1961. After a seemingly lengthy hiatus, Gordon's place was finally taken in March 1962 by his former IMA colleague George Fletcher, who had previously been involved with engine design and manufacture at Allbon Engineering and IMA but had become surplus to IMA's requirements when the decision was taken in early 1962 to wind down IMA's production of the FROG range.

We'll never know what impact Fletcher's arrival might have had upon ED's model engine range, because on April 29th, 1962, shortly after Fletcher's arrival, a major fire seriously damaged the ED premises at Island Farm Road, West Molesey, Surrey. Other legends to the contrary, this fire was a result of arson by two youths during the course of a break-in, a crime for which they were subsequently apprehended and convicted.

The consequent loss of machinery, records and stock was a disaster for the company, from which it never really recovered. However, a fair proportion of the vital castings and materials were salvaged, and thanks to George Fletcher's efforts ED were once again back in business soon after the fire, albeit with substantially reduced production capacity and a significantly truncated range. The company name was also changed at this time from Electronic Developments (Surrey) Ltd. to ED Engineering & Electronics Ltd. Some older designs like the Comp Special had been dropped already, and now others such as the Baby, Pep, Hornet and Bee were also progressively dropped, with only the Super Fury, Racer, Hunter, Sea Otter and (for a time at least) the Fletcher-designed 1 cc Cadet carrying on as before.

None of this was sufficient to save the "original" ED company, and after a brief flirtation in 1963 with having one or two badge-engineered models (notably the 1.5 cc Hawk) manufactured in West Germany by the makers of the Webra range, the company underwent the first of a succession of ownership changes which resulted in most of the then-existing range being terminated. But that's another story, to be related elsewhere...

The dropping of the Pep from the range in 1962 meant of course the cancellation of ED's assembly and servicing contract with Bardsley's. However, this was by no means the end of the story! Under the terms of their parting of the ways with ED, it appears that the Brentford company was left free to make whatever use they chose of the design and perhaps the remaining parts inventory. It's possible that ED owed them some money for engines already produced and this was the way in which they settled the debt.

Regardless, the next move in the saga was the establishment of a new company in Brentford named De-Za-Lux Developments Ltd. It might be assumed at first sight that this was simply a reorganization of Bardsley's under a new name. However, Bardsley's had many irons in the engineering fire, making it appear more probable that this was actually a new venture altogether, perhaps funded by RipMax Ltd. who distributed the products of the new company. Some kind of tie-in with Bardsley's at the formative stage is implied by the fact that De-Za-Lux Developments seemingly took over the entire Pep project, likely including the remaining parts inventory, establishing themselves only a short distance down High Street in Brentford from Town Meadows, at number 231 to be precise. However, there's currently no evidence that the two firms were formally connected.

Taking the established Pep design as their starting point, De-Za-Lux Developments undertook some more development work on their own, including an increase in the displacement to 0.92 cc. The additional displacement was achieved through an increase in the bore from 0.410" to 0.438 in., the stroke remaining unchanged at 0.375" Weight was unchanged at 2 ounces even, a factor which was achieved by the elimination of the integral steel cooling fins in favor of a turned screw-on aluminium cooling jacket along with a number of other changes in the cylinder design.

The initial examples of the ZA 92 were based upon a standard Pep crankcase from which the ED identification was removed by hand. These early engines appear to have been produced primarily to use up existing stocks of Pep crankcases. The resulting engine appeared on the market in around May 1963, being sold in this form as the ZA Griffin.

The supply of original Pep crankcase castings appears to have been exhausted by September 1963, since it was in that month that a revised version of the engine made its appearance. This featured a crankcase which reflected the use of a modified die to produce the castings. The revised castings incorporated slight changes to the mounting lug and carburettor configurations along with the elimination of the former ED identification. From that point onwards, the engine was marketed as the ZA 92. Both models were marketed exclusively by RipMax.

The ZA was hailed at the time as a new entry into the British market, but in effect it was at heart nothing more than an over-bored Pep with a few alterations. It was extremely odd how few people spotted this at the time ...certainly, the ZA 92 received a far higher accolade from the media and the modelling fraternity than the poor old Pep had ever done. Its measured performance level of 0.082 BHP @ 11,800 rpm (Aeromodeller, January 1964) was well up to expectations for a plain-bearing sports diesel of its displacement.

In this disguise, the Pep lived on for a few years more, earning a favorable reputation among British modellers. It was indeed a very nice little engine—I certainly enjoyed using my own second-hand example, which I still have. The company which produced it did not survive down the years—the site of 213 High Street is now buried under a supermarket car park!

Conclusion

So there we have it! The Pep was undoubtedly something of a compromise design which suffered to some degree from having been developed to an artificially-tight schedule rather than up to a standard. It also arrived on the market too late to benefit in commercial terms from the British small-engine craze which triggered its development but which was over-supplied and began cooling down quite soon after the Pep's appearance. However, when viewed objectively in terms of its practical qualities, it emerges as a perfectly useable engine having a performance which was well up to par with that of the majority of its domestic competitors.

It's clear that the Pep saga had some influence upon the later fortunes (or misfortunes) of the "original" ED company. However, that does not detract from the fact that it was actually an attractive and well-made little engine which was undoubtedly able to give good service to the relatively few individuals who cared to give it a far trial. In my personal view, it deserves a far more positive reputation than it has been accorded in the past!