The early years at MVVS:

The Classic Glow-Plug Models

by Adrian Duncan

-

Background

Background -

MVVS Takes On The World

MVVS Takes On The World -

A New Direction: MVVS Develops Their First Stunt Motor

A New Direction: MVVS Develops Their First Stunt Motor -

The MVVS 5.6A On Test

The MVVS 5.6A On Test -

Turning Up The Heat: The MVVS 2.5R-58

Turning Up The Heat: The MVVS 2.5R-58 -

The MVVS 2.5R-58 Design Considerations

The MVVS 2.5R-58 Design Considerations -

A Change In Policy

A Change In Policy -

The MVVS 2.5R-58 Competition Record

The MVVS 2.5R-58 Competition Record -

The MVVS 2.5R-58 On Test

The MVVS 2.5R-58 On Test -

A Russian clone: The MD 2.5 Moscow

A Russian clone: The MD 2.5 Moscow -

Conclusion

Conclusion

The Czechoslovakian MVVS company is well known to present-day fliers as a long-established manufacturer of high-quality model engines of various types. The company is operated today as a privatised commercial enterprise in direct marketplace competition with other model engine manufacturers worldwide.

However, it was not always so. In fact, the origins of MVVS had far more to do with cold-war politics than with commercial ambitions. During its first five years of existence, the MVVS organization did not produce a single commercial model engine, instead focusing solely on the development and production of individually-built limited-edition competition engines which were made available exclusively to a handful of leading Czech fliers for their use in international competition.

Naturally, the fact that no revenue was generated from engine sales during this period meant that these activities were undertaken entirely at State expense. This situation could not continue forever, and in 1958 the decision was taken to begin the process of making the MVVS enterprise self-sustaining by entering the field of commercial model engine manufacture.

Two of the earliest designs which were selected for limited commercial production were glow-plug models which shared a common heritage. These were the MVVS 2.5R-58 and the MVVS 5.6A, both of which compiled outstanding contest records in different fields at the highest levels of International competition. In this article, we'll examine the chain of circumstances which led to the development of these models as well as analyse the engines themselves. In addition, we'll review the contest records compiled by the two designs. Finally, we'll mention a few spin-off designs from other manufacturers.

Before proceeding, however, it's necessary to pay tribute to the work of Jir� Kalina, whose well-known 1980 book Model�rsk� Motory ("Model Engines") contains perhaps the most comprehensive published summary of the evolution of MVVS. The fact that this book only ever appeared in Kalina's native Czech language has hitherto severely restricted access to the invaluable information which it contains. However, through the use of a combination of a very smart Optical Character Reader plus a good translation program, I've been able to develop a reasonably coherent English rendition of the portions of the book relating to MVVS. I've drawn heavily upon this in writing the following text, and I freely admit that I'm very much following in Kalina's footsteps in presenting the following information, much of which is appearing for the first time in the English language. Thanks, Jir�—we're all in your debt!

A further recommended book on this topic is "Czech Model Engines" by Jir� Linka and Jan Kafka. The text of this book is rendered both in Czech and English, making it far more universally accessible than Kalina's effort. Although short on historical detail, this excellent and highly recommended book contains fine images of many of the engines discussed below. I have used a number of these images to illustrate the following text, giving due accreditation in each case.

I must also take this opportunity to apologize for the poor quality of some of the images used to illustrate this article. However, the fact that we are talking for the most part about individually-constructed "specials" means that direct access to original examples is simply not available. We therefore have to do the best that we can on the basis that any illustration is surely better than none at all!

Background

The MVVS story begins in 1953, when the Czechoslovakian state authorities decided that there was international prestige and political capital to be gained through the achievement of Communist success in the field of model aeroplane competition at the World Championship level. At first sight, it may seem a little odd that aeromodelling would be seen as a worthwhile activity into which to pour State resources. In fact, an important element of the Communist agenda at this time was to get their message of technological superiority out not merely to the leadership of the Western bloc but perhaps more importantly to the ordinary citizens of the countries in question. As an activity widely practised at the time by members of a broad spectrum of Western society (far more widely than it is today), aeromodelling provided a perfect stage on which to demonstrate the technical capabilities of the Communist states to the Western population at large.

To further this agenda, the Czechs established a state-sponsored model development centre at Brno called the Model�rsk�ho V�zkumn�ho a V�vojov�ho Strediska (Modelling Research & Development Centre), better known by its initials of MVVS. This initiative owed much to the efforts of Zdenek Husicka, who was an icon among Czech modellers and a world record holder at the time.

Husicka was an experienced and very capable free-fight competitor who had become interested in model engines prior to the onset of WW2. His first design was the Letn� 6.3 spark ignition engine which was later produced in small numbers during the wartime years by Gustav Bu�ek in Prague. In 1939 he constructed three examples of the Husicka 22.5cc sparker, which was a very advanced design for its time.

By the time the war ended, Husicka had become aware of the diesel engines which had been developed during the wartime period in his native Czechoslovakia as well as in other countries such as Switzerland, Sweden and Germany. This led him to begin a collaboration with the legendary Josef Pfeffer, which resulted in the development of a number of new engine designs over the following 5 years or so. Notable among these designs was the Letmo MD-2.5 diesel, a 2.47cc rear disc valve (RV) development of the crankshaft front rotary valve (FRV) Husicka 2.5 model. A prototype of the original Letmo MD-2.5 was used by Husicka in 1949 to finish third in the Czechoslovakian free-flight championships with an innovative model design featuring a revolutionary tail configuration and a folding two-blade propeller. He went on to win both the 1950 and 1951 Czech free flight championships with further developments of this model and motor.

By 1949, Husicka had also become interested in the growing field of control-line speed, an activity which he approached with his usual dedication. From the outset his models were extremely aerodynamic and used drop-off dolly undercarriages. Following a somewhat shaky start when his first model refused to take off from the dolly, doing tether car impressions instead (!), Husicka used his refined 1950 design to establish a new Czech control-line speed record for 2.5cc models at 65.32 mph. The engine was a tuned example of Husicka's own Letmo MD-2.5 design. At around this same time he also constructed some of the first glow-plugs in Czechoslovakia using some platinum-iridium wire which a colleague had somehow managed to obtain. These plugs had metric threads.

However, Husicka did not stop there. In 1951 he developed a new model which was fitted with a further refinement of the Letmo engine design, the prototype Letmo MD-2.5 Super. Using this combination, he won the 1951 Czechoslovakian championship at a speed of 90.22 mph which he topped in May 1952 at Ostrava by establishing a new FAI international speed record for the 2.5cc class at 97.4 mph. He then went on to win the 1952 Czech championship for the second straight year at an even more impressive speed of 102.2 mph, thus topping his own existing record. Some going in 1952 for a 2.5 cc radial-port diesel!

Another noteworthy model built by Husicka in 1952 was a 10cc design powered by a Nordec RG10 engine which Husicka had somehow managed to obtain from England. This combination recorded a speed of 129.56 mph at a contest in Brno in September 1952. As far as I'm able to determine from the records currently at my disposal, this was one of the fastest speeds ever officially recorded by a Nordec in competition. The engine was most likely one of the very rare Nordec Special Series II models—surely no-one ever got the Mk. I Nordec to go that fast!?!

Husicka carried on into 1953, but in that year a serious illness forced him to retire from the field of serious model competition. However, he retained his wealth of experience in all aspects of model design and engine development along with a keen ongoing interest in the sport itself. Following the less-than-satisfactory results achieved in a 1953 international contest between modellers from Czechoslovakia and Hungary (always a heated rivalry!), Husicka drew attention to the lack of suitable engines for use by Czech modellers in such competitions, particularly (at that time) in the prestigious 5cc and 10cc classes. This open criticism from such a respected figure in the Czech modelling world led directly to the government decision to establish the MVVS model research centre at Brno. In view of his demonstrated capabilities and commitment, Husicka was an obvious choice for the post of Director of the new facility.

The Centre opened its doors on October 15th, 1953, with the primary goal of developing engines and model designs which would propel Czech modellers to the achievement of World Championship honours. From an early date, the Centre was largely staffed by recognized experts in the field of competition aeromodelling. In early 1954 Husicka was joined by fellow modelling experts Lubo� Koc� and Josef Sladk�, thus creating the nucleus of a formidable in-house design and competition team. The Centre was very sparsely equipped at the outset, but this situation was progressively rectified as time went by.

Success was not long in coming. The first engine design produced by the new Center appeared in 1954. This was the Dooling-influenced 5cc MVVS 5/1954-D which was individually constructed in very small numbers. Using this engine, Mir Zatocil achieved the first honours for MVVS in International competition when he won the 5cc class at the International Competition for People's Democratic States in 1954 in Moscow. Zatocil's winning speed of 124.3 mph placed him ahead of the Hungarian representative Geza Egerv�ry, who used an American Dooling .29 in his model. Although the design of the MVVS 5/1954-D owed much to that of the Dooling, this was still a notable achievement less than twelve months after the Centre's establishment. Husicka's connection with the Letmo range led to this design being put into limited production outside the MVVS workshops under the Letmo 5 designation. This was the first of a number of initiatives involving the manufacture of MVVS "clones" by others.

A further successful design from 1954 was the 1.5cc MVVS 1.5/1954 model which was made in both diesel and glow-plug forms. This was developed primarily for free flight use and was sufficiently impressive that the diesel version subsequently became the basis for the well-known START 1.8 cc model which entered commercial production in 1957.

Zatocil's 1954 success in the 5cc category was certainly praiseworthy given the standard of the prevailing Dooling, McCoy, Super Tigre and ETA opposition. The 5cc category had in fact been the official FAI control line speed World Championship class in 1954, which explains the initial focus upon this category on the part of the MVVS design team. However, this was set to change in 1955 with the adoption by the FAI of the 2.5cc limit for future World Championship control line speed events. This decision shifted the engine development spotlight very decisively to the 2.5cc category. MVVS immediately began working hard on a new design to comply with this displacement limit. To assist in this effort, the staff was further expanded by the early 1955 addition of Jaroslav Koc� and Karl G�tz.

At the National control-line competition held at Prague in the Spring of 1955, Josef Sladk� achieved a speed of 108.56 mph with the new MVVS model S-25 racing engine, thus establishing a new Czech record. A further improved model, designed and constructed by Sladk� and colloquially known as the SK-25 "Broucek" model, was in preparation for the upcoming 1955 World Championship.

MVVS Takes On The World

By mid 1955 the new 2.5cc engines had reached the stage at which the MVVS team felt ready to challenge the best that the rest of the world had to offer. Accordingly, designer Josef Sladk� showed up at the 1955 Control Line World Championship meet in Paris with a model powered by his one-off MVVS SK-25 "Broucek" powerplant and walked away with the top honours in the Speed category. Sladk�'s winning speed was 112 mph—a fine performance by the standards of the day for a 2.5cc model and a notable improvement over his earlier showing at the Spring meeting in Prague using the S-25 design.

This result must have been a bitter pill for the favoured Italian team to swallow. The Italians did manage to occupy the next three places using their Super Tigre G.20S engines, thus winning the team championship. The other two Czech entries of Mir Zatocil and Vaclav Smejkal occupied fifth and eleventh places, using prototypes of the MVVS 2.5/1955-D engine. These performances enabled the Czech team to finish in second place overall behind the Italians, in addition to winning the individual title. Quite a debut!

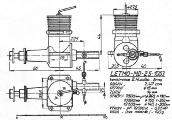

Sladk�'s one-off 2.49 cc engine was in most respects a conventional racing motor of its time—lightweight ringed aluminum piston, twin ball-bearing shaft, oversized transfer passage, ultra-short stroke (16.0/12.4 mm), etc., etc.� Its one departure from the conventional "racing engine" formula was its use of a crankshaft front rotary valve (FRV) instead of the more fashionable rear disc valve (RV), probably influenced by the results achieved up to that time by the Italians with their FRV Super Tigre G.20 engines.�The intake on Sladk�'s engine was offset to face directly into the airscrew slipstream, the idea presumably being to take maximum advantage of the "ram air" effect. The engine used suction fuel feed from a metal chicken-hopper tank which supplied fuel to an offset needle valve. Its most striking visual feature was the expanding-section rearward-swept exhaust stack.

The MVVS 2.5/1955-D motors used by the other two team members in Paris differed somewhat from Sladk�'s winning powerplant. They retained the FRV induction but featured more conventional bore/stroke measurements of 15/14 mm. Jaroslav Koc� subsequently rebuilt one of these engines in rear disc valve form and won with it at the 2nd annual International People's Democratic States contest in Vrchlabi, Czechoslovakia He recorded a speed of 111.84 mph on the 11th of September 1955, subsequently achieving a significantly higher speed of 126.47 mph on thinner lines to establish a new 2.5cc world record. This modified engine became the prototype for the following year's 2.5/1956-D model.

It must be recalled that the MVVS engines which were developed during this period were not commercially motivated in any sense but were created simply to provide a small and select group of Czech experts such as Sladk� and Koc� with engines that would give them every chance of achieving top honours against International competition. Cost was no object ...the Cold War was at its height, and international prestige in all spheres of activity was everything!

Sladk�'s 1955 World Championship win left the MVVS research centre facing the usual problem encountered by winners in any field of activity—having reached the top, how were they to stay there?� The answer of course was by continuing to develop the remarkable 2.5cc glow-plug engines that had served Sladk� and Koc� so well.� But the pressure was on—Super Tigre had become used to winning and would not take their 1955 defeat lying down.�Already they were pointing the way toward the future with a lapped piston version of their G.20S model, and further improvements were in the works which were soon to result in the introduction of the improved Super Tigre G.20V design. Additional competition was forthcoming from the Italian Barbini company, who were poised to enter the fray with their excellent B.40 TN offering. Moreover, there were already signs that experts in other countries such as Hungary and Great Britain were beginning to take a serious interest in this class of competition.

Looking into the future and having regard to the remarkable performances achieved by Jaroslav Koc� with his modified MVVS 2.5/1955-D engine, the MVVS designers decided that the very precise timing, short gas pathway, rapid opening and closing and tuning flexibility of the rotary disc valve were the key to staying ahead of the opposition.�The crankshaft rotary valve that had served Super Tigre so well for some years with their G.20 design had carried Sladk� to the top of the heap in 1955, but MVVS wanted the flexibility and short direct-entry gas passage that the disc valve provided.�They had used this system all along in their 5cc racing models, and were to continue to do so. Now the 2.5cc models were to follow a similar pattern.

Accordingly, during the winter of 1955-56 MVVS embarked upon a program of further development of their 2.5cc racing glow-plug model using RV induction as a major element of their evolving design strategy. Doubtless Koc�'s very successful rear-disc modification of the MVVS 2.5/1955-D served as the basis for these developments. The resulting prototypes showed considerable promise and the design that was individually produced in minimal numbers for the exclusive use of selected Czech experts, the MVVS 2.5/1956�D, proved to be a formidable competition powerplant.

Using the new 2.5/1956-D engine (apart from Sladk�, who stuck with his 1955-winning SK-25 "Broucek" engine to finish in a 6th place tie), members of the Czech team took four of the top ten places at the 1956 World Championship meeting held in late September at Florence, Italy. They thus won the team championship over the favoured Italian home team, although their best individual showing was Vaclav Smejkal's 4th place at 121.8 mph—a substantial improvement over Sladk�'s winning performance of the previous year but still well down on Englishman Ray Gibb's remarkable winning speed of 131.1 mph using the Carter Special. The new Barbini B.40 TN had a spirited debut at this meeting, placing third at 124.3 mph for Italy's Giovanni Cellini and thus finishing ahead of all the MVVS entrants.

A real rarity which appeared at this meeting was a one-off MVVS prototype disc-valve glow-plug motor known as the S-25R. This design employed a fascinating concept—differential displacement! It feature a ringed alloy piston having a diameter at the power-head end of 16 mm, which combined with the 12.4 mm stroke to give an upper cylinder displacement of 2.49 cc. However, the piston featured a step at the bottom of the skirt which gave the piston a diameter of 18 mm as seen from the crankcase. The lower cylinder was of course stepped to match. The result was a crankcase displacement of 3.16 cc. The intent was clearly to enhance the motor's pumping capacity and thus promote the ability to induce and transfer more fuel mixture. The S-25R was reportedly more powerful than the conventional versions, but was not used in the actual event in Florence due to designer Sladk�'s concern that the bore measurement at the bottom of the cylinder might possibly give rise to disqualification. Possibly true, but still ... neat idea!

The MVVS engines used by Sladk� and his compatriots were individually built in very small numbers to the highest standards.�It would clearly have been impossible to produce equivalent engines commercially at anything like a reasonable price, and no attempt was made at this time to do so at the MVVS workshops. However, a need was now perceived for the production of more affordable engines of similar design for the use of a larger spectrum of aspiring flyers in order for them to gain the experience necessary to challenge for positions on the Czech team.

Accordingly, in 1957 a "consumer" version of the MVVS 2.5/1956-D was put into series production at an entirely separate production facility under the name of Vltavan.�Known as the Prague-Modrany factory, this facility was located in Prague, very distant from the MVVS workshops in Brno. A 5cc model based upon the earlier MVVS 5/1954-D was also produced. The Vltavan engines were named for the Vltava River which flows through Prague. We have discussed these engines in detail elsewhere.

Although their handling and running qualities were generally good, the Vltavan versions of the MVVS racing models unfortunately lacked the precision of their MVVS prototypes and hence failed to approach MVVS standards of performance.�They did however represent a source of engines of reasonable if not world-beating performance with which aspiring competition flyers could gain vital experience. As such, it's probable that they went a long way towards achieving their intended purpose.

A New Direction: MVVS Develops Their First Stunt Motor

Throughout the period just described, the MVVS center had focused much of its attention upon the development of glow-plug engines for all-out speed work. This changed in 1957, when MVVS commenced the design of what was to become the MVVS 2.5D-58 diesel, developed primarily for free-fight work in which diesels still predominated due to their higher torque. But that's another story, to be told elsewhere ...

More to the point in the context of the present article, MVVS further expanded their competition horizons in 1957 by developing their first control line stunt glow-plug motor, the 5.6A. Prior to this, they had developed an updated version of their successful MVVS 5/1954-D design mentioned earlier, retaining the Dooling-influenced crankcase configuration and rear disc valve induction employed on the earlier model. Bore and stroke of this variant were 20mm x 15.7mm respectively. Like all previous MVVS designs, the resulting MVVS 5R-57 model was individually built in very small numbers for the use of recognized Czech experts. One such example was used by MVVS employee Bohumil Studen� to break the world Class II speed record at 151.6 mph in September 1957.�

It's worth noting in passing that this design was later put into limited series production with minimal changes in 1964 under the designation MVVS 5R. The illustrated example has its exhaust stack oriented to the right (viewed from the rear), but published drawings from the contemporary Czech modelling media indicate that the engines were actually supplied with their stacks on the left-hand side. We will discuss the rationale for this orientation in a later section of this article.

Although perfectly suited to model aircraft use, the 5R seems to have found its greatest favour in the field of tethered hydroplane racing, in which it enjoyed considerable contest success over a period of several years, establishing a number of records in the process.

Returning to 1957, more or less concurrently with their development of the 5R-57 experts-only racing engine, the MVVS Centre undertook the development of a 5.6cc stunt motor which used many of the components of the companion 5cc speed engine. Unusually for a stunt motor, this new model employed a rear disc valve made of a Tufnol-like material. It utilized the same Dooling-style crankcase casting and twin ball-race front bearing unit as the 5R-57 and also retained the lightweight ringed alloy piston and rear disc valve of the 5cc racing model. The 20mm bore was unchanged, but the stroke of the stunt model was increased by 2.3mm to 18.0mm, both to provide the additional displacement and generate improved torque at lower revs.�In addition, the disc valve and cylinder port timing were tailored to the speeds expected for a stunt engine, where torque at moderate revs was far more important than sheer top-end power.�The engine used a revised backplate incorporating a downdraft carburettor, the idea being to keep the engine nice and compact and have the intake readily accessible for hand starting.

The 5.6A appears to have been supplied by the factory with its exhaust stack on the left-hand side (looking forward in the direction of flight). Period photographs clearly show that the engine used successfully by Czech stunt expert Josef Gabris featured that orientation, as does my own LN and apparently unflown example. Furthermore, the example tested by the staff of American Modeller magazine in 1962 (see below) also had its stack on the left.�

It's my personal opinion that there were good reasons for the factory adopting this exhaust orientation, a point which we'll discuss in detail when we get to the MVVS 2.5R-58 in a subsequent section of this article. That said, several illustrations in the well-known books Model�rsk� Motory by Jir� Kalina and Czech Model Engines by Jir� Linka and Jan Kafka show examples of this engine with the stack on the right. It's entirely possible that these engines may have been switched around by their owners.

The MVVS 5.6A had an outstandingly successful international debut, being used by Josef Gabris to win the stunt category at the 1958 Expo International meeting at Brussels, flying against the best that the rest of the world had to offer.�The engine subsequently joined the 25-D diesel and 2.5R-58 glow models by being put into small-scale series production for wider distribution beginning in 1959.�It remained a favourite among leading Eastern European stunt flyers for several decades. Along with a string of consistently high placings during the intervening years, Gabris won a pair of consecutive World titles in 1966 and 1968, still using the same engine. Indeed, the 5.6A continued to place internationally at the very highest levels deep into the 1970's. The engine was still sufficiently competitive as late as 1976 to power the Czech team to third place overall in that year's control-line stunt World Championships. The success of the engine over such a long period of time actually forced MVVS to resume limited production for a time beginning in 1970, offering both control-line and R/C models.

By any standard, the MVVS 5.6A must surely be considered one of the all-time great stunt motors. The Fox 35 is traditionally seen as the most successful stunt motor of them all, and in terms of usage it richly deserves that accolade. However, if success at the International level over an extended period of time is your criterion, then the MVVS 5.6A offers a very strong challenge to the Fox. To remain competitive at World Championship level over a period of almost 20 years during a time of rapid engine development represents an outstanding achievement by the 1957 MVVS design team.

Perhaps the most impressive aspect of the outstanding record compiled by the 5.6A was the fact that these successes were achieved in a competition category for which its prototype, the 5R-57 racing engine, had never been envisioned! A fine example of taking what you had and adapting it to meet an entirely different set of requirements.

In 1960 the 5.6A was joined by the initial prototypes of a new model called the MVVS 5.6AL.�This was a far simpler design which abandoned the ringed piston and rear disc valve induction of the 5.6A in favour of a lapped piston set-up (hence the L), along with the use of crankshaft front rotary valve induction.�It also pointed the way to the future by adopting the same twin opposing reverse-flow transfer system that had been pioneered by Enya in the mid-fifties with their 2.5 cc diesel and later employed by MVVS in their 2.5D-58 and 2.5-D diesels.�It was somewhat lighter than the 5.6A at 185 gm and was far more compact.

The intention of the designers was apparently to offer a lower-cost and lighter-weight stunt engine which would meet the needs of a broader spectrum of the modelling public. However, tests showed that it was significantly less powerful than the 5.6A model—the manufacturers claimed only 0.54 BHP @ 13,800 rpm as opposed to their cited figures of 0.63 BHP @ 15,100 rpm for the 5.6A.� Accordingly, serious Czech stunt fliers like Gabris continued to use the latter design for international events. The 5.6AL appears to have remained a "consumer" engine throughout its production life. It was evidently never offered in an R/C version.

The MVVS 5.6A On Test

The MVVS 5.6A was the subject of a 1962 test by the staff of American Modeller magazine. Although not named, the tester was almost certainly Peter Chinn. The relevant report appeared in the August 1962 issue of the magazine as part of an extremely interesting article about Eastern bloc engines entitled Iron Curtain Engines—Da? Nyet? There's considerable internal evidence to suggest that the entire article was in fact authored by Chinn.

Whoever he was, the tester reported most favourably on the engine both in terms of its construction and its performance. Bore and stroke were correctly reported as 20.0mm x 18.0mm respectively for a displacement of 5.66cc. This compares with the dimensions of the parent 5R-57 speed engine, which used a bore and stroke of 20mm x 15.7mm for a displacement of 4.98cc.� Weight of the 5.6A was reported as being 7.25 ounces, which is very close to the factory's claimed weight of 210 gm. Mine weighs almost exactly the latter figure.�

The claimed output of 0.63 BHP @ 15,100 rpm for the 5.6A does not appear to be an unreasonable claim by any means when one looks at the rather advanced specification of the engine. However, the example tested by American Modeller could not match these figures, their published findings being 0.54 BHP @ 13,200 rpm on a 3% nitro fuel—pretty much the same as the MVVS factory claim for the alternative 5.6AL.�No doubt the individually-prepared "works" engines from 1957-58 may well have approached the factory-claimed figures. Even the "production" version such as that tested by American Modeller would likely do so on a more heavily nitrated fuel. However, it seems unlikely that the MVVS designers would have envisioned the use of heavily-nitrated fuels for stunt purposes.�Quite apart from the cost, nitro was by all accounts next to impossible to obtain in the Iron Curtain countries during the late 50's and early 60's unless you were extremely well connected.�

Still, the cited performance was very good indeed for a .35 cuin stunt engine, and the starting and running qualities of the motor were reportedly beyond reproach. My own example confirms these impressions completely—it is extremely easy to start and runs superbly with excellent needle response. I've never flown mine, but I have no doubt at all that it would be a very fine performer in a model.

While they were busy developing what came to be an all-time stunt classic, MVVS had of course remained very active in the control line speed category in which they had first made their name. Let's return to 1957 to take up that story once more.

Turning Up The Heat: The MVVS 2.5R-58

Although the MVVS 2.5/1956-D had done very well at the International level in 1956 and had remained ahead of the Super Tigre opposition, it had still finished behind the individually-constructed specials used by Ray "Gadget" Gibbs of Great Britain and Miclos Vitkovics of Hungary as well as the factory-tuned Barbini B.40 of Italy's Giovanni Cellini. Clearly there was a need to up the ante still further if MVVS was to return to the top of the results sheet in 1957.

In the face of the ever-mounting opposition, the MVVS design team went back to the drawing board and decided to try the effect of reverting to the "bulge bypass" form of transfer system which had been pioneered in the USA by Dooling and had been used for some time in the 5cc MVVS designs. This configuration had the dual advantages of minimizing both crankcase volume and piston weigh as well as improving piston cooling.

The carburettor assembly of the 2.5/1956-D had evidently proved entirely satisfactory, so all that was seen as being necessary was a change in the main crankcase/cylinder/piston setup. The resulting design was something of a cobbled-up affair—it retained the backplate of the 2.5/1956-D (albeit in a different orientation) and also in effect used the same front end, but featured a revised crankcase casting which incorporated the bulge bypass. The piston and cylinder liner were of course amended to suit the revised transfer system. In most respects the new model was simply a scaled-down version of the record-setting 5cc MVVS 5R-57 mentioned earlier.

Cobbled-up it may have been, but there was no doubt at all regarding the effectiveness of this design change. At the 1957 Control Line Speed World Championships held in August 1957 at Mlada Boleslav near Prague, Czechoslovakia, the MVVS-powered home team simply pulverized the opposition, taking the individual title courtesy of Sladk�'s 134.22 mph effort as well as four of the top five placings. The sole top-five intruder was the fourth-placed Hungarian Gyula Krizsma, still using his own specials which were soon to evolve into the MOKI designs. The winning motor was a prototype of what was to become one of MVVS's all-time classic models, the 2.5R-58.

Only ten examples of the new design had been produced in the MVVS workshops for the 1957 championships. As chief designer for the Centre, Josef Sladk� presumably had the pick of the batch. The factory claimed that tests on Sladk�'s actual winning engine had shown flash figures as high as 0.61 BHP @ 22,000 rpm on a fuel containing 40% nitromethane and 20% nitrobenzene. If true, this was almost certainly the highest specific output ever obtained up to that point from a model engine. Frankly, one has to wonder whether a degree of psychological pressure was being exerted here ...

Whatever its true output, there was no denying the overwhelming success of the new design. However, there were clear signs that this dominance would not long go unchallenged. An event which must have given the MVVS designers some pause for thought was the July 1st, 1957 opening of the State-sponsored MOKI centre in nearby Hungary, which was then still recovering from the Soviet Union's violent November 1956 suppression of the 1956 anti-Communist Hungarian revolution. The establishment of the MOKI institute was an initiative undertaken by the reconstituted Hungarian Department of Defense, who established a design centre at Buda�rs airport, a few miles west of the center of Budapest. The MOKI initials stood for Modell Kis�rleti Int�zet, which in Hungarian means Institute for Experimental Modelling. This move by the Hungarians thus exactly paralleled the similar initiative which had been taken by the Czechs in 1953 when they established MVVS.

Like MVVS, the MOKI Institute owed its establishment in large part to the efforts of a single individual, in this case the expert flier and experienced engine designer Gyula Krizsma, who had been associated with the Alag engines among others and had achieved the previously-mentioned fourth-place finish in the 1957 World Control-Line Speed Championships shortly after the establishment of MOKI. The goal of the new establishment was the development and construction of engines for use in model aircraft as well as for military purposes. One of the first priorities was the development of a racing 2.5 cc glow-plug motor which would beat the all-conquering MVVS and Super Tigre opposition.

The establishment of the MOKI Institute came too late for the development of a new MOKI design to overcome the MVVS juggernaut in 1957. However, it was clear that this would be very far from the case in 1958—further development of Krizsma's 1957 engine by MOKI would undoubtedly result in a highly competitive contender in 1958. Not only that, but Super Tigre were not standing pat—they had their lapped-piston version of the G.20/15 well sorted and were now experimenting with the use of crankcase pressure fuel feeds which would allow them to use larger carburettor throat areas and thus further improve an already strong performance.

In addition, things were beginning to stir in America, where Bill Wisniewski was already at work at K&B in California developing the special 2.5 cc engines that were to take him to the highest levels of World Championship speed competition by 1960 and were to lead to the release of K&B's famous Series 61 and Series 64 models.

Despite these clear indications of more intense competition to come, the total dominance which the revised MVVS design had exercised in 1957 seems to have convinced MVVS that their 1957 winner would require relatively little modification to remain on top in 1958. Consequently they contented themselves with making only a few relatively minor experience-based tweaks to the 1957 championship-winning prototypes to produce their classic 2.5R-58 model.

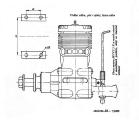

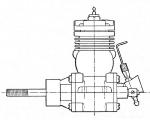

The MVVS 2.5R-58 Design Considerations

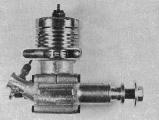

The MVVS 2.5R-58 was basically a conventional racing engine of its day, featuring the classic combination of detachable front and rear covers, twin ball-bearing shaft, ringed aluminum piston, rear rotary disc valve, offset plug, etc.� All cast components were produced by sandcasting—scarcely surprising in view of the very limited production envisioned at this time. Bore and stroke of the 2.5R-58 were the standard Continental 15 mm x 14 mm respectively for a displacement of 2.47 cc. The engine weighed in at 5.1 ounces.�Claimed output for the team engines was 0.44 BHP at 19,000 rpm—rather lower than the cited figures for Sladk�'s 1957 winner, but still very impressive indeed by the standards of the day.

When confronted with one of these engines, one notices immediately that it follows the lead of several earlier Czechoslovakian designs in reverting to the "bulge bypass" set-up derived from the Dooling 29, a system which had been used by MVVS on their larger glow engines since 1954 and applied to their 1957 2.5 cc World Championship winner. However, the most intriguing thing that draws one's attention when examining this engine is the very unusual position and orientation of the intake venturi.�This is located at the bottom of the backplate rather than in the more conventional upper right position (viewed from the rear). Furthermore, it is angled to the right in such a manner that it protrudes slightly beyond the outline of the main casting.�Hence, mounting the engine in a speed pan would require that either the pan or the venturi (or both) be trimmed to allow the engine to be mounted within the pan and still maintain adequate air flow to the intake.

The origin of this rather odd intake orientation becomes apparent when one looks at the rear view of this motor alongside that of the contemporary Vltavan 2.5. The Vltavan was copied directly from the earlier 2.5/1956�D version of the MVVS 2.5 which had the venturi in the conventional location and orientation. When MVVS designed their 1957 championship engines, they decided (for reasons to be discussed below) that the backplate intake port needed to be relocated to the bottom central location. This orientation was retained in the 1958 design, indicting that MVVS themselves were convinced of its effectiveness on the basis of results achieved.

To accomplish this, they simply took the backplate from the earlier 1956 model and rotated it through 90 degrees. All that was then required was to position the drive pick-up in the disc valve at 90 degrees from its former location in order to re-establish the correct timing.� One can clearly see in the attached rear view how the outline of the backplate mounting flange where it joins the main case (behind the needle valve) is intended to conform to a normal case when it is rotated through a 90 degree angle.� Presumably this use of an existing component was undertaken for reasons of economy—it side-stepped the need to make a new backplate pattern and indeed allowed the use of already-existing components taken from earlier and now obsolete models. It also maintained a tangential component of the velocity of the gas entering the crankcase though the venturi, which may also have been a consideration as we shall soon see.

In his November 1960 test of the MVVS 2.5R-58 (see below), Peter Chinn noted this anomaly but failed to consider the possible reasons for this seemingly awkward arrangement. However, reasons there must surely have been—the arrangement had been pioneered on the 1957 2.5cc and 5cc "works specials" and unquestionably would not have been transferred to the 1958 2.5cc model without good cause. So it's worth trying to understand the designers' thinking in this context. �Let's have a go ...

In order to understand what was going on here, it's necessary to look at the chicken-and-egg syndrome and try to sequentially identify the design considerations which appear to have influenced the designers' thinking. I've given this a lot of thought and have come to the conclusion that this unusual backplate arrangement had its origins in the decision to adopt the Dooling bulge-bypass system which had been in use on the larger MVVS racing glow engines since 1954. Let's try to trace the domino effect which stemmed from this decision. ��

The Dooling transfer system employs a hemispherical cavity on the transfer side which serves at the bypass passage. This cavity has no direct communication with the lower crankcase, thus possessing the advantage of minimizing crankcase volume and thus improving the engine's base compression and pumping efficiency. However, the absence of direct communication with the lower crankcase means that an alternative pathway has to be provided for fuel mixture to enter the bypass cavity.

The requirement is met through the provision of large ports in the piston skirt which correspond to similar ports in the cylinder liner at and around bottom dead centre. These liner ports are in turn aligned with the lower portion of the bypass cavity. This arrangement ensured excellent communication between the crankcase interior and the bypass passage at all times when the transfer ports are open. However, it necessarily results in a piston from which much of the skirt on the transfer side has to be removed. In the case of the MVVS engines (and their Vltavan derivatives), these skirt ports were very large indeed, eliminating even more of the piston skirt than usual on the transfer side, to the point where there was virtually no skirt left! �

Now with the exhaust stack located on the right in the conventional manner, the side-load during the power stroke would all be directed to the transfer side of the piston.� But this side of the piston was extremely poorly equipped to deal with these loads—there simply wasn't much of it left! Not a good situation either for mechanical reliability or engine longevity. �

However, there was an obvious fix—switch things around so that the exhaust stack was on the left (viewed from the rear). �If this were done, the power stroke side-thrust would be taken by the unbroken side of the piston skirt.�The almost non-existent transfer side would only have to deal with the far lesser loads involved in the compression stroke.

So there were compelling mechanical arguments in favour of a left-side location of the exhaust stack. But what about the possible effect upon transfer efficiency? If such a relocation of the exhaust stack would have compromised engine performance in any way, there's no possibility that the MVVS designers would have adopted it—they would have accepted that the price to be paid for improved mechanical integrity was simply too high in performance terms.�In a World Championship speed context, ultimate performance was the imperative rather than longevity. �

So the performance implications of making this change must surely have been well considered by the MVVS design team. Here another consideration entered the picture—that of crankcase swirl.� The gas in the crankcase of a two-stroke engine does not sit still—it swirls quite strongly in the direction of rotation of the shaft.� At the speeds at which racing glow-plug engines were even then operating, this swirl effect was quite considerable. Speed engine designers were beginning to appreciate the potential benefits of this and were planning their engines to maximise the positive effect of crankcase swirl on the transfer process.�The swirl imparted considerable velocity and hence kinetic energy to the mixture in the case, and this energy could be harnessed to help move the gas into the bypass passages more rapidly if those passages were appropriately placed and designed. In effect, the crankcase was being seen as a kind of centrifugal pump which could assist in the transfer process (remember, this was before the advent of tuned pipes!).

Now in the case of a conventional cross-flow loop-scavenged engine in which the base of the vertical bypass is open to the crankcase, considerations of the swirl effect would seem to indicate that locating the bypass on the left (and hence the exhaust on the right) should take maximum advantage of the swirl effect in an engine having the normal direction of rotation. The fresh charge of mixture will swirl with the spinning crank and head tangentially straight up the bypass in a vertical direction.�In fact, one of the first things that every serious user of the K&B Series 61 and Series 64 racing engines did before even running them was to switch the case around to bring the exhaust stack to the right (I know, because I was one of those users!). The left-hand stack location was K&B's trademark "house style", but the right-hand location worked measurably better in practise at higher speeds, for the reasons stated above.

So the conventional orientation of the cylinder works fine with the typical vertical bypass passage opening directly off the crankcase in the normal manner for loop-scavenged motors. But in the case of a Dooling set-up, the mixture enters the bypass more horizontally than vertically, crossing just below the piston crown in order to do so (and thereby contributing very significantly to the cooling of the piston crown). �If you think about the swirl effect for a second, it becomes intuitively apparent that a bulge bypass transfer system is best located on the right of the engine!� The swirl effect will then throw the gas straight into the bulge where it is wanted. �Clearly, the MVVS designers thought this through very carefully and concluded that the location of the exhaust stack on the left side of the engine was both mechanically desirable and more efficient in term of the gas transfer from the case to the cylinder. Decision taken ...photographs of Sladk�'s 1957 winning engine clearly show that this stack orientation was undoubtedly applied to the team engines. Wonder if anyone ever tried this with an actual Dooling ...?!?

But what about the implications for the incoming charge of mixture which was to be transferred during the next cycle? �Well, if one thinks about the fact that we want the cool fresh gas to enter the case, be picked up by the crank-induced swirl, cool the piston and �arrive at the entry to the bypass at just the right time, we may gain some insight into the reasons why MVVS located the intake where they did.� If you mentally follow the swirl with the Dooling-type transfer set-up on the right (viewed from the rear) and the intake located at the base of the backplate, you'll see that the cool fresh charge entering the case during the induction phase will swirl with the crank, cool the piston and arrive at the piston ports at just the right time and heading in the desired direction with considerable kinetic energy. �

This might be expected to minimize the residence time in the crankcase of a given incoming charge of mixture—good for internal cooling. Not only that, but the rather odd orientation of the intake itself (angled to the right) would impart a tangential component to the velocity of the incoming gas charge in the direction of swirl, thus minimizing any disruption of the swirl effect as the fresh charge entered the case. �Finally, the induction port would be completely unobstructed by the con-rod big end during the entire induction phase. Job done ...�

Based upon the above line of reasoning, I have little doubt that the orientation of the case with the exhaust on the left was an intentional and well thought-out element of the design and that the unusual location and orientation of the intake were intended to maximise the engine's efficiency in moving the fuel mixture from the point of entry into the bypass, cooling the piston along the way. In effect, MVVS were trying to maximize the contribution of crankcase swirl to the overall pumping efficiency of the engine, as well as trying to promote improved piston cooling. They were also improving the engine's mechanical integrity. The examples encountered today with stacks on the right (and occasionally with the backplates incorrectly positioned) are almost certainly the result of interference on the part of owners who are unaware of the designer's intentions.

I may be wrong, of course, but that's how I see it at present.�If anyone out there has a better explanation for the odd placement of the intake on this engine, let's hear it!� I maintain that there must have been a compelling reason for the engine being set up as it was.�The above explanation makes sense to me at least ...

Regardless of the thinking behind the engine's design, there was no doubt that it had been overwhelmingly successful in 1957. However, 1958 was a somewhat different story—MOKI had arrived with a vengeance! At the 1958 Expo International meeting at Brussels in Belgium, the first two places in control-line speed were occupied by members of the Hungarian team using the newly-developed MOKI engines. The best that the Czechs could manage was a third place finish by Jaroslav Koci, whose best speed of 129.9 mph fell short of both Sladk�'s 134.22 mph winning speed from 1957 and Imre Toth's winning figure of 134.20 mph for 1958 using his new MOKI.

Of course, if the Czechs had been able to repeat their 1957 performances, they would have been right in there for a chance at the overall win. Viewed in that light, their decision to stand pat with what amounted to the same engine that they had used in 1957 might be seen as justified—they could not have foreseen that their team members would fail to extract comparable performances to those achieved in 1957 from what was presumably a further-refined design.

As it was, the Czech team had to content themselves with third, fourth and fifth individual places and second place in the team standings behind the Hungarians. The Italians used their now-traditional Super Tigre G 20S and V engines with lapped pistons, but for the first time used a pressure fuel tank in which the pressure was supplied from the engine crankcase. Despite this, they could not match the performances put up by the Iron Curtain specials.

A Change In Policy

While the MVVS factory specials were continuing to make a strong showing in International competition as of 1958, the same could not be said for the Vltavan clones which were manufactured quite independently in Prague. Although those engines ran well and doubtless provided a wider circle of aspiring Czech modellers with the opportunity to gain valuable experience, the Vltavan name was conspicuous by its absence from contemporary international contest results sheets. The only record that I can find of a Vltavan appearing in international competition was an official flight by Britain's Pete Wright at the 1957 championship meeting. Wright switched to a Vltavan (probably obtained at the meeting given the fact that production had only just commenced) after his Barbini B.40 TN expired, but his speed of just over 100 mph was no threat to Sladky's winning 134.2 mph figure.

Accordingly, it was becoming increasingly apparent that the strategy of putting large numbers of second-rate MVVS clones into the hands of ordinary modellers was perhaps not the most productive course of action in terms of improving the capabilities of Czech contest modellers. If a way could be found to increase the availability of actual MVVS engines, the fliers who had been struggling to overcome the shortcomings of the Vltavan models would have far better equipment with a greatly reduced frustration factor and would thus face fewer barriers to the achievement of far higher standards of performance.

In addition, the plain fact was that as matters stood, the MVVS operation represented an ongoing drain upon State resources. As long as it was limited to the development and manufacture of minimal numbers of racing "specials" for the exclusive use of a mere handful of top-ranked modellers, the operation generated no revenue. This state of affairs was clearly unsustainable.

Accordingly, it was in 1958 that MVVS took the first steps towards becoming a major commercial supplier of high-quality competition model aero engines to modellers in general rather than to a few selected experts.�They took on a number of extra workers at the centre and added more production equipment.�Once this was done, several of their engines were put into small-scale production for wider distribution than had formerly been possible.

The first engine to be produced in this way was the MVVS 25-D, a plain-bearing development of the Type 2.5D-58 ball-bearing diesel. This engine was very well received, and deservedly so—it was a good �un!� In his test of the 25-D published in the November 1958 issue of Model Aircraft, Peter Chinn characterized it as "the most powerful plain bearing 2.5cc diesel yet produced", reporting an output of 0.295 BHP @ 15,800 rpm—an outstanding figure for a plain-bearing diesel in 1958. I have the illustrated well-used example which I still fly occasionally over 50 years after it was made, and boy does it go!�

In the following year of 1959 the 25-D was joined by the 2.5R-58 and 5.6A glow-plug models. The original 2.5R-58 was of course an individually-built "experts-only" model designated for the exclusive use of a few top Czech speed flyers. When the decision was taken to put the 2.5R-58 into series production, the original 1958 design was carried over more or less wholesale, although there must surely have been a realization that assembly tolerances would necessarily be somewhat compromised by the constraints imposed by the production line, which would dictate that each engine would receive considerably less individual attention. Certainly, the custom-made 2.5R-58 engines used by the 1958 Czech team members do seem to have had a better performance than the production-line version of 1959. Kalina's book (page 123) records a claimed output for the "works" 2.5R-58 of 0.44 BHP at 19,000 rpm, which substantially exceeds the factory claim of 0.38 BHP at 18,500 rpm made for the following year's production model. It would thus appear that the degree of precision and individual attention applied to the construction and fitting of this rather complex design had a considerable bearing upon its final performance. It's difficult to feel much surprise at this ...

The 2.5R-58 was produced in relatively limited numbers, albeit vastly higher than those of previous years. The production versions were all given serial numbers which were stamped into the underside of the left-hand mounting lug (looking forward in the direction of flight). According to Kalina, some 2000 of them were made in total over a three-year period. My own pair bear the serial numbers 833 and 1865, seemingly consistent with Kalina's estimate.

Use of the engine was by no means confined to model aircraft—Kalina tells us that the 2.5R-58 also put up a number of record performances in both airscrew and waterscrew-driven tethered hydroplanes as well as being used successfully in model cars.

From the standpoint of the present-day collector, one consequence of the 2.5R-58's relatively low production figures coupled with its outstanding performance was that very few of those who managed to acquire one did so merely to look at it—most of them got used for their intended competition purposes. Moreover, those that did see competition use (the majority) tended to suffer the usual fate of competition engines by being modified in various ways to better tailor them to their intended applications. As a result, unflown examples of the engine in original unmodified form are very rare today.

The MVVS 2.5R-58 Competition Record

We already reviewed the outstanding results achieved in 1957 with the original prototypes of the MVVS 2.5R-58. We also saw that while the engine carried similar levels of performance into 1958, this proved insufficient to stem the MOKI tide in that year. Let's see how the engine fared in subsequent international events.

1959 was very much a development year at MVVS as the Centre strove to become established on a sound commercial footing not only by engaging in series production of the 2.5R-58, the 5.6A and the 25-D but also by developing several new models which were intended from the outset as production models rather than experts-only specials. The latter included the previously-discussed lapped-piston MVVS 5.6AL (which eventually appeared in 1960); the prototype of a new 1cc diesel (which finally entered series production in 1962); and a forerunner of the giant motors now so familiar to today's R/C flyers in the shape of the 26cc MVVS 26-59, of which only some 16 examples ended up being manufactured.

It appears that the change in focus and the effort involved in switching the MVVS centre over from a research centre to a series producer of model engines limited the availability of staff time for the further development of the 2.5R series. The engine was not entirely neglected, receiving a few minor tweaks (including a needle-roller big-end bearing) to create an individually-constructed variant known as the 2.5R-59. The claimed output of this model was increased to 0.47 BHP @ 19,500 rpm—a truly stellar performance by 1959 standards.

It's important to note at this point that the engine tested by Peter Chinn in November 1960 (see below) was incorrectly assigned the 1959 designation. In fact, Chinn's test engine was a production version of the MVVS 2.5R-58 described earlier—Kalina makes this very clear in his book. The 2.5R-59 with its needle-roller big-end bearing was intended strictly for use by the Czech team and never saw series production. However, most of the Czech team members were MVVS employees and it appears that it was not found possible to free up enough staff time to allow participation in the 1959 World C/L Championships at Brussels, Belgium. Accordingly, the 2.5R-59 did not see contest action outside Czechoslovakia in 1959.

However, this was certainly not true of the production version of the 2.5R-58! The majority of these engines initially remained within the Iron Curtain countries, but a few examples found their way to the West and were put to good use there.� At the 1959 World C/L Championship meeting at Brussels, K. Jaaskelainen of Finland managed a very creditable 120.5 mph for 6th place using one of the early production versions of the 2.5R-58 which he had somehow acquired. A highly creditable performance for a single individual working without official support!

By 1960, when the World Championships were held at MOKI's home base at Buda�rs airport near Budapest, things at the MVVS Centre had stabilized to the point where a return to the fray was possible. Moreover, there must have been a considerable incentive within the Czech team to demonstrate that they were still well able to give MOKI a run for their money in MOKI's own back yard! The 2.5R-59 was ready and waiting for its chance to show what it could do.

Apart from that, by 1960 considerably more examples of the production MVVS 2.5R-58 had found their way into the hands of modellers outside Czechoslovakia. While the 2.5R-59 was used by the Czech team at the 1960 Championships, the "production" version of the 2.5R-58 appeared in the hands of entrants from several other countries including the returning K. Jaaskelainen of Finland (121.2 mph), the USSR entries of Michal Vasilchenko (125.5 mph) and V. Natalenko (126.8 mph) and the German entrant G. Zeigler (108.7 mph). MVVS was thus very internationally represented!

Of course, the joker in the pack at this event was the appearance of the American team using the special individually-built engines developed by Bill Wisniewski and Craig Asher along with the very effective but extremely dangerous (and soon to be banned) fuel additive tetra-nitromethane. Although the Americans had a variety of technical troubles at the meeting which prevented them from achieving their full potential, they proved to all unbiased observers that their equipment was undoubtedly capable of recording official speeds well into the 150 mph bracket under ideal conditions. None of the European teams could match this potential.

Despite this, the performances achieved at this meeting by the official Czech team were most impressive and were in fact the best ever achieved using an MVVS 2.5R engine. Admittedly, this was significantly helped by the fact that the Czechs followed the lead of the Americans by using mono-line control for the first time. Zbynek Pech's third-place speed of 141.1 mph at the 1960 meeting was the fastest speed ever recorded by a 2.5R in a sanctioned FAI event, handily beating the best MOKI speed of 133.6 mph at the same meeting (using two lines). Indeed, had it not been for the fact that the 146.6 mph two-line winning speed of Italy's Ugo Rossi was inexplicably allowed to stand despite having been produced by flagrant whipping in clear contravention of the rules (as proved by numerous photographs), Pech would (and therefore should) have finished second behind the moral victor Bill Wisniewski of the USA.

To further rub it in as far as MOKI was concerned, after the conclusion of the contest Pech established a new world record of 152 mph for the 2.5 cc class using 0.011" mono-line, which was thinner than permitted for the actual championship event. This was the all-time fastest speed ever recorded by the MVVS 2.5R-59, and a highly creditable one at that. Such a performance clearly implies that the peak power output claims for the "works" engines were little if at all exaggerated.

A surprising number of MVVS 2.5R-58 engines appeared in the following year at the 1961 Criterium of Aces meeting in Belgium in the hands of flyers from Sweden, Belgium, Switzerland and Germany in addition to the 2.5R-59's used by the official Czech team. However, speeds had dropped a lot by then in view of the new FAI fuel restriction requiring a straight methanol/castor blend. Zbynek Pech's second-place speed of 125.0 mph, only just behind Imre Toth's winning 125.7 mph figure with his MOKI, highlights the effect which the new fuel restrictions had had on performance. The eventual return to the speeds seen in 1960 had to await the mid-�60's advent of the tuned pipe, which naturally made engines like the 2.5R obsolete overnight.

Of course, Iron Curtain products were not viewed positively in America during this period given the state of Cold War tension between the USA and the Iron Curtain bloc. Despite this, one American modeller who did fly one of these engines was Lt. David Cotton, who used a 2.5R-58 in 1961 for speed flying in the United States, reaching speeds of 119 mph under the new FAI rules (no nitro) and as much as 138 mph on nitro. These were the highest speeds ever achieved with one of these engines outside the official Czech team. Lt. Cotton's engine finally expired when it threw a rod after Cotton had used it to qualify to fly in the 1961 US team eliminators. Probably just as well—the spectacle of an American competitor using an Iron Curtain engine in an International competition might not have been viewed favourably in certain circles at the time, particularly given Lt. Cotton's military connections ...

The MVVS 2.5R-58 On Test

One of the above-mentioned escapee examples of the MVVS 2.5R-58 ended up being loaned to resident Model Aircraft engine tester and commentator Peter Chinn, who included the engine in his excellent series of tests published in that magazine. Chinn's test report appeared in the November 1960 issue.

For reasons which are unclear at this late juncture, Chinn called the engine the MVVS 2.5/1959. All I can say is that I have never seen a Czech reference to this model under any name other than the MVVS 2.5R-58. Accordingly, I will continue to use this name for the engine. The 2.5R-59 was a tweaked version (as described above) which was never put into series production.

When we look at the illustrations which accompanied Chinn's test, we notice that the example tested by him had its exhaust stack switched over to the right!�� As discussed earlier, these engines never left the factory set up in that manner—see pages 122 and 140 of Kalina's book, and note also my own "untouched" examples illustrated in the attached photos as well as contemporary photos of the engines in use during their heyday. Both the MVVS 5R-57 and the 2.5R-58 were similarly set up, presumably for the very good and sufficient reasons noted earlier. The case of Chinn's test example must have been switched over by the engine's owner.

In his November 1960 test, Peter Chinn noted the apparent anomaly of the intake location but failed to consider the possible reasons for this rather awkward �arrangement. If my previous analysis of the basis for the orientation of the engine's major components is correct, then reversing the case as on Chinn's test example would completely negate the effectiveness of the induction and transfer design as well as being a retrograde step in mechanical terms.�Once we accept this, we may understand why Chinn failed to achieve the claimed level of performance from his test example of this engine.� He obtained the still-creditable figure of �0.35 BHP at 18,500 rpm on 40% nitro, whereas the factory claimed 0.38 BHP at 18,500 rpm on 45 % nitro for the series-production version of the engine.� Pretty close, admittedly, but perhaps the orientation of the cylinder made just that little bit of difference ...

Chinn commented on the excellent compression seal provided by the two piston rings, and I can confirm that—my two run-in but unflown examples feel far more like lapped engines than ring-equipped models!� Another feature that drew favourable comment was the design of the rotor disc.� Most unusually, this was made of cast iron on this engine—a very durable and suitable material, albeit rather heavy. The disc was very carefully balanced, with the same excellent disc mounting system as used on previous MVVS engines and their Vltavan derivatives being employed. The result was a rotary valve that was second to none in the context of its times.

Chinn was extremely impressed with this engine, characterising it as "a remarkable 2.47 cc glow-plug motor". I've bench-run both of my own examples of the engine and can confirm that they are remarkably easy to start and run both smoothly and powerfully.� They are well up on my Vltavan 2.5's for revs. Quality of construction is superb, especially where it counts. I'm thus able to endorse Chinn's impressions completely.

A Russian clone: The MD 2.5 Moscow

Naturally, the introduction of the MVVS 2.5R-58 as a small-scale production model spelled the end of the Vltavan engines—by 1960, production of those engines seems to have ceased. The Czechs had realised that with racing engines it was more important to maintain standards of quality than it was to aim for mere quantity.� But the Russians had yet to learn this lesson, and this was to lead to a repeat of the Vltavan situation with the MVVS 2.5R-58.

At the time in question, the Russians were beginning to take a strong interest in aiming for top honours in the modelling field themselves.� Like the Czechs before them, they decided that one of the elements of a successful training program for Russian competition flyers would be the provision of readily-available engines with which these flyers could gain experience.�To that end, beginning in 1957 they arranged for the series production of what amounted to replicas of several established competition engine originating from outside the USSR. The facility at which these "consumer-grade" engines were produced was located in Moscow and was primarily involved with defence production. The production of model engines was added to the previously-existing workload of this facility as a sideline, the goal being to provide a range of competition engines for the use of Russian modellers in developing the skills required to compete at the International level.

Early products of this operation included copies of the Webra Mach I and Super Tigre G 21/29 models. The Super Tigre clone was designated the MD-5 Kometa, a quite successful effort which was destined to remain in production for several decades. In 1960 the Kometa was joined by a copy of none other than the MVVS 2.5R-58. Presumably this arose from the fact that members of the USSR team had used MVVS engines with some success from 1958 through 1960 and were thus very familiar with the design.

The new Russian production was designated the MD-2.5 Moscow. There were reportedly plans to produce some 10,000 examples over a 5-year period, but it seems highly unlikely that this figure was achieved.�The motor was to all intents and purposes a copy of the MVVS original, but like the Vltavans before it the MD-2.5 lacked the precision necessary to realize or even approach the full potential of the excellent design upon which it was based. As noted above, the rather complex MVVS design was more than usually dependent upon extremely precise construction to deliver its full potential, and the MD model never came close to achieving this production standard, falling even further short than its Vltavan predecessor.

The MD-2.5 design differed in a few respects from that of the MVVS, few of them positive.�The intake was more conventionally and hence conveniently oriented for mounting, but it was not positively secured in any way, merely plugging tightly into its housing in the backplate!� The exhaust stack was oriented to the right as supplied—again a retrograde step in some ways. The disc valve was made from aluminum instead of cast iron, a clear step backwards. The individual components were generally quite well made but were very poorly matched and fitted. This was of course a guarantee of sub-standard performance in a design which depended overwhelmingly upon precision of construction to realize its full performance potential.

The makers claimed an output of 0.30 BHP for this engine.�Perhaps this might have been possible with an example which was carefully assembled from selected components. �However, a 1962 test of an off-the-shelf example obtained by the staff of American Modeller magazine found only 0.24 BHP on 30% nitro—not too impressive by comparison with the MVVS original!� Poor compression seal was cited as a major contributing factor. Further details of the MD-2.5 appeared in the previously-mentioned article entitled Iron Curtain Engines—Da? Nyet? which appeared in the August 1962 issue of American Modeller.

It appears that the MD-2.5 did not remain in production for the planned 5-year period, being supplanted by superior Russian-made Super Tigre G.20 clones fairly quickly following its introduction. This did not stop the MD factory, however—in addition to the Super Tigre G.20 copies, they continued to turn out a number of other models, including the aforementioned MD-5 Kometa. Like its smaller relative, this engine too failed to approach the performance of the original, and for very similar reasons. However, it was a perfectly useable engine which remained in production for many years right up to the final collapse of the USSR in 1989 and perhaps beyond.

Conclusion

As we mentioned earlier, the MVVS 5.6A remained highly competitive in international stunt competition right through the mid-1970's, only giving way to more up-to-date designs as the �70's drew to a close. However, the situation with respect to the control-line speed arena was far less static—standards of all-out performance were rising at a very rapid rate during the period covered by this article. The 1961 introduction of the K&B .15R Series 61 had already raised the bar, and a lacklustre performance by the Czech team at the 1962 World Championships at Kiev made it obvious that the competitive days of the MVVS 2.5R series were numbered ...

This forced the MVVS Centre to take a completely fresh look at the design approach to their high-performance 2.5 cc glow-plug engines. In fact, they had begun to experiment with a new rear-exhaust 2.5cc model as early as 1960. The results of their thinking began to appear in late 1963 in the form of the first prototypes of the rear-exhaust MVVS 2.5RL motors. Thus an era ended and a new one began.

Still, the 1957 "bulge-bypass" MVVS 2.5R engines had by no means disgraced themselves! Remaining competitive at the highest levels against all comers for 5 years with minimal design changes was no mean feat and one which underscored the excellence of the original designs. And of course, the 5.6A soldiered on ...

So there we leave MVVS at the dawn of a new era in model engine design. We hope that you've enjoyed this look at their first decade. Long may they continue!