Keilkraft Cobra 049

and the British 1/2A Revolution

by Adrian Duncan

2007-04-31

Revised:

2011-11-17

2012-08-28

|

|

|

| Click on images to view larger picture. | ||

In this essay we focus our attention upon an engine that was part of the British .049 glow "revolution" of 1959-60: the Keilkraft Cobra .049.

This neat little engine did not remain long enough on the market or sell in sufficient numbers to have left much of a legacy, and a certain amount of mis-information has subsequently grown up about it. Most people to whom one speaks about the Cobra have never actually seen one and appear to believe that it was an amalgam of Cox components grafted onto a set of British-made castings. While this may be a forgivable error in view of the engine's general appearance, it is in fact far from being the case, so it's time to set the record straight once and for all!

Our intent here is to do our best to set out the facts regarding this engine on the basis of a detailed examination of a surviving example as well as reference to its relatively few appearances in the modelling media. We will also attempt to place the engine in context and in doing so gain a few insights into the British 1/2A glow revolution of which it was a part.

Background

In the initial post-WW2 race to produced ever-smaller and lighter model engines, the compression ignition or "diesel" engine enjoyed a distinct early advantage due to the fact that it didn't require the heavy and bulky ignition support system required by its spark-ignition rivals. As the displacement and hence the power potential of a spark ignition engine went down, the proportion of the overall powerplant weight accounted for by the ignition system went up, with dire impacts upon the effective power-to-weight ratio. At some point, a lower limit was reached below which the power-to-weight ratio became prohibitive. The practical lower limit for this form of ignition was probably achieved by the Atom and Arden spark ignition engines of .099 cu. in (1.6 cc) displacement.By contrast, several European makers such as Allouchery and Micron soon showed what was possible in terms of making sub-miniature model diesels down to displacements which were completely impracticable using spark ignition, with Allouchery establishing the ultimate mark with their jewel-like 0.16 cc Eclair diesel. British makers were not long in following with such designs as the Amco .87, the Mills 0.75 cc, the Ace 0.5 cc, the Comet 0.4 cc, the Kalper 0.32 cc. and the Kemp Hawk 0.25 cc.

However, the commercial development of the glow-plug by Ray Arden in 1947 eliminated the aforesaid ignition system and thus paved the way towards smaller and lighter assisted-ignition model engines than had previously been dreamed of. By 1949, only some two years after the development of the commercial glow-plug, engines of .049 cu. in (0.81 cc) displacement or even less were appearing on the American market in ever-increasing numbers. These quickly assumed a position of considerable market importance in the USA. Volume manufacturers such as K&B, Herkimer (with their OK Cub series), Atwood, Anderson and McCoy were soon flooding the US domestic market with large numbers of engines in this displacement category, the consequence being that a price war developed which had the effect of reducing the selling prices of such engines to the point where they were readily affordable by almost anyone who wanted to become involved with powered model flying. A new class known as 1/2A was soon established to accommodate these then-revolutionary little powerplants in a competition context.

In 1952 the ranks of the American 1/2A manufacturers were swelled by the introduction of the first such engine produced in its entirety by the L. M. Cox company. Prior to that time, Leroy Cox had been producing powered trans-axle units for model cars based on Anderson Baby Spitfire .045 and .060 piston/cylinder units. The 1952 Space Bug represented Cox's initial step towards becoming one of the world's leading model engine manufacturers, a status which was achieved largely on the basis of the success achieved by the company's successive .049 (1/2A) offerings.

Meanwhile, the majority of modellers over in Europe remained true to the compression-ignition ("diesel") engines with which they had become far more comfortable than had their American colleagues, at least in the smaller and mid-displacement categories. It was generally recognized that the glow motor enjoyed certain advantages in the larger displacements (over 3.5 cc) as well as in a pure speed context, but for the lesser displacements and for more general uses the diesel was widely considered superior in Europe.

The attractions of small models were just as evident to the Europeans as they were to the Americans, and diesel engines of comparable displacement to the American 1/2A glows were in wide use by the early 1950's, with the Mills .75 being very much in the forefront of this movement in Britain. Initially, these small diesels tended to out-perform their glow cousins of similar displacement, particularly when it came to swinging the larger airscrews favoured by sport flyers. They didn't rev up as high, but they moved more air!

In 1951-52 there was a minor revolution within the British marketplace, with no less than four established British engine lines (Frog, ED, Allbon and Elfin) being expanded to include new second-generation 0.5 cc (.030 cu. in.) diesel models. Despite their small displacement and light weight, these performed very respectably and were generally considered by their British owners to perform in a sport-flying context at least on a par with the American .049 glows which were by that time appearing on British flying fields in small but ever-increasing numbers.

However, all of this was blown right out of the water in the following year (1953) with the introduction by Cox of the famous .049 Thermal Hopper. The performance of this fabulous little reed-valve glow-plug engine leapfrogged that of the 0.5 cc and even the 0.8 cc British diesels at one fell swoop. Davies-Charlton fought back vigorously with their excellent little 0.76 cc Merlin diesel of 1954, which was in fact a superior engine to the Cox for sport-flying use, and International Model Aircraft also joined in the fun in 1956 with their equally good Frog 80 Mk. I diesel. However, the ultimate performance of these fine little powerplants still fell short of that of the Cox model, and the introduction in 1957 of the Holland Hornet further underlined the fact that, when it came down to all-out performance, the glow-plug motor no longer needed to take a back seat to the diesel in any displacement category.

Since its inception, the glow-plug motor had maintained a place in British modelling in the larger sizes, where its general superiority to the diesel had long been recognized, particularly for control-line speed. However, the advent of engines like the Cox and Holland .049 models as well as the championship-winning OS Max 15 of the mid-1950's contributed to the commencement of a period of re-appraisal of the glow-plug motor on the part of British and Continental modellers in terms of its broader applicability to the smaller displacement categories which they had hitherto seen as being largely the preserve of the diesel. This movement began to take shape in around 1958 and had gained considerable momentum by 1959, to the point that the editors of the 1959 "Aeromodeller Annual" specifically commented upon the fact that the "attempted come-back of the glow-plug motor" had been a noteworthy point of interest during the 1959 season!

|

|

|

|

|

The practical results of this movement were not long in appearing in the British marketplace. Imports of Cox 1/2A models were stepped up, and in the latter half of 1959 a number of British manufacturers re-staged the revolution of 1951-52 by entering the 1/2A glow motor market themselves. International Model Aircraft got the ball rolling by introducing the Frog .049 glow-plug version of their established Frog 80 diesel; Davies-Charlton responded by releasing the Bantam, which was to all intents and purposes a bored-out glow-plug ignition version of their well-established 0.55 cc Allbon Dart diesel; and Allen-Mercury announced the A-M .049, which was simply a straight copy of the well-established American Wen-Mac .049 glow motor produced in Britain under license from Wen-Mac. All three of these new British 1/2A motors were tested together as a group by Ron Warring, the results being published in an unusual triple test which appeared in the January 1960 issue of Aeromodeller magazine, then edited by Ron Moulton.

Now, it's noteworthy that none of the above designs embodied any truly original thinking in their conception. All of them either borrowed heavily from existing designs already in production by their respective manufacturers or (in the case of the A-M) were nothing short of a licensed copy of an American existing design. This probably reflects the unmistakable fact that when it came to manufacturing engines at the kind of low unit production costs that could be achieved by American volume producers such as Cox, the British makers with their far smaller market could not hope to compete and thus sought to find savings elsewhere, such as in development costs. In hindsight, this was probably a mistake, of which more in its place below.

However, such thinking was by no means confined to the above three British engine manufacturers at this time. During 1959 the major British firm of E. Keil & Co., producers of the very popular Keilkraft line of model kits, was quietly finalizing arrangements with a hitherto unknown model engine manufacturer to market an .049 glow made to an original specification but drawing heavily upon an existing design by others! In that same January 1960 issue of Aeromodeller, a rather unusual announcement appeared in the regular "Motor Mart" feature of the magazine. This was to the effect that the plans supplied with the newly-introduced Keilkraft "Firefly" 1/2A control-line stunt model kit showed a hitherto unheralded glow-plug engine—the Cobra .049! A very odd way indeed to announce a new engine—show it on a kit plan with no other form of prior announcement!

The "Motor Mart" article, which was clearly written in late 1959 to meet the editorial deadline for the January 1960 issue, stated that inquiries (presumably directed to Eddie Keil and/or Eddie Cosh, General Manager at Keilkraft and past editor of rival magazine, Model Aircraft) regarding the manufacturer of this engine had drawn a blank beyond eliciting the information that they were "...London-based and not without modelling experience" [1]. Conversely, Peter Chinn later stated "The engine is the product of of a company new to model engine manufacture, John Rodwell Ltd., of Hornchurch..." [2]. All that was said at the time regarding the release of the engine was that it was "not yet ready for distribution" but that it "should be in the shops in the new year (ie, 1960)". Clearly, the two Eddies were playing their cards very close to the chest when it came to discussing this engine—rather odd given the fact that this was a golden opportunity to promote it and that Keilkraft themselves had blown the whistle with their "Firefly" plan depiction! The "Aeromodeller" article was illustrated with reproductions of the "Firefly" plan illustrations, since no photograph was apparently made available by Keil & Co.!

As a 13-year old schoolboy at the time in question, I was a regular flyer of 1/2A models, the attraction being that you could obtain used 1/2A engines very cheaply at the time coupled with the further economic incentives that the models themselves were cheap and easy to build and a day's flying could be enjoyed on a relatively small amount of (to me!) expensive fuel. So when a wealthier club-mate bought a "Firefly" kit I shamelessly borrowed the plan (sorry, Eddie!) and constructed my own example for my battered but highly serviceable old fifth-hand Allbon Merlin diesel. But I noted the Cobra .049 shown on the plan, and waited with interest for its further appearances in the media and on the market.

|

|

|

|

Aeromodeller reported that the Cobra, in its final packaging, was displayed at the Keilkraft Trade Show held in Manchester June 27-30th, 1960 [3]. The first advertisement for the Cobra appeared in October 1960, some nine months or more after the appearance of its three British-made rivals. The actual manufacturers turned out to be John Rodwell Ltd. of Hornchurch, Essex—not exactly in the heart of London but close to Keilkraft who were located in Wickford, Essex. The subsequent test by Ron Warring supports Chinn's estimation regarding Rodwell's prior model engine involvement as he states that the makers were "[a] firm with no previous experience in model engine production...". He also states that the engine had been under development for "three or four years". Clearly it had taken Rodwell some time to get things right!

The only obvious departures from the views published with the 1959 "Firefly" plan were the addition of the name "Cobra" cast in relief into the underside of the crankcase and the fact that the starter spring which had been depicted on the plan views was omitted on the production model. In actual fact, the engine was such a good hand-starter that the spring was scarcely necessary.

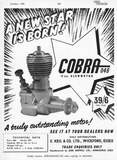

The Cobra .049 was marketed exclusively by E. Keil & Co. Ltd. for the very competitive price of �1/19/6. The packaging was outstanding by British standards—an American-style bubble pack which presented the engine very attractively. The initial advertisement placed in "Aeromodeller" in October 1960 was also very eye-catching. However, the engine does not appear to have been promoted all that aggressively thereafter, and distribution of the engine throughout Britain appears to have been less than comprehensive. I personally never encountered a Cobra .049 in any of the South Yorkshire model shops which I used to haunt—I would certainly have noticed if one had appeared for sale given the fact that I was watching out for it. Nor did an example ever appear in the hands of any of my many aeromodelling friends and colleagues—again, I would have noticed.

In fact, the initial public appearance of the Cobra as far as I was concerned came in the form of a test by Ron Warring which appeared in the October 1960 issue of "Aeromodeller" magazine (of which more below). The previously-mentioned advertisement also appeared for the first time in that same October 1960 issue. The test report itself was extremely favourable, and a figure of 0.052 BHP @ 15,000 rpm was recorded, which compared well with similar figures obtained for the competing British models and was in fact well up to par with the Cox Babe Bee, for which Warring recorded 0.056 BHP @ 13,000 rpm in his May 1961 test of that model. The Cobra's price of £1/19/6 also undercut that of the Babe Bee, which sold at the time in Britain for £2/2/6.

A second test of the Cobra appeared in the January 1961 issue of the rival publication Model Aircraft. Although unattributed, there can be little doubt that the tester was Peter Chinn. This test was guardedly positive rather than being universally complimentary. Chinn had two examples for test, the first of which proved hard to start due to a loosely-fitted main bearing assembly. The second sample was far better, hence being used for the test. Chinn made the comment that none of the then-current crop of British .049 glow-plug engines were as good as they might be, the Cobra being no exception. Nonetheless, handling and high-speed running qualities of the better example were quite good, although needle settings became rather critical at higher speeds. Chinn found a slightly lower output than Warring, a peak of 0.049 BHP being recorded at 14,600 rpm. Nonetheless, this represented the highest power-to-weight ratio of any of the four British .049 glow-plug engines which had then been tested by Chinn.

A synopsis of the Cobra test from Aeromodeller also appeared in the 1961-62 "Aeromodeller Annual", directly above similar entries for the Cox .049 models [5]. But despite what appeared to be quite a promising send-off, actual examples of the Cobra still failed to put in an appearance in my area at least. Certainly it failed to appear in the "World's Model Engines" feature of the 1963 "Aeromodeller Plans Handbook" published during the latter part of that year. The next and final picture of the Cobra in Keilkraft advertising appeared on the back cover of the June 1961 issue of Aeromodeller where it appeared to accompany Keilkraft's kits—not hard to figure out where the profit came from!

For the following 30 years or more, during which time I made the jump from flyer of odd-ball motors to collector and restorer of same, I didn't encounter a single example of this engine, which seemed to confirm my understanding that it hadn't made much of an impression upon the market. I was therefore pleasantly surprised to finally encounter not one but two real live examples being offered for sale! These had been bought new as a pair by the same individual, who intended to build a twin-engine model for them but never got around to doing so, although he did use them both individually for a while. Since they were both complete and in quite nice condition, I quickly snapped them up and found them to be very useful little motors which performed well by comparison with contemporary rivals such as the Babe Bee.

I am thus in a position to describe this neat little motor in detail for the record. A task which is long overdue, in my book; here goes!

Why the new model?

Even the limited amount of information apparent from the two views of the engine presented on the "Firefly" plan made it abundantly clear at the outset that the design of the Cobra .049 owed much to the Cox 1/2A series of engines. Although the "Motor Mart" article refrained from saying so, the similarities were so obvious that at the time I and many others felt it to be likely that the engine must have been planned in consultation with, or at least with the blessing of, the L. M. Cox company in California.

But then, why would Cox go along with this? By 1959 their own engines were being imported into Britain in ever-increasing numbers by the A. A. Hales organization and were beginning to sell quite well—why participate in an exercise to increase the competition to their own products by lending their support to a rival domestic production which on the face of it was to all practical purposes one of their own designs?

As it turns out, they did no such thing. In actual fact, as will be made clear, the Cobra was unquestionably an all-British production throughout. OK, so that leaves us with a different question—if Cox had nothing to do with the Cobra, then what would motivate a fledgling British manufacturer like Rodwell to go into direct competition with Cox with an engine that was so clearly inspired by the Cox design? Where was the target market niche?

The major technical factors that I myself can see coming into play here are the issues of mounting and fuel supply. For whatever reason(s), the majority of British model designs were arranged for beam mounting, and radially-mounted production engines of British origin were few and far between by this time. Even those that were amenable to radial mounting, such as the DC diesel series, were also equipped with beam mounts. Basically, the average British modeller had come to expect the use of beam mounting and was comfortable with that arrangement. The use of radial mounting as required with the Cox 1/2A range up to 1959 generally required considerable modification to the front end of the fuselage to accommodate the engine in most British designs. Many people resisted the need to do this, and I actually recall this being a frequently-stated criticism of the Cox engines at the time, valid or otherwise.

At the time, control-line was all the rage in Britain, and 1/2A control line was particularly popular among the many teenage flyers like myself on account of the relatively low start-up investment and running costs involved. This led to another frequently-voiced criticism of the Cox engines from my personal recollection—the fact that one was more or less compelled to use the integral tank supplied with these engines. These tanks took up quite a bit of space directly behind the engine, and some of them were less than completely suitable for control-line flying. In addition, the fuel load was well forward of the model's centre of gravity, which thus changed during flight as the tank ran out. Even in a free flight context, the Cox metal tanks were downright unsuitable for timing free flight runs by observing the residual fuel level in the tank. British modellers tended to favour the flexibility of being able to use a tank of their own choosing that was tailored to the application in question and could be located more flexibly.

A non-technical factor that may also have come into play was the fact that the slogan "Buy British!" still meant something in those far-off days of almost a half-century ago. People in Britain were still positively influenced by the term "Made in England" applied to most forms of goods, and if a British product of comparable quality and performance to its overseas counterpart could be obtained for anything like a comparable price, it was likely to be favourably received in the British marketplace.

It would appear that the promoters of the Cobra .049 had noted all of these factors and had decided that there would be a domestic market for a competitively-priced British-made engine which was to all intents and purposes a Cox model but which used beam mounting and allowed the use of a tank of the owner's choice, either free flight or control line. However, it would not have escaped their notice that, despite their mounting and fuel supply issues, the Cox engines had acquired a deservedly high reputation for quality and performance by this time. Hence the Cobra's overt similarity to the Cox was likely seen as a further sales incentive. Besides, why re-invent the wheel? The clincher was the belief, mistaken or otherwise, that such an engine could be produced in Britain at a price which would undercut that of the Cox imports after payment of import duty.

Unfortunately for the promoters of the Cobra, Cox themselves were in the process of addressing some of these very issues! Cox's wonderful little 1959 Space Hopper not only employed beam mounting but also did away with the built-in tank, leaving the choice of tank up to the user in accordance with the intended application. It also used a twin-transfer cylinder which allowed it to reach levels of performance which put all of its British rivals to shame. This cannot have helped the cause of the British .049 glow engines.

OK, so how closely did the designer of the Cobra follow the Cox pattern? Let's find out...

Description

There's no doubt at all that at first glance the Cobra looks exactly like a Cox product. It's also an indisputable fact that the engine was produced to Cox standards of quality All fits and finishes are beyond reproach. Prior to becoming a Cobra owner myself, the few people that I ever talked to who claimed to know anything at all about this engine invariably told me that it was an amalgamation of some bought-in Cox components grafted onto a set of British-made castings. Seemed reasonable to me at the time—Keilkraft were big enough at the time to have brokered a deal of that kind with Cox.

There's no doubt at all that at first glance the Cobra looks exactly like a Cox product. It's also an indisputable fact that the engine was produced to Cox standards of quality All fits and finishes are beyond reproach. Prior to becoming a Cobra owner myself, the few people that I ever talked to who claimed to know anything at all about this engine invariably told me that it was an amalgamation of some bought-in Cox components grafted onto a set of British-made castings. Seemed reasonable to me at the time—Keilkraft were big enough at the time to have brokered a deal of that kind with Cox.

But now that we have a few actual examples to dissect, let's check this out at first hand with a view towards replacing legend with fact! And where better to start than at the heart of the motor and the most obviously "Cox" component—the cylinder? I may as well come right out and say that, appearances to the contrary, the Cobra cylinder is not a standard Cox item. It certainly shares enough common features that there can be no doubt whatsoever that it was directly inspired by the Cox design. But it is most definitely not a bought-in Cox cylinder of the type fitted to their other engines.

The similarities to the Cox are obvious from looking at the images of the Cobra cylinder side by side with one from a Cox Babe Bee of similar vintage. Both blued-steel cylinders are of one-piece construction with very thin cooling fins, a single internal flute bypass port and twin exhaust ports. The porting in fact is effectively identical. Bores are certainly identical, to the point that the Cobra piston fits perfectly in the Cox cylinder and vice versa. Both engines employ a seemingly identical replaceable glow head instead of a permanent head with a tapping for the glow-plug. The glow head screws into a threaded socket at the top of the cylinder, and this socket is 0.154 in. deep on both cylinders. Thread pitches on both cylinders are identical.

The differences are less obvious, but they're there regardless! First off, it's easy to spot the more "rounded" profile of the cylinder fins on the Cobra cylinder. The more observant scrutinizers will also note that the threaded spigot which screws into the top of the crankcase is longer on the Cobra than it is on the Cox—the Cobra spigot extends for 0.140 in. below the seating flange, while that on the Cox only extends down by 0.114 in. The threads on the sockets are identical, however, and the Cobra cylinder will screw right into a Cox case, and vice versa. The fact that the con rod lengths and crankpins are also identical actually means that the piston/cylinder sets can be interchanged and used with either motor.

Another difference which may be spotted is the fact that the Cobra cylinder wall is far thicker above the exhaust level than its Cox counterpart. This is consistent with then-established British practise of generally using thicker cylinders than American manufacturers. The external diameter of the Cobra cylinder at exhaust port level (0.506 in.) is slightly less than that of the Cox (0.515 in.), but this diameter continues unchanged above the exhaust ports at the base of the cooling grooves, whereas the Cox cylinder wall is substantially thinner above the lowest cooling fin. The rounding of the cooling fin contour on the Cobra may well be intended to restore lost cooling fin depth due to the thicker cylinder walls at the base of the fins.

A more subtle difference which was reported by Warring in his published test was the fact that the Cobra again followed standard British practise by being made of hardened steel, by contrast to the unhardened mild steel used in the Cox cylinders. I have to say that my two examples do not support this description—both of them have unhardened steel cylinders which appear to be of identical specification to that used in the Cox. It is possible that the early models, of which Warring's was presumably one, did feature hardened cylinders and that this was changed on the later models. There's no way to be certain on this point unless further examples are brought to our attention.

Both of my examples arrived with what appeared to be standard off-the-shelf Cox glow-heads of the period which sealed using thin copper gaskets which again appeared to be Cox items or exact copies. As noted earlier, the depth of the glow-head sockets on both the Cox and the Cobra cylinders are identical, as is the thread pitch used. I can't see this being merely coincidental. The cylinder thread on one of my two Cobras is rather tight, and I found that to fit a new replacement Cox head without binding required that the thread on the glow-head be chased in order to relieve its diameter very slightly. The other engine accepted a standard Cox head with no difficulty. This appears to be an incidental variation on the engine in question, and is probably related to the fact that threads on the Cobra appear to be cut to the British Whitworth standard of some 55° included angle, while the threads on the Cox glow-heads was cut to the American standard of 60°. Now 60 into 55 will go, but can make for a slightly tight fit.

This raises an interesting question to which I don't have the answer. Did Rodwell make his own glow heads for the Cobra or did he use bought-in Cox items and expect his customers to use Cox replacements? Glow-plug manufacture is a highly specialized process which has little in common with engine manufacture as such, and Rodwell could certainly have used Keilkraft's influence to obtain Cox glow-heads in bulk at wholesale prices through A. A. Hales. In doing so he would have neatly sidestepped the requirement to develop the very specialized manufacturing capability required to make exact replicas of Cox glow-heads. Without a shred of proof to back up this assertion, logic persuades me that this is most probably what he did—the challenge of tooling up for the new engine would be quite sufficient without having to worry about embarking on glow-head manufacture as well. But I freely admit that I could be wrong here.

Turning now to the piston/rod set-up, it is once again clear that we're looking at direct Cox influence—the same basic ball-and-socket small-end design is employed and con-rod lengths are identical. However, there are some interesting departures. The main one is the fact that the Cobra uses a light alloy rod which is retained in its socket by a slotted steel retaining cup which in turn is held in place by a steel circlip located in a shallow groove in the interior piston wall. This arrangement had been used by Cox in their earlier .049 models but had been abandoned as of 1957 in favour of a hardened steel rod which was swaged into a bearing cup formed integrally in the piston interior. The advantage of this latter set-up was that it simplified assembly and the bearing could be re-set to take up play using a suitable tool to re-swage the cup.

At first sight it seems a little odd that the makers of the Cobra would elect to go back to the earlier and in some ways less satisfactory system in which rod wear could not be taken up. But if we believe Warring's assertion noted earlier that the Cobra had been under development for "three or four years", it is possible to make sense out of it. Cox appear to have made the switch from the system used in the Cobra to their later all-steel set up during 1957. If Warring is to be believed, the Cobra was already well into the development stage by that time, and the design of (and tooling for) the rod and piston may well have been already finalized as of 1957 using the then still-current Cox arrangement as a guide. The decision to stick with this arrangement despite Cox's abandonment of it was presumably production-based.

One visible consequence of this difference in approach is the fact that the Cobra piston is not copper-plated either internally or on the crown. This was done in the revised Cox engines to prevent the hardening process applied to the piston wearing surfaces from affecting the area of the con-rod bearing cup so that it remained soft enough to be swaged over after the rod was installed. With the type of small-end retention system used on the Cobra, this is not necessary and the entire piston is hardened.

Reader Jon Fletcher subsequently contacted us to state that his own example of the Cobra has a steel rod with a swaged socket, like the later Cox models. I can only say that all four examples now in my own possession have the alloy rod set-up described earlier and they are numbered at both ends of the serial numbering sequence as well as in the middle. Moreover, the bores of the Cobra and Cox engines are identical and direct experimentation has shown that a Cox piston/rod unit fits the Cobra cylinder/shaft combination perfectly. It may be that Jon has a unit that has been retrofitted in this manner. There's no doubt that the later Cox system is far more durable.

The most obvious visible departure from the Cox design is of course the use of die-castings for the crankcase and backplate units instead of solid extruded bar stock. The internal machining of the crankcase is identical to that of the Cox series, including the groove for the con rod big end to prevent the rod from fouling the reed valve. The reed valve spigot machined into the front of the backplate casting is also of identical external diameter and depth to that used in the Cox radial mount reed-valve engines, and the backplate mounting holes are spaced identically as well. In fact, the only difference here is that the Cobra backplate fixing screws are 8 BA items rather than the 2-56 items used by Cox. Hence a Cox Babe Bee backplate can be used with the Cobra case and working components if one uses 8 BA screws of sufficient length, and likewise the Cobra backplate can be fitted to a Cox reed-valve front end using 2-56 screws.

Turning now to the crankshaft, this appears at first sight to be dimensionally identical to that used in the Cox series. Certainly the nominal journal diameter of 0.216 in.is identical, as are the overall length, the crank-disc and the crankpin diameter. However, the stroke of the Cobra is fractionally shorter at 0.376 in. as opposed to 0.382 in for the Cox. Combined with the shared bore of 0.406 in, this gives the Cobra an actual displacement of 0.798 cc as opposed to the 0.810 cc of the Cox. Presumably the manufacturers saw the 0.8 cc cut-off as being potentially significant in the context of the British market given that any new European contest class for these motors might well be based on the metric displacement limit of 0.8 cc rather than the 0.05 cubic inch limit used by the Americans.

The only other observable difference in the shaft is that the Cobra prop screw is threaded 5BA instead of the 5-40 thread used by Cox. All of this confirms that the shaft is not a bought-in standard Cox component. The prop driver looks exactly like its Cox counterpart, but is anodized blue.

Looking now at the reed valve, the reed itself is clearly a direct Cox clone as is the retaining circlip—in fact, the Cobra components are directly interchangeable with their Cox counterparts. But here we see additional evidence of independent thinking. The basic induction system is identical to that of the Cox, but a few key dimensions are different. The bore at the narrowest part of the Cobra's venturi throat where the single fuel orifice enters the bore is very slightly larger than that of the Cox Babe Bee. Throat diameters are 0.0625 in. and 0.0580 in. respectively. Not much of a difference, true, but the fact that the Cobra also has a straight unimpeded approach to the venturi throat without the right-angle bend in the induction tract of the Babe Bee should theoretically at least result in a slightly less impeded induction system with equally good suction.

The form of the induction tract on the reed side of the fuel orifice is also different. The Babe Bee induction tract expands uniformly from just past the throat to the back of the reed, the diameter at that point being 0.141 in. The Cobra induction tract expands more gradually as it progresses from the throat towards the reed, reaching a diameter of 0.125 in. some distance behind the reed but then expanding sharply at about a 60 degree angle to yield a diameter at the back of the reed of 0.200 in. This significantly increases the area of the reed which is affected by the differential pressures inside and outside the crankcase, and also increases the circumference of the reed seat past which gas has to flow. This should in theory result in a more responsive reed set-up and one which can pass more gas for a given reed opening.

The next component requiring our examination is the needle valve. Once again, the needle is not a bought-in Cox component—it is a trifle more bulky and is threaded 6BA. This is a metric thread with about 47.9 threads per inch (TPI); significantly more coarsely than the 80 TPI thread used on the Cox counterpart. Otherwise, the arrangements are essentially identical to those on the Cox.

The form of the backplate on the Cobra is highly unusual—like the Cox, it can be located in any one of four positions to accommodate differing mounting configurations, but it's a fact that all of these positions place the needle in a rather odd and sometimes awkward position. Cox were later to use a rather similar backplate unit on their RTF "Spook" model, but that unit used a more conventionally-located needle position. The rather odd orientation of the Cobra needle valve appears to have been forced upon the designer by considerations of clearance between the needle and the cylinder.

So what does all of the above tell us? In summary, that the only components which could conceivably be bought-in standard Cox components are the glow-head plus the reed and its retaining circlip! Everything else differs in some respects from the components used on the then-contemporary Babe Bee model which the Cobra most closely mimics. A formal connection with Cox could scarcely be justified by the need to obtain reeds or glow-heads, so the inescapable conclusion is that, legends and rumours to the contrary, the Cobra was indeed an all-British production and a highly commendable one at that.

Serial Numbers

The few examples of the Cobra that have come directly to my personal attention have all borne a four-digit serial number stamped very neatly into the underside of the crankcase below the "Cobra" name. There are no letters or symbols involved, suggesting that the engines were simply numbered sequentially as they came off the line. My own examples are numbered 1061, 4060, 5687 and 5892 respectively (the latter two bought new as a pair, remember), while Tim Dannels has engine number 1679. The fact that we have yet to see an engine with a serial number having fewer than four digits strongly suggests that the serial numbering sequence started at 1000. This was by no means an uncommon practise among model engine manufacturers. If this is indeed the case, it suggests that at least 5000 and possibly more examples must have been made and presumably sold—a puny total by comparison with Cox, but a worthy figure nonetheless for a British production by a new manufacturer engaging in a highly competitive marketplace. One wonders where they all are now? With these production numbers, they really should be more common than they appear to be! The "disposable engine syndrome" again, no doubt!The End of the Line

By mid-1963, a mere three years avter release, the Cobra appears to have disappeared from the marketplace. This raises two very basic questions—why did the engine disappear so quickly; and if it was in fact in production for three years, why are there apparently so few survivors, relatively speaking? Surely a production period of even three years would have resulted in far more engines being produced.

At this same time, the competing Bantam and Frog .049 glows were still soldiering merrily on. Indications are that the Cobra was every bit as good an engine as either of them, so why would a quality product like the Cobra which was competitively priced, attractively presented and well up to the competition in performance terms vanish so relatively swiftly from the market, leaving so few survivors in a relative sense?

There appear to be three possibilities:

- The L. M. Cox company took a hand by threatening legal action against the companies involved with selling what was undeniably an unauthorized Cox derivative, thus forcing an early termination of production. There is absolutely no evidence for this and no precedent for Cox taking similar action in other such cases, but it cannot be discounted as a possibility, albeit in my own view by far the least likely.

- The engine didn't sell. At first sight this appears to be supported by the relative scarcity of surviving examples plus the fact that I personally don't recall ever seeing one of these engines in use at the time, although I saw plenty of Bantams and a few Frogs and A-M's. But if this was the case, it's hard to see why—on sheer merit, the engine really ought to have sold! This explanation also falls short of convincing me.

This said, reader Jon Fletcher has shared his personal recollection that the Cox Babe Bees that were used in the Cox RTF models at the time were somewhat inconsistent, having a disconcerting habit of slowing down and stopping for no very good reason even before take-off. In the minds of British modellers, this trait seems to have been associated with the use of reed valve induction, and this in turn may have given rise to a measure of sales resistance as far as the Cobra was concerned. A valid point, but even so this explanation also falls somewhat short of convincing me.

- The engines sold OK when they were finally released, but the manufacturers quickly found that they weren't making any money on the engines and either failed financially or made a business decision to turn to other more lucrative work. As we have seen, the engine was produced to very high standards using American production techniques and represented a considerable start-up investment in dies, tooling and packaging. It seems entirely possible that the profit margin imposed upon the manufacturer by Keilkraft's undoubted need to price the engine competitively proved insufficient to recover this investment and that Rodwell may have either been forced out of business or cut his losses and turned to other more remunerative work.

If this scenario is correct, the spotty distribution, the early departure from the marketplace and the relative scarcity of surviving examples would all be explained—the makers would have become painfully aware of the unsustainable profit situation quite early on in the game and terminated production very quickly after fulfilling the minimum production requirement under the terms of their agreement with Keilkraft, leaving the latter to sell off those engines that had been produced, which they did over the next few years. The previously-noted lack of the required fervor by Keilkraft in promoting and distributing the engines would also be explained under this scenario—why push a product that you already knew to have no future?

Personally, I think that the last of the above scenarios is by far the most likely—it explains all of the surrounding circumstances. In the end, what probably killed the Cobra was the painful fact that it was simply impossible for a small British manufacturer to make money producing an engine to Cox standards at the low unit cost figures with which Cox was able to work with their multiple rows of automated machines. In an interview with Leroy Cox which was published years later in the Engine Collector's Journal, Cox noted that he costed the engines simply on the number of manufacturing operations required to produce them, using a figure of I cent per operation!! Based on that standard, the Babe Bee was being produced at a manufacturer's cost of about thirty cents each (approximately 2s 6d at the time)! How could any small British engineering firm compete with that and make any money?

Whichever way it went, the Cobra was undeniably a brave attempt to meet the American manufacturers head-on and compete with them on the basis of their own standards. There seems equally little doubt that on merit alone the disappearance of the Cobra from the scene was both undeserved and premature.

The Cobra Seen in Context

The above description should have made it clear that the Cobra stood out from among the early British .049 glow contenders in one very important respect—it was an all-new production from the ground up and hence represented a very significant start-up investment which the others all attempted to side-step by piggy-backing upon existing productions in one way or another. True, it borrowed heavily from the Cox .049 models in terms of its general design concept, but in doing so it was borrowing from the most successful 1/2A glow motor design of the period. And what's so wrong with that?!? Almost all engines incorporate a significant degree of borrowing anyway, and if you're going to borrow, then borrow from the best! And if you're going to produce a glow derivative, far better to do so from a glow prototype rather than a diesel!In retrospect, it appears to me that most of the Brit manufacturers made a fundamental error in 1959 when they decided to jump on the .049 glow bandwagon after sales of such engines began to take off in Britain. Instead of developing their own designs, they went the cheap 'n easy route of either taking an existing diesel design of their own and modifying it for glow operation or (in the case of Allen-Mercury) simply buying the right to reproduce a straight copy of an existing American design. They really didn't put any effort into developing a purpose-built glow model. The makers of the Cobra were alone in taking that approach.

That's why the Cobra stands out for me from among the 1959 Brit .049 glow crop. In my opinion, Rodwell took a very commendable and logical approach towards the development of that engine—he resisted the temptation to re-invent the wheel and took the most demonstrably successful American .049 glow of the day as his starting point (no diesel heritage to overcome) but reconfigured the engine to appeal to the British market (beam mounting, no integral fuel tank, etc) and introduced a few functional design changes of his own. A very well-focused approach which contrasts with that taken by Allen-Mercury, who simply copied. And it's also far more rational than the approach taken by both DC and Frog, who took existing diesels as their starting points—the successful conversion from diesel to glow is seldom that straightforward. Not only that, but Rodwell appears to have adopted American production techniques as well, thereby achieving a highly comparable level of overall quality. He really deserved better success than he seems to have achieved.

For me, the far better-known DC Bantam represents an instructive comparison and an example of lost opportunity. It was released with great fanfare in late 1959 and received a glowing accolade from Ron Warring in his January 1960 test. But unfortunately, examples as good as the one that he tested appear to have been few and far between! Many of those that found their way into the hands of modellers (and there were a lot of them—everyone rushed to buy a Bantam!) quickly proved themselves to be gutless wonders, albeit very light, compact and well made! The sense of let-down was quite palpable at the time, and the Bantam probably did more to turn the tide of prejudice against the Brit .049 glows among serious modellers than any other engine. The release of a radial mount Deluxe version of the Bantam in 1962 did little to change this perception since its performance was essentially identical, as Warring's August 1962 test confirmed.

As a Brit schoolboy flier myself at the time, I actually recall most of the keener flyers giving up on their Bantams in disgust when they found out how gutless they really were—I've never known how Ron Warring got the figures that he did in his January 1960 and August 1962 tests! I always suspected that he must have got "hand-picked" engines from the factory—certainly, my faithful old Allbon Merlin diesel would bury a Bantam any day! I did pick up a slightly used Bantam myself for a few bob from a disgruntled owner, and it was (and still is!) just as gutless as its reputation suggested—my present-day Cobras certainly out-perform it!! The only way to get a Bantam to go is to pour in the nitro and hope for the best!

After that, most of the more serious modellers either went back to the Cox's that they knew performed dependably and well or re-activated their trusty diesels. However, for all its lack of all-out performance the Bantam was undeniably an inexpensive, well-made, light, easy-handling and very docile engine well suited to low-key sport flying and beginner familiarization, and these qualities helped it to continue to sell well as a sport/beginner engine and to survive in production until 1971, when it was replaced by the far superior DC Wasp and its radial mount companion which was marketed for a few years as the Frog .049 Venom.

Now if the Bantam had been the DC Wasp at the time of its release in 1959, things might well have been very different! The Wasp was an original design (insofar as any design is original!) and a far stronger performer than the Bantam. Furthermore, there was absolutely no technological reason why DC couldn't have released the Wasp in 1959 instead of the Bantam. In hindsight, if they had done so instead of adapting a smaller diesel to .049 glow operation, there's little doubt that they would have had a far greater impact on the domestic market and done much to overcome the prejudice against British .049's that the Bantam helped to engender. In short, the Wasp was the DC .049 model that probably should have been released in 1959 instead of the Bantam.

The original Frog .049 was an even more gutless wonder and a rather bulky one at that, and the word soon got around, adding to the prejudice against Brit .049's that the Bantam had already begun to engender. So people in Britain carried on using the diesel version of the Frog, simply because it was in fact a superior engine, the consequence being that the Frog .049 glow only survived until about 1964 and hence is a relatively rare item today. This further underscores my point—why develop a glow model of an existing diesel, and a glow model at that which failed to perform up to the same standard as its diesel counterpart? Surely far better to develop an all-new purpose-built glow model, or use a successful glow prototype rather than a diesel!

The A-M .049 was really little better than the Bantam in performance terms, and in any case was so obviously a straight copy of the Wen-Mac that any success that it enjoyed (which appears to have been rather limited) simply reflected upon its American originators rather than Allen-Mercury and the British model engine industry. So it did little or nothing to overcome the prejudice that soon developed towards the British .049 glows. It appears to have disappeared from the marketplace by mid 1963—like the Cobra, it was not listed in the "World's Model Engines" feature of the 1963 "Aeromodeller Plans Handbook".

Reviewing the above litany, it becomes clear in hindsight that, far from being merely a "Cox clone", the Cobra was in fact the most progressive and original production of the four British .049 glows which appeared in 1959-60. If the DC Wasp had been released in 1959 as it certainly could have been, it would have been an equally worthy contender and the ultimate fate of the Brit .049 glows in general and the Cobra in particular might have been different.

The RTF Dalliance

Having their own .049 glow, Keilkraft followed the American example with the release of an all plastic, Ready-to-Fly (RTF) model, choosing a very British subject, namely the Hawker Hurricane of Battle of Britian Fame. The first advertisement for the model appeared simultaneously on the back cover of Aeromodeller and the inside front cover of Model Aircraft in January 1962. It is surprising that they did not pull out the stops to get this in the December issues in which they had ran advertising for their very cheap, all sheet balsa, EeZeBUILT semi-scale model kits; probably profit margin at work again. But in February they were back to advertising their balsa models and RTFs received no further mention for a full year with the regular Keilkraft back page of the January 1963 issue of Aeromodeller being devoted to the imported Wen-Mac RTF range. No mention of the Cobra powered Hurricane ever appeared again.

Having their own .049 glow, Keilkraft followed the American example with the release of an all plastic, Ready-to-Fly (RTF) model, choosing a very British subject, namely the Hawker Hurricane of Battle of Britian Fame. The first advertisement for the model appeared simultaneously on the back cover of Aeromodeller and the inside front cover of Model Aircraft in January 1962. It is surprising that they did not pull out the stops to get this in the December issues in which they had ran advertising for their very cheap, all sheet balsa, EeZeBUILT semi-scale model kits; probably profit margin at work again. But in February they were back to advertising their balsa models and RTFs received no further mention for a full year with the regular Keilkraft back page of the January 1963 issue of Aeromodeller being devoted to the imported Wen-Mac RTF range. No mention of the Cobra powered Hurricane ever appeared again.

But the dies for an RTF must have been a major investment, so the Hurricane resurfaced almost two years later in a corner of their Aeromodeller back page for December 1964 where it was surrounded by Wen-Mac RTF imports. The model now sported an upright mounted Wen-Mac .049 with their patented Rotomatic recoil starter. In this form, the Hurricane continued on for over ten years. The page shown here is taken from the Keilkraft Handbook of 1969. These Handbooks appeared more or less annually between 1946 and 1980, and not surprisingly, today are highly collectable references [6].

But the dies for an RTF must have been a major investment, so the Hurricane resurfaced almost two years later in a corner of their Aeromodeller back page for December 1964 where it was surrounded by Wen-Mac RTF imports. The model now sported an upright mounted Wen-Mac .049 with their patented Rotomatic recoil starter. In this form, the Hurricane continued on for over ten years. The page shown here is taken from the Keilkraft Handbook of 1969. These Handbooks appeared more or less annually between 1946 and 1980, and not surprisingly, today are highly collectable references [6].

To close the book on the Hurricane, those hard working dies soldiered on well into the 70's, with one more "engine change", this time to a McCoy .049 although truth be told the only difference was the manufacturer and the engraving in the crankcase die, but that's another story. For the records, the McCoy powered version appeared on the February 1971 back cover; the chrome plated "Silver Hurricane" (which added a few pence short of £2 to the price) permiered on the December 1974 back cover.

To close the book on the Hurricane, those hard working dies soldiered on well into the 70's, with one more "engine change", this time to a McCoy .049 although truth be told the only difference was the manufacturer and the engraving in the crankcase die, but that's another story. For the records, the McCoy powered version appeared on the February 1971 back cover; the chrome plated "Silver Hurricane" (which added a few pence short of £2 to the price) permiered on the December 1974 back cover.

A Cobra Look-Alike

I'm greatly indebted to Tim Dannels for information regarding an obscure engine that might easily be mistaken for a Cobra spin-off. This is the Argentinian COM .049. Much of Tim's information on this engine came from Argentinian engine aficionado Arc�ngel Armesto, who interviewed the maker of the COM .049, one Oscar Nocera.It appears that Nocera had been designing and constructing .049 glow and diesel models in the 1960's for his own use. However, in the early 1970's a market niche became apparent to him, and he commenced the small-scale commercial manufacture of an .049 glow which he called the COM .049. He was assisted in this effort by the talented machinist Jorge Straseri. The initials COM stood respectively for his daughter Cecelia, his son Oscar and his wife Mausy.

The COM .049 was manufactured in two distinct series, both using a Cox-style piston/cylinder set-up. The Series 1 models used a bar-stock crankcase and a screw-in reed-valve carburettor set-up very reminiscent of the earlier Cox Space Hopper design. The Series 2, however, used a cast crankcase and backplate combination very much like those used in the Cobra .049 apart from a more Cox-like configuration of the carburettor. At first glance, the resemblance to the Cobra is quite striking, the main immediately observable difference being the mounting of the needle valve. However, there is no evidence that Nocera was in any way influenced by the "British Cox".

The COM project was initially quite successful, with over 1,500 engines being manufactured and sold domestically. Unfortunately, changing political conditions in 1974 resulted in an economic collapse which forced the cessation of production.

Summary

So there we have it—far from being "merely" a clone of the all-conquering Cox, the Cobra was in fact a very well-focused and competently executed design which represented perhaps the most rational of the various approaches taken by British manufacturers in 1959-60 to jump on the .049 glow-plug bandwagon. If the rest had all been as good, the cause of the British .049 glows would have been very well served. The Cobra deserves to be far better remembered than it has been to date.Addendum

The response to the Cobra review was quite remarkable. This prompted me to seek out another Cobra for the collection and I was fortunate enough to locate a low serial number edition that came with some surprises. The engine serial number is 1061. It's not uncommon for manufacturers to start numbering from a high number, so this may actually be engine #61! At first glance, it is just another Cobra, without any blacking applied to the cylinder—it's not faded; it was never there! But close inspection starts to show subtle differences; disassembly and measurement shows even more.

The response to the Cobra review was quite remarkable. This prompted me to seek out another Cobra for the collection and I was fortunate enough to locate a low serial number edition that came with some surprises. The engine serial number is 1061. It's not uncommon for manufacturers to start numbering from a high number, so this may actually be engine #61! At first glance, it is just another Cobra, without any blacking applied to the cylinder—it's not faded; it was never there! But close inspection starts to show subtle differences; disassembly and measurement shows even more.

First, the cylinder flange is significantly larger in diameter and actually overhangs the crankcase. Next, the exhaust ports are smaller in height and located lower down the cylinder, being 0.018" narrower, with the top of the port 0.012" lower than the later models. Internally, it appears that the blow-down period (the lag between the opening of exhaust and transfer) is of greater duration on the early model. Taken all together, the changes would increase top end RPM, at the expense of fuel economy.

At the rear, the fuel nipple is shorter, and the venturi throat is smaller, being 0.058" in diameter. This is the same throat diameter as that of the Cox Bebe Bee! The throat on the later models was increased to a diameter of 0.0625" giving in a 16% increase in area. The venturi on the early model extended 0.24" from the rear of the backplate, while that on the later models is only 0.18" in length.

At the rear, the fuel nipple is shorter, and the venturi throat is smaller, being 0.058" in diameter. This is the same throat diameter as that of the Cox Bebe Bee! The throat on the later models was increased to a diameter of 0.0625" giving in a 16% increase in area. The venturi on the early model extended 0.24" from the rear of the backplate, while that on the later models is only 0.18" in length.

It seems that at some point, probably quite early on, Rodwell decided (or was told by KeilKraft) that he needed to beef up the top end a little. So he made the exhaust ports deeper, adding most of the extra on the top edge to give earlier opening. He shifted the transfer port up by the same amount to have it open earlier as well, maintaining roughly the same time-lag between the opening of the exhaust ports and the subsequent opening of the transfer port. Finally, he added 16% more throat area to the intake venturi. This is all completely consistent with an objective of improving the engine�s top-end performance. All of this seems to say that the engine was still under development when it was released and shows the value of examining as many examples as possible from both ends of an engines production life.

It seems that at some point, probably quite early on, Rodwell decided (or was told by KeilKraft) that he needed to beef up the top end a little. So he made the exhaust ports deeper, adding most of the extra on the top edge to give earlier opening. He shifted the transfer port up by the same amount to have it open earlier as well, maintaining roughly the same time-lag between the opening of the exhaust ports and the subsequent opening of the transfer port. Finally, he added 16% more throat area to the intake venturi. This is all completely consistent with an objective of improving the engine�s top-end performance. All of this seems to say that the engine was still under development when it was released and shows the value of examining as many examples as possible from both ends of an engines production life.

References:

| [1] | anon: Motor Mart, Aeromodeller, Vol XXV, No 288, January 1960, Model Aeronautical Press Ltd, UK, p38. |

| [2] | Chinn, P: Latest Engine News, Model Aircraft, Vol 19, No 232, October 1960, Percivial Marshall & Co. Ltd, UK, p307. |

| [3] | anon: Keilkraft Show, Aeromodeller, Vol XXV, No 296, September 1960, Model Aeronautical Press Ltd, UK, p489. |

| [5] | Laidlaw-Dickson DJ, Rushbrooke CS: Engine Analysis, Aeromodeller Annual 1961-62, Argus Press Ltd, London, p129. |

| [6] | Miles I, Betny S: Keilkraft: Complete Guide to the Famous Handbooks, SAM35 Yearbook, Dorking Litho Ltd, Surrey UK, 2006, p95. |

This page designed to look best when using anything but IE!

Please submit all questions and comments to

[email protected]

|

Unless otherwise expressed, all original text, drawings, and photographs created by

Ronald A Chernich appearing on the Model Engine News web site are licensed under a Creative Commons Attribution-Noncommercial-Share Alike 3.0 License. |

|